Académique Documents

Professionnel Documents

Culture Documents

Alstom 13E2

Transféré par

jparmarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alstom 13E2

Transféré par

jparmarDroits d'auteur :

Formats disponibles

POWER

Superior flexibility / Superior performance

GT13E2

GAS TURBINE

Power,

productivity, profit

02

Wherever they operate worldwide, utilities and independent power producers have to cope with rapid

changes - tougher emissions legislation and fierce competition not least among them.

At the same time they need to reduce production costs yet major power interruptions dramatically

illustrate the danger of cutting cost at the expense of reliability. To increase long-term profits, even

at a time of volatile fuel and electricity prices, it is vital to continue to raise efficiency and productivity.

Alstoms GT13E2 gas turbine offers the highest engine efficiency of conventional class gas

turbines yet has long inspection intervals. With millions of fired hours of operation to

its credit, the GT13E2 is the perfect core of a power plant, designed to produce reliable,

competitively priced electricity.

The GT13E2 offers superior flexibility through two operating modes one maximises performance,

the other maximises operating time between inspection intervals. In addition, the engine can actively

support grid frequency with high response and no extra lifetime factors.

The GT13E2, whose gas turbine technology has earned its stripes over the years, is designed

for a wide range of applications. It can operate as a stand-alone turbine in a new or existing

power plant design or as part of a turnkey power plant. Applications cover electrical power

generation in base load, intermediate or peak duty. It can be used in industrial applications

such as aluminium smelters or desalination plants. With its modularised and pre-tested

auxiliaries, the GT13E2 can be brought on-line quickly to support phased plant construction.

Right technology, right products

Alstoms gas turbines stand out for their high cost efficiency,

availability and flexibility.

The range covers a wide spectrum of products, including machines

for both the 50 Hz and 60 Hz markets. They can operate either in

simple cycle or combined cycle and are fuelled by natural gas,

medium or low calorific gases or light oil; with on-line fuel switch

over capability eliminating dependency on any one fuel.

Unmatched efficiency

The GT13E2 has the highest open-cycle efficiency of conventional class gas

turbines close to 37% (ISO) with a high exhaust energy level. This offers

significant fuel cost savings over competing technologies for a wide variety

of applications. It is achieved by carefully optimizing existing proven

technology without the need for expensive and high-maintenance

technologies used in some advanced gas turbines. The benefit of lower

operating cost is, therefore, not compromised by higher maintenance costs

or reduced availability.

Operational flexibility

The GT13E2 can operate in either a performance optimised mode or a lifetime

optimised mode without having to change hardware. Both respond to

increasingly volatile markets by allowing the operator to select, on-line, the best

operating mode to maximise profit. Operational flexibility also includes the

ability to handle wide fluctuations in gas composition. In addition, the engine

can operate on diesel oil (with or without water injection for NOx control), with

an on-line switch-over between gas and oil even at full load.

Low maintenance cost/

longer inspection intervals

The GT13E2 has a number of family assets. Firstly, the maintenance-free welded

rotor eliminates the need for major overhauls. Secondly, the fully annular

combustor does not require any combustor inspections. With the GT13E2, you

can achieve maintenance intervals of 36,000 Equivalent Operating Hours (EOH)

between hot gas path inspections. This makes the GT13E2 the ultimate choice

for operating regimes with a higher sensitivity to O&M costs and availability.

Continuous evolution

The GT13E2 continues to be at the cutting edge thanks to constant technology

evolution. These incremental improvements use the engineering tools validated

at the Alstom Test Power Plant and confirmed with test campaigns in the field.

Two retrofittable upgrades on the GT13E2 are a prime illustration improved

turbine blading with the flexible operating concept and a compressor upgrade.

03

GT13E2:

the benefits

Designed for dependable,

low cost operation

The welded rotor design eliminates maintenance work such

as restacking and disk replacement or factory rotor overhaul

and thus eliminates the need for a so called major overhaul

of the GT.

Low-stage loaded compressor

The 21-stage compressor with its low stage loading yields

a high surge margin and high reliability.

Variable inlet guide vanes control airflow efficiently, increasing

part load efficiency and starting reliability.

Annular combustor

A fully annular combustion chamber distributes the

circumferential temperature evenly while avoiding problem

zones such as cross-firing tubes or transition pieces. In

addition the annular combustion systems of Alstom do not

need a so called "combustor inspection" as for can-annular

systems which reduces the amount of maintenance leading to

higher availability.

Every component of the GT13E2 is the result of

time-tested design principles, thorough validation and

manufacturing processes conforming to the highest standards.

Maintenance-free welded rotor

Alstoms welded rotor was first introduced in 1929 for steam

turbines and has been operating successfully in both Alstom

gas and steam turbines. The rotor is welded from forged discs

that ensure high rotor stiffness with two-bearing support.

04

Rotor manufacturing

welding process.

Dry low NOx EV burner

EV (EnVironmental) burner technology, operating successfully

for several millions of hours throughout the Alstom gas turbine

fleet, gives long burner life, no maintenance between hot gas

path inspection and low emissions.

The EV burner gives the benefit of dry low NOx combustion

for operation with different natural gases, with the option to

run with liquid fuel as an alternative.

Turbine

Advanced aerodynamics and multi-convective cooling schemes

contribute significantly to the GT13E2s outstanding efficiency.

The design of the first turbine stage, combined with thermal

barrier coating (TBC) and conservative firing temperatures,

allows extended inspection intervals of up to 36,000 EOH.

All Inconel 738 conventional cast turbine airfoils and heat

shields ensure long parts life and allow for full, cost-effective

refurbishment.

Axial exhaust system

The straight-line arrangement of gas turbine and heat recovery

steam generator (HRSG) facilitates compact plant layouts.

The elimination of the turning elbow reduces back-pressure

and turbulence at the HRSG inlet. This improves unit

performance in simple and combined cycle mode.

05

06

Flexibility and efficiency

The longer and more flexible inspection intervals that

the GT13E2 offers, linked to higher efficiency when required,

provide the optimal hedging against fuel price uncertainty.

Extended inspection

intervals

One of the key benefits of the GT13E2

is the ability to operate with extended

inspection intervals for low fuel cost

applications or in schemes where fuel

is provided by the power off-taker

(Tolling or Energy Conversion

schemes). You get this benefit with

only a marginal reduction in efficiency

and output. The GT13E2s optimised

operation mode allows for 36,000

equivalent operating hours between

Hot Gas Path inspections.

Efficiency

The GT13E2 has the highest efficiency

of conventional class gas turbines in

simple cycle. It offers unrivalled

performance in markets where fuel

prices are high or fluctuate regularly.

