Académique Documents

Professionnel Documents

Culture Documents

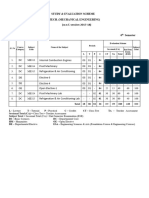

Subject Internal Combustion Engine Semester 5th Trade Mechanical Year 3rd

Transféré par

Kareem VazquezCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Subject Internal Combustion Engine Semester 5th Trade Mechanical Year 3rd

Transféré par

Kareem VazquezDroits d'auteur :

Formats disponibles

INSTRUCTION FOR FACULTY

1. Absentee slip be filled daily for all classes and submitted to the

Registrar/A.O.

2. Monthly report is submitted till 3

rd

of every month (Separately for separate

subjects).

3. Teacher assessment form to be filled daily after the class.

4. Syllabus is attached in the attendance register.

5. Attendance is marked as 1, 2, 3, 4If student is absent, Absent be marked

and date of classes taken to be mentioned in the attendance registers.

6. If the faculty wants to exchange class with other faculty that has to be

informed prior to taking class to the Registrar. A/O

7. Date of column to be made for mentioning dates.

8. If there is holiday, then it has to be mentioned.

9. After mid term examination, answer sheets to be checked within a week and

award list submitted.

10. Faculty to take presentation/quizzes of the students if the course completes

before time.

11. Classes scheduled as per academic calendar of the University is to be

adhered.

SUBJECT: INTERNAL COMBUSTION ENGINE & GAS TURBINE

SUBJECT CODE: ME-307-F

FACULTY NAME: LOVE BHARDWAJ

PREPARED BY: LOVE BHARDWAJ

CHECKED BY: B.C. KUMAR (H.O.D.M.E.)

SUBMITTED FOR DIRECTOR SIR APPROVAL

MANAGEMENT EDUCATION AND RESEARCH INSTITUTE

COLLEGE OF ENGINEERING AND TECHNOLOGY

(DEPARTMENT OF MECHANICAL ENGINEERING)

LESSON PLAN FILE

Name of the Faculty: LOVE BHARDWAJ

Semester: 5

th

ME

Subject: INTERNAL COMBUSTION ENGINE AND GAS TURBINE

INDEX

S.NO NOMENCLATURE Page No.

1. Syllabus as per MDU 3

2. Focal Points 4

3. Course objective 5

4. Lesson Plan 6-10

5. Important Questions 11

6. Assignments 12-20

7. Question papers & MCQs 21-25

8. Notes 26-41

9. Attendance Sheet 42

10. Monthly Report 43

11. Student Feedback Report 44

(5

th

Semester of MECH (IC ENGINE) syllabus as per MDU)

ME- 307F INTERNAL COMBUSTION ENGINES & GAS TURBINES

Section A

Air Standard Cycles: Internal and external combustion engines; classification of I.C.

Engines, Cycles of operation in four stroke and two stroke I.C. Engines, Wankel Engines,

Assumptions made in air Standard cycle; Otto cycle; diesel cycle, dual combustion cycle,

comparison of Otto, diesel and dual combustion cycles; sterling and Ericsson cycles; air

standard efficiency, specific work output, specific weight; work ratio; mean effective

pressure; deviation of actual engine cycle from ideal cycle. Problems. Carburetion, fuel

Injection and Ignition systems: Mixture requirements for various operating conditions in

S.I.Engines; elementary carburetor, Requirements of a diesel injection system; types of

inject systems; petrol injection, Requirements of ignition system; types of ignition systems

ignition timing; spark plugs. Problems.

Section B

Combustion in I.C. Engines : S.I. engines; Ignition limits; stages of combustion in S.I.

Engines; Ignition lag; velocity of flame propagation; detonation; effects of engine variables

on detonation; theories of detonation; octane rating of fuels; pre-ignition; S.I. engine

combustion chambers, Stages of combustion in C.I. Engines; delay period; variables

affecting delay period; knock in C.I. engines, Cetane rating; C.I. engine combustion

chambers. Lubrication and Cooling Systems: Functions of a lubricating system, Types of

lubrication system; mist, wet sump and dry sump systems; properties of lubricating oil;

SAE rating of lubricants, engine performance and lubrication, Necessity of engine cooling;

disadvantages of overcooling; cooling systems; air-cooling, water cooling; radiators.

