Académique Documents

Professionnel Documents

Culture Documents

Bro PMT de en

Transféré par

Marian DunareanuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bro PMT de en

Transféré par

Marian DunareanuDroits d'auteur :

Formats disponibles

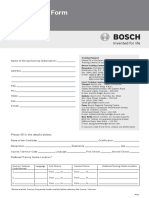

Rolling Bearings and System

Solutions for Medical Technology

FAG Plant Engineering Center

FAG Sales Engineering Center

INA Plant Engineering Center

INA Sales Application Engineering

2

T h e C o m p a n y

The Schaeffler Group: Together we move the world ...

Schaeffler Group Industrial Medical Technology Segment: In the market, for the market

The Schaeffler Group has over 180 locations throughout the world theres one in your area, too!

Wherever possible, we manufacture our products in close proximity to our customers In the market, for the market. Our global network of Engineering Centers

is able to draw upon the expertise and resources of the entire Schaeffler Group. Were happy to provide assistance and advice!

The Schaeffler Group ranks among the

worlds leading international rolling

bearing manufacturers and is a renowned

supplier to all major automakers. The

companies of the Schaeffler Group suc-

cessfully compete in over 60 industrial

sectors, including the medical technology

field a segment in which we have

decades of experience.

With our INA and FAG brands, we offer a

portfolio of components and system solu-

tions that is unmatched in terms of quality

and scope. Our product line encompasses

almost 40,000 a catalog bearings as well as

numerous solutions that are tailored to our

customers specific needs. With regard to

medical technology, our formidable brands

such as Barden and IDAM complement the

Schaeffler Groups vast range of products.

High-volume production runs combined

with state-of-the-art manufacturing

technology allow for extremely cost-

effective production. Our global network

of Engineering Centers constantly

develops sophisticated yet economical

solutions by applying creative ideas to

specific customer requirements.

1

2

3

4

3

T h e P r o d u c t R a n g e

... of medical technology.

New design perspectives for moving axes

Applications in the operating room ... ... in ophthalmology ... in dentistry ... in computer tomography and many

other areas

In-house test rigs where finished

products can be analyzed, too

Expert customer support from the

initial design stage right up to delivery

of the finished product

Chemical and physical labs

for testing lubricants, for example

For over 100 years, our profession has

been to develop and supply bearings

that safely and efficiently support

moving machine parts. When it comes

to products that provide movement in

medical technology applications, we

are an engineering partner as well as a

reliable supplier.

What can you expect from us?

Comprehensive application-focused

support and solutions throughout

all stages of the product life cycle

Exceptional quality and durability

Superior innovative skills

Completely new approaches for your

designs, thanks to solutions that are

often unconventional and remarkably

simple

Solutions designed for easy installation

Highest levels of operational safety

High operating speeds combined with

low noise levels

Cutting-edge materials, e. g., non-

magnetic, hardened rolling bearing steel

Radiation-resistant products

Fulfilling your technical vision is our

challenge. Take advantage of our

expansive product portfolio and let us

become your engineering partner!

On-site calculation support

4

E n g i n e e r i n g & S e r v i c e

Our global Medical-Systems Engineering

Teams can provide support in all phases

of the product-development process.

Take advantage of our proven expertise

in a wide variety of sectors and products!

Design

Our strength lies in our ability to develop

customer-specific components and

system solutions by drawing upon our

comprehensive line of products from

our INA, FAG, Barden, and IDAM brands.

By collaborating with the customer early

on in the development process, we can

take full advantage of state-of-the-art

CAE-tools, many of which have been

developed in-house.

Calculation and bearing selection

Bearinx

, the Schaeffler Groups inno-

vative calculation program, has proven

itself for years to be a critical tool in

elevating the performance of machines

and devices. This program allows us to

approach systems from a holistic per-

spective, thereby producing the best-

possible designs that take into account

all of the boundary conditions. Only

then can the optimal rolling bearing

application be determined, which, in

turn, maximizes the improvements to

the systems efficiency.