The combination of high power output

and high conventional class availability

in both simple and combined cycle are

compelling advantages. The

performance optimised operation mode

also offers the lowest Cost of Electricity

(CoE) when fuel prices are high.

The importance

of flexibility

Where demand is seasonal or fuel prices

are volatile, the ability to switch between

operation modes on-line provides an

added operational advantage. The

GT13E2 has been designed to deliver

the high operational flexibility that allows

a plant owner to maximise profits with

the same hardware.

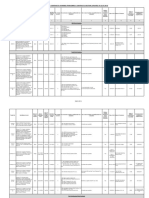

Investment

Cost

Fuel

Cost

O&M

Cost

Baseload

Intermediate

Peaking

CoE (cents/kWh) CoE (cents/kWh)

LIFETIME CONCEPT PERFORMANCE CONCEPT

IMPACT OF CAPITAL COST AND O&M COST (I.E. INSPECTION INTERVALS)

IMPACT OF FUEL COST (I.E. EFFICIENCY)

Operating regime

Fuel price

07

Meeting customer requirements

Our long experience working with customers and

our understanding of different markets across the globe

enable us to adapt to a variety of customer needs.

Low fuel prices

When fuel prices are low, O&M costs

have a significant impact on the total

Cost of Electricity (CoE). To keep O&M

costs down, as plant owner you may

decide to run the plant with longer

inspection intervals. Using this operation

mode of the GT13E2, maintenance

costs can be contained since the EOH

Hot Gas Path inspection intervals run

to 36,000 equivalent operating hours.

Furthermore, at around 0.2%, the

reduction in simple-cycle efficiency is

negligible. The contributions of O&M,

fuel and capital costs to the total Cost

of Electricity, and the preferable

configuration, are shown in the figure

below.

High fuel and/or

electricity prices

When fuel prices are high, the fuel

portion of CoE becomes the dominant

cost factor. Here, efficiency has a huge

leverage effect. You cannot influence

the fuel prices, but you can strive to get

maximum power from the fuel to partly

compensate.

The performance optimised operation

mode of the GT13E2 assures

maximum power - the highest power

output in its class, with the added

benefit of high efficiency, both in simple

cycle and combined cycle, at high

availability and reliability levels.

In times of peak demand, when

electricity prices are high, switching to

the performance optimised operation

mode allows you to maximise

revenues. Alstom also offers integrated

inlet cooling and power increase

options that give even more operational

flexibility for following a variable

electricity demand.

A key aspect is integration,

because it can substantially enhance

flexibility and performance. As a gas

turbine plant EPC contractor, this would

include the following requirements:

TThe gas turbine should be designed

for simple and cost effective

integration into the overall plant.

TIn-depth, comprehensive user

information should be readily available.

TApplication consulting needs to be

available when required.

As a plant owner/operator, you would add

the following requirements to the list:

TOperational flexibility to support plant

dispatch requirements such as quick

start-up, fuel flexibility, black start,

power augmentation, air inlet cooling.

TOperational stability to accommodate

sudden load changes, active grid

frequency support, black grid

restoration, partial or global load

rejection.

TAn efficient Operation and

Maintenance regime.

08

Seamless integration

Developing, building, and operating a profitable gas turbine

power plant goes far beyond selecting components with

promising individual specification parameters.

With the Alstom GT13E2 gas turbine,

all the above come as standard.

The GT13E2 is the result of years of

Alstom experience in gas turbine plant

design and construction. This

experience goes back to the worlds first

commercial gas turbine plant in

Neuchatel, Switzerland, in 1939. Today,

Alstom is the leading EPC contractor

worldwide, with technology for all plant

components in house.

The GT13E2 is also backed by Alstoms

plant operating and maintenance

service expertise, with a portfolio from

spare parts delivery up to full operation

and maintenance. Operational support

is also available on a 24 hour / 7 day

basis with the on-line Alstom Monitoring

and Diagnosis System (AMODIS).

09

1] Engine design

T Compact arrangement, particularly for multi-unit or

combined-cycle configurations.

T Lower investment and better use of lay-down space by

using a common crane.

T Reduced dust ingestion and longer filter life from an

elevated air intake location.

T Effective maintenance of indoor or outdoor

configurations through a spacious off-base GT

enclosure.

T Quick installation and start-up through pre-assembled

and pretested mechanical and electrical auxiliaries.

T A comprehensive standard scope for low integration

and maintenance costs and high availability.

T A generator breaker, eliminating costly HV in-feed for

start-up.

T A static starting device to allow for multiple starts.

T A TOPAIR high-efficiency totally enclosed air-cooled

generator avoiding the use of hydrogen and the

corresponding expensive auxiliaries.

T Full on-site maintainability of the engine.

2] Scope flexibility

T As both a leading equipment OEM and a major turnkey

constructor, Alstom can tailor its scope to meet any

customer needs.

T With our experience, we can contribute to projects of

any size or scope from a single gas turbine unit to a

full turnkey operation.

T Additional services such as training, spare parts and

customised operation as well as maintenance solutions

can be provided, depending on customer requirements.

3] Project Development Support

T Project feasibility studies and commercial modeling.

T Plant concept and technical/commercial assessment.

T Site evaluation and foundation engineering.

T Permitting and environmental impact analysis.

T Site access and heavy equipment transport studies

and advice.

T Grid interface and grid stability studies.

T Financial engineering assistance.

T Plant design.

4] Integration Support

T Engineering documents available to customers and

in electronic form for simple integration into bid or

project documentation.

T Staggered provision of information to match the

projects development phase:

- Application Information Package for project

development.

- Proposal Integration Package for proposal support.

- Project Start-Up Package for contract start phase.

T Commitment on power train performance is also

provided as part of the life-cycle cost analysis.

GT13E2 key benefits

10

The GT13E2 in action delivering profit

The GT13E2 is Alstoms answer to the increasing worldwide demand for high-performance

gas turbines. Equally suitable for combined-cycle and open-cycle plants, it supports almost

every type of application.

With more than one hundred GT13E2s

in operation and millions of fired hours

to its credit, this superior gas turbine

has already built an impressive track

record of reliability and performance in

various stringent conditions.

FKirina / ALGERIA

2xGT13E2, 292 MW

Fuel: natural gas/oil No.2

Sonelgaz base load simple cycle power

plant, operating since October 2004,

is a key support of the Algerian grid

at its far northeastern end. The plant

is located 120 km South-East of

Constantine, the third largest city in

Algeria.

The plant was built on a turnkey basis

in record time, from contract signing to

the first units commercial operation

date. The second unit was on-line one

month later both units completed

exactly on time.

