Académique Documents

Professionnel Documents

Culture Documents

Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities

Transféré par

JM SVDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities

Transféré par

JM SVDroits d'auteur :

Formats disponibles

2024

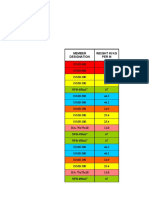

AMS 4086

AMS 4087

AMS 4088

AMS-T-700/3

ASTM B210

3003

ASTM B210

AMS-T-700/2

AMS4065

AMS4067

ASME SB234

5052

AMS 4069

AMS4070

AMS4071

ASTM B 210

ASME SB210

ASTM B 234

ASTM B 483

AMS-T-700/4

6061

AMS 4079

AMS 4080

AMS4081

AMS 4082

AMS 4083

ASME SB210

ASTM B 210

ASTM B 234

ASTM B 241

ASTM B 483

AMS-T-700/6

MIL-P25995

AMS-T-7081

6063

ASTM B483

ASTM B241

MIL-P-25995

7050 7068 7075

ASTM B 210

AMS-T-700/7

K749A

H A R D A L L O Y T U B E & P I P E

DRAWN SEAMLESS ALUMINUM TUBE CAPABILITIES

2024

O

T3

3003

O

H12

H14

5052

O

H32

H34

6061

O

T4

T6

6063

T6

T831

T832

7050

O

T6

T76

7068

O

T6

7075

O

T6

T76

T73

K749A

T6

Wall

Inches

0.018 - .250

Millimeters

0.46 - 6.35

www.kaiseraluminum.com | KA-TPH-DSC-1.09

STANDARD ALLOYS & TEMPERS

STANDARD ALLOYS & SPECI FI CATI ONS*

DI MENSI ONAL RANGES

Inches

0.125 - 3.00

Millimeters

3.18 - 76.20

Feet

0.50 - 20.00

Meters

0.15 - 8.00

Not es

Some specications are no longer available but are provided for reference.

Press minimums vary from 500 - 3,000 lbs. Call for availability.

Wall Thickness (in.)

0.110 - 0.180

0.181 - 0.280

0.281 - 0.374

0.375 - 0.499

1.625/2.249 2.250/2.999 3.000/3.999 4.000/4.500

Outside Diameter (in.)

H A R D A L L O Y T U B E & P I P E

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

2024

O

T3

T3511

5052

O

7005

F

7046

O

7050

F

7075

O

T6

T6511

www.kaiseraluminum.com | KA-TPH-ESC-1.09

STANDARD ALLOYS & TEMPERS

2024

ASTM B241

ASTM B221

AMS 4152

ASME SB221

AMS-QQ-A-200/3

5052

ASTM B241

ASTM B221

ASME SB241

7005

ASTM B221

7046 7050 7075

ASTM B241

ASTM B221

AMS 4154

AMS-QQ-A-200/11

STANDARD ALLOYS & SPECI FI CATI ONS

DI MENSI ONAL RANGES - ALLOYS 2024, 5052, 7050, 7075

1.501/1.999 2.000/2.999 3.000/3.999 4.000/4.500 1.050/1.500

Wall Thickness (in.)

0.088 - 0.129

0.130 - 0.180

0.181 - 0.218

0.219 - 0.280

0.281 - 0.374

0.375 - 0.499

0.500 - 0.749

Outside Diameter (in.)

DI MENSI ONAL RANGES - ALLOYS 7005, 7046

This area identies available Extruded Seamless Aluminum Tube dimensional ranges. This area identies available Extruded Seamless Aluminum Tube dimensional ranges.

Not es

Press minimums vary from 500 - 3,000 lbs. Call for availability.

0.018-0.250

Mechanical Property LimitsHard AlloyDrawn Seamless Aluminum Tube

2024

. . 2024-O

ALLOY

AND

TEMPER

WALL

THICKNESS

inches mm

TENSILE STRENGTH

ULTIMATE YIELD

KSI MPa KSI MPa

min. max. min. max. min. max. min. max.

Elongation %

Min. Full Section

Specimen

32.0 . . 221 . . 15.0 . . 103 0.46-6.35

0.018-0.024

0.025-0.049

0.050-0.250

64

64

64

10

12

14

2024-T3 . .

. .

. .

441

441

441

. .

. .

. .

42.0

42.0

42.0

. .

. .

. .

290

290

290

. .

. .

. .

0.48-0.61

0.64-1.24

1.27-6.35

0.018-0.024

0.025-0.049

0.050-0.250

14.0

14.0

14.0

. .

30

35

3003-O 19.0

19.0

19.0

96

96

96

130

130

130

5.0

5.0

5.0

. .

. .

. .

34

34

34

. .

. .

. .

0.48-0.61

0.64-1.24

1.27-6.35

3003

0.018-0.250 17 . . 3003-H12 . . 117 . . 12.0 . . 83 . . 0.48-6.35

0.018-0.024

0.025-0.049

0.050-0.250

20.0

20.0

20.0

3

5

8

3003-H14 . .

. .

. .

138

138

138

. .

. .

. .

17.0

17.0

17.0

. .

. .

. .

117

117

117

. .

. .

. .

