Académique Documents

Professionnel Documents

Culture Documents

Des Cote Actuated Globe Valves

Transféré par

Orueta Claudio0 évaluation0% ont trouvé ce document utile (0 vote)

480 vues4 pagesvalves

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentvalves

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

480 vues4 pagesDes Cote Actuated Globe Valves

Transféré par

Orueta Claudiovalves

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Bellows Sealed Actuated Globe Valves

for on-off and control service

Tyco reserves the right to change the contents without notice DEFNB-0006-EN-0005

A complete valve and actuator unit designed

specifically for hazardous applications

Actuated valves are major components

of process engineering control loops.

Actuated valve integrity is a necessity

today for reducing plant maintenance

costs, increasing process availability

and conformity with environmental and

emission regulations.

Descote/K lein have developped a

complete range of actuated valves

based on the bellows sealed globe

valves models 2100B, 2500, 1900

(M egastar) and 1700 (Polystar).

These valves are normally equipped

with our linear pneumatic actuator

M odel Bimatic.

Applications for these valves are

throroughly described in the detailed

product leaflets.

O ur actuated globe valve range

includes

Actuated on-off valves

Control valves

Emergency shut-down valves

Actuated and control valves are easily

assembled using standard items :

Valves

M ounting assembly

Actuation

Accessories

Detailed specifications are determined

by the actual service conditions for

each valve.

Application range and limitations

Actuated on-off valves are available for a wide range of applications

Control valves are manufactured for selected applications, i.e.:

Valves M odel 2100 and 2500 limited to Critical Hazardous Liquefied Gases

Valves M odel 1700 and 1900 limited to Hot O ils.

All Control valves, due to their single seat design are limited to applications

without any cavitation.

Quality Assurance

ISO 9001 approved.

Descote control valve

installed on Chlorine unit

(Germany)

Valve selection

M anual valve M odel 1700, 1900, 2500, 2100 and any other bellows sealed globe valves from the standard Descote/K lein range can be changed into

actuated valves. This adaptation from manual to on-off or control valve is easily performed with standard mounting kits.

M anual on-off valves can be actuated on site, in a workshop or insitu, using mounting kits or direct ISO fllange assembly.

Seat tightness

3 levels of seat tightness are available.

Level 1 : Class IV ASM E/ANSI B16.104/FCI 70.2

Level 2 : Class VI ASM E/ANSI B16.104/FCI 70.2

Level 3 : 0 bubble, nitrogen tested at maximum ?P

O ur control valves can be dual function, i.e. control and isolation, when selected with Class 2 or 3 seat tightness.

Considering the actual working conditions and the required tightness level, we can supply :

Hard seat design, metal to metal, including stellite

Soft seat design, in a wide range of polymer or elastomer materials. Selection is made according to the fluid characteristics.

Dual design, combining the advantages of of both hard and soft seats.

O ur design include integral and replacable, screwed in seats.

Bellows selection

Actuated on-off valves are equipped with standard bellows designed for a minimum of 10 000 full stroke open/close cycles at the full maximum rated

pressure.

Control valves can be equipped with :

Standard class bellows as the above

Special class extra long heavy duty bellows. These are designed for 100 000 cycles at full maximum service pressure.

Actuator selection

O ur standard actuated valve range is supplied with our BIM ATIC linear pneumatic actuator.

BIM ATIC actuators can be :

Air to open, spring close

Air to close, spring open

Double acting

Please refer to BIM ATIC leaflet for characteristics and accessories.

O ther actuator types can be fitted to meet customer requirements.

Bellows Sealed Actuated Globe Valves

Design criteria for on-off and control services

Tyco reserves the right to change the contents without notice

Conversion of a manual valve model 2100 or

2500 into an actuated valve.

Direct ISO 5211

flange assembly

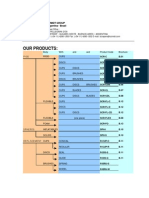

DN15 DN20 DN25 DN40 DN50 DN80 DN100 DN150 DN200 DN250

Body Seat 1/2 3/4 1 11/2 2 3 4 6 8 10

Diameter

mm inch

3 1/8 0, 10 0, 20 0, 30

6 1/4 0, 60 1 1, 20

10 3/8 1, 70 2

13 1/2 3 3, 5 4

20 3/4 5 6

25 1 10 13 14

32 11/4 18 20

40 11/2 30 32

50 2 43 55 60

65 21/2 70 77

80 3 80 86 90

100 4 143 160

125 5 240

150 6 310

175 7 420

200 8 540 600

CVs are in US GPM (DIN K V = CV/1, 16)

Linear, on-off or equal %

curve characteristics

O n-off

CV VALUE

VALVE STRO K E

Positioner

O ur standard control valves are equipped with ECK ART SRI 986 positioner.