The plant layout was prepared such that

the planned addition of further units,

including the conversion to combined

cycle can be accomplished without

disturbing the operation of the Phase 1

portion of the plant.

Ever since FKirina has gone commercial,

it has been a cornerstone of Sonelgaz

power supply to the Algerian national

grid. With its exceptional reliability and

availability, the plant has become one of

Sonelgaz premiere moneymakers.

Cockburn / AUSTRALIA

1xKA13E2-1, 240 MW

Fuel: natural gas/oil No. 2

Western Powers 240 MW combined-

cycle Cockburn power plant is situated

adjacent to the existing coal-fired

power plant in Kwinana, 30 km south

of Perth in Western Australia.

The GT13E2 in simple cycle

T Efficient, reliable operation

T Packaged for fast, low-cost

installation

T Fast start and loading

T Excellent grid stabilising

capability

The GT13E2 in combined cycle

T High exhaust energy and

temperature for superior

thermodynamic performance

T Cold-end drive and axial exhaust

for reduced exhaust system

pressure losses and better layout

T Available pre-engineered multi-

shaft configurations

Kuala Langat,

Malaysia.

11

The plant supplies power to the states

south-western region and the state

capitals metropolitan area. The

strategic location is near an established

transmission infrastructure, natural gas

fuel supply pipelines and cooling ocean

water. The construction began in June

2002 and cold commissioning took

place at the end of March 2003.

Completion was achieved in early

October 2003, nearly four months

ahead of schedule.

Kuala Langat / MALAYSIA

1xKA13E2-3, 670 MW

Fuel: natural gas/oil No. 2

This cogeneration plant was the first of

several independent power projects

with the GT13E2 in Malaysia. Owned

by Genting Sanyen Power, the 667 MW

combined-cycle plant was built on a

fast track, completed only 24 months

after contract signing two months

ahead of schedule. The first turbine

was installed in simple cycle mode in

November 1994 and all three were

being operated by March 1995. With

the completion of the steam cycle, the

plant generated 667 MW and supplied

57 tons/hour of process steam to the

adjacent paper mill. Power output has

been increased in steps since 2002 by

upgrading the gas turbines to the latest

version. In early 2007, all gas turbines

were upgraded to a flexible operating

mode that allows choosing on-line

between higher output and extended

lifetime.

Ras Abu Fontas B & B1 /

QATAR

8xGT13E2, total 1000 MW

Fuel: natural gas

Ras Abu Fontas B, in commercial

operation since 1995, is the largest and

most important power and water

production plant in Qatar. The power

plant is based on five gas turbines type

GT13E2, operating in simple cycle with

a nominal capacity of 625 MW of

power at 48C ambient temperature.

The desalination plant is designed for

a water production of 150,000 m

3

per

day. To meet the rapidly growing power

demand, the power plant capacity has

been augmented by 377 MW with the

completion in 2002 of the expansion

Ras Abu Fontas B1, with three additional

gas turbines of same GT13E2 type.

All eight gas turbines are installed in one

air-conditioned gas turbine building.

Operating on natural gas from 14

different sources, with a wide range of

gas compositions without any hardware

change, the power plant has

demonstrated its exceptional fuel

flexibility.

12

Alba / BAHRAIN

Power station 3 & 4

2xKA13D-3, 723MW/2xKA13E2-2, 807MW

Fuel: natural gas/oil No.2 / natural gas

With an installed production capacity

of more than 800,000 tonnes per year,

Aluminium Bahrain (Alba) is currently

one of the largest modern aluminium

smelters in the world.

The main power system supplying

the aluminium pot lines is run

independently from the national grid

system, thus puting some unusual

electrical system control requirements

on the captive power system. High gas

turbine and combined cycle flexibility

and continuous reliability are a must.

3/4 of Alba installed power generation

capacity is supplied by Power Stations 3

& 4 installed by Alstom. The GT13D gas

turbines of Power Station 3 have been

continuously improved and upgraded,

resulting in increased performance,

extended inspection intervals, increased

expected lifetime and improved overall

availability. The NOx emissions have also

been considerably reduced.

The GT13E2s of Power Station 4 operate

in the lifetime optimised mode and are

able to cope with the possibility of large

power surges.

The gas turbines GT13D and GT13E2

have demonstrated their excellent

capabilities in powering an industrial

plant with stringent reliability and

flexibility requirements.

Pelican Point / AUSTRALIA

1xKA13E2-2, 480 MW

Fuel: natural gas

In 1998, the government of South

Australia knew it would need to act

quickly if it was to prevent power

shortages. It decided to call on the

private sector; the result was Pelican

Point, a 500 MW combined-cycle

power project developed on a fast

track basis by National Power. The

plant increased South Australias

generating capacity by 20 per cent.

Alstom was awarded the turnkey

project in 1999 by National Power

South Australia Investments Ltd, a

subsidiary of National Power plc. The

plant is equipped with two GT13E2

gas turbines and has been operational

since September 2000. The turbines

are equipped with advanced high-

efficiency, low-emission burner

technology to help meet the strict

environmental requirements at the

site. Alstom also supplied the overall

power plant control system, plant

engineering, and associated

installation and commissioning.

Lumut Extension /

MALAYSIA

1xKA13E2-3, 650 MW

Fuel: natural gas/oil No. 2

The Lumut IPP project is playing an

important role in meeting Malaysias

increasing power demand. When

Alstom won the turnkey contract to

supply another block to the GT13E2

based 1,400 MW combined-cycle

power plant Lumut in Malaysia, it

made the plant the largest independent

(IPP) CCPP in Southeast Asia.

After the 1997 crisis, the government

wanted a new peaking plant to be in

operation by the end of 2001. With an

existing plant at Lumut and therefore

an available infrastructure, it decided to

look at expanding the site to increase

the capacity of the plant. In order to be

operational before the projected

Lumut extension,

Malaysia

13

shortage, the new Lumut Block 3

would have to be given fast track

status, and in order to have power

available to meet the expected

demand, the project developers

invested in a bypass stack. This allowed

open-cycle operations so that 431 MW

would be available while work was

being done to convert the plant to

combined cycle.

The Lumut power plant is located in

the state of Perak, Malaysia. The

customer is GB3 Sdn Bhd, a fully

owned subsidiary of Malakoff Berhad.

Malakoff is the largest independent

power producer in Malaysia with a total

power generating capacity of over

2,000 MW. Alstom was responsible

for the supply of 3x165 MW GT13E2

gas turbines, a steam turbine, three

HRSGs, electrical generators, the entire

auxiliary system, control system and

interconnection facility. Alstom was

also responsible for the supervision of

erection and commissioning works.