1.27-6.35

.64-1.24

1.27-6.35

0.018-0.250 25.0 . . 5052-O 35.0 172 241 6.0 41 . . . . 0.48-6.35

5052

0.018-0.250 31.0 . . 5052-H32 . . 213 . . 23.0 . . 159 . . 0.48-6.35

0.018-0.250 34.0 . . 5052-H34 . . 234 . . 26.0 . . 179 . . 0.48-6.35

0.018-0.250 . . 15 6061-O 22.0 . . 152 . . 14.0 . . 97 0.48-6.35

6061

0.025-0.049

0.050-0.250

30.0

30.0

16

18

6061-T4 . .

. .

207

207

. .

. .

16.0

16.0

. .

. .

110

110

. .

. .

0.64-1.24

1.27-6.35

0.025-0.049

0.050-0.250

42.0

42.0

10

12

6061-T6 . .

. .

290

290

. .

. .

35.0

35.0

. .

. .

241

241

. .

. .

0.64-1.24

1.27-6.35

0.025-0.049

0.050-0.250

33.0

33.0

12

14

6063-T6 . .

. .

228

228

. .

. .

28.0

28.0

. .

. .

193

193

. .

. .

0.64-1.24

1.27-6.35

6063

0.025-0.250 28.0 5 6063-T831 . . 193 . . 25.0 . . 172 . . 0.64-6.35

0.025-0.049

0.050-0.250

41.0

40.0

8

8

6063-T832 . .

. .

283

276

. .

. .

36.0

35.0

. .

. .

248

241

. .

. .

0.64-1.24

1.27-6.35

7050

0.025-0.250 . . 8 7050-O 40.0 . . 276 . . 21.0 . . 145 0.64-6.35

0.025-0.250 85.0 5 7050-T6 . . 586 . . 74.0 . . 510 . . 0.64-6.35

0.025-0.250 80.0 5 7050-T76 . . 552 . . 69.0 . . 476 . . 0.64-6.35

7068

0.025-0.250 . . 8 7068-O 40.0 . . 276 . . 21.0 . . 145 0.64-6.35

0.025-0.250 88.0 5 7068-T6 . . 607 . . 84.0 . . 579 . . 0.64-6.35

7075

0.025-0.049

0.050-0.250

. .

. .

10

12

7075-O 40.0

40.0

. .

. .

276

276

. .

. .

21.0

21.0

. .

. .

145

145

0.64-1.24

1.27-6.35

0.025-0.250 77.0 8 7075-T6 . . 455 . . 66.0 . . 530 . . 0.64-6.35

0.025-0.250 77.0 8 7075-T76 . . 455 . . 64.0 . . 441 . . 0.64-6.35

0.025-0.250 66.0 10 7075-T73 . . 530 . . 56.0 . . 386 . . 0.64-6.35

K749A

0.025-0.250 95.0 7 K749A-T6 . . 655 . . 91.0 . . 627 . . 0.64-6.35

KA-TPH-MP1-1.09

All

Mechanical Property LimitsHard AlloyExtruded Seamless Aluminum Tube

2024

. . 12 2024-O

ALLOY

AND

TEMPER

WALL

THICKNESS

inches mm

TENSILE STRENGTH

ULTIMATE YIELD

KSI MPa KSI MPa

min. max. min. max. min. max. min. max.

Elongation %

Min. Full Section

Specimen

35.0 . . 241 . . 19.0 . . 131 All

0.110-0.249

0.250-0.500

57.0

60.0

10

10

2024-T3

2024-T3511

. .

. .

393

414

. .

. .

42.0

44.0

. .

. .

290

303

. .

. .

2.8-6.32

6.35-12.7

All 25.0 . . 5052-O 35.0 172 241 10 . . 69 . . All

5052

All . . . . 7005-F . . . . . . . . . . . . . . All

7005

All . . 10 7046-O 35.0 . . 241 . . 28.0 . . 193 All

7046

All . . . . 7050-F . . . . . . . . . . . . . . All

7050

All . . 10 7075-O 40.0 . . 276 . . 24.0 . . 165 All

7075

0.110-0.249

0.250-0.499

78.0

81.0

7

7

7075-T6

7075-T6511

. .

. .

538

558

. .

. .

70.0

73.0

. .

. .

483

503

. .

. .

2.79-6.32

6.35-12.7

All . . 12 2024-O 35.0 . . 241 . . 19.0 . . 131 All

2024

0.110-0.249

0.250-0.500

57.0

60.0

12

12

2024-T3

2024-T3511

. .

. .

393

414

. .

. .

42.0

44.0

. .

. .

290

303

. .

. .

2.8-6.32

6.35-12.7

All . . 10 7075-O 40.0 . . 276 . . 24.0 . . 165 All

7075

0.110-0.249

0.250-0.499

78.0

81.0

7

7

7075-T6

7075-T6511

. .

. .

538

558

. .

. .

70.0

73.0

. .

. .

483

503

. .

. .

