Académique Documents

Professionnel Documents

Culture Documents

Well Lifecycle Process Overview: © The Robert Gordon University

Transféré par

paulusama20 évaluation0% ont trouvé ce document utile (0 vote)

39 vues36 pagesHydrocarbon deposits originate from the remains of plants and animals. Over millions of years the organic matter decayed and decomposed under conditions of extreme pressure and heat into what we know today as hydrocarbon products. Hydrocarbon deposits may be found in liquid, gaseous, and solid form but they all consist of the same base elements, hydrogen (13% by weight) and carbon ( 87%)

Description originale:

Titre original

Well Lifecycle Slides

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentHydrocarbon deposits originate from the remains of plants and animals. Over millions of years the organic matter decayed and decomposed under conditions of extreme pressure and heat into what we know today as hydrocarbon products. Hydrocarbon deposits may be found in liquid, gaseous, and solid form but they all consist of the same base elements, hydrogen (13% by weight) and carbon ( 87%)

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues36 pagesWell Lifecycle Process Overview: © The Robert Gordon University

Transféré par

paulusama2Hydrocarbon deposits originate from the remains of plants and animals. Over millions of years the organic matter decayed and decomposed under conditions of extreme pressure and heat into what we know today as hydrocarbon products. Hydrocarbon deposits may be found in liquid, gaseous, and solid form but they all consist of the same base elements, hydrogen (13% by weight) and carbon ( 87%)

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 36

1

The Robert Gordon University

Well Lifecycle

Process Overview

2

So just where does oil come from?

Hydrocarbon deposits originate from the remains of

plants and animals. Over millions of years the organic

matter decayed and decomposed under conditions of

extreme pressure and heat into what we know today

as hydrocarbon products. These may be found in

liquid, gaseous, and solid form but they all consist of

the same base elements, hydrogen (~13% by weight)

and carbon (~ 87%).

3

Cycle of Deposition

WEATHERING & EROSION

of igneous, sedimentary and

metamorphic rocks

TRANSPORT OF DEBRIS

by wind, running water, etc.., and

DEPOSITION in the sea

SUBSIDENCE

accompanied by compression and

cementation of loose sediments

FOLDING & UPLIFTING

accompanied by volcanic activity and

igneous intrusions

Rocks can be arranged into a few groups of closely related

types depending on the size and nature of the mineral

forming the rock:

I gneous: solidified from a molten mass - made up of a

few minerals of definite composition - crystals - and each

recognizable. Silica is present in almost all igneous rocks.

Eg quartz - almost entirely silica).

Sedimentary: Accumulated on land or in water from

debris of existing rock. There are only 4 main varieties:

Arenaceous - Sandy

Argillacous - Clay

Calcerous - Lime

Organic - Remains of plants and animals

Metamorphic: Rocks that have been altered by heat

and pressure. Heat causes the mineral to re-crystallise and

turn into a simpler and more stable form. Pressure allows

them to to grow and re-arrange themselves - they have a

definite grain

4

The Earth beneath our feet ...

The extent of reservoirs is dependent on the structure

of the earths crust. Where movement of the earths

various layers along geological fault lines is excessive

then it is these layers that are pushed into mountains

and valleys creating conditions conducive to the

formation of oil bearing rock. The natural fault line

barriers usually prevent the migration of hydrocarbon

products and encourage their accumulation.

The majority of hydrocarbon accumulations are located

between the depths of 7,000 - 13,000 feet although

discoveries of new hydrocarbon areas are now being

found underneath existing reservoirs at depths up to

15,000 feet.

5

ERA SYSTEM AGE (approx.) millions of years

QUATERNARY Recent

Pleistocene

0

0.01

CAENOZOIC or TERTIARY Pliocene

Miocene

Oligocene

Eocene

Palaeocene

2

7

26

38

54

MESOZOIC or SECONDARY Cretaceous

J urassic

Triassic

65

136

195

PALAEOZOIC or PRIMARY Permian

Carboniferous

Devonian

Silurian

Ordovician

Cambrian

225

280

345

395

440

500

AZOIC or ARCHAEAN Pre-Cambrian

Origin of Earth from-

570

4500

Just how long has it been there?