Ruwais / UNITED ARAB

EMIRATES

4xGT13E2 500 MW

Fuel: natural gas

In 1998 Alstom was awarded an order

for the Ruwais power and desalination

plant in Abu Dhabi, United Arab Emirates.

The cogeneration plant, operating since

August 2000, provides 500 MW of

power and eight million gallons of water

per day for Abu Dhabi National Oil

Company (ADNOC). The facility is

located in the coastal industrial area of

Ruwais, 230 km west of the capital Abu

Dhabi City. Alstom supplied four

GT13E2 gas turbines and generators,

along with the associated HRSGs and

desalination plant. We also provided the

overall plant control system, the BoP

equipment and complete engineering,

installation and commissioning work.

Phu My / VIETNAM

1xKA13E2-2, 450 MW

Fuel: natural gas/oil No. 2

The Phu My power plant is Vietnams

largest power complex helping to serve

the countrys increasing electricity

demand. The complex is located in the

southern part of the country, 80 km

northeast of Ho Chi Minh City, and all

power plants are of the gas turbine

combined cycle type. The first plant has

been operational since mid 1990s

and the last plant was completed in

May 2006, now with the total capacity

of over 3,800 MW making it the largest

power generating complex in Vietnam.

Alstoms power plants in the complex

include:

- Phu My 2.1 - 300 MW, commercial

operation 1997

- Phu My 2.1 - Add-On 160 MW,

commercial operation 2003

- Phu My 4 - 450 MW, commercial

operation 2004

- Phu My 2.1 - 160 MW add-on,

commercial operation 2006

All plants feature Alstoms GT13E2

gas turbine, which has the capability

for on-line switchover from fuel-gas

to fuel oil and vice versa.

All plants were awarded to Alstom

as turnkey contracts in consortium

with Marubeni Corporation and Lilama

(Vietnam Machinery Erection Cooperation).

Power Train

Arrangments

Alstom has extensive experience

with various sizes of multishaft

arrangement in all types of

operative regimes from base load

to daily start and stop, in utility,

cegeneration and industrial

applications.

Steam Turbine

Alstom steam turbines offer:

T HP turbine shrink ring design for sustained efficiency and fast start-up

T welded rotor design for fast start-up and low maintenace

T single bearing designs for compact arrangement

T single lateral exhaust designs also available

for lower foundations and lower first costs.

1

Heat Recovery Steam

Generator (HRSG)

Alstom's range of HRSGs provide:

Tdrum type of once-through technology

Toptimised hot and cold end

performance for maximised combined

cycle efficiency

Thigh thermal flexibility for fast start up

Thighly modularised design for fast site

erection

4

Gas Turbine

Alstom gas turbines - the core of any

combined cycle plant.

3

Keppel, Singapour.

The Alstom Power Train

Turbogenerator

Alstom turbogenerators demonstrate

high efficiency, reliability and availability

with low maintenance requirements.

TOPAIR

T multi-chamber Totally Enclosed

Water to Air Cooled (TEWAC)

system for high efficiency

T self retightening stator end windings

for low maintenance

T proven relaibility in various

applications and shaft arrangements.

2

1

2

2

3

4

14

Alstom Power R&D

We aim for the best utilisation of the Customers

investment, the earths materials and the fuel used, through

efficiency, availability and cost reduction. The increased

environmental concern means that we place a focus on

minimising CO

2

emissions through the development of

mitigation and renewable technologies for application in

new and retrofit installations.

The engineering and R&D workforce totals 5,500 people,

of which 4,000 are in engineering and 1,500 in R&D in

22 R&D centres. There are 13 laboratories with dedicated

infrastructure, equipment and testing facilitities.

Alstom Power R&D policy takes a global approach which has

several benefits. First, it puts the work where the expertise is

located. Secondly, it helps to nurture close contacts with

universities and design institutes that can complement our in-

house efforts. Thirdly, it enables us to stay in touch with

global customers' expectations, anticipate their needs and

lead the technology trends.

Alstom Power works with more than 30 universities worldwide.

We establish close, long-term links with institutions and

professors who are experts in fields which are important to

us, for example, with MIT and Stanford Research Institute on

CO

2

, Grenoble and Lausanne universities on hydro turbines,

Cologne's DLR on combustion, Oxford University on heat

transfer as well as with engineering institutes in China, India

and Russia.

In the field of international collaboration, Alstom Power has

played a leading role in establishing the European technology

platform for zero emission fossil fuel power generation (ZEP).

The Gas Turbine Test Power Plant

The Gas Turbine Test Power Plant located in Birr, Switzerland,

provides a unique environment for maintaining Alstoms

competitive advantage through product improvement, all

within the proximity of Alstom's R&D facility, the gas turbine

development department and the manufacturing facility.

The shortened feedback loop (in terms of time and distance)

of field experience helps in speeding up design validation

and implementation in Alstom's gas turbine fleet. The Gas

Turbine Test Power Plant, in combination with the Product

Support organization and the GT development department

puts Alstom in a position to insure seamless implementation

of evolutionary product improvements.

Alstom Power R&D is decidedly market and customer oriented

and focuses on creating innovative technologies to apply at all

stages of our products life cycles.

GT Test Power Plant at the

rotor factory in Birr, Switzerland.

15

16

POWER SERVICE PORTFOLIO

Full operation O&M

General/daily maintenance o&M

Operation & maintenance support Risk mitigation

by dedicated

OEM

Operation &

Maintenance

Contracts

Service

Agreements

(LTSA)

Purchase

Orders

Optimization of costs

and performance

o&m

Planned & unplanned maintenance m

Planned outages Support & Consulting

Field Services

Parts

Purchase Order

s

s

s

s

(

s

(

g

Alstom offers extensive service experience in power

generation. It has a complete range of services from

traditional spare parts supply and field service specialists to

the full operation and maintenance of gas turbine and

combined-cycle power plants. As the Original Equipment

Manufacturer (OEM) we are ideally placed to provide

continuous plant improvement packages, e.g. performance

upgrades, lifetime extensions or emission reduction packages

to meet changing market requirements during a plants

operational lifetime.

With over 100 years experience and an installed fleet of more

than 650 GW, Alstoms 200 Local Service Centers (LSCs),

located in 70 countries, are there to provide local facilities and

expertise directly to our customers, keeping your plant

competitive.