2.79-6.32

6.35-12.7

Mechanical Property LimitsHard AlloyExtruded Seamless Aluminum Shapes Mechanical Property LimitsHard AlloyExtruded Seamless Aluminum Shapes

KA-TPH-MP2-1.09

TABLE 12.20 DiameterDrawn Round Tube

TOLERANCE

W

in. plus and minus

ALLOWABLE DEVIATION OF MEAN DIAMETER ALLOWABLE DEVIATION OF MEAN DIAMETER

E

ALLOWABLE DEVIATION OF DIAMETER AT ANY POINT ALLOWABLE DEVIATION OF DIAMETER AT ANY POINT

FROM SPECIFIED DIAMETER (Size) FROM SPECIFIED DIAMETER FROM SPECIFIED DIAMETER (Size) FROM SPECIFIED DIAMETER

R

Difference between AA or BB and speci Difference between AA or BB and specied diameter Difference between AA or BB and speci Difference between AA or BB and speci

Difference between (AA + BB) NON-ANNEALED AND Difference between (AA + BB) NON-ANNEALED AND

and speci and specied diameter NON-HEAT-TREATED ed diameter NON-HEAT-TREATED and speci and speci

HEAT-TREATED ANNEALED

TUBE TUBE

TUBE

T

TUBE

Col. 1 Col. 2 Col. 3 Col. 4 Col. 5 Col. 1 Col. 2 Col. 3 Col. 4 Col. 5

Up thru 0.500 .003 .003 .006 .018 Up thru 0.500 .003 .003 .006 .018

0.5011.000 .004 .004 .008 .024 0.5011.000 .004 .004 .008 .024

1.0012.000 .005 .005 .010 .030 1.0012.000 .005 .005 .010 .030

2.0013.000 .006 .006 .012 .036 2.0013.000 .006 .006 .012 .036

3.0015.000 .008 .008 .016 .048 3.0015.000 .008 .008 .016 .048

5.0016.000 .010 .010 .020 .060 5.0016.000 .010 .010 .020 .060

6.0018.000 .015 .015 .030 .090 6.0018.000 .015 .015 .030 .090

8.00110.000 .020 .020 .040 .120 8.00110.000 .020 .020 .040 .120

10.00112.000 .025 .025 .050 .150 10.00112.000 .025 .025 .050 .150

SPECIFIED

DIAMETER

in.

TABLE 12.21 Width and DepthDrawn Square, Rectangular, Hexagonal and Octagonal Tube

TOLERANCE

W

in. plus and minus

ALLOWABLE DEVIATION OF WIDTH OR DEPTH ALLOWABLE DEVIATION OF WIDTH OR DEPTH ALLOWABLE DEVIATION OF WIDTH OR DEPTH ALLOWABLE DEVIATION OF WIDTH OR DEPTH

AT CORNERS FROM SPECIFIED WIDTH OR DEPTH NOT AT CORNERS AT CORNERS FROM SPECIFIED WIDTH OR DEPTH NOT AT CORNERS

FROM SPECIFIED WIDTH OR DEPTH FROM SPECIFIED WIDTH OR DEPTH

R U

Difference between AA and speci Difference between AA and specied Difference between AA and speci ed Difference between AA and speci Difference between AA and speci Difference between AA and speci ed ed Difference between AA and speci ed Difference between AA and speci

width or depth width, depth, or distance across width or depth width, depth, or distance across ats width or depth width, depth, or distance across width or depth width, depth, or distance across

SQUARE, SQUARE,

SQUARE, RECTANGULAR

SQUARE, SQUARE,

HEXAGONAL, OCTAGONAL HEXAGONAL, OCTAGONAL

RECTANGULAR

Col. 1 Col. 2 Col. 3 Col. 4 Col. 1 Col. 2 Col. 3 Col. 4

Up thru 0.500 .003 .006 Up thru 0.500 .003 .006

0.5011.000 .004 .008 0.5011.000 .004 .008

1.0012.000 .005 .010 1.0012.000 .005 .010

2.0013.000 .006 .012 2.0013.000 .006 .012

3.0015.000 .008 .016 3.0015.000 .008 .016

5.0016.000 .010 .020 5.0016.000 .010 .020

6.0018.000 .015 .030 6.0018.000 .015 .030

8.00110.000 .020 .040 8.00110.000 .020 .040

10.00112.000 .025 .050 10.00112.000 .025 .050

The tolerance for the width is the

value in Col. 3 for the dimension

equal to the depth, and conversely,

but in no case is the tolerance less

than at the corners.

Y

SPECIFIED

WIDTH

OR

DEPTH

Q

in.

Q

When outside diameter, inside diameter, and wall thickness (or their

equivalent dimensions in other than round tube) are all specied, standard

tolerances are applicable to any two of these dimensions, but not to all three.

When both outside and inside diameters or inside diameter and wall thick-

ness are specied, the tolerance applicable to the specied or calculated

O.D. dimension shall also apply to the I.D. dimension.

W

When a dimension tolerance is specied other than as an equal bilateral

tolerance, the value of the standard tolerance is that which applies to the

mean of the maximum and minimum dimensions permissible under the

tolerance of the dimension under consideration.

E

Mean diameter is the average of two diameter measurements taken at

right angles to each other at the same longitudinal location on the tube.