Bearinx

allows us to perform a

detailed analysis of the rolling bearings,

so that the contact pressure acting on

each individual rolling element is fac-

tored into the calculation even for the

most complex shaft systems. For the

design engineer, this level of attention

to detail provides an extra measure of

security.

New ideas, creative solutions ...

Steel, brass, plastic: ball cages made from a variety

of cutting-edge materials

Special filtered greases for precision applications Acoustic testing laboratory at Schaeffler Group

Industrials Corporate Testing Center

Bearing design with Bearinx

: ensuring operational

safety by simulating all boundary conditions

All results, including, for example, cal-

culated rating life, can be provided in

tabular form or as diagrams, depending

on your document needs.

Testing

The new product is tested only after

all of the calculations have been opti-

mized. If desired, customer samples

can be tested in one of our R&D Centers

under all conditions and for all functions

from wear behavior to noise. Once

a series of stringent tests under simu-

lated field conditions has been com-

pleted, volume production can begin!

Tribology

Lubrication has a significant impact on the

reliability and operating life of a bearing.

We thoroughly test all the greases used

for the initial lubrication of our products

in our in-house lubricant laboratory prior

to their use. Applications intended for

medical technology are also subjected

to additional tests, including resistance

to radiation. In this product segment,

particular attention is paid to for-life

lubrication.

5

Materials

The application determines the material

and you determine the application.

Then, we select from a wide range of

cutting-edge materials, combining them

into the perfect mix for your product:

Corrosion-resistant special steels,

such as Cronitect

and Cronidur 30

Hardened, non-ferromagnetic rolling

bearing steels, e. g., X5CrNi1810

Temperature-resistant high-perfor-

mance plastics, such as PEEK

Wear-resistant industrial ceramics (Si

3

N

4

).

Surface coatings

Coatings can profoundly improve a

variety of bearing characteristics, such

as wear, corrosion-resistance, run-in

behavior, dry-running characteristics,

resistance to media, behavior under

lubrication-starved conditions, etc. For

example, Corrotect

electroplated corro-

Herzogenaurach: new coatings and the attendant techniques for applying them

are developed in our in-house Surface Technology Center

Coatings for Medical Technology Applications

Corrosion

protection for steel

and aluminum

Anti-wear

protection for

raceways

Reducing friction

Improving running-

in behavior

sion protection is employed whenever

especially effective corrosion protection

is a priority. Powder coating, on the

other hand, is used if sanitary conditions

and aesthetically pleasing design are

important considerations.

... utilizing cutting-edge materials

Expertise in materials: a Cronitect

hybrid bearing and a linear guidance system

made from amagnetic hardened rolling bearing steel with ceramic balls

Corrotect

A, F, C

Corrotect

ZK

(Zinc)

Durotect

HA

(Hard anodizing)

Durotect

NP

(Electroless nickel)

Durotect

CK

(Protect A)

Durotect

CM

(Protect D)

Durotect

M

(Manganese phosphate)

Durotect

Z

(Zinc phosphate)

Durotect

B

(Black oxide finishing)

B r a n d s & P r o d u c t s

Our brands your competitive advantage

Creative Technology: INA rolling bearings and plain bearings, INA linear guidance systems

For decades, INA has been synonymous with creative application engineering, state-

of-the-art manufacturing technology, as well as close development partnerships with

customers. Our ability to innovate arises from our companys singular philosophy

that constantly encourages outside-the-box thinking. Because many of our products

are manufactured in large production runs through forming (instead of machining),

they are particularly economical. In this area, INAs expertise is unrivaled.

6

Barden precision ball bearings

Barden is a premium brand that specializes in high-quality and super-precision rolling

bearings. Manufactured in the U.S. and Great Britain, these bearings are primarily

geared toward aviation and aerospace applications as well as equipment used in

dental technologies and x-ray equipment. All Barden bearings with outer diameters

ranging between 3 mm and 300 mm are assembled under clean-room conditions.