Northern & Central North Sea (incl West of Shetland)

Oil: Mainly in Jurassic sandstones (e.g. Brent,

Statfjord, Magnus, Hutton). But also in Lower Tertiary

sandstones (e.g. Forties, Frigg, Maureen, Claymore),

and in Cretaceous fractured chalk (Ekofisk).

Southern North Sea

Gas: In Upper Carboniferous and Permian

sandstones.

Irish Sea (Morcambe Bay)

Gas: In Triassic sandstones

6

Oil in place

An oil reservoir should not be thought as some

underground cavern full of oil and gas at a pressure.

Usually the hydrocarbons exist within the structure of

porous rock like a sponge full of water

See also next slide

7

How much oil?

Rock Matrix

Pore Space

(Porosity)

But

Pore space

without

communication

is no good. We

need ..

Permeability

But

Pore space

without

communication

is no good. We

need ..

Permeability

Porosity

is expressed as

a % of pore

space vs. total

rock volume

Porosity

is expressed as

a % of pore

space vs. total

rock volume

8

Drilling process overview Stage 1

Geological data is

gathered and

interpreted by

geophysicists and

geologists looking at

where, when, and at

what depth there could

be hydrocarbons in

place

9

Initially by using ...Seismic data

Subsurface formations are

mapped by measuring the

time taken for acoustic

pulses generated in the

earth to return to the

surface after reflection or

refraction from interfaces

between geological

formations with different

physical properties

To examine the effect of a falling weight, Ludger Mintrop built a

mechanism to drop a 4000 kg iron ball from 14 metres height

(1908)

During Word War 1 German scientist Ludger Mintrop

invented a portable seismograph to locate Allied

artillery. By recording earth vibrations from positions

opposite Allied bombardments he could calculate gun

positions so accurately that the first shot from a

German gun would often make a direct hit. However,

varying velocities among geological formations through

which the vibrations passed induced errors into

distance calculations, but, by making certain

assumptions about the geology, corrections could be

made to compute distance.

After the war Mintrop reversed the process by

measuring distances and computing the geology from

earths vibrations on his portable seismograph.

In April 1923 he was granted a US patent

10

Initially by using ...Seismic data

Subsurface formations are

mapped by measuring the

time taken for acoustic

pulses generated in the

earth to return to the

surface after reflection or

refraction from interfaces

between geological

formations with different

physical properties

To examine the effect of a falling weight, Ludger Mintrop built a

mechanism to drop a 4000 kg iron ball from 14 metres height

(1908)

During Word War 1 German scientist Ludger Mintrop

invented a portable seismograph to locate Allied

artillery. By recording earth vibrations from positions

opposite Allied bombardments he could calculate gun

positions so accurately that the first shot from a

German gun would often make a direct hit. However,

varying velocities among geological formations through

which the vibrations passed induced errors into

distance calculations, but, by making certain

assumptions about the geology, corrections could be

made to compute distance.

After the war Mintrop reversed the process by

measuring distances and computing the geology from

earths vibrations on his portable seismograph.

In April 1923 he was granted a US patent

11

Initially by using ...Seismic data

Subsurface formations are

mapped by measuring the

time taken for acoustic

pulses generated in the

earth to return to the

surface after reflection or

refraction from interfaces

between geological

formations with different

physical properties

To examine the effect of a falling weight, Ludger Mintrop built a

mechanism to drop a 4000 kg iron ball from 14 metres height

(1908)

During Word War 1 German scientist Ludger Mintrop

invented a portable seismograph to locate Allied

artillery. By recording earth vibrations from positions

opposite Allied bombardments he could calculate gun

positions so accurately that the first shot from a

German gun would often make a direct hit. However,

varying velocities among geological formations through

which the vibrations passed induced errors into

distance calculations, but, by making certain

assumptions about the geology, corrections could be

made to compute distance.

After the war Mintrop reversed the process by

measuring distances and computing the geology from

earths vibrations on his portable seismograph.