R

Not applicable to coiled tube or tube having a wall thickness less than

2 percent of the specied outside diameter. The tolerance for tube with wall 2 percent of the speci 2 percent of the speci

thickness less than 2 percent of the specied outside diameter is determined thickness less than 2 percent of the speci thickness less than 2 percent of the speci

by multiplying the applicable tolerance in columns 3 thru 5 as follows:

2% to 2% exclusive1.5 tolerance

1% to 2% exclusive2.0 tolerance

1% to 1% exclusive3.0 tolerance

% to 1% exclusive4.0 tolerance

T

For the T8 tempers of 6063 the tolerance in Column 3 apply.

Y

Example: The width tolerance of 1 3 inch rectangular tube is plus and

minus 0.008 inch, and the depth tolerance is plus and minus 0.012 in.

U

Not applicable to annealed (O temper) tube.

Footnotes for Tables 12.20 and 12.21

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc. KA-TPH-AA1-1.09

TABLE 12.22 DiameterDrawn Oval, Eliptical

and Streamline Tube

TOLERANCE

Q W

in.

LENGTH OF LENGTH OF

MAJOR AXIS, in. MAJOR AXIS, in.

Difference between Difference between

AA and AA and

specied length speci speci speci ed length ed length speci ed length speci

Col. 1 Col. 2 Col. 3

Up thru 2.500 +.040 .025 +.025 .015

2.5014.250 +.050 .035 +.035 .025

4.2516.000 +.070 .050 +.055 .040

6.0018.000 +.100 .085 +.080 .060

8.00110.000 +.160 .140 +.115 .085

EQUIVALENT

ROUND

DIAMETER

T

in.

LENGTH OF LENGTH OF

MAJOR AXIS, in. MAJOR AXIS, in.

Difference between Difference between

AA and AA and

speci

Col. 1 Col. 2 Col. 3

Up thru 2.500 +.040

2.5014.250 +.050

4.2516.000 +.070

6.0018.000 +.100

8.00110.000 +.160

LENGTH OF LENGTH OF

MAJOR AXIS, in. MAJOR AXIS, in.

Difference between Difference between

AA and AA and

ed length speci

Col. 1 Col. 2 Col. 3

.025 +.025

.035 +.035

.050 +.055

.085 +.080

.140 +.115

TABLE 12.23 Corner RadiiDrawn Tube

TOLERANCE

W

in.

ALLOWABLE DEVIATION FROM

SPECIFIED RADIUS

Difference between radius A and

specied radius speci speci

Sharp Corners +Q-yr

0.0160.187 Q-yr

0.188 and over 10%

SPECIFIED

U

RADIUS

in.

ALLOWABLE DEVIATION FROM

SPECIFIED RADIUS

Difference between radius A and

speci

Sharp Corners +

0.0160.187

0.188 and over 10%

TABLE 12.24 Wall ThicknessDrawn Round and Other-Than-Round Tube

TOLERANCE

Q W

in. plus and minus

ALLOWABLE DEVIATION OF MEAN WALL ALLOWABLE DEVIATION OF WALL THICKNESS

THICKNESS

E

FROM SPECIFIED AT ANY POINT FROM SPECIFIED WALL THICKNESS

WALL THICKNESS (Eccentricity)

ROUND, NON-HEAT- ROUND, HEAT-TREATABLE ALLOYS AND

TREATABLE ALLOYS

Y

OTHER THAN ROUND, ALL ALLOYS

Difference between (AA+BB) and

specied wall thickness speci speci

Col. 1 Col. 2 Col. 3 Col. 4

0.0100.035 .002 .002

0.0360.049 .003 .003

0.0500.083 .004 .004

0.0840.120 .005 .006

0.1210.203 .006 .008

0.2040.300 .008 .012

0.3010.375 .015 .020

0.3760.500 .020 .030

Plus and minus 10% of specied

wall thickness, min 0.003

SPECIFIED

THICKNESS

R

in

ALLOWABLE DEVIATION OF MEAN WALL ALLOWABLE DEVIATION OF WALL THICKNESS

THICKNESS

WALL THICKNESS (Eccentricity)

ROUND, NON-HEAT- ROUND, HEAT-TREATABLE ALLOYS AND

TREATABLE ALLOYS

Difference between (AA+BB) and

speci

Col. 1 Col. 2 Col. 3 Col. 4

0.0100.035 .002 .002

0.0360.049 .003 .003

0.0500.083 .004 .004

0.0840.120 .005 .006

0.1210.203 .006 .008

0.2040.300 .008 .012

0.3010.375 .015 .020

0.3760.500 .020 .030

ALLOWABLE DEVIATION OF MEAN WALL ALLOWABLE DEVIATION OF WALL THICKNESS

FROM SPECIFIED AT ANY POINT FROM SPECIFIED WALL THICKNESS

WALL THICKNESS (Eccentricity)

ROUND, NON-HEAT- ROUND, HEAT-TREATABLE ALLOYS AND

TREATABLE ALLOYS

Col. 1 Col. 2 Col. 3 Col. 4

0.0100.035 .002 .002

0.0360.049 .003 .003

0.0500.083 .004 .004

0.0840.120 .005 .006

0.1210.203 .006 .008

0.2040.300 .008 .012

0.3010.375 .015 .020

0.3760.500 .020 .030

ROUND, NON-HEAT- ROUND, HEAT-TREATABLE ALLOYS AND

Col. 1 Col. 2 Col. 3 Col. 4

Footnotes for Tables 12.22 Through 12.24

Q

Footnotes for Tables 12.22 Through 12.24 Footnotes for Tables 12.22 Through 12.24

When outside diameter, inside diameter, and wall thickness (or their

equivalent dimensions in other-than-round tube) are all specied, standard

tolerances are applicable to any two of these dimensions, but not to all three.