FAG precision rolling bearings: Innovation in Motion

For over 100 years, FAG has epitomized precision, premium quality and comprehen-

sive service for all things related to rolling bearings. In plants located throughout the

world, FAG manufactures ball bearings, rolling bearings, housings and accessories

for all industrial sectors. Innovations are methodically planned into this process. A

superlative R&D program, creative engineering, and close proximity to our customers

guarantee success.

IDAM direct-drive technology

From a technological perspective, IDAM linear and rotary direct drives lead the

industry and offer the perfect solution for every application. They are complemented

by direct-drive positioning systems with their required control systems and mecha-

tronic assemblies. With increasingly stringent requirements in terms of dynamics,

precision and cost effectiveness, direct drives are steadily gaining acceptance in

modern medical technology.

77

Choose from literally thousands of designs!

From a vast array of rolling bearing com-

ponents and materials, we have created

nearly 40,000 different types of bearings.

Better yet, all of them are standard solu-

tions, and every one of them can be found

in our catalog. If you are searching for the

most cost-effective and technologically

optimized bearing for your machine parts,

this is the first place to look!

The benefit for you: premium quality

and reliability in every bearing. Along

with the promise that our products will

demand very little of your valuable time

during operation. This is because we

specialize in solutions that are easy to

assemble and require minimal main-

tenance. Indeed, we often are able to

supply entire assemblies that only have

to be screwed in place, because the

individual components have been per-

fectly matched to each other and to the

mating parts. Our modular architecture

is supported by a comprehensive lineup

of accessories and service plans, ranging

from seals to the most appropriate sur-

face coating for the individual bearing

parts to lubrication.

And in that rare event that our standard

bearings do not exactly meet your needs,

we will be more than happy to develop a

customized solution to your specifications.

Talk to us!

R o t a r y A p p l i c a t i o n s

Reliable and quiet:

Rolling bearings from INA and FAG in medical applications

Time-honored mechanical components

continue to carry the load in the

development of medical devices. Ball

bearings and roller bearings guide

moving parts - even when placed inside

powerful magnetic fields. They support

virtually all the equipment used in the

operating room, or smoothly rotate x-ray

cameras quietly and vibration-free.

A safer operating room thanks to

matched pairs of angular contact needle

roller bearings

In todays operating rooms, ceiling mounts

have to be able to securely support a

growing number of increasingly heavy

devices. This is where matched pairs of

preloaded INA angular contact needle

roller bearings make a significant tech-

nical contribution.

In contrast to the ball bearings previously

employed in such situations, the bearing

cross section of these formed rolling

bearings is considerably smaller, while

their static load safety factor and tilting

rigidity are significantly higher. Thanks

to relatively large inside diameters,

supply lines and other cables can easily

pass through these bearings. A powder

coating (specially approved for medi-

cal applications) is used to protect the

outer rings from corrosion.

8

Clever ideas for modern operating rooms: INAs modular

needle roller bearing system provides an extra margin

of safety for the positioning and support systems in

ceiling mounts

From extremely rigid and lightweight axial bearings

... and a supplementary electromechanical brake

... to complete units with mounting systems ...

Innovation: mechatronic bearing

support system for CT scanners

Close collaboration with several

renowned computed tomography (CT)

manufacturers has yielded a world-class

innovation: an integrated mechatronic

bearing system that consists of a highly

accurate and quiet hybrid thin-section

bearing with direct drive along with

high-precision mating parts.

The bearing itself is a further develop-

ment of an idea from FAGs work in aero-

space technology. As such, it possesses

all of the features that are most impor-

tant for CT scanners: 100 % operational

reliability with the highest level of

running accuracy and minimal noise

levels. Using our bearing system, it is

easily possible to turn the trend toward

ever-increasing CT-scanner speeds into

reality, as velocities exceeding 400 rpm

have already been achieved.

Another benefit for manufacturers of

CT systems: the pre-assembled and

pre-tested bearing support and drive

This is where the patient benefits the most: the CT scanners with integrated mechatronic FAG bearing support

systems are considerably more precise and operate more quietly. Consequently, the examination takes less time

Technology transfer with diameters that are measured

in meters: an innovative thin section bearing with

ceramic balls originally developed for helicopters,

now used in medical equipment applications

9

Drive units for CT scanners with an integrated

mechatronic bearing support system from FAG

system can be installed as a single unit.