In April 1923 he was granted a US patent

12

Initially by using ...Seismic data

Subsurface formations are

mapped by measuring the

time taken for acoustic

pulses generated in the

earth to return to the

surface after reflection or

refraction from interfaces

between geological

formations with different

physical properties

To examine the effect of a falling weight, Ludger Mintrop built a

mechanism to drop a 4000 kg iron ball from 14 metres height

(1908)

During Word War 1 German scientist Ludger Mintrop

invented a portable seismograph to locate Allied

artillery. By recording earth vibrations from positions

opposite Allied bombardments he could calculate gun

positions so accurately that the first shot from a

German gun would often make a direct hit. However,

varying velocities among geological formations through

which the vibrations passed induced errors into

distance calculations, but, by making certain

assumptions about the geology, corrections could be

made to compute distance.

After the war Mintrop reversed the process by

measuring distances and computing the geology from

earths vibrations on his portable seismograph.

In April 1923 he was granted a US patent

13

Drilling process overview Stage 2

From this initial

information costs are

estimated to prepare

an AFE (Application

for Expenditure) for

submission to

management

14

Drilling process overview Stage 3

Drilling engineers

start the process of

designing the well in

conjunction with the

geologists, reservoir

engineers and well

completion specialists

15

Things like.....

Rig Selection

Permits & Legislative compliance

Blow Out Prevention

Casing Design

Mud Programme

Solids Control Systems

Drill Bit Options

Directional Drilling Requirements

Logging (evaluation) Programme

Completion Requirements

HS&E (Health, Safety & Environmental) Aspects

... To name but a few...

16

Drilling process overview Stage 4

The next stage is the

construction of the

well using drilling

equipment suitable for

the pressure and

hazards expected

17

Well types

Wildcat: Little or no previous drilling exploration activity in the

area

Exploratory: Geological target selection based on seismic data,

and geological modelling i.e. no previous drilling in

the prospective horizon

Appraisal: Delineates the reservoirs boundaries, usually

drilled after the exploratory discoveries

Producers: Drilling into a known reservoir

Infill: Drilling in known productive portions of the

reservoir that have not been properly drained.

This is usually done later in the life of the

reservoir

Re-entry: Existing well re-entered to deepen, side-track,

complete, or re-complete

Others include: Step out - usually from an existing

borehole, but is used to probe for reservoir boundaries

I nj ector: - producing wells are often reversed in to

injectors to maintain reservoir pressure - water, gas or

steam are injected to flood the oil and gas toward the

designated producer

18

Drill Bits are used to cut / crush the rock

Roller Cone

PDC

These are made-up to heavy large diameter series

of tubes, collectively called...

Roller cone - so called because each of the three cones

rotate independently , running on ball / race bearings

or journal type friction bearings. Cutting action is by

digging or crushing the rock

PDC means Polycrystalline Diamond Compacts -

wafers of man made diamonds used to shear the

formation.

Natural diamond on a solid steel mould - used for very

hard formations

19

... the Bottom Hole Assembly BHA

Drill Collar

Connection

Hevi-Wate Drill Pipe

Stabilizer

Basic elements only - things like motors, MWD, LWD,

Jars also form part of the BHA but are probably the

subject of another presentation

20

Drilling fluids: Mud - has to:

cool and lubricate the bit, drillstring, and to clean the bottom

of the hole

carry cuttings to surface

remove cuttings from the mud at surface minimise possible

subsequent formation damage

control formation pressures and to maintain hole integrity

assist in well logging operations

minimise corrosion of the drillstring, casing and tubing,

minimise contamination problems

minimise torque, drag and pipe sticking propensities, improve

drilling rate

A complete and comprehensive mud plan must be

included in the well planning process. Drilling fluids are

designed to solve or minimise many drilling problems.

The major factors that have to be covered include the

above.

