Académique Documents

Professionnel Documents

Culture Documents

Aggregate Op Tim Ization

Transféré par

End End0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pagecoarse

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentcoarse

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageAggregate Op Tim Ization

Transféré par

End Endcoarse

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Credit Jim Lafrenz, Director of

Airports at ACPA National, for challenging

some of us in the concrete industry here in

North Dakota to expand our understanding

of current concrete technology.

Specifically, Jim has offered insight into the

matter of aggregate optimization to achieve

mixes that resist segregation, enhance dura-

bility and improve workability. This topic

is very timely as we search for answers to

ride and smoothness issues on newly con-

structed Continuously Reinforced Concrete

Pavements (CRCP) for highways.

Aggregate optimization has been one

of the least understood tools for ride and

smoothness enhancements in all of the con-

crete paving industry up until recently. In

addition to Mr. Lafrenz, recent comments

from James Shilstone, a noted national

expert in concrete mix technology, and Jim

Mikulanec, National Staff Member of

ACPA, have added credibility to the bene-

fits of aggregate optimization.

Much of the dialogue that has followed

aggregate optimization in recent years has

been based on durability benefits of reduc-

ing mix paste (cementitious and water) con-

tents through the use of uniformly graded

aggregates to fill voids in the matrix. The

theory has followed that paste is the least

durable component of concrete, while

aggregate is the most durable. Therefore,

following optimization techniques similar

to the 0.45 Power Curve for asphalt aggre-

gate gradations seemed to benefit concrete

also. Even nominal attempts to fill gaps in

concrete gradations have brought profound

benefits for lower concrete permeability

characteristics at lower paste contents, as

shown by recent NDDOT funded research

at University of North Dakota.

Mr. Lafrenz' interest in mix improve-

ments come from his work with the U.S.

Air Force in the early 1990's. While Chief

Engineer in charge of runway con-

struction at air bases throughout the

country, he noted an excessively high

rate of durability issues on new pave-

ments, mostly due to FOD (foreign

object damage) on high performance

aircraft. After much investigation, it

was determined that mixes would

sometimes segregate, allowing a small

curl of paste and sand to form at the

edges of the slip-form paver box which

would then be placed at the construction

joint between paver passes. This paste was

determined to be the primary source of the

North Dakota Chapter, Inc. - ACPA Page10

Aggregate Optimization

FOD, so investigations into ways to prevent

the segregation lead to creation of the tools

we now have available. Included in our

new tool box is the Constructability Chart,

as shown in inset. The spreadsheet that

leads to the calculation of points on the

Chart reflects the benefits of adding mid-

size aggregates to the mix proportions. The

use of more uniformly graded aggregates

has been found to

be a major solu-

tion to problems

of segregation in

normal mixes, as

compared to our

ordinary gap grad-

ed mixes com-

posed of large

stone and sand.

From the ride

and smoothness

side of the discus-

sion, major contri-

butions were

made to the dis-

cussion by Mr.

Mikulanec at the

2003 Spring

Concrete

Conference in

Bismarck. Jim

noted that as the

National Sales

Manager for

CMI, a major

U.S. paver manu-

facturer, about

90% of his troubleshooting visits to proj-

ects for ride and smoothness issues by the

contractor were related to aggressive (un-

optimized) aggregate gradations.

Workability on these projects was so poor

that the pavers were incapable of compen-

sating without excessive vibration. Use of

aggregate optimization techniques, he

reported, improved workability to the

extent that pavement smoothness was no

longer an issue.

Mr. Lafrenz has offered a spreadsheet

to be used for evaluating aggregate grada-

tions for workability. Engineers at the

Fargo and Valley City Districts of the

NDDOT, as well as others in the private

sector, have received some simple training

in the spreadsheet usage. Others who

would like to advance the benefits of dura-

bility and workability through usage of

these techniques should contact the ND

concrete associations for help. The

NDRMCPA Administrative Offices are at

(701) 2550-7250, while ACPA Chapter

offices are 701-232-6972. You may also

contact Dave Sethre directly at (701)371-

4497. Hank Hauge (LaFarge Dakota) has

also offered to assist in working with the

spreadsheet; you may contact him at

(701)840-8032.

For additional information on back-

ground and interpretation of aggregate opti-

mization and Constructability Charts, check

out an article co-written by Mr. Lafrenz and

Mr. Shilstone as posted on our website at

www.ndconcrete.com/techarticles.html. We

wish to thank the hard work that these gen-

tlemen have endured to contribute to this

all important work in mix design enhance-

ment. DCS

This chart is used to plot constructability trends from workability and

coarseness factors. The center of the target is at about coarseness

factor = 60 and workability factor = 35.