Long-term service contracts

Alstoms long-term service contracts are flexible in scope of

services and equipment covered as well as contract duration

in order to meet your unique business requirements. Their

modular scope allows tailor made packages to be assembled

based on the level of risk mitigation and guarantees required,

enabling you to choose the correct contract model that fits

your strategy in terms of operating and maintaining your

power generation assets. With traditional purchase order

contracts, customers can purchase spare parts according to

their needs. Service agreements can add guaranteed

availability and fixed prices for parts, services and consulting.

With our Operations and Maintenance contracts, customers

can have Alstom employees operating and / or maintaining

their plants.

Our experience covers over 25 plants and 60 gas turbines of

the GT13E2 type with long term service contracts. Such

contracts with the OEM benefit from the extensive first-hand

experience gained from site operations and make full use

of the knowledge gained from the complete installed fleet.

With our service contracts, our partners obtain significantly

more value to ensure key requirements (depending upon

scope of supply) are met:

T Predictable operation & maintenance costs

T Reliability and availability

T Heat rate and power output

T Environmentally sound products

T 24 hour / 7 day plant support

T Broad OEM experience

Service during operation

17

Plant Support Centre

Alstoms Plant Support Centre (PSC)

located in Baden, Switzerland, offers

remote, fast and comprehensive

technical support for the whole power

plant around the clock. In addition to

trouble shooting, the PSC provides data

monitoring services including early

warnings and Monitoring & Diagnostic

Reports, assessment of health

parameters and consulting regarding

performance and RAM (reliability,

availability, maintainability)

optimization. The PSC reduces

operational risks through its focus on

pro-active monitoring, which provides

early warning of emerging equipment

problems through advanced diagnostic

programs.

Plant Integrator

creating customer value

Plant Integrator is Alstom's unique concept that creates

value for our customers. Plant Integrators starting point

is the customers viewpoint. It then systematically analyses,

measures and optimises the specific customer benefits

desired, technically, economically and ecologically. As a result,

Plant Integrator matches customer needs and priorities with

products and services, delivering a thoroughly tailored

solution and maximising customer value. This then becomes

the benchmark for future fine-tuning and upgrades.

The unrivalled Plant Integrator offering from Alstom covers

the full palette, from single component packages and control

systems to power islands and complete plants, operation and

maintenance services, as well as retrofit solutions.

Plant Integrator benefits to customers:

T Improve cash flow by achieving lowest costs

T Generate more power

T Increase installation efficiency

T Burn less fuel

T Improve operational flexibility

A world leader in

clean power generation

Alstom is a global leader in the world of power

generation and sets the benchmark for innovative and

environmentally friendly technologies.

The company designs, manufactures and delivers state-of-

the-art products and systems to the power generation

(gas, coal and hydro power plants) and industrial markets.

In addition, Alstom provides the conventional equipment for

nuclear power plants.

Our objective is to build the cleanest integrated power

solutions for our customers. We supply and integrate all

components of a clean power system, from boilers to air

quality control and energy recovery systems. We also have

extensive experience in retrofitting, upgrading and

modernising existing power plant equipment. We can also

boast unrivalled expertise in project management for all types

and sizes of power generation systems small to large as

well as single equipment to complete turnkey solutions.

Alstoms unique offering brings real value to our customers.

With our innovative plant integration concept, we help

operators to maximise their plant performance, while fully

complying with environmental regulations and obligations.

Expertise in clean power solutions

Plant operators today face multiple challenges in their efforts

to make their plants more competitive, while complying with

the different environmental regulations.

Alstom is delivering clean power solutions now. As the

uncontested leader in clean power generation technologies,

we provide the cleanest integrated power solutions

on the market.

Lumut, Malaysia.

18

A world leader

Alstom supplies major equipment for 25% of

the worlds installed base, making us:

N1 in turnkey power plants

N1 in air quality control systems

N1 in hydro turbines and generators

N1 in the number of installed boilers

worldwide

N1 in installed turbines and generators

for nuclear power plants

N1 in steam turbine retrofit and integrated

retrofit projects

They cover all plants (both existing and new ones), all energy

sources (from fossil fuels to hydro and nuclear), and all

emissions (NOx, SOx, Mercury, particulate matter).

Alstom offers the complete range of products designed to help

power plants to either reduce pollutant and CO

2

emissions, or

to produce clean electricity from the outset.

For example, we deliver new coal-fired power plants with an

advanced supercritical design using proven clean combustion

solutions that are integrated with state-of-the-art emission

controls. Similarly, we improve the thermal and

environmental efficiency of existing power plants by

retrofitting plant components or upgrading the whole system.

Investing in the future of clean power

Alstom is uniquely placed as a plant integrator and full-service

provider to design and manufacture all the components

of a clean power plant, from turbines such as the GT13E2

to generators, boilers and air quality control systems.

Alstom also invests substantially in the research and

development of new, environmentally friendly power solutions.

Together with partners, universities and customers in Europe

and the United States, we are working on collaborative

projects to develop solutions for pre- and post-combustion

CO

2

capture and oxy-firing.

Research in action

In addition to our own R&D efforts to develop new emission

control technologies and improve existing techniques, we are

also involved in a number of public projects and partnerships,

notably in the field of CO

2

capture and storage. The CASTOR

project (founded by the European Union) is studying

procedures for post-combustion separation that lower the cost

of CO

2

capture and develop an understanding of the long

term storage mechanism. Within the ENCAP programme

(founded by the European Union), research is under way to

develop new pre-combustion and post-combustion CO

2

capture technologies. The Zero Emission Fossil Fuel Power

Plants (ZEP) technology platform launched by the European

Commission aims to develop and deploy new competitive

options for zero emission fossil fuel power plants.

Dunkirk combined cycle

power plant, France.

19

P

T

-

P

E

/

B

P

R

O

B

/

G

T

1

3

E

2

0

7

/

e

n

g

/

T

M

G

/

0

6

.

0

9

/

C

H

/

6

2

6

2

-

A

l

s

t

o

m

,

t

h

e

A

l

s

t

o

m

l

o

g

o

a

n

d

a

n

y

a

l

t

e

r

n

a

t

i

v

e

v

e

r

s

i

o

n

t

h

e

r

e

o

f

a

r

e

t

r

a

d

e

m

a

r

k

s

a

n

d

s

e

r

v

i

c

e

m

a

r

k

s

o

f

A

l

s

t

o

m

.

T

h

e

o

t

h

e

r

n

a

m

e

s

m

e

n

t

i

o

n

e

d

,

r

e

g

i

s

t

e

r

e

d

o

r

n

o

t

,

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

t

h

e

i

r

r

e

s

p

e

c

t

i

v

e

c

o

m

p

a

n

i

e

s

.