When both outside and inside diameters or inside diameter and wall thick-

ness are specied, the tolerance applicable to the specied or calculated

O.D. dimension shall also apply to the I.D. dimension.

W

When a dimension tolerance is specied other than as an equal bilateral

tolerance, the value of the standard tolerance is that which applies to the

mean of the maximum and minimum dimensions permissible under the

tolerance for the dimension under consideration.

E

The mean wall thickness of round tube is the average of two measure-

ments taken opposite each other. The mean wall thickness of other-than-

round tube is the average of two measurements taken opposite each other

at approximate center line of tube and perpendicular to the longitudinal axis

of the cross section.

R

When dimensions specied are outside and inside, rather than wall thick-

ness itself, allowable deviation at any point (eccentricity) is plus and minus

10 percent of the mean wall thickness but not less than 0.003 inch.

T

Equivalent round diameter is the diameter of the circle having a circumfer-

ence equal to the perimeter of the tube.

Y

For coiled tube, values in Column 4 apply.

U

If unspecied, the radius shall be Q-ew in. maximum including tolerances.

Footnotes for Tables 12.22 through 12.24

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc. KA-TPH-AA2-1.09

TABLE 12.25 StraightnessDrawn Tube

TOLERANCE

Q W

in.

ALLOWABLE DEVIATION FROM STRAIGHT

D(max)

IN TOTAL LENGTH OR IN ANY

MEASURED SEGMENT OF ONE FT.

OR MORE OF TOTAL LENGTH

Up thru 0.374 .500 Measured length, ft.

0.3755.999 .010 Measured length, ft.

6.000 and over .020 Measured length, ft.

SPECIFIED

OUTSIDE

DIAMETER

OR WIDTH

in.

ALLOWABLE DEVIATION FROM STRAIGHT

D(max)

IN TOTAL LENGTH OR IN ANY

MEASURED SEGMENT OF ONE FT.

OR MORE OF TOTAL LENGTH

Up thru 0.374 .500

0.3755.999 .010

6.000 and over .020

TABLE 12.26 Twist

R

Drawn Tube

TOLERANCE

Q W

Degree

ALLOWABLE DEVIATION FROM STRAIGHT

Y (max) in degrees

IN TOTAL LENGTH OR

IN ANY MEASURED

MAXIMUM

SEGMENT OF ONE FT. OR

FOR TOTAL

MORE OF TOTAL LENGTH

LENGTH

Up thru 1.499 1 Measured length, ft. 7

1.5002.999 Measured length, ft. 5

3.000 and over Measured length, ft. 3

SPECIFIED

WIDTH

in.

ALLOWABLE DEVIATION FROM STRAIGHT

Y (max) in degrees

IN TOTAL LENGTH OR

IN ANY MEASURED

SEGMENT OF ONE FT. OR

MORE OF TOTAL LENGTH

Up thru 1.499 1

1.5002.999

3.000 and over

Measured length, ft. 7

Measured length, ft. 5

Measured length, ft. 3

TABLE 12.27 LengthDrawn Tube

TOLERANCEin. plus except as noted TOLERANCEin. plus except as noted

ALLOWABLE DEVIATION FROM SPECIFIED LENGTH ALLOWABLE DEVIATION FROM SPECIFIED LENGTH

STRAIGHT COILED STRAIGHT COILED

SPECIFIED LENGTHft.

Up Over 12 Over 30 Up Over 12 Over 30 Up Over 12 Over 30

thru thru thru Over Up thru Over 100 250 500 and thru thru thru Over Up thru Over 100 250 500 and thru thru thru Over Up thru Over 100 250 500 and thru thru thru Over Up thru Over 100 250 500 and thru thru thru Over Up thru Over 100 250 500 and

12 30 50 50 100 to 250 to 500 over 12 30 50 50 100 to 250 to 500 over 12 30 50 50 100 to 250 to 500 over 12 30 50 50 100 to 250 to 500 over 12 30 50 50 100 to 250 to 500 over

Up thru 0.249 Up thru 0.249 E-i . . +5%, 0% 10% 15% 20% . . +5%, 0% 10% 15% 20% . . +5%, 0% 10% 15% 20% . . +5%, 0% 10% 15% 20% . . +5%, 0% 10% 15% 20%

0.2501.249 Q-i E-i 1 +5%, 0% 10% 15% 20% 1 +5%, 0% 10% 15% 20% 1 +5%, 0% 10% 15% 20% 1 +5%, 0% 10% 15% 20% 1 +5%, 0% 10% 15% 20%

1.2502.999 Q-i E-i 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . .

3.0007.999 E-qy T-qy U-qy 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . .

8.000 and over 8.000 and over E-i 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . . 1 . . . . . . . .