Aggregate optimization has

been one of the least under-

stood tools for ride and

smoothness enhancements...

It's Time has Come

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- AsphaltDocument182 pagesAsphaltEnd EndPas encore d'évaluation

- Highway Design PDFDocument14 pagesHighway Design PDFRajesh BabuPas encore d'évaluation

- Flexible Pavement Design ToolDocument13 pagesFlexible Pavement Design ToolRolando LópezPas encore d'évaluation

- Safety Factor For StoneDocument4 pagesSafety Factor For StonePaulPas encore d'évaluation

- 240 87605434Document68 pages240 87605434thegemisherePas encore d'évaluation

- BS 598 104 1989 PDFDocument18 pagesBS 598 104 1989 PDFEnd EndPas encore d'évaluation

- Structures: Highway Design Standards 2010Document45 pagesStructures: Highway Design Standards 2010GILBERTO POZZIPas encore d'évaluation

- RIDOT Highway Design ManualDocument104 pagesRIDOT Highway Design ManualEnd EndPas encore d'évaluation

- Bentley MicroStation v10 Installation InstructionsDocument4 pagesBentley MicroStation v10 Installation InstructionsEnd End0% (3)

- BLENDING of MSS Mix Design TypeDocument3 pagesBLENDING of MSS Mix Design TypeEnd EndPas encore d'évaluation

- Quality Audit of Bogie OverhaulDocument24 pagesQuality Audit of Bogie OverhaulEnd End100% (1)

- Railway Stations SpecsDocument288 pagesRailway Stations SpecsFranklin GarciaPas encore d'évaluation

- DBMDocument29 pagesDBMEnd EndPas encore d'évaluation

- Group 2 Wall Panel SystemsDocument30 pagesGroup 2 Wall Panel SystemsAlwyn Ramos100% (1)

- (CRMB) 60 Bitumen Test Results Nov 10Document26 pages(CRMB) 60 Bitumen Test Results Nov 10End EndPas encore d'évaluation

- Polymer Modified Asphalt Properties and PerformanceDocument39 pagesPolymer Modified Asphalt Properties and PerformanceEnd End100% (1)

- Testing Fresh Concrete. DensityDocument14 pagesTesting Fresh Concrete. Densitymanil_50% (1)

- Catálogo de Peças de Reposição: 6415,6615 TRACTORSDocument752 pagesCatálogo de Peças de Reposição: 6415,6615 TRACTORSMiguel MattiesPas encore d'évaluation

- Concept For Road Design (Super Elevation and Vertical Curve Calculations)Document2 pagesConcept For Road Design (Super Elevation and Vertical Curve Calculations)End EndPas encore d'évaluation

- AggregateDocument57 pagesAggregateEnd EndPas encore d'évaluation

- 261 Road Fly Ash EmbankDocument4 pages261 Road Fly Ash Embanksandeep kumarPas encore d'évaluation

- Test Method - AggDocument23 pagesTest Method - AggEnd EndPas encore d'évaluation

- Calibration of Rapid Moisture Meter No. R-1Document20 pagesCalibration of Rapid Moisture Meter No. R-1End EndPas encore d'évaluation

- Test Method - AggDocument23 pagesTest Method - AggEnd EndPas encore d'évaluation

- Test Method OthersDocument15 pagesTest Method OthersEnd End100% (1)

- (WWW - Entrance-Exam - Net) - SSC Paper For Mechanical Engineering PDFDocument14 pages(WWW - Entrance-Exam - Net) - SSC Paper For Mechanical Engineering PDFVaisakh SomakumarPas encore d'évaluation

- Upgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisDocument2 pagesUpgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisEnd EndPas encore d'évaluation

- Material Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksDocument8 pagesMaterial Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksEnd EndPas encore d'évaluation

- (Paper) Computer General Knowledge For Bank Examination (For Bank PO Exam)Document12 pages(Paper) Computer General Knowledge For Bank Examination (For Bank PO Exam)pravit08Pas encore d'évaluation

- StripDocument666 pagesStripEnd EndPas encore d'évaluation

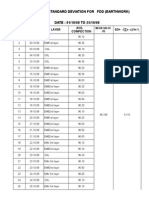

- Standard Deviation Analysis of Earthwork SectionsDocument8 pagesStandard Deviation Analysis of Earthwork SectionsEnd EndPas encore d'évaluation

- CBR - 3 - EnergyDocument187 pagesCBR - 3 - EnergyEnd End100% (1)

- 10-Appendix - 1700 - IDocument2 pages10-Appendix - 1700 - IEnd EndPas encore d'évaluation