T

h

e

t

e

c

h

n

i

c

a

l

a

n

d

o

t

h

e

r

d

a

t

a

c

o

n

t

a

i

n

e

d

i

n

t

h

i

s

d

o

c

u

m

e

n

t

i

s

p

r

o

v

i

d

e

d

f

o

r

i

n

f

o

r

m

a

t

i

o

n

o

n

l

y

.

N

e

i

t

h

e

r

A

l

s

t

o

m

,

i

t

s

o

f

f

i

c

e

r

s

n

o

r

e

m

p

l

o

y

e

e

s

a

c

c

e

p

t

r

e

s

p

o

n

s

i

b

i

l

i

t

y

f

o

r

o

r

s

h

o

u

l

d

b

e

t

a

k

e

n

a

s

m

a

k

i

n

g

a

n

y

r

e

p

r

e

-

s

e

n

t

a

t

i

o

n

o

r

w

a

r

r

a

n

t

y

(

w

h

e

t

h

e

r

e

x

p

r

e

s

s

o

r

i

m

p

l

i

e

d

)

a

s

t

o

t

h

e

a

c

c

u

r

a

c

y

o

r

c

o

m

p

l

e

t

e

n

e

s

s

o

f

s

u

c

h

d

a

t

a

o

r

t

h

e

a

c

h

i

e

v

e

m

e

n

t

s

o

f

a

n

y

p

r

o

j

e

c

t

e

d

p

e

r

f

o

r

m

a

n

c

e

c

r

i

t

e

r

i

a

w

h

e

r

e

t

h

e

s

e

a

r

e

i

n

d

i

c

a

t

e

d

.

N

o

l

i

a

b

i

l

i

t

y

i

s

a

c

c

e

p

t

e

d

f

o

r

a

n

y

r

e

l

i

a

n

c

e

p

l

a

c

e

d

u

p

o

n

t

h

e

i

n

f

o

r

m

a

t

i

o

n

c

o

n

t

a

i

n

e

d

i

n

t

h

i

s

b

r

o

c

h

u

r

e

.

A

l

s

t

o

m

r

e

s

e

r

v

e

s

t

h

e

r

i

g

h

t

t

o

r

e

v

i

s

e

o

r

c

h

a

n

g

e

t

h

i

s

d

a

t

a

a

t

a

n

y

t

i

m

e

w

i

t

h

o

u

t

f

u

r

t

h

e

r

n

o

t

i

c

e

.

I

f

a

n

y

p

r

o

v

i

s

i

o

n

o

f

t

h

i

s

d

i

s

c

l

a

i

m

e

r

i

s

h

e

l

d

b

y

a

n

y

c

o

m

p

e

t

e

n

t

a

u

t

h

o

r

i

t

y

t

o

b

e

i

n

v

a

l

i

d

o

r

u

n

e

n

f

o

r

c

e

a

b

l

e

i

n

w

h

o

l

e

o

r

i

n

p

a

r

t

t

h

e

v

a

l

i

d

i

t

y

o

f

t

h

e

o

t

h

e

r

p

r

o

v

i

s

i

o

n

s

a

n

d

t

h

e

r

e

m

a

i

n

d

e

r

o

f

t

h

e

p

r

o

v

i

s

i

o

n

i

n

q

u

e

s

t

i

o

n

s

h

a

l

l

n

o

t

b

e

a

f

f

e

c

t

e

d

.

D

e

s

i

g

n

a

n

d

r

e

a

l

i

s

a

t

i

o

n

:

L

e

s

E

d

i

t

i

o

n

s

S

t

r

a

t

g

i

q

u

e

s

.

P

h

o

t

o

c

r

e

d

i

t

s

:

2

0

0

7

B

r

y

o

n

P

a

u

l

M

c

C

a

r

t

n

e

y

|

w

w

w

.

a

t

e

l

i

e

r

-

m

c

c

a

r

t

n

e

y

.

c

o

m

,

A

l

s

t

o

m

a

n

d

o

t

h

e

r

s

.

P

r

i

n

t

e

d

o

n

p

a

p

e

r

m

a

d

e

w

i

t

h

p

u

r

e

E

C

F

(

E

l

e

m

e

n

t

a

l

C

h

l

o

r

i

n

e

F

r

e

e

)

e

c

o

l

o

g

i

c

a

l

c

e

l

l

u

l

o

s

e

p

r

o

d

u

c

e

d

f

r

o

m

t

r

e

e

s

g

r

o

w

n

i

n

p

r

o

d

u

c

t

i

o

n

f

o

r

e

s

t

s

u

n

d

e

r

r

e

s

p

o

n

s

i

b

l

e

m

a

n

a

g

e

m

e

n

t

,

a

n

d

s

e

l

e

c

t

e

d

r

e

c

y

c

l

e

d

t

h

r

e

e

-

l

a

y

e

r

f

i

b

r

e

s

.

Alstom (Switzerland) Ltd

Brown-Boveri Strasse 7

CH-5401 Baden

Switzerland

Phone +41 56 205 70 58

Fax +41 56 205 28 88

www.alstom.com

Vous aimerez peut-être aussi

- Gt13e2 Gas TurbineDocument20 pagesGt13e2 Gas TurbineJohann Alexander Caballero Bohorquez100% (3)

- SGT-2000E Series: Siemens Gas TurbineDocument10 pagesSGT-2000E Series: Siemens Gas TurbineRoozbeh PPas encore d'évaluation

- 05 GT13E2+Rotor+Information HandoutsDocument21 pages05 GT13E2+Rotor+Information HandoutsShangker Kanesh100% (3)

- Gas Turbine Control & Protection: Presentation ONDocument46 pagesGas Turbine Control & Protection: Presentation ONrahulNrana100% (2)

- GE Frame 9Document4 pagesGE Frame 9Umar Saeed100% (1)

- Mechanical Interview Questions & Answers (Gas Turbine)Document14 pagesMechanical Interview Questions & Answers (Gas Turbine)ChiduPas encore d'évaluation

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversD'EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversÉvaluation : 5 sur 5 étoiles5/5 (2)

- 1-Gas Turbine DesignDocument56 pages1-Gas Turbine DesignMohammed Yusuf100% (2)

- 9fa PDFDocument3 pages9fa PDFsujiv_sujiv1278Pas encore d'évaluation

- Gt13e2 Gas Turbine 2012 UpgradeDocument2 pagesGt13e2 Gas Turbine 2012 UpgradeJJ100% (1)

- DLN 1.0 MS9001Document20 pagesDLN 1.0 MS9001Atif Khan100% (9)