O ther positioner makes and models can be supplied.

Positioner

We manufacture manual valves with regulating discs to provide manual flow control.

This design is particularly applicable to control valve by-pass; the plant can then be operated when the control valve requires maintenance.

Accessories

O n-off and control valves can be delivered with a wide range of accessories.

Limit switches

Solenoid valve

Safety manual override

Field bus

Bellows Sealed Actuated Globe Valves

Design criteria for on-off and control services

Tyco reserves the right to change the contents without notice

CV range

Top mounted safety manual override Pillar mounted switches for direct stem

position detection

Item Description

860. Actuator top cover

900. Limit switches dry contact type

901. Proximity switches inductive type

902. Junction box

950. Positioner

910. Solenoid valve

913. Air fitter regulator

914. Air speed control to adjust valve

opening/closing time

924. Protective device from moving part

Linear

Equal %

Bellows Sealed Actuated Globe Valves

range

Tyco reserves the right to change the contents without notice

M odel 2100B control valve Actuated bellows sealed globe valves

(thermal oil)

O n-off valve M odel 2100B D

2

O /He lines

isolation

M odel 2100B with electric actuator

O n-off valve M odel 2100B Co unloading

station

Control valve M odel 2100B - Chlorine unit O n-off valves M odel 2200 with safety manual

override - liquefied gas storage

M anufacturing facilities

9, avenue Jean-Jaurs

69320 Feyzin - France

Phone +33 (0)4 72 89 25 00

Fax +33 (0)4 72 89 25 25

Telex F370 457

M anufacturing facilities

BP 10 - Perrigny

39570 Lons le Saulnier France

Phone +33 (0)3 84 87 22 22

Fax : +33 (0)3 84 24 60 40

For any further information, please contact :

1 your local tyco sales office

2 or descote-klein@ tyco-valve.com

Phone : +33 (0)4 72 89 25 00 Fax : +33 (0)4 72 89 25 25

M ail : descote 9 avenue Jean Jaurs 69320 Feyzin - France

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- STMG1620Document66 pagesSTMG1620ramon hidalgo100% (2)

- Type "S" Relay Valve (Volume Booster) : Service ManualDocument6 pagesType "S" Relay Valve (Volume Booster) : Service Manualayman akrabPas encore d'évaluation

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1Pas encore d'évaluation

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutPas encore d'évaluation

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroPas encore d'évaluation

- AIRTORQUEDocument20 pagesAIRTORQUEPaula MendesPas encore d'évaluation

- Air Compressor Piping DiagramDocument2 pagesAir Compressor Piping DiagramOrueta ClaudioPas encore d'évaluation

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2Pas encore d'évaluation

- TankerDocument60 pagesTankerlopezdestructionPas encore d'évaluation

- Double Block and Bleed ValveDocument16 pagesDouble Block and Bleed ValveBa Jun Thối100% (1)

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 pagesRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezPas encore d'évaluation

- CV Training InstDocument21 pagesCV Training Instxentrer100% (1)

- Ata 47Document74 pagesAta 47Alejandro SiliezarPas encore d'évaluation

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmPas encore d'évaluation

- KOMOTO General CatalogDocument20 pagesKOMOTO General Catalogwalkingharmony100% (1)

- Model 2100bDocument4 pagesModel 2100bkeyur1109Pas encore d'évaluation

- Offshore Pipeline Engineering Materials & Welding Module Construction PracticeDocument56 pagesOffshore Pipeline Engineering Materials & Welding Module Construction PracticeOrueta Claudio100% (1)

- ME Fuel Valves Tester - Woo Am - WBTD-1100Document10 pagesME Fuel Valves Tester - Woo Am - WBTD-1100john smith100% (3)

- Technical Bulletin: Valtek Flowtop Control ValveDocument20 pagesTechnical Bulletin: Valtek Flowtop Control ValverohitkushPas encore d'évaluation

- Safety Relief ValvesDocument52 pagesSafety Relief ValvesHamza NoumanPas encore d'évaluation

- Autocad Plant3d Quick Reference GuideDocument2 pagesAutocad Plant3d Quick Reference GuideHanna Obeid100% (1)

- Section 23 21 00 - Hydronic Valves and SundriesDocument22 pagesSection 23 21 00 - Hydronic Valves and Sundriesvaradarajck893Pas encore d'évaluation