- (Tinna) PMB E-40 Bitumen Test Results 07.05.10Document32 pages(Tinna) PMB E-40 Bitumen Test Results 07.05.10End EndPas encore d'évaluation

- (App 1.1 (Vi) ) 334 - 3 (Tumala) (20m) - FDocument4 pages(App 1.1 (Vi) ) 334 - 3 (Tumala) (20m) - FEnd EndPas encore d'évaluation

- Chryso - STICK SBADocument2 pagesChryso - STICK SBAErAmitGuptaPas encore d'évaluation

- Operating Manual: Cutter KU 130 ACDocument189 pagesOperating Manual: Cutter KU 130 AClemuelPas encore d'évaluation

- Designing The New For Our Time?: TerraceDocument2 pagesDesigning The New For Our Time?: TerraceJelai100% (1)

- Ms-Project Revised Work Program Nyegezi-Mwanza 26feb2023Document1 pageMs-Project Revised Work Program Nyegezi-Mwanza 26feb2023Lenny ErastoPas encore d'évaluation

- 1280a4-8310-43c1 Rev F1Document31 pages1280a4-8310-43c1 Rev F1Stephen LowPas encore d'évaluation

- CompactGrid - Mounting Instructions V2 I400176GB PDFDocument8 pagesCompactGrid - Mounting Instructions V2 I400176GB PDFCamilo Andres Bayona AguileraPas encore d'évaluation

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPPas encore d'évaluation

- Senior Civil Engineer ResumeDocument7 pagesSenior Civil Engineer ResumetomzaycoPas encore d'évaluation

- Liftparker Mobil: Parking and Temporary Storage of Vehicles Up To 3200 KGDocument6 pagesLiftparker Mobil: Parking and Temporary Storage of Vehicles Up To 3200 KGSid Ali RABEHIPas encore d'évaluation

- OVER-TIME RECORD FOR HANOI PILOT LIGHT METRO LINE PROJECT UNDER 40 CHARACTERSDocument1 pageOVER-TIME RECORD FOR HANOI PILOT LIGHT METRO LINE PROJECT UNDER 40 CHARACTERSVũ Thành CôngPas encore d'évaluation

- Presentation 1 Water Proofing MaterialsDocument39 pagesPresentation 1 Water Proofing Materialsananya mukerjeePas encore d'évaluation

- SikaGrout 112 - Pds en PDFDocument2 pagesSikaGrout 112 - Pds en PDFabegaa aberaPas encore d'évaluation

- Large Slow Speed Engine Bed Plate ConstructionDocument12 pagesLarge Slow Speed Engine Bed Plate ConstructionVyasaraj Kumar0% (1)

- Construction Progress Report No. 1: Date Issued: August, 2021Document8 pagesConstruction Progress Report No. 1: Date Issued: August, 2021Ibrahim DawudPas encore d'évaluation

- Dokumen - Tips - Diagrama Esmeriladora Dewalt Dwe4120 b3Document4 pagesDokumen - Tips - Diagrama Esmeriladora Dewalt Dwe4120 b3PedroPas encore d'évaluation

- Regienalism and Expressienism: The Modernism of John LautnerDocument44 pagesRegienalism and Expressienism: The Modernism of John LautnerDenisa BalajPas encore d'évaluation

- Six Main Types of WiresDocument21 pagesSix Main Types of WiresRájDèép TrìpâţhíPas encore d'évaluation

- 2019-10-15 Daily Observation Report CilamayaDocument1 page2019-10-15 Daily Observation Report CilamayaghifariaghniaPas encore d'évaluation

- SOLAS Requirements Maintenance Safety SystemsDocument3 pagesSOLAS Requirements Maintenance Safety SystemsMahamiPas encore d'évaluation

- Boq Standard SST 50m XL Outdoor Protelindo JabarDocument50 pagesBoq Standard SST 50m XL Outdoor Protelindo JabarHeri SetiawanPas encore d'évaluation

- Ten Commandments For The Prestressed Concrete EngineerDocument1 pageTen Commandments For The Prestressed Concrete EngineerSheenah TelanPas encore d'évaluation

- DIY Concrete SinkDocument6 pagesDIY Concrete SinkJuliano. PQMPas encore d'évaluation

- Is 12727 PDFDocument14 pagesIs 12727 PDFJanardhana ReddiPas encore d'évaluation

- Itb - I-008Document12 pagesItb - I-008Godwin A.udo-akanPas encore d'évaluation

- Rebar + Epcon G5 capacity tableDocument31 pagesRebar + Epcon G5 capacity tableHerrys Eka Maulana MaulanaPas encore d'évaluation