SPECIFIED

ALLOWABLE DEVIATION FROM SPECIFIED LENGTH ALLOWABLE DEVIATION FROM SPECIFIED LENGTH

OUTSIDE DIAMETER STRAIGHT COILED STRAIGHT COILED

OR WIDTH

in. Up Over 12 Over 30 Up Over 12 Over 30

TABLE 12.28 Flatness (Flat Surfaces)

Other-Than-Round Drawn Tube

TOLERANCE

E

in.

ALLOWABLE DEVIATION FROM FLAT

Maximum allowable distance Y

Up thru 0.500 .003

0.5011.000 .004

1.0012.000 .005

2.0013.000 .006

3.0015.000 .008

5.0016.000 .010

6.0018.000 .015

8.00110.000 .020

10.00112.000 .025

SPECIFIED

WIDTH OR DEPTH

in.

ALLOWABLE DEVIATION FROM FLAT

Maximum allowable distance Y

Up thru 0.500 .003

0.5011.000 .004

1.0012.000 .005

2.0013.000 .006

3.0015.000 .008

5.0016.000 .010

6.0018.000 .015

8.00110.000 .020

10.00112.000 .025

Footnotes for Tables 12.25 Through 12.30

Q

Footnotes for Tables 12.25 Through 12.30 Footnotes for Tables 12.25 Through 12.30

Tolerance is applicable when weight of tube on at surface minimizes

deviation.

W

Not applicable to annealed (O temper) tube.

E

Not applicable to annealed (O temper) tube, coiled tube, or tube having

a wall thickness less than 0.020 inch or less than 2% of the equivalent

round diameter. Equivalent round diameter is the diameter of a circle having

a circumferance equal to the perimeter of the tube.

R

Twist is normally measured by placing the drawn tube on a at surface

and at any point along its length measuring the maximum distance between

the bottom surface of the drawn tube and the at surface. From this mea-

surement, the actual deviation from straightness of the drawn tube at that

point is subtracted. The remainder is the twist. To convert the standard twist

tolerance (degrees) to an equivalent linear value, the sine of the standard

tolerance is multiplied by the width of the surface of the section that is on

the at surface. The following values are used to convert angular tolerances

to linear deviation:

Maximum allowable

Tolerance, linear deviation

degrees inch per inch of width

0.004

0.009

1 0.017

1 0.026

3 0.052

5 0.087

7 0.122

9 0.156

15 0.259

21 0.358

Footnotes for Tables 12.25 through 12.28

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc. KA-TPH-AA3-1.09

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Dasco HvacDocument35 pagesDasco HvacrafaelPas encore d'évaluation

- Jis G3444Document12 pagesJis G3444yapsguanPas encore d'évaluation

- Crescentbay Reef Towers: Formwork Design SummaryDocument4 pagesCrescentbay Reef Towers: Formwork Design SummarykosdsdsPas encore d'évaluation

- SAIL StructuralsDocument10 pagesSAIL StructuralsKonathala RajashekarPas encore d'évaluation

- 1200 1300Document18 pages1200 1300wyerengrPas encore d'évaluation

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranPas encore d'évaluation

- Guardrail DesignDocument8 pagesGuardrail Designundf25Pas encore d'évaluation

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiPas encore d'évaluation

- Power System Analysis - Stevenson - Grainger - AnnexDocument5 pagesPower System Analysis - Stevenson - Grainger - AnnexSaghir AhmadPas encore d'évaluation

- Drawn Vs Extrude TubesDocument26 pagesDrawn Vs Extrude TubesAlejandro GonzalesPas encore d'évaluation

- Felker LineCard-WebView 100319Document4 pagesFelker LineCard-WebView 100319vineethPas encore d'évaluation

- NavojiDocument193 pagesNavojianon_419810527Pas encore d'évaluation

- Soporte AAC - KcmilDocument6 pagesSoporte AAC - Kcmilmzabala99Pas encore d'évaluation

- National Electrical Code 2002 - Tabla 310.60 - PDFDocument11 pagesNational Electrical Code 2002 - Tabla 310.60 - PDFkabirseba100% (1)

- TUBACEX Power Generation 10Document12 pagesTUBACEX Power Generation 10walitedisonPas encore d'évaluation

- Clutch Release BearingDocument32 pagesClutch Release Bearingvaibhav ahujaPas encore d'évaluation

- ICL-PPT11-24-Plumbing in Hydraulic SystemsDocument24 pagesICL-PPT11-24-Plumbing in Hydraulic SystemsGovindaraja GopalakrishnanPas encore d'évaluation

- Is StandardDocument10 pagesIs Standardsarkararup100% (1)

- Tecnofil Catalogo2022Document8 pagesTecnofil Catalogo2022Cesar OteroPas encore d'évaluation

- Pipe ThicknessDocument26 pagesPipe ThicknessMehman NasibovPas encore d'évaluation

- Astm A29Document22 pagesAstm A29jangaswathiPas encore d'évaluation

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745Pas encore d'évaluation

- Outside MicrometersDocument1 pageOutside MicrometersAntonio DíazPas encore d'évaluation