This saves time and lowers costs.

L i n e a r A p p l i c a t i o n s

For bearings that securely support longitudinal axes:

linear solutions from the Schaeffler Group

The Schaeffler solution comes ready

to install, is technically brilliant, and

provides the customer with significant

economic benefits. The basis of the

new curved guidance system is an alu-

minum-extruded section with hardened

shafts made from corrosion-resistant

steel. Particularly innovative: the inte-

grated locating/non-locating bearing

solution, which can compensate for any

dimensional inaccuracies in the mating

component. The non-locating bearing is

designed as a profiled track roller with a

movable inner ring; in this case, in the

form of a needle roller bearing one of

our specialties. The benefit is constant

resistance to displacement, regardless

of the x-ray tubes position.

Profile rail guides give examination

tables a smooth ride

An electronic system enables the exami-

nation table to be adjusted and posi-

tioned in a smooth and fluid manner.

The INA brand encompasses the worlds

most comprehensive portfolio of linear-

guidance system products. Thanks to

their modular layouts, seemingly dis-

parate solutions to applications can

be joined together quickly and cost-

effectively. For years, leading equipment

manufacturers have valued the cost

savings that these ready-to-install

bearing units provide allowing them to

create ever more compact devices that

require fewer mechanical components.

From a customers application:

a complete solution for the C-arm

The customer presented us with the

following challenge: the highest-possible

picture quality with as little stress on

the patient as possible. The objective

was to find a linear guidance system that

enables the x-ray tube to be positioned

above the C-arm smoothly and precisely.

Resistance to radiation and quiet opera-

tion were additional requirements.

Ensuring a comfortable and stress-free environment for the patient: we offer a line

of low-noise and smooth-running profile rail guides that are specially designed

for examination tables

Minimal edge pressure reduced wear of the mating

track: smooth-running INA track rollers with optimized

outside surface profile

10

11

And we supply the appropriate mecha-

tronic assembly in the form of smooth-

running, high-capacity profile rail guides.

For those situations where loud noise is

unacceptably disruptive, we are pleased

to present a truly innovative product, our

silent type: a 4-row linear ball bearing

and guideway assembly whose spacers,

strategically placed between the balls,

significantly reduce running noise. The

bearings low rolling resistance allows the

examination table to be smoothly and

precisely positioned. Another significant

benefit is that the guidance system

even in the standard design is virtually

maintenance-free for life, thanks to a

lubricant reservoir positioned right next

to the raceways load zones.

Rugged shaft guidance systems for

dentists chairs

The fluid, uninterrupted motion that

patients expect from their dentists

chair requires a shaft guidance system

for the height-adjustment mechanism

that is both smooth and rugged. To that

end, our customers can expect a sophis-

ticated lineup of linear ball bearings,

housings, shafts and accessories.

The bearings are available in lightweight

designs that employ either plastic or

solid cages; corrosion-resistant versions

(with coated surfaces) are also available,

if desired. All of these products require

minimal installation space and very

little maintenance.

Our linear ball bearings are also extremely

rigid, an essential prerequisite for

ensuring the designs ruggedness.

Superior resistance to chemicals used

for cleaning and sterilization is an

added benefit.

Linear solutions from the Schaeffler Group

economical and reliable.

Test them for yourself!

Our silent type: spacers dampen the noise level

of this linear recirculating ball bearing and guideway

assembly

For even higher loads: a flat cage guidance system

for limited strokes

For high loads: six rows of balls provide a high level

of safety in heavy-load applications

Shaft guidance system with INAs self-adjusting linear

ball bearing: misalignments are easily compensated

12

P r e c i s i o n A p p l i c a t i o n s

Accurate analysis requires precision mechanisms:

ready-to-install bearing solutions from a single source

INAs Linear Technology sector provided

the perfect solution for the longitudinal

axes in the pipette-handling unit: a 4-row

linear recirculating ball bearing and

guideway assembly with Corrotect

coating for the main axis, as well as two

corrosion-resistant, double-row miniature

guidance systems for the y and z axes.