- IGV Operational Principle - 1Document5 pagesIGV Operational Principle - 1ramkrishnaPas encore d'évaluation

- GT Operation (Nanjin)Document146 pagesGT Operation (Nanjin)Ady FardyPas encore d'évaluation

- Gek 116689Document32 pagesGek 116689HAPas encore d'évaluation

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LPas encore d'évaluation

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash SrivastavaPas encore d'évaluation

- GE Gas Turbine IGV AngleDocument8 pagesGE Gas Turbine IGV Angleramkrishna100% (1)

- IGV, Servos and LVDT - Automation & Control Engineering ForumDocument1 pageIGV, Servos and LVDT - Automation & Control Engineering ForumHBNBILPas encore d'évaluation

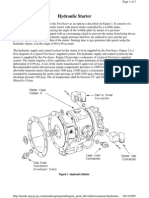

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezPas encore d'évaluation

- Pivot Arm Turning GearDocument24 pagesPivot Arm Turning Gearoom_tgw100% (1)

- Trip OilDocument3 pagesTrip Oilchdeepak96100% (1)

- Overview of Start-Up of Gas TurbineDocument38 pagesOverview of Start-Up of Gas TurbineJulio Cesar Barajas Aguilar100% (1)

- Torque Converter Voith Torque ConverterDocument22 pagesTorque Converter Voith Torque ConverterDewayne MaddenPas encore d'évaluation

- Dry Low Nox 2.0+ System Operation: Ge Power SystemsDocument10 pagesDry Low Nox 2.0+ System Operation: Ge Power SystemsFernando Piaggio100% (1)

- Frame 9e Gas Turbine PresentationDocument98 pagesFrame 9e Gas Turbine PresentationSONU100% (1)

- GE Gas TurbineTheoryDocument62 pagesGE Gas TurbineTheorysalamadel100% (2)

- Dry Low NoxDocument10 pagesDry Low NoxIvan Poma Montes100% (1)

- DLN2+ HRDWDocument21 pagesDLN2+ HRDWnabil160874100% (4)

- 7FA Gas Turbine GT DataSheetsDocument7 pages7FA Gas Turbine GT DataSheetsAbisholita MecaTronics100% (1)

- GE 9FA Water Wash PROCEDURE FinalDocument43 pagesGE 9FA Water Wash PROCEDURE FinalAbdelaziz EldeebPas encore d'évaluation

- Detailed Hot Section Mapping of Siemens SGT 600 PDFDocument19 pagesDetailed Hot Section Mapping of Siemens SGT 600 PDFfrdnPas encore d'évaluation

- Calibration ProcedureDocument2 pagesCalibration ProcedureChidiebere Samuel OkogwuPas encore d'évaluation

- What Is The Difference Between Dln-1 & Dln-2? Like ReplyreportDocument49 pagesWhat Is The Difference Between Dln-1 & Dln-2? Like ReplyreportSahariar Bin Shafique100% (1)

- Swirl AngleDocument3 pagesSwirl AngleNIGERE100% (4)

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 pagesVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifPas encore d'évaluation

- GT ProtectionDocument3 pagesGT ProtectionHarin100% (1)

- Gas Turbine Compressor Wash System ModificationDocument13 pagesGas Turbine Compressor Wash System Modificationprasad5034Pas encore d'évaluation

- GT Various Systems (G)Document62 pagesGT Various Systems (G)shtiwari2002100% (2)

- Compressor Maintenance Water WashingDocument30 pagesCompressor Maintenance Water WashingMajid Motahari100% (1)

- Better Understanding of Gas Turbine ControlDocument117 pagesBetter Understanding of Gas Turbine ControlShahzad James100% (1)

- MS Fa 6593Document668 pagesMS Fa 6593Jeya PrakashPas encore d'évaluation

- Gas Turbine Heat Rate Versus EOHDocument2 pagesGas Turbine Heat Rate Versus EOHAbdulyunus Amir100% (1)

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Industrial Gas Turbines - Siemens PDFDocument8 pagesIndustrial Gas Turbines - Siemens PDFeankiboPas encore d'évaluation

- Future Trend of Gas Turbine DevelopmentDocument6 pagesFuture Trend of Gas Turbine DevelopmentT/ROX100% (1)

- Lube Oil System: ١ - ﺖﻳﺰﻟا ﻚﻨﺗ nk Oil Ta) 001 BB 10 MBV (Document15 pagesLube Oil System: ١ - ﺖﻳﺰﻟا ﻚﻨﺗ nk Oil Ta) 001 BB 10 MBV (kamal arabPas encore d'évaluation

- GFA - GT Exhaust Spread ProblemDocument5 pagesGFA - GT Exhaust Spread Problemأمير معروف100% (1)

- Igv 7eaDocument2 pagesIgv 7eaSamir BenabdallahPas encore d'évaluation

- Terms and Abbreviation For GE Gas TurbinesDocument3 pagesTerms and Abbreviation For GE Gas TurbinesFazalur Rehman Babar100% (1)

- Gas Turbine StartupDocument9 pagesGas Turbine StartupSturovo TurboPas encore d'évaluation

- C10518078 PDFDocument20 pagesC10518078 PDFJessica ChandlerPas encore d'évaluation

- Exhaust Temperature SpreadDocument5 pagesExhaust Temperature Spreadchdeepak96100% (6)

- Gas Turbine: Superior Flexibility / Superior PerformanceDocument20 pagesGas Turbine: Superior Flexibility / Superior PerformancejparmarPas encore d'évaluation

- Gas Turbine: Unique in Its Fuel Flexibility and ReliabilityDocument16 pagesGas Turbine: Unique in Its Fuel Flexibility and ReliabilityMônica Nascimento100% (1)

- Gt24 and Gt26 Gas TurbinesGBDocument24 pagesGt24 and Gt26 Gas TurbinesGBwangchao821100% (1)

- Alstom GT24>26Document20 pagesAlstom GT24>26Shin Hye Yean100% (3)

- CatalogoTurbineaGas PDFDocument34 pagesCatalogoTurbineaGas PDFshihabjamaan0% (1)

- Turbina de Gas GT24 y GT26 AlstomDocument20 pagesTurbina de Gas GT24 y GT26 AlstomDiana RsendizPas encore d'évaluation

- Alstom Nuclear PlantDocument57 pagesAlstom Nuclear Plantjparmar100% (1)

- Steam Turbine Book For Engineering StudentsDocument663 pagesSteam Turbine Book For Engineering Studentsjparmar100% (1)