- Precision Tube: Cold Rolled Tube Product RangeDocument4 pagesPrecision Tube: Cold Rolled Tube Product RangedvtherionPas encore d'évaluation

- P202301 PR B CS STD 0001Document16 pagesP202301 PR B CS STD 0001Nitin SakpalPas encore d'évaluation

- Catalog Profile Cu Pereti SubtiriDocument52 pagesCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- NTPC FGD Talcher: Raw Material Requirement - 05.04.2022: S. No. Grade Thick/Profile (MM) Width (MM) Length (MM)Document9 pagesNTPC FGD Talcher: Raw Material Requirement - 05.04.2022: S. No. Grade Thick/Profile (MM) Width (MM) Length (MM)Tamil Arasu SPas encore d'évaluation

- Acsr Al Bare-Rev 04Document1 pageAcsr Al Bare-Rev 04Ae SuwaphanPas encore d'évaluation

- BorrarxxxDocument4 pagesBorrarxxxHeco NicPas encore d'évaluation

- A1-3 EXT'N RevisedDocument13 pagesA1-3 EXT'N RevisedSean Franz VilardoPas encore d'évaluation

- SA RawlboltDocument2 pagesSA Rawlboltpower_generator133850% (2)

- Pipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed FittingsDocument27 pagesPipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed Fittingsrodhiba1Pas encore d'évaluation

- Especificacion API 5lDocument44 pagesEspecificacion API 5ljpcc1986100% (1)

- RJ45 Modular Jack With Magnetic Filter: Section 11Document20 pagesRJ45 Modular Jack With Magnetic Filter: Section 11hendpraz88Pas encore d'évaluation

- Building Roll (KBR) : Light Weight, No Sagging Nor SettlingDocument8 pagesBuilding Roll (KBR) : Light Weight, No Sagging Nor SettlingPhan LongPas encore d'évaluation

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocument6 pagesSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForIngrid Tatiana RojasPas encore d'évaluation

- Gage Block TolerancesDocument6 pagesGage Block TolerancesAna Gabriela OjedaPas encore d'évaluation

- Cable Profile For Prestressing and Calculation of Eccentricities of Substiture CableDocument4 pagesCable Profile For Prestressing and Calculation of Eccentricities of Substiture Cablerabindra choudhary0% (1)

- Powell Valve Catalog 2000Document175 pagesPowell Valve Catalog 2000naytunaung7650Pas encore d'évaluation

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocument5 pagesDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresPas encore d'évaluation

- Properties of PipeDocument5 pagesProperties of PipeWiwi NorzahraPas encore d'évaluation

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- Column With Uniaxial MomentDocument37 pagesColumn With Uniaxial MomentRONALD AYALA HUARACHIPas encore d'évaluation

- PIPE SpecificationDocument6 pagesPIPE SpecificationNamta GeorgePas encore d'évaluation

- A Complete Guide To Pipe SizesDocument25 pagesA Complete Guide To Pipe SizesahmedPas encore d'évaluation

- Working PressureDocument11 pagesWorking Pressureshojaee1063Pas encore d'évaluation

- EN6114Document14 pagesEN6114akayirPas encore d'évaluation

- Navoji - PodatciDocument88 pagesNavoji - PodatciNikolat84Pas encore d'évaluation

- Balance QTY For RA Bill 40Document8 pagesBalance QTY For RA Bill 40rautrabishankarPas encore d'évaluation

- Flowmeter SelectionDocument4 pagesFlowmeter SelectionsrshahPas encore d'évaluation

- Astronomical Instruments and AccessoriesD'EverandAstronomical Instruments and AccessoriesPas encore d'évaluation

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysD'EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- 1275Document40 pages1275JM SVPas encore d'évaluation

- Geostatistics 2001Document198 pagesGeostatistics 2001JM SV100% (5)

- HALO LED Strip Lighting (Peru)Document2 pagesHALO LED Strip Lighting (Peru)JM SVPas encore d'évaluation

- Sistema de AnclajeDocument56 pagesSistema de AnclajeJM SVPas encore d'évaluation

- Remicsa Cable Bolts AccesoriosDocument1 pageRemicsa Cable Bolts AccesoriosJM SVPas encore d'évaluation

- DSI Underground Systems Cable Bolts USDocument14 pagesDSI Underground Systems Cable Bolts USDonald Culqui VallePas encore d'évaluation

- Guidelines For Use of The Scaled Span MethodDocument34 pagesGuidelines For Use of The Scaled Span MethodJM SVPas encore d'évaluation

- Lab Testing For Empirical DesignDocument10 pagesLab Testing For Empirical DesignJM SVPas encore d'évaluation

- Product BarChipR50 EmailDocument2 pagesProduct BarChipR50 EmailJM SVPas encore d'évaluation

- 19 Proposed Design Methodology For ShotcreteDocument31 pages19 Proposed Design Methodology For ShotcreteMagdy BakryPas encore d'évaluation

- 03 DriftingDocument19 pages03 DriftingJM SVPas encore d'évaluation

- Data InglDocument127 pagesData InglDaniel Luna0% (1)