The engineers were also able to rely on a

Schaeffler product for the rotary motions:

angular contact ball bearing units were

employed as spindle bearings in both

the main drive as well as in the drive

system for the device used for drawing

the liquid into the pipette.

Consequently, the primary bearing units

as well as the overall technical design

support were provided by a single

source. As for the customer he was

extremely pleased with the combination

of high-quality bearing units, compre-

hensive support and outstanding delivery

quality. Every one of the requirements

in the specifications was fulfilled

beyond the customers expectations,

Constant advances in laboratory auto-

mation require continuous improvements

in mechatronic machine parts. This calls

for smooth-running, compact and sturdy

bearing subassemblies that can be easily

integrated. For example

High-quality bearing units for laboratory

automation

One of our customers, a laboratory-

equipment manufacturer, was looking

to automate the process for analyzing

test specimens by using a powered 3-axis

motion and positioning system and, in

doing so, create a reproducible pipette-

handling procedure. The specifications

developed by the manufacturer and

Schaeffler engineers were quite extensive,

calling for:

Smooth, quiet operation

Uniform displacement resistance for

continuous sequences of motions

Corrosion-resistant design suitable for

use in a laboratory environment

Precise and repeatable positioning

Minimal number of parts, straightfor-

ward design of mating components

Minimal maintenance requirements.

12

Ready to install: miniature linear module for precise

positioning

Laboratory testing device using a 3-axis handling

system for automatic pipette filling

Effective corrosion protection: linear recirculating

ball bearing and guideway assembly with patented

Corrotect

rust-proofing

13 13

especially since the bearing solutions,

including the corrosion-protection

requirements, were able to be combined

using standard catalog products.

This cost-to-value relationship has

become the blueprint for success in lab

automation equipment. Thanks to ready-

to-install rotary and linear bearing units,

the layout of the mechanical components

inside the device could be simplified

and the unit itself ended up being more

compact; consequently, the number

of mechanical components could be

reduced.

Innovative precision solutions

in all areas of medical technology

The example from the medical-analysis

arena described above is representative

of a wide variety of other applications

including lens-grinding machines in

ophthalmology, phoropters as well as

cutting-edge dental technology in

which Schaefflers innovative bearing

solutions have had a compelling impact.

A single bearing, where once two were needed: INA

bearing for rotary and linear movements used inside

a milling jigs work spindle

CAD/CAM is revolutionizing dentistry: shown above is a device used for computer-aided ceramic restoration

in a dental practice

High-precision and low-friction: INAs linear guidance

system used in a scanner unit for eyeglass frames

(generates the lens-grinding program)

14

X - r a y a n d D e n t a l T e c h n o l o g y

High speed in dentistry

Among rolling bearing applications,

dental handpieces (often also referred

to as dental drills) represent one of the

greatest challenges. The small ball

bearings rotate at speeds of up to

500,000 rpm, often under difficult con-

ditions (consider the debris generated

during dental treatments or sterilization

in autoclaves). This frequently leads to

premature bearing failure.

Barden miniature ball bearings can

extend the operating life of handpieces,

thereby lowering overall costs. In addi-

tion, vibrations are reduced giving the

dentist more control.

Ceramic balls are used in high-speed

applications. These balls are harder,

lighter and more wear-resistant than steel

balls. They generate lower centrifugal

forces, thereby reducing loads and wear.

A new honing process improves the

surface quality of the raceway, which

results in a quieter bearing. Improved

Products from inside the clean room:

Barden a member of the Schaeffler Group

Barden quality: precision rolling bearings are

assembled under stringent clean room conditions

Innovative x-ray bearing units enable scans with the

highest resolution

For high-vacuum applications: bearing unit used in

high-speed x-ray tubes

Also available in small lot sizes: Barden ball bearings

with accuracy that exceeds ISO P4 standards

end caps reduce the gap between the

inner ring and sealing shield by 60 %.