Section C

Engine Testing and Performance: Performance parameters: BHP, IHP, mechanical

efficiency, brake mean effective pressure and indicative mean effective pressure, torque,

volumetric efficiency; specific fuel consumption (BSFC, ISFC), thermal efficiency; heat

balance; Basic engine measurements; fuel and air consumption, brake power, indicated

power and friction power, heat lost to coolant and exhaust gases; performance curves.

Problems Air pollution from I.C. Engine and Its remedies: Pollutants from S.I. and C.I.

Engines, Methods of emission control; alternative fuels for I.C. Engines; the current

scenario on the pollution front.

Section D

Rotary Compressors: Root and vane blowers; Static and total head values; Centrifugal

compressors Velocity diagrams, slip factor, ratio of compression, pressure coefficient, pre-

whirl; Axial flow compressor- Degree of reaction, polytropic efficincy, surging, choking and

stalling, performance characteristics, Problems. Gas Turbines: Brayton cycle; Components

of a gas turbine plant; open and closed types of gas turbine plants; Optimum pressure ratio;

Improvements of the basic gas turbine cycle; multi stage compression with inter-cooling;

multi stage expansion with reheating between stages; exhaust gas heat exchanger,

Applications of gas turbines. Problems.

MANAGEMENT EDUCATION AND RESEARCH INSTITUTE

COLLEGE OF ENGINEERING AND TECHNOLOGY

INTERNAL COMBUSTION ENGINE & GAS TURBINE

B.E. 5th SEMESTER (Mechanical Engineering)

Course Lecturer-Mr. Love Bhardwaj

COURSE OBJECTIVE-

In the subject the fundamentals of how the design and operation of internal

combustion engines affect their performance, operation, fuel requirements, and

environmental impact. Topics include fluid flow, thermodynamics, combustion,

heat transfer and friction phenomena, and fuel properties, with reference to engine

power, efficiency, and emissions. Students examine the design features and

operating characteristics of different types of internal combustion engines: spark-

ignition, diesel, stratified-charge, and mixed-cycle engines. Class includes lab

project in the Engine Laboratory.

METHODOLOGY-

i. The pedagogy will be lectures and assignments.

ii. Audio Visual aids will be used during the course.

iii. Surprise tests and Quiz

iv. Industrial visits and seminars

EVALUATION-

Besides the semester end examination, the students will be continuously assessed

during the course on the following basis:

i. Mid Term Examinations : 20 Marks

ii. Internal Assessment : 30 Marks

(Assignments : 15 Marks)

(Attendance : 15 Marks)

iii. End Semester Examination : 100 Marks

Total : 150 Marks

Internal Combustion Engines & Gas Turbines

Code: ME-307-F

TEACHING PLAN

5th Semester (Mechanical Engg.) Session 2013-14

Detailed Course Outline References No. of

Session

s

Dates of lectures

Section A

Air Standard Cycles:

Internal and external combustion

engines; classification of I.C.

Engines, Cycles

of operation in four stroke and two

stroke I.C. Engines, Wankel Engines,

Assumptions made in air

standard cycle; Otto cycle; diesel

cycle, dual combustion cycle,

comparison of Otto, diesel and dual

combustion cycles; sterling and

Ericsson cycles; air standard

efficiency, specific work output,

specific

weight; work ratio; mean effective

pressure; deviation of actual engine

cycle from ideal cycle.

Problems

Accessories:

Carburetion, fuel Injection and

Ignition systems: Mixture

requirements for various operating

conditions

in S.I.Engines; elementary

carburetor, Requirements of a

diesel injection system; types of

inject

systems; petrol injection,

Requirements of ignition system;

types of ignition systems ignition

timing;

spark plugs. Problems

.

Text Books:

1. Internal

Combustion

Engines V.

Ganesan, Pub.-

Tata McGraw-

Hill.

2.Gas Turbines

- V. Ganesan,

Pub.- Tata

McGraw Hill.

3. Engineering

fundamental of

the I.C.Engine

Willard W.

Pulkrabek Pub.-

PHI,India

Reference

Books:

1. Internal

Combustion

Engines & Air

pollution- Obert

E.F, Pub.-

Hopper & Row

Pub., New York

2.Internal

Combustion

Engines

Fundamentals-

John B.