- FLACslope - User's GuideDocument82 pagesFLACslope - User's Guidetinafine100% (1)

- Vulcantut01 110221214800 Phpapp01Document545 pagesVulcantut01 110221214800 Phpapp01JM SVPas encore d'évaluation

- 2DBench TutorialDocument16 pages2DBench TutorialJM SVPas encore d'évaluation

- Tutorial Examine 2DDocument22 pagesTutorial Examine 2DJM SV75% (4)

- Automating Scientific Data Analysis Part 1 - by Peter Grant - Towards Data ScienceDocument7 pagesAutomating Scientific Data Analysis Part 1 - by Peter Grant - Towards Data ScienceMarcial Puente ChavezPas encore d'évaluation

- Oo LabDocument327 pagesOo Labtamilarasi87thulasiPas encore d'évaluation

- Acrolinx: Tone of VoiceDocument12 pagesAcrolinx: Tone of VoiceMark OwenPas encore d'évaluation

- UAE Media LandscapeDocument17 pagesUAE Media LandscapeM. Waqas AbdullahPas encore d'évaluation

- Soot (PM) SensorsDocument22 pagesSoot (PM) SensorsAhmed AlsheikhPas encore d'évaluation

- Star Clip Art - Google SearchDocument1 pageStar Clip Art - Google SearchHM - 06BE 839268 McClure PSPas encore d'évaluation

- PSLC Professional Lighting 17-18 - Accent LightDocument14 pagesPSLC Professional Lighting 17-18 - Accent LightAhmed salahPas encore d'évaluation

- Company Name Weld Procedure SpecificationDocument3 pagesCompany Name Weld Procedure SpecificationJorge Valdera100% (1)

- Smartaisle Containment Brochure EnglishDocument32 pagesSmartaisle Containment Brochure EnglishAsad NizamPas encore d'évaluation

- Review of Literature and Studies Related LiteratureDocument21 pagesReview of Literature and Studies Related LiteratureKavin Dela CruzPas encore d'évaluation

- Project QuestionDocument35 pagesProject Questiongnger308Pas encore d'évaluation

- Prospekt - SCROLL - ENG RENNERDocument8 pagesProspekt - SCROLL - ENG RENNERAriantoPas encore d'évaluation

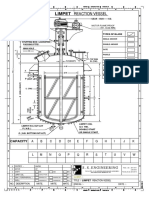

- Limpet Reaction Vessel PDFDocument1 pageLimpet Reaction Vessel PDFarajamani78Pas encore d'évaluation

- Natalie Venegas ResumeDocument2 pagesNatalie Venegas Resumeapi-302645353Pas encore d'évaluation

- Solve The Inverse Kinematics of Robot Arms Using Sand Cat Swarm Optimization SCSO AlgorithmDocument5 pagesSolve The Inverse Kinematics of Robot Arms Using Sand Cat Swarm Optimization SCSO AlgorithmMohamed BensaadallahPas encore d'évaluation

- Dr. Jyotismita MishraDocument2 pagesDr. Jyotismita MishrashajithuPas encore d'évaluation

- Best of Definition and Types of ResearchDocument42 pagesBest of Definition and Types of ResearchZe MeliePas encore d'évaluation

- Disc-Mower-Parts Fella SM 270Document4 pagesDisc-Mower-Parts Fella SM 270JanuszPas encore d'évaluation

- Free Research ReportsDocument205 pagesFree Research ReportsRajkumar TiwariPas encore d'évaluation

- SAKLOLO UX Case StudyDocument15 pagesSAKLOLO UX Case Studynashi16Pas encore d'évaluation

- Ultimate CX Ebook51Document39 pagesUltimate CX Ebook51vvsshivaprasadPas encore d'évaluation

- Edif Echo PC Analyzer - Service Manual PDFDocument21 pagesEdif Echo PC Analyzer - Service Manual PDFkartopolloPas encore d'évaluation

- Assignment No.2: Areeba Mughal S17BBAH051Document3 pagesAssignment No.2: Areeba Mughal S17BBAH051Areeba MughalPas encore d'évaluation

- GM Maint Catalog PDFDocument38 pagesGM Maint Catalog PDFMarcelo ArayaPas encore d'évaluation

- Assignment 3 (SEE 312) : Part ADocument3 pagesAssignment 3 (SEE 312) : Part ANaveen SrivastavaPas encore d'évaluation

- Trainiing BeckhoffDocument45 pagesTrainiing BeckhoffĐại TrầnPas encore d'évaluation

- FemtocellDocument20 pagesFemtocellSonamAggarwalManan0% (1)

- ReviwerDocument6 pagesReviwerCed RickPas encore d'évaluation

- PMD - Front Sprint2021-20 ScenariosDocument42 pagesPMD - Front Sprint2021-20 ScenariosHuy Quang PhạmPas encore d'évaluation

- Rajah Di Bawah Menunjukkan Susunan Radas Untuk Membina Suatu GegantiDocument36 pagesRajah Di Bawah Menunjukkan Susunan Radas Untuk Membina Suatu GegantiYusfalina Mohd YusoffPas encore d'évaluation