- Allam CycleDocument20 pagesAllam CyclejparmarPas encore d'évaluation

- Gas Turbine: Superior Flexibility / Superior PerformanceDocument20 pagesGas Turbine: Superior Flexibility / Superior PerformancejparmarPas encore d'évaluation

- Sealing in TurbomachineryDocument62 pagesSealing in Turbomachineryjparmar100% (1)

- Degradation of Combined Cycle Power PlantDocument2 pagesDegradation of Combined Cycle Power PlantjparmarPas encore d'évaluation

- Supercritical Technology in IndiaDocument4 pagesSupercritical Technology in IndiajparmarPas encore d'évaluation

- 7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its ClassDocument4 pages7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its Classjparmar100% (2)

- GE 9HA Gas TurbineDocument4 pagesGE 9HA Gas TurbinejparmarPas encore d'évaluation

- Toshiba CO2 Plant Dec14Document5 pagesToshiba CO2 Plant Dec14jparmarPas encore d'évaluation

- J Parmar - D Gilmartin O&M PaperDocument14 pagesJ Parmar - D Gilmartin O&M PaperjparmarPas encore d'évaluation

- GEOELEC - Binary-Plant Pisa BombardaDocument41 pagesGEOELEC - Binary-Plant Pisa BombardajparmarPas encore d'évaluation

- MHI To Supply Six M501J Gas Turbines For A 2,600MW Plant in Taiwan - TurbomaDocument2 pagesMHI To Supply Six M501J Gas Turbines For A 2,600MW Plant in Taiwan - TurbomajparmarPas encore d'évaluation

- Integration of First Principles and Empirical Modeling Technologies For Improved Plant Reliability and Efficiency - Feb12Document8 pagesIntegration of First Principles and Empirical Modeling Technologies For Improved Plant Reliability and Efficiency - Feb12jparmarPas encore d'évaluation

- An Example Evaluation of IGCC Performance Test Code ASME PTC 47 by Anand, Parmar Et AlDocument7 pagesAn Example Evaluation of IGCC Performance Test Code ASME PTC 47 by Anand, Parmar Et AljparmarPas encore d'évaluation

- GE Advance Material and CoatingDocument30 pagesGE Advance Material and Coatingkhunplatt100% (1)

- Siemens 1 GTX 100 TurbineDocument16 pagesSiemens 1 GTX 100 TurbinejparmarPas encore d'évaluation

- Alstom Country Sheet India 2021 ENDocument2 pagesAlstom Country Sheet India 2021 ENCHIRAG JIVANIPas encore d'évaluation

- SteamTurbine Brochure MidDocument20 pagesSteamTurbine Brochure MidSubrata Das100% (1)

- Citadis - Sales Brochure - Eng - Sept 2014 - LD PDFDocument16 pagesCitadis - Sales Brochure - Eng - Sept 2014 - LD PDFIngeniumDemPas encore d'évaluation

- Numerical Protection PDFDocument14 pagesNumerical Protection PDFDrashti PatelPas encore d'évaluation

- Oil Guns and Gas Firing Equipment PDFDocument24 pagesOil Guns and Gas Firing Equipment PDFPravin KumarPas encore d'évaluation

- PRASA - Case Study - ENDocument2 pagesPRASA - Case Study - ENPTOIR FPTK UPIPas encore d'évaluation

- 2 Shivansh InstafinancialsDocument419 pages2 Shivansh InstafinancialsYesBroker InPas encore d'évaluation

- Alstom Transport PresentationDocument20 pagesAlstom Transport PresentationmarioerasurePas encore d'évaluation

- Gbu Ip Plta Saguling2 PDFDocument4 pagesGbu Ip Plta Saguling2 PDFAfifah Nurul MaulinaPas encore d'évaluation

- Alstom Inspection Robotics Lecture Technology TransferDocument52 pagesAlstom Inspection Robotics Lecture Technology TransferDžoš FrešPas encore d'évaluation

- List of Contracts AwardedDocument21 pagesList of Contracts AwardedShailesh GangPas encore d'évaluation

- Company Approved Manufacturers - 13042014Document190 pagesCompany Approved Manufacturers - 13042014Mohideen SikanderPas encore d'évaluation

- LAA 421 C0U 1400033 A - Methodology For Vibration Mitigation in Corridor 1&2Document26 pagesLAA 421 C0U 1400033 A - Methodology For Vibration Mitigation in Corridor 1&2Anup Pandey100% (1)

- Sample Detailed CVDocument18 pagesSample Detailed CVpepenapao1217Pas encore d'évaluation

- CCJ7 ProductsandServiceslDocument16 pagesCCJ7 ProductsandServiceslsmvhoraPas encore d'évaluation

- Powering The World: With Ge'S Solutions For Nuclear Turbine IslandsDocument24 pagesPowering The World: With Ge'S Solutions For Nuclear Turbine IslandsShanon RustoffPas encore d'évaluation

- Servovalvereference ListDocument10 pagesServovalvereference Listramnadh803181Pas encore d'évaluation

- 02 Areva Distribution Acquisition Presentation tcm50 307707Document29 pages02 Areva Distribution Acquisition Presentation tcm50 307707Aizat RazakPas encore d'évaluation

- PML - ElectricalDocument7 pagesPML - ElectricaltarsudinPas encore d'évaluation

- Alstom Grid Brochure ENGDocument6 pagesAlstom Grid Brochure ENGMalavika GhoshPas encore d'évaluation

- BSE Listed Comapnies - 20.12.12Document132 pagesBSE Listed Comapnies - 20.12.12rtos123Pas encore d'évaluation

- Thailand FactsheetDocument5 pagesThailand FactsheetNattanapong KongtrakulPas encore d'évaluation

- Mobile SubstationsDocument7 pagesMobile SubstationsAnonymous EVFw59Pas encore d'évaluation

- CMRL PS Ohe 01 2017Document33 pagesCMRL PS Ohe 01 2017rajimuruganPas encore d'évaluation

- TURBO 1 - 2012 - GTs-rev.A PDFDocument140 pagesTURBO 1 - 2012 - GTs-rev.A PDFAshraf AbdelrahmanPas encore d'évaluation

- EDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Document3 pagesEDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Ramesh-NairPas encore d'évaluation

- Alstom Delivers India's First Semi High-Speed Regional Train For Delhi-Meerut RRTS ProjectDocument2 pagesAlstom Delivers India's First Semi High-Speed Regional Train For Delhi-Meerut RRTS ProjectSahil Ullah KhanPas encore d'évaluation

- MOBIL L - Ind - Prod - Summary - 2010 PDFDocument56 pagesMOBIL L - Ind - Prod - Summary - 2010 PDFCorina StanculescuPas encore d'évaluation