Heywood, Pub.-

McGraw Hill,

15

17/8/2013-5/9/2013

New York

Section B

Combustion in I.C. Engines:

S.I. engines; Ignition limits; stages

of combustion in S.I. Engines;

Ignition

lag; velocity of flame propagation;

detonation; effects of engine

variables on detonation; theories of

detonation; octane rating of fuels;

pre-ignition; S.I. engine combustion

chambers, Stages of

combustion in C.I. Engines; delay

period; variables affecting delay

period; knock in C.I. engines,

Cetane rating; C.I. engine

combustion chambers

Lubrication & Cooling

System:

Functions of a lubricating system,

Types of lubrication system; mist,

wet sump and dry sump systems;

properties of lubricating oil; SAE

rating of lubricants, engine

performance and lubrication,

Necessity of engine cooling;

disadvantages of overcooling;

cooling

systems; air-cooling, water cooling;

radiators

Text Books:

1. Internal

Combustion

Engines V.

Ganesan, Pub.-

Tata McGraw-

Hill.

2.Gas Turbines

- V. Ganesan,

Pub.- Tata

McGraw Hill.

3. Engineering

fundamental of

the I.C.Engine

Willard W.

Pulkrabek Pub.-

PHI,India

13

6/9/2013-24/9/2013

Section C

Engine Testing & Performance:

Performance parameters: BHP, IHP,

mechanical efficiency, brake

mean effective pressure and

indicative mean effective pressure,

torque, volumetric efficiency;

specific

fuel consumption (BSFC, ISFC),

thermal efficiency; heat balance;

Basic engine measurements; fuel

and air consumption, brake power,

indicated power and friction

power, heat lost to coolant and

exhaust gases; performance curves.

Problems

Air pollution from I.C. Engine and

its remedies:

Pollutants from S.I. and C.I.

Engines, Methods of

emission control; alternative fuels

for I.C. Engines; the current

scenario on the pollution front

Text Books:

1. Internal

Combustion

Engines V.

Ganesan, Pub.-

Tata McGraw-

Hill.

2.Gas Turbines

- V. Ganesan,

Pub.- Tata

McGraw Hill.

3. Engineering

fundamental of

the I.C.Engine

Willard W.

Pulkrabek Pub.-

PHI,India

10

1/10/2013-12/10/2013

Section D

Rotary Compressors:

Root and vane blowers; Static and

total head values; Centrifugal

compressors-

Velocity diagrams, slip factor, ratio

of compression, pressure

coefficient, pre-whirl; Axial flow

compressor- Degree of reaction,

polytropicefficincy, surging, choking

and stalling, performance

characteristics, Problems.

Gas Turbines:

Brayton cycle; Components of a

gas turbine plant; open and

closed types of gas

turbine plants; Optimum

pressure ratio; Improvements of

the basic gas turbine cycle; multi

stage

compression with inter-cooling;

multi stage expansion with

reheating between stages;

exhaust gas

heat exchanger, Applications of

gas turbines

.

Text Books:

1. Internal

Combustion

Engines V.

Ganesan, Pub.-

Tata McGraw-

Hill.

2.Gas Turbines

- V. Ganesan,

Pub.- Tata

McGraw Hill.

3. Engineering

fundamental of

the I.C.Engine

Willard W.

Pulkrabek Pub.-

PHI,India

9

15/10/2013-26/10/2013

ADD ON

1. RAMJET-

It is the Air-Breathing

system used in many air

crafts.We will study the

different parts of SU-Engine

kept in workshop.

2. HELICOPTER ENGINE-

It is also a air breathing

engine which provide

upward thrust to helicopter

and we will analyse its parts

kept in workhop.

2

29/10/2013-30/10/2013

TOTAL HOURS:49

MANAGEMENT EDUCATION AND RESEARCH INSTITUTE

COLLEGE OF ENGINEERING AND TECHNOLOGY

I NTERNAL COMBUSTI ON ENGI NE & GAS TURBI NE

ME-307-F

B.TECH MECH. 5

TH

SEMESTER

I MPORTANT TOPI CS OF

(I NTERNAL COMBUSTI ON ENGI NE & GAS TURBI NE)

SECTION-A SECTION-B SECTION-C SECTION-D

1. What are I C & EC

engines?

2. Difference b/w 2

stroke and 4 strokes.