As a result, less grinding dust enters the

bearing and grease retention is improved.

On the cutting edge: x-ray bearing units

Bearing-support assemblies for the

spinning x-ray anode can attain speeds

in excess of 10,000 rpm under harsh

operating conditions: in addition to

withstanding high voltage, the bearings

must also operate in a vacuum environ-

ment at 10 8 torr and at temperatures

that can reach 400 to 500 C.

Barden x-ray bearings have races inte-

grated in the shaft and have a full-comple-

ment design. In order to provide effective

lubrication under such extreme condi-

tions, we employ coatings that are applied

using plasma and ion-beam technology.

The performance of our x-ray tube bearings

is evaluated and verified in our in-house

x-ray bearing test facility under simulated

thermal and vacuum test conditions.

Ball bearings can lower your costs: get the longest

life out of your dental handpieces with Barden

miniature bearings

15

Drives and bearing arrangements from a single source:

IDAM direct drives deliver an innovative system solution

IDAM direct drives are particularly appro-

priate in medical technology applications

that require the highest levels of preci-

sion and dynamics, long operating life

as well as cost-effective performance.

By directly connecting the motor to

the moving mass, the number of

required components as well as the

design space is reduced. Increased

dynamic and static rigidity, combined

with lower elasticity, enable extremely

precise positioning in applications

ranging from high-precision motors

in collimators for treating tumors to

high-performance dynamic drive units

for computed tomography to machines

used for manufacturing stents, surgical

needles, endoscopy components, and

many others.

Examples of IDAM system solutions

HSR and HSRV-series rotary drives

are particularly suited to high-speed

applications and CT scanners. With

Open frame positioning system for testing substrates

special coil adapters, these low-vibra-

tion motors achieve relative speeds of

50 m/s.

Medical laboratories are expected to

analyze an ever-increasing number

of samples in the shortest amount of

time possible. Conventional drive sys-

tems often lack the performance capa-

bilities to satisfy these requirements.

Consequently, mechatronic systems

are becoming increasingly common

in medical-technical analysis stations

in which only small masses have to

be moved. The perfect combination of

high-precision INA linear systems and

direct drives from IDAM allow speci-

mens to be positioned to a level of

accuracy in the single-digit m range.

Combining sophisticated medical

technology with modern direct drive

technology can produce products that

have the ability to save lives. Such

was the case when we worked with

a customer to develop a direct-drive

D i r e c t D r i v e s

L1-series linear motors for applications that require

high levels of accuracy and performance

Compact 2-axis system for optical scanning

laser precision cutting device for

manufacturing stents. Uniting new

laser beam sources with rotary and

linear direct drives from IDAM resulted

in an innovative machine concept with

superior accuracy and performance.

IDAM direct drives: precise, flexible,

efficient. Curious? Wed be happy to

prove it to you: sales@ina-dam.de

M

A

T

N

R

0

2

9

8

7

3

2

4

0

-

0

0

0

0

/

P

M

T

/

U

S

-

D

/

2

0

1

0

0

8

1

/

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

b

y

M

a

n

d

e

l

k

o

w

I

m

a

g

e

s

u

s

e

d

w

i

t

h

k

i

n

d

p

e

r

m

i

s

s

i

o

n

o

f

B

e

h

n

k

,

C

a

r

l

Z

e

i

s

s

M

e

d

i

t

e

c

,

E

s

s

i

l

o

r

,

L

L

T

A

p

p

l

i

k

a

t

i

o

n

G

m

b

H

,

P

h

i

l

i

p

s

M

e

d

i

z

i

n

S

y

s

t

e

m

e

,

S

i

e

m

e

n

s

M

e

d

i

c

a

l

S

o

l

u

t

i

o

n

s

,

S

i

r

o

n

a

D

e

n

t

a

l

S

y

s

t

e

m

s

,

T

r

u

m

p

f

K

r

e

u

z

e

r

Every care has been taken to ensure the

correctness of the information contained

in this publication but no liability can be

accepted for any errors or omissions.