- ASCO Miniature Valve Products (AV017R5)Document96 pagesASCO Miniature Valve Products (AV017R5)vasudeva yasasPas encore d'évaluation

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestPas encore d'évaluation

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryPas encore d'évaluation

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaPas encore d'évaluation

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftPas encore d'évaluation

- Kent IntrolDocument15 pagesKent IntrolVladimir VuletinPas encore d'évaluation

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresPas encore d'évaluation

- Butterfly Valve-Concentric DesignDocument6 pagesButterfly Valve-Concentric Designbharadwaj037Pas encore d'évaluation

- Maxon A Ha NiseriesDocument4 pagesMaxon A Ha Niseriescrown1973Pas encore d'évaluation

- Topworx Valvetop D-Series With GO Switches ManualDocument20 pagesTopworx Valvetop D-Series With GO Switches ManualJuan LuisPas encore d'évaluation

- Danfoss Non Return ValvesDocument28 pagesDanfoss Non Return Valveskostaviga777Pas encore d'évaluation

- Riser Module 747m VictaulicDocument2 pagesRiser Module 747m Victaulicrvalentino2012Pas encore d'évaluation

- Pneutrainer eDocument24 pagesPneutrainer eSiscaNduetz-NduetzGaxMauGalauPas encore d'évaluation

- Cryogenic CatalogDocument12 pagesCryogenic CatalogjbaptistaaPas encore d'évaluation

- Trunnion Mounted Ball Valves API 6D & 6ADocument2 pagesTrunnion Mounted Ball Valves API 6D & 6A2009tamerPas encore d'évaluation

- BRH Eplug Rotaryshaftvalves GeDocument28 pagesBRH Eplug Rotaryshaftvalves GeJosh FryPas encore d'évaluation

- Wcenbr1040 01Document12 pagesWcenbr1040 01shahganPas encore d'évaluation

- Flowserve PDFDocument12 pagesFlowserve PDFnadrivPas encore d'évaluation

- Tom Wheatley Swing Check Valves (New)Document24 pagesTom Wheatley Swing Check Valves (New)Carlos Cardenas SochaPas encore d'évaluation

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuPas encore d'évaluation

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenPas encore d'évaluation

- Mead Isonic V1 Series (WWW - Mead.co - Uk)Document4 pagesMead Isonic V1 Series (WWW - Mead.co - Uk)Mead Engineering Services LtdPas encore d'évaluation

- AVK Fire BrochureDocument28 pagesAVK Fire BrochureMahmoud YasseinPas encore d'évaluation

- H 04437Document4 pagesH 04437E_Amr_SorourPas encore d'évaluation

- I Nnov at IV e Solut Ions: Innovative SolutionsDocument12 pagesI Nnov at IV e Solut Ions: Innovative Solutionsleandroperao5374Pas encore d'évaluation

- Dsi Bsi - Direct and Belt Driven Square Inline Fans - Catalog 4205 PDFDocument28 pagesDsi Bsi - Direct and Belt Driven Square Inline Fans - Catalog 4205 PDFBalanSelvamPas encore d'évaluation

- Series: Control ValvesDocument20 pagesSeries: Control ValvesHugo SA de CVPas encore d'évaluation

- Cami Ball ValveDocument4 pagesCami Ball ValvescribdkhatnPas encore d'évaluation

- h06974 MC Series IcvDocument2 pagesh06974 MC Series IcvLoganBohannonPas encore d'évaluation

- Bettis Cba 300 Series Pneumatic Actuators Us DataDocument6 pagesBettis Cba 300 Series Pneumatic Actuators Us DatasusantoPas encore d'évaluation

- Skymark Vac8 25t Engineering Guide PDFDocument16 pagesSkymark Vac8 25t Engineering Guide PDFBraulio Ramón PeñaPas encore d'évaluation

- Vad 213Document11 pagesVad 213Sen Van0% (1)

- Valtek Guardian II Hydrofromed Bellows SealDocument6 pagesValtek Guardian II Hydrofromed Bellows Sealابزار دقیقPas encore d'évaluation

- (Aseptomag) Double Chamber Valve - Type DKDocument3 pages(Aseptomag) Double Chamber Valve - Type DKaaro_oraalPas encore d'évaluation

- BFV STD - SpecdamperDocument39 pagesBFV STD - Specdamperkselvan_1Pas encore d'évaluation

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujPas encore d'évaluation

- TS BellowsDocument2 pagesTS BellowsRujisak MuangsongPas encore d'évaluation

- Actuator DRD DREDocument35 pagesActuator DRD DRESandi AslanPas encore d'évaluation