3. Different cycles.

4. I dling, cruising, high

power

5. Types of I njection

system

6. Battery-coil ignition

system

1. Variables affecting

the delay period

2. Phenomenon of

knocking in CI engine

and compare it with SI

engine knock

3. Factors tending to

reduce detonation and

knocking in SI and CI

engine

4. Cetane and octane

number

5. Explain the 2 types

of cooling system

6.Different methods to

cool engine

1. Engine efficiencies

2. What is horse power

3. Morse test and

Motoring method

4. Hybrid vehicles &

major components of

Hybrid engines

5. Automobile

companies

manufacture hybrid

vehicles

1. Surging

2. Choking and

polytrophic efficiency

3. Slip factor and derive

an expression for same

4. Advantage and

disadvantages of gas

turbine

5. Classify the gas

turbine cycle

6. Difference between

gas turbine and steam

turbine.

Course Lecturer- MR. LOVE BHARDWAJ

ASSIGNTMENT-1

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:-23/08/2013

Date of Submission:-27/08/2013

Date of Discussion:-30/08/2013

Q1-What is IC & EC engines and give each example.

Q2-Difference b/w 2 stroke and 4 stroke.

Q3-Why 2 stroke are not in use now days?

Q4- Explain Sterling cyle?

Q5 -Explain Ericsson cycle?

Q6- Derive dual comustion cycle?

Q7-For an engine working on the ideal Dual cycle,the compression ratio is 10 and the

maximum pressure is limited to 70bar.If the heat suppplied is 1680kj/kg,find the pressure

and temperatures at the various salient points of the cycle and the cycle efficency.The

pressure and temprature of air at the commencement of compression are 1bar and 100C

respectively. Assume Cp=1.004kj/kgk and Cv=0.717kj/kgk for air.

ASSIGNTMENT-2

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:-30/08/2013

Date of Submission:-3/09/2013

Date of Discussion:-6/09/2013

Q1-What are the 3types of air-fuel mixture and explain them.

Q2-Explain idling,cruising,high power.

Q3-State the essential requirements of a spark ignition.

Q4-What are the types of Injection system.

Q5-Give short note of one of the injection system.

Q6-Explain the Battery-coil ignition system.

Q7-Explain hot-cold plug with the help of neat sketch

ASSIGNTMENT-3

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:-6/09/2013

Date of Submission:-10/09/2013

Date of Discussion:-13/09/2013

Q1-What is delay period?

Q2-Explain the variables affecting the delay period?

Q3-Name various theories of detonation. Explain pre-ignition.

Q4-Explain the phenomenon of knocking in CI engine and compare it with SI engine

knock.

Q5-Explain the comustion stages in CI engine.

Q6-Defines the factors tending to reduce detonation and knocking in SI and CI engine

.

Q7-Difference between cetane and octane number.

ASSIGNTMENT-4

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:-13/09/2013

Date of Submission:- 17/09/2013

Date of Discussion:- 20/09/2013

Q1-What is the necessity of engine cooling?

Q2-Compare air cooling with water cooling system.

Q3-What is the Evaporative cooling system?

Q4-How the Evaporative cooling system is different from Pressure cooling system?

Q5-Explain the 2 types of cooling system.

Q6-What are radiators.

Q7-How the engine is cooled,define different methods

ASSIGNTMENT-5

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:- 20/09/2013

Date of Submission:- 24/09/2013

Date of Discussion:- 27/09/2013

Q1-What are the engine efficiencies?

Q2-A 4 cyclinder petrol engine operates on the 4-stroke cycle, the bore of each cylinder is

70mm and the stroke 100mm. The clearance volume per cylinder is . At a speed of 400rpm,

the fuel consumption is 20kg/h and the torque developed is 150Nm.

Calculate

(i)The brake power

(ii)The brake mean effective pressure.

(iii)The brake thermal efficiency,if calorific value of the fuel is Kj/Kg

(iv)The relative efficiency on a brake power basis assuming the engine works on constant

volume cycle.

Q3-A single cylinder 4 stroke oil engine works on diesel cycles. The following readigs

correspond to full load condition.