We reserve the right to make technical

changes.

Schaeffler Technologies GmbH & Co. KG

Issued: 2010, August

This publication or parts thereof may not

be reproduced without our permission.

Schaeffler Technologies

GmbH & Co. KG

Georg-Schfer-Strasse 30

97421 Schweinfurt (Germany)

Phone +49 9721 91-6791

Fax +49 9721 91-6424

Internet www.fag.com

Contact us at:

meditech@schaeffler.com

Publications available at:

FAGinfo@schaeffler.com

Schaeffler Technologies

GmbH & Co. KG

Industriestrasse 1 3

91074 Herzogenaurach (Germany)

Phone +49 9132 82-2039

Fax +49 9132 82-4898

Internet www.ina.com

Contact us at:

meditech@schaeffler.com

Publications available at:

info@schaeffler.com

Vous aimerez peut-être aussi

- RfeDocument8 pagesRfedunareanu_marian8668Pas encore d'évaluation

- LP C2Document18 pagesLP C2Marian DunareanuPas encore d'évaluation

- Limba Engleza Curs Practic - Nivel MediuDocument51 pagesLimba Engleza Curs Practic - Nivel Mediucif_catalin100% (16)

- Curs Limba SuedezaDocument1 pageCurs Limba SuedezaMarian Dunareanu0% (1)

- 0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Document7 pages0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Marian DunareanuPas encore d'évaluation

- Curs 12 MeeDocument13 pagesCurs 12 MeeMarian DunareanuPas encore d'évaluation

- GC DGCDocument10 pagesGC DGCMarian DunareanuPas encore d'évaluation

- RDHDocument20 pagesRDHMarian DunareanuPas encore d'évaluation

- Round ToolingDocument18 pagesRound Toolingdunareanu_marian8668Pas encore d'évaluation

- Power CylindersDocument12 pagesPower CylindersMarian DunareanuPas encore d'évaluation

- Au RDocument7 pagesAu RMarian DunareanuPas encore d'évaluation

- Dpds DPDLDocument24 pagesDpds DPDLMarian DunareanuPas encore d'évaluation

- DSC Capabilities Neu Eng 09 2011 FinalDocument12 pagesDSC Capabilities Neu Eng 09 2011 FinalMarian DunareanuPas encore d'évaluation

- Pin PackagesDocument23 pagesPin PackagesMarian DunareanuPas encore d'évaluation

- VacuumDocument13 pagesVacuumMarian DunareanuPas encore d'évaluation

- Manual Clamping Technology: I-3 - I-6 Section 1 - 9Document5 pagesManual Clamping Technology: I-3 - I-6 Section 1 - 9Marian DunareanuPas encore d'évaluation

- Automation U1 2011 GBDocument1 pageAutomation U1 2011 GBMarian DunareanuPas encore d'évaluation

- 'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Document10 pages'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Marian DunareanuPas encore d'évaluation

- MedicalDocument12 pagesMedicalMarian DunareanuPas encore d'évaluation

- IntroDocument1 pageIntroMarian DunareanuPas encore d'évaluation

- 01 Vertical ClampsDocument44 pages01 Vertical ClampsElvin PolancoPas encore d'évaluation

- DPGDocument12 pagesDPGMarian DunareanuPas encore d'évaluation

- DpeDocument6 pagesDpeMarian DunareanuPas encore d'évaluation

- Intro 00Document3 pagesIntro 00Marian DunareanuPas encore d'évaluation

- OverviewDocument4 pagesOverviewMarian DunareanuPas encore d'évaluation

- DLT BelDocument24 pagesDLT BelMarian DunareanuPas encore d'évaluation

- DlttanruDocument14 pagesDlttanruMarian DunareanuPas encore d'évaluation

- Ai 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Document10 pagesAi 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Marian DunareanuPas encore d'évaluation