- 7 Com PDFDocument16 pages7 Com PDFMarco AntonioPas encore d'évaluation

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARPas encore d'évaluation

- Ci NLDocument12 pagesCi NLanuraePas encore d'évaluation

- Valvula YarwayDocument12 pagesValvula YarwayRobert VillavicencioPas encore d'évaluation

- Ball Valves - R43/R44 Trunnion MountedDocument10 pagesBall Valves - R43/R44 Trunnion MountedThomasFrenchPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Our Products:: Szmidt Group Argentina - BrasilDocument1 pageOur Products:: Szmidt Group Argentina - BrasilOrueta ClaudioPas encore d'évaluation

- Hojas Con Fotos 020404Document4 pagesHojas Con Fotos 020404Orueta ClaudioPas encore d'évaluation

- Welding Course 1Document79 pagesWelding Course 1Orueta ClaudioPas encore d'évaluation

- ANSI Flange RatingsDocument5 pagesANSI Flange Ratingssuperfly1984Pas encore d'évaluation

- 325 Hydraulic SystemDocument7 pages325 Hydraulic SystemUMA AKANDU UCHEPas encore d'évaluation

- T227/U03/ PPP 3: Correcting UnitsDocument24 pagesT227/U03/ PPP 3: Correcting Unitsbaba maachoPas encore d'évaluation

- Section14 Logic ElementsDocument48 pagesSection14 Logic ElementsHENRY LLOFREL CORREA LOPEZPas encore d'évaluation

- TROUBLESHOOTING / Component Layout: Control Valve SideDocument2 pagesTROUBLESHOOTING / Component Layout: Control Valve SideSAULPas encore d'évaluation

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Document5 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Elias EliasPas encore d'évaluation

- Modelling Cascaded Split Range (Casc-Src) Controllers in Aspen Hysys DynamicsDocument3 pagesModelling Cascaded Split Range (Casc-Src) Controllers in Aspen Hysys Dynamicspedro kaiserPas encore d'évaluation

- Solenoid Control Valve: Product FeaturesDocument2 pagesSolenoid Control Valve: Product FeaturesXavierPas encore d'évaluation

- Mech 1300 Fluid Power SyllabusDocument4 pagesMech 1300 Fluid Power SyllabusTimothy FieldsPas encore d'évaluation

- Product Catalogue 2013 Low Res VersionDocument82 pagesProduct Catalogue 2013 Low Res VersionNaing Oo KyawPas encore d'évaluation

- EB 8484-1 EN: Translation of Original InstructionsDocument144 pagesEB 8484-1 EN: Translation of Original Instructions廖江連Pas encore d'évaluation

- Ger 2461d Speedtronic Mark I Mark II ControlsDocument23 pagesGer 2461d Speedtronic Mark I Mark II ControlsMuhammad Zahari100% (1)

- PB 0101 Rev 2Document16 pagesPB 0101 Rev 2gk218Pas encore d'évaluation

- Product Catalog Samson at A Glance: Production Sites StaffDocument174 pagesProduct Catalog Samson at A Glance: Production Sites Staffkhaled saeedPas encore d'évaluation

- CIM and Automation Lab ManualDocument39 pagesCIM and Automation Lab ManualHareesha N G67% (3)

- Control Valves HandbookDocument3 pagesControl Valves HandbookDadang Ibnu Setyawan100% (1)

- Lesson Plan MechatronicsDocument2 pagesLesson Plan MechatronicsChetan GhatagePas encore d'évaluation

- Control Valve - 3wayDocument2 pagesControl Valve - 3wayrockykrishPas encore d'évaluation

- Samson Globe Control ValveDocument12 pagesSamson Globe Control ValveShishir DwivediPas encore d'évaluation

- Roc On Water Control ValveDocument4 pagesRoc On Water Control ValveSBeardPas encore d'évaluation

- Preaction System Design GuideDocument15 pagesPreaction System Design GuideMarkPas encore d'évaluation

- Valves PDFDocument13 pagesValves PDFShehab NaeemPas encore d'évaluation

- Cla-Val 390-02Document45 pagesCla-Val 390-02Irvin PachecoPas encore d'évaluation

- TMP - 1Document2 pagesTMP - 1Freddy SantanderPas encore d'évaluation

- Pneumatic Ball On-Off Valve/150LB (Fail Close) Tag Number: ESDV 201 A/B NO: 1Document12 pagesPneumatic Ball On-Off Valve/150LB (Fail Close) Tag Number: ESDV 201 A/B NO: 1mohsalehi1391Pas encore d'évaluation