(i)Area of indicator diagram

(ii)Length of the diagram

(iii)Spring constant

(iv)Speed of the engine

(v)Load on the brake

(vi)Spring reading

(vii)Diameter of the brake drum

(viii)Fuel consumption

(ix)Calorific value of the fuel

(x)Diameter of the cylinder

(xi)Stroke of the piston

Find the following

(a)Friction power

(b)Mechanical efficiency

(c)Brake thermal efficiency

(d)Brake mean effective pressure.

Q4-A 4 cylinder engine running at 1200rpm deliers 20KW.The average torque when one

cylinder was cut is 110nm. Find the indicated thermal efficiency if the calorific value of the

fuel is 43MJ/Kg and the engine uses 360grams of gasoline per KWH.

Q5- What is horse power and define 8HP.

Q6- Give a short note on Morse test and Motoring method.

Q7-Define Brake specific fuel consumption and state its importance.

ASSIGNTMENT-6

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:- 27/09/2013

Date of Submission:- 1/10/2013

Date of Discussion:- 4/10/2013

Q1-What are the major constituents which contributes to air pollution in SI engines?

Q2-What are the difficulties experienced in using hydrogen as fuel for SI engines?

Q3-What modifications are required to carrried out in the enigne while using H2 as fuel?

Q4-What are Hybrid vehicles.

Q5-What are the major components of Hybrid engines

Q6-How CNG vehicles works on Hybrid engine?

Q7-Which automobile companies manufacture hybrid vehicles?

ASSIGNTMENT-7

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:- 4/10/2013

Date of Submission:- 8/10/2013

Date of Discussion:- 11/10/2013

Q1-Explain the degree of reaction.

Q2-What is surging?

Q3-What is choking and polytropic efficiency?

Q4-Explian various types of rotary compressor with diagram.

Q5-Define slip factor and derive an expression for same.

Q6-What are positive displacement type of Rotary compressors?

Q7-Explain power input factor

ASSIGNTMENT-8

Subject: IC Engine & Gas Turbine

Branch: Mechanical

Subject Code: ME-307-F Semester: 5th

Proposed Date of Allotment:- 11/10/2013

Date of Submission:- 15/10/2013

Date of Discussion:- 18/10/2013

Q1-List the advantage and disadvantages of gas turbine?

Q2-How gas turbine works?

Q3-What are the application of gas turbine?

Q4-Classify the gas turbine cycle?

Q5-Difference between gas turbine and steam turbine?

Q6-A closed cycle gas turbine consists of a 2 stage compressor and a 2 stage turbine. All the

components are mounted on the same shaft the pressure and temperaure at the inlet of the

1

st

stage compressor are 2 bar and 25c. The maximum cycle temperature and pressure are

limited to 850C and 8bar. A perfect inter-cooler is used between the 2 compressors and a

reheater is used between the 2 turbines. Gases are heated in the reheater to 850C before

entering into the LP turbine.

Assuming the compressor and turbine efficiencies as 0.83,Find-

(i)Cycle efficiency without regenerator.

(ii)With regenrator whos effectiveness is 0.65

(iii)If the IP developed by the plant is 310KW.Find the mass of fluid circulated.Air is used

in the working fluid.

Q7-List the advantage and disadvantages of gas turbine over diesel or petrol engines.

B. E.

Fifth Semester Examination, May 2006

I.C. Engine

(ME-307)

NOTE: Attempt only 5 questions, take at least 2 questions from each part.

[PART-I]

Q.1. Derive an expression for the air standard efficiency on a volume basis of engines working

on Otto, Diesel and limited pressure cycle. Also compare the above cycles, for the same

compression ratio and heat input.

Q.2. Describe the combustion phenomenon in S.I. Engines, and discuss the effect of fuel air

ration, compression ratio, Engine load, engine speed and turbulence on flame propagation.

Q.3. Attempt the following-

(a)Compare air swirf in C.I. Engines with turbulence in S.I. Engines.

(b)Write short note on the A/F ratio requirement of S.I. Engines from no

load to full load.

Q.4. Attempt the following-

(a)Describe different types of injection nozzles and discuss their relative advantages and

disadvantages.

(b)Write short note on compressed natural gas (CNG) as an I.C. Engine fuel.

[PART-II]

Q.5. How the post timing diagram of 2-stroke cycle engine is different than that of 4-stroke cycle

engine. Explain scavenging process in two stroke engine.

Q.6. Describe a battery ignition system, with the help of a neat sketch, used in automobiles.