- DlbtanruDocument12 pagesDlbtanruMarian DunareanuPas encore d'évaluation

- Pneumatic Clamps: DestacoDocument32 pagesPneumatic Clamps: DestacoMarian DunareanuPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Repo KitDocument11 pagesRepo KitManish AhirePas encore d'évaluation

- 600 HDocument16 pages600 HOscar Marino Campo BonellPas encore d'évaluation

- Chauhan Project On Marketing StrategiesDocument39 pagesChauhan Project On Marketing StrategiesSandiep SinghPas encore d'évaluation

- EV Magazine Nov2023Document76 pagesEV Magazine Nov2023mahendranPas encore d'évaluation

- Parts Service Manual - Usats - Isuzu Diesel PDFDocument72 pagesParts Service Manual - Usats - Isuzu Diesel PDFCesarPas encore d'évaluation

- SWOT Analysis in Action at Škoda: Franchised DealersDocument4 pagesSWOT Analysis in Action at Škoda: Franchised DealersMerjem MerjemPas encore d'évaluation

- XUV 700 (5 Seater) XUV 700 (7 Seater)Document1 pageXUV 700 (5 Seater) XUV 700 (7 Seater)key logsPas encore d'évaluation

- Capital AllowancesDocument4 pagesCapital AllowancesAr BobPas encore d'évaluation

- Ch18 SG BLTS 8eDocument20 pagesCh18 SG BLTS 8eHolli Boyd-White100% (1)

- 26 Bosch AA Training Programme Application FormDocument2 pages26 Bosch AA Training Programme Application FormManjeet SinghPas encore d'évaluation

- 0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxDocument4 pages0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxAndry PriyantoPas encore d'évaluation

- Uk X19CatalogueDocument54 pagesUk X19Cataloguevincenzo_sepe6439Pas encore d'évaluation

- Baotian Service ManualDocument200 pagesBaotian Service ManualJoakim LainePas encore d'évaluation

- TM9 801 1944 PDFDocument545 pagesTM9 801 1944 PDFArielPas encore d'évaluation

- Mercedes Benz PDFDocument23 pagesMercedes Benz PDFManisha DeewanPas encore d'évaluation

- VW Wheels and Tyres Guide - ArchiveDocument513 pagesVW Wheels and Tyres Guide - Archivefulltransmission67% (3)

- I M Mech PTODocument21 pagesI M Mech PTOedwin23a100% (1)

- Chapter 1 Case Sullivan Ford Auto World (Questions)Document4 pagesChapter 1 Case Sullivan Ford Auto World (Questions)Phuu Phuu MyintPas encore d'évaluation

- ED Auto PresentationDocument25 pagesED Auto PresentationRaghav NevatiaPas encore d'évaluation

- Bertele Tribune Technical-Building SolutionsDocument8 pagesBertele Tribune Technical-Building SolutionsBrett CastroPas encore d'évaluation

- IATA Recommended Charges Codes (CIMP - XML Listing)Document34 pagesIATA Recommended Charges Codes (CIMP - XML Listing)altauprieten100% (1)

- Project Report On Supply Chain ManagemenDocument26 pagesProject Report On Supply Chain ManagemenVyankatesh YadavPas encore d'évaluation

- Auction Pricelist 032522Document26 pagesAuction Pricelist 032522wallen dPas encore d'évaluation

- Grove GMK6350Document20 pagesGrove GMK6350cornel_lupuPas encore d'évaluation

- BST ProjectDocument26 pagesBST ProjectLakshay SethPas encore d'évaluation

- Nine Speed TransmissionDocument2 pagesNine Speed TransmissionRodrigo Retamal0% (1)

- Subaru RecallDocument4 pagesSubaru RecallThe Republican/MassLive.comPas encore d'évaluation

- MRF Annual-Report-2018Document79 pagesMRF Annual-Report-2018goudPas encore d'évaluation

- GM Case StudyDocument14 pagesGM Case StudyMarcelo Vieira100% (1)

- Comptitive PDFDocument102 pagesComptitive PDFhusePas encore d'évaluation