The drilling fluid programme must be designed to

satisfy the highest priority requirements for drilling the

prospective well, especially well control

21

Drilling fluids: Mud - has to:

cool and lubricate the bit, drillstring, and to clean the bottom

of the hole

carry cuttings to surface

remove cuttings from the mud at surface minimise possible

subsequent formation damage

control formation pressures and to maintain hole integrity

assist in well logging operations

minimise corrosion of the drillstring, casing and tubing,

minimise contamination problems

minimise torque, drag and pipe sticking propensities, improve

drilling rate

A complete and comprehensive mud plan must be

included in the well planning process. Drilling fluids are

designed to solve or minimise many drilling problems.

The major factors that have to be covered include the

above.

The drilling fluid programme must be designed to

satisfy the highest priority requirements for drilling the

prospective well, especially well control

22

Carry

Cuttings

to

Surface

Reduce

Rotational

Torque

Form

Filter

Cake

Stabilize

Formation

Lubricate

Drill Bit

23

Liner

Casing ... protects the newly drilled hole

Intermediate

Casing

Surface

Casing

Casing setting depths are directly affected by

geological conditions. In some cases, the prime

criterion for selecting casing seats is to cover exposed,

severe lost circulation zones. In others, the seat

selection may be based on differential sticking

problems, perhaps resulting from pressure reduction in

the field. In deep wells, however the primary

consideration is usually based on controlling abnormal

formation pressures and preventing the exposure to

weaker shallow zones.

Selecting casing seat depths for pressure control

purposes starts with knowing geological conditions

such as formation pressure and fracture gradients.

After these have been established, the engineer will

design a casing programme based on the assumption

that he already knows the behaviour of the well even

before it is drilled.

24

Main functions of casing strings:

Consolidate unstable formations that have just been

drilled through

Contain any pressures that may be encountered

Separate any different pressure regimes

Provide structural support for the BOPs and diverters

Protect sensitive formations from contamination

Provide a suitable environment for installation of

production or testing equipment such as packers,

downhole valves, tubing, liner hangers etc.

25

Cementing ...

is performed to secure

casing strings, and

isolate zones for

production purposes

as well as solve

various hole problems

Inner Casing

String

Cement

being

injected

Cement

Sheath

Outer Casing

String

Casing strings are usually cemented in the hole to

isolate the troublesome zones behind the casing from

deeper formations to be drilled. It is also used to

isolate high-pressure formations below the casing from

the weaker shallower ones. Cement is normally placed

behind the casing in a single or multiple stage

technique. The single stage pumps cement down the

casing and up the annulus. To stop the cement U-

tubing a backpressure valve is fitted at the bottom of

the casing. It is drilled out after the cement has

hardened. In a multistage cement job the first stage is

like a single stage one. The next stage is pumped

though a special port collar at the desired location up

the annulus. Liners are cemented in a slightly different

fashion as they are usually run on the end of drill pipe.

The cement slurry has to run through the pipe prior to

entering the liner annular space

26

Packer

Production

Tubing

Production

Fluids

Casing String

Christmas

Tree

When a well has been

drilled and cased it

must now be

Completed in order

to produce the

hydrocarbons residing

in the reservoir

Completions

The Christmas tree provides connection and isolation between

the wellbore and production equipment. There are usually

automatic valves fitted that are fail safe i.e. master valve and

wing valve with hydraulic cylinders to open them and springs to

close them

The automatic valves, including the downhole safety valve, are

usually connected to the platform or control point ESD system

Flow string systems are the components used in the tubing

string to conduct produced fluids from the reservoir to the

surface. They can include tubing, mandrels and nipples, flow

couplings, sliding sleeves, side mandrel pockets for gas lift

valves and backpressure valves

Packers provide the annular seal between the tubing and the

production casing. They must be able to withstand high

differential pressures and still maintain an effective seal. They

are usually classed into retrievable and permanent. The

permanent type is held in place by opposing slips and can be set

with wireline or tubing conveyed methods. Retrievable packers

can be weight set, mechanical set, or hydraulically set

27

Modern completions

Choosing the proper size of flow string can affect

reservoir performance to some degree. Tubing with a

restricted inner diameter can cause high-pressure

losses. Since this pressure is the driving energy that

forces fluids out of the reservoir any wasteful source of

pressure dissipation can cause lower primary reservoir

recovery. The tubing string should be sized to allow for

optimum production with a minimum tubing size. Well

completions involve placing flow control equipment at

the surface and in the tubing string.