Q.7.What is evaporative cooling? How does the temperature vary within the cylinder, during

cycle? Why overcooling is harmful in an engine?

Q.8.The following readings were obtained from a test on a single cylinder oil engine working on

the four stroke cycle.

Area of indicator diagram=4.1 cm^2, length of indicator diagram=6.25cm, indicator spring

rating=0.9mm, cylinder bore and stroke=105mm & 150mm, respectively, mean diameter of

brake wheel=0.6m, brake load=18kg, spring balance reading=3kg, engine speed=480rpm.

Calculate: (a)brake power, (b)indicated power, and (c)mechanical efficiency.

Vous aimerez peut-être aussi

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsD'EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (9)

- IceDocument3 pagesIceJaniPas encore d'évaluation

- Advanced IC Engine Course Outline - 2019Document3 pagesAdvanced IC Engine Course Outline - 2019Kumaran PalaniPas encore d'évaluation

- IC New Course FileDocument5 pagesIC New Course FiledearsaswatPas encore d'évaluation

- ME604 (ICE>) Lecture NoteDocument125 pagesME604 (ICE>) Lecture NoteKamna KumarPas encore d'évaluation

- IC EngineDocument2 pagesIC EnginePrince SethiPas encore d'évaluation

- IC Engines & Jet Propulsion Course OutlineDocument2 pagesIC Engines & Jet Propulsion Course OutlineSubash AppuPas encore d'évaluation

- ME605 - Internal Combustion Engineering PDFDocument3 pagesME605 - Internal Combustion Engineering PDFRajkumar SinghPas encore d'évaluation

- Ic Engine and Gas TurbineDocument2 pagesIc Engine and Gas TurbineShaik YaseenPas encore d'évaluation

- ME 204 Thermal Engineering KTUDocument3 pagesME 204 Thermal Engineering KTUSunil BhaskarPas encore d'évaluation

- ISO 9001 Certified College's IC Engine Course PlanDocument8 pagesISO 9001 Certified College's IC Engine Course PlanmallikarjunbpatilPas encore d'évaluation

- Form 1 Course OutlineDocument5 pagesForm 1 Course Outlinearslan khanPas encore d'évaluation

- Course Outline IC Engine and Reciprocating MachineDocument2 pagesCourse Outline IC Engine and Reciprocating MachineheonetubePas encore d'évaluation

- Mechanical Engineering VII Sem SyllabusDocument3 pagesMechanical Engineering VII Sem Syllabussaurabh1116Pas encore d'évaluation

- Course Outline22Document2 pagesCourse Outline22Siraj Mohammed100% (1)

- Lecture 1 - Introduction To Internal Combustion EnginesDocument29 pagesLecture 1 - Introduction To Internal Combustion EnginesYussufPas encore d'évaluation

- Svs College of Engineering: Name of The Faculty: S. SettuDocument25 pagesSvs College of Engineering: Name of The Faculty: S. SettuBala SundarPas encore d'évaluation

- AU201 SI Engines and CombustionDocument3 pagesAU201 SI Engines and CombustionvaisakmctPas encore d'évaluation

- Internal Combustion EnginesDocument3 pagesInternal Combustion EnginescharulapPas encore d'évaluation

- 4th Year CoursesDocument59 pages4th Year CoursesMohammed A IsaPas encore d'évaluation

- Internal Combustion Engine: A detailed look at fuel supply systems, ignition, combustion, governing and testing of IC enginesDocument2 pagesInternal Combustion Engine: A detailed look at fuel supply systems, ignition, combustion, governing and testing of IC engineskrishnaPas encore d'évaluation

- Chhattisgarh Swami Vivekanand TechnicalDocument8 pagesChhattisgarh Swami Vivekanand TechnicalLakshminarayana ChPas encore d'évaluation

- Mec333 SyllabusDocument2 pagesMec333 Syllabus11gargdinesh7Pas encore d'évaluation

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19AkashPas encore d'évaluation

- Bachelor of Technology (Mechanical Engineering) Kurukshetra University, KurukshetraDocument12 pagesBachelor of Technology (Mechanical Engineering) Kurukshetra University, KurukshetraAaushKumarPas encore d'évaluation

- Lovely Professional University, Punjab: Internal Combustion Engines V. Ganesan, Pub.-Tata Mcgraw-HillDocument10 pagesLovely Professional University, Punjab: Internal Combustion Engines V. Ganesan, Pub.-Tata Mcgraw-HillVikas PoddarPas encore d'évaluation

- B. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalDocument10 pagesB. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalAbhishek MePas encore d'évaluation

- Internal Combustion EnginesDocument2 pagesInternal Combustion EnginesDhaval PanchalPas encore d'évaluation

- Syllabus For Intermediate Heat TransferDocument3 pagesSyllabus For Intermediate Heat TransferShaurya PalPas encore d'évaluation

- Internal Combustion Engine & Gas Turbine SyllabusDocument45 pagesInternal Combustion Engine & Gas Turbine SyllabusSamrat ChaulagainPas encore d'évaluation

- ICE Course CurriculumDocument3 pagesICE Course CurriculumHtat Myat AungPas encore d'évaluation

- MEC 3621 - Internal Combustion EngineDocument6 pagesMEC 3621 - Internal Combustion EngineFarith AhmadPas encore d'évaluation

- EMEDocument3 pagesEMEVirani BharatPas encore d'évaluation

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityRavi Teja TPas encore d'évaluation

- ATD SyllabusDocument3 pagesATD Syllabusprashanth prabhuPas encore d'évaluation

- M 89Document2 pagesM 89navneetkpatil8409Pas encore d'évaluation

- ME605-N-C Internal Combustion EngineDocument3 pagesME605-N-C Internal Combustion Enginesnehalbhalerao20.booksPas encore d'évaluation

- Content Beyond SyllabusDocument5 pagesContent Beyond SyllabusasdhavalePas encore d'évaluation

- GTU Applied Thermodynamics SubjectDocument3 pagesGTU Applied Thermodynamics SubjectAkashPas encore d'évaluation

- BE Syllabus of Mumbai Uni5Document10 pagesBE Syllabus of Mumbai Uni5Rajendra B PawarPas encore d'évaluation

- GTU Automotive Combustion Technology CourseDocument2 pagesGTU Automotive Combustion Technology CoursemannuvpatelPas encore d'évaluation

- National University of Engineering Mechanical-Electrical Engineering ProgramDocument2 pagesNational University of Engineering Mechanical-Electrical Engineering Programjimmy jimenez barriosPas encore d'évaluation

- Power Engineering FundamentalsDocument5 pagesPower Engineering FundamentalsShriram SinghPas encore d'évaluation

- Combustion Engine Emissions: Course Code: BTM 709 Credit Units: 03 Course ObjectiveDocument1 pageCombustion Engine Emissions: Course Code: BTM 709 Credit Units: 03 Course ObjectiveSanjay GomastaPas encore d'évaluation

- Birla Institute of Technology and Science-Pilani - Hyderabad CampusDocument3 pagesBirla Institute of Technology and Science-Pilani - Hyderabad CampusAgtPas encore d'évaluation

- Aice 8 TH Sem Qbank June 2013Document17 pagesAice 8 TH Sem Qbank June 2013Mohanraj SubramaniPas encore d'évaluation

- Mechanical Engineering-6 Sem NewDocument17 pagesMechanical Engineering-6 Sem Newbeastboy00077Pas encore d'évaluation

- ICEDocument5 pagesICEArihant ShijuPas encore d'évaluation

- FTM Course PlanDocument9 pagesFTM Course PlanmallikarjunbpatilPas encore d'évaluation

- Basic Mechanical EngineeringDocument2 pagesBasic Mechanical EngineeringAPOLLO Sem 4 I.T.Pas encore d'évaluation

- ADVANCED Ic Engine VtuDocument2 pagesADVANCED Ic Engine VtuNitish DesaiPas encore d'évaluation

- Birzeit University - Faculty of Engineering Mechanical Engineering Department Internal Combustion Engines-ME 535 Course OutlineDocument2 pagesBirzeit University - Faculty of Engineering Mechanical Engineering Department Internal Combustion Engines-ME 535 Course OutlineMohammad SandoukaPas encore d'évaluation

- 2 MarksDocument19 pages2 MarksDinesh Kumar100% (1)

- Internal Combustion EnginesD'EverandInternal Combustion EnginesConstantine ArcoumanisÉvaluation : 4 sur 5 étoiles4/5 (4)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsD'EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsPas encore d'évaluation

- Mechanical Engineering Science: In SI UnitsD'EverandMechanical Engineering Science: In SI UnitsÉvaluation : 5 sur 5 étoiles5/5 (4)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyD'EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyPas encore d'évaluation

- Petroleum Production Engineering, A Computer-Assisted ApproachD'EverandPetroleum Production Engineering, A Computer-Assisted ApproachÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Quiz 10 Boiler, Engines and TurbinesDocument13 pagesQuiz 10 Boiler, Engines and Turbinesashishutage_50897935Pas encore d'évaluation

- 2003 KX250 Race TuningDocument4 pages2003 KX250 Race TuningKidKawie100% (1)

- GME INTERVIEW TOPICSDocument3 pagesGME INTERVIEW TOPICSAthul P PPas encore d'évaluation

- Marine Fitter PDFDocument64 pagesMarine Fitter PDFNavneet100% (1)

- PumpsDocument123 pagesPumpsglazetm50% (2)

- Evinrude ServiceManual2012 40-50-60-65-75-90 PDFDocument426 pagesEvinrude ServiceManual2012 40-50-60-65-75-90 PDFadolfoc26188% (8)

- Cat 793c Manual ServicioDocument232 pagesCat 793c Manual ServicioFzl2100% (13)

- AK70023 ManualDocument18 pagesAK70023 ManualpkrajniPas encore d'évaluation

- Ic Engine Research PaperDocument7 pagesIc Engine Research Paperh03ch3b4100% (1)

- Internal Ballistics of Spring Piston AirgunsDocument36 pagesInternal Ballistics of Spring Piston AirgunsDomingoTavella100% (3)

- Question Topic WiseDocument5 pagesQuestion Topic WisePagan jatarPas encore d'évaluation

- Mds ManualDocument20 pagesMds ManualStefanHristozovPas encore d'évaluation

- 14.09.2023 - Chapter 1 - Introduction To IC EnginesDocument70 pages14.09.2023 - Chapter 1 - Introduction To IC EnginesAditya RatleyPas encore d'évaluation

- BSA D14 175 Bantam Supreme Sports Bushman Maintenance Instruction Manual PDFDocument37 pagesBSA D14 175 Bantam Supreme Sports Bushman Maintenance Instruction Manual PDFjvdkjdlkkPas encore d'évaluation

- Workshop ManualDocument52 pagesWorkshop ManualMarko ZgPas encore d'évaluation

- MEO Class 4 Oral QuestionsDocument33 pagesMEO Class 4 Oral QuestionsAnkit Batra50% (2)

- 10 - Starting and ReversingDocument4 pages10 - Starting and ReversingAisha Zaheer100% (3)

- 350 ManualDocument52 pages350 Manuallocor45100% (1)

- Two Stroke PetrolDocument93 pagesTwo Stroke PetrolPrince Tiwari DETL 27Pas encore d'évaluation

- A-65 & A-75 SeriesDocument77 pagesA-65 & A-75 SeriesRicardo UrioPas encore d'évaluation

- F23 Brochure SoftDocument2 pagesF23 Brochure SoftMike NgPas encore d'évaluation

- Engine Room Simulator (Ers 4000)Document7 pagesEngine Room Simulator (Ers 4000)youngfp80% (5)

- Small Helmholtz Course: © Frits OvermarsDocument3 pagesSmall Helmholtz Course: © Frits OvermarsSaddam shinPas encore d'évaluation

- Diesel EngineersDocument18 pagesDiesel EngineerslalindaPas encore d'évaluation

- Me Gi Gie Pump Vaporizer Unit For LNG and Ethane EngDocument5 pagesMe Gi Gie Pump Vaporizer Unit For LNG and Ethane Engionut nicolaePas encore d'évaluation

- Imo 2020Document8 pagesImo 2020Abhinav VermaPas encore d'évaluation

- MZ TuningDocument24 pagesMZ TuningJawaCz100% (2)

- 91 Introduction To Internal Combustion EnginesDocument35 pages91 Introduction To Internal Combustion Enginesraghu.entrepreneurPas encore d'évaluation

- CM50Document14 pagesCM50Sheri Gniadek-chacoPas encore d'évaluation

- MAN ProgrammeDocument260 pagesMAN Programmedimas kukuhPas encore d'évaluation