28

Drilling process overview Stage 5

Once the well has been

completed and is

flowing for commercial

purposes, it has to be

maintained with

occasional intervention

work for replacement of

worn parts e.g. leaking

down-hole safety

valves, and to gather

pressure and

temperature

information for

reservoir management

29

Produced Oil can be processed and stored ready for

tankering in Floating Production, Storage and Offloading

(FPSO) Vessels

30

Or... By subsea pipelines etc...

31

.... Monitoring ....

Detailed reservoir

models and

simulations are

constantly updated as

new development-

drilling data becomes

available enabling

effective Field

Management

32

Drilling process overview - 6

Abandonment - this is

the stage when the

reservoir is depleted

and seabed or land is

returned to its natural

environment

33

How an Oil Company is Generally Structured

Oil Company

(or Well operator)

Drilling Engineering Formation Evaluation Accounts Operations Reservoir Engineering Production Engineering Geology

Drilling Superintendent

Wells in Progress

34

How a Drilling Contractor is Generally Structured

Drilling Contractor

Accounts Rig Manager Rig Design & Maintenance

Tool Pusher Rig 1

Driller

Derrickman

Rig Crew

Tool Pusher Rig 2 (etc.

Driller

Derrickman

Rig Crew

35

Drilling Service companies

Drilling Service Companies

Drilling Fluids Drilling Cements

Directional Drilling Casing Running

Formation Evaluation Mud Logging

Drilling Bits Tool Rental

Well Completion Equipment Many others .....etc.

36

Further Reading

Virtual Campus: ENM201 Wells an

Introduction

MIs Drilling Fluids Engineering Manual Chapter

1 Introduction

http://science.howstuffworks.com/oil-

drilling.htm/printable

http://science.howstuffworks.com/oil-

refining.htm/printable

http://www.glossary.oilfield.slb.com/Default.cfm

Vous aimerez peut-être aussi

- Refraction SeismicDocument68 pagesRefraction Seismicbharath35kumar100% (1)

- Summary of Christopher Knight & Alan Butler's Civilization OneD'EverandSummary of Christopher Knight & Alan Butler's Civilization OnePas encore d'évaluation

- Petroleum Technology Atmadeep Dutta (18BCM0135) Digital Assignment 1Document29 pagesPetroleum Technology Atmadeep Dutta (18BCM0135) Digital Assignment 1Atmadeep DuttaPas encore d'évaluation

- EXAM 3 Study GuideDocument24 pagesEXAM 3 Study GuideIsmael MorenoPas encore d'évaluation

- Engineering Characterization of EarthquakesDocument47 pagesEngineering Characterization of EarthquakesEman SuhermanPas encore d'évaluation

- Exploration MethodsDocument82 pagesExploration MethodsTushar VermaPas encore d'évaluation

- Lecture 1 Introduction To EGEDocument46 pagesLecture 1 Introduction To EGEbhargav reddyPas encore d'évaluation

- REVIEWERDocument20 pagesREVIEWERMarvin AbugaoPas encore d'évaluation

- CIVL1180 - 06sep2023Document27 pagesCIVL1180 - 06sep2023jv5gfmjd4xPas encore d'évaluation

- 8 Geophysical Surveying of Archaeological Sites: John W. Weymouth and Robert HugginsDocument23 pages8 Geophysical Surveying of Archaeological Sites: John W. Weymouth and Robert HugginsÖzlem ÇetinPas encore d'évaluation

- EarthquakeDocument39 pagesEarthquakeMbiko SabeyoPas encore d'évaluation

- Engineering GeologyDocument269 pagesEngineering GeologyEl Patrick100% (2)

- SeismographDocument14 pagesSeismographapi-456663516100% (1)

- What Is Measured During A Seismic SurveyDocument15 pagesWhat Is Measured During A Seismic SurveyWormixs MasterPas encore d'évaluation

- Lector02 GP102Document19 pagesLector02 GP102Nishant ManglaPas encore d'évaluation

- History of LoggingDocument5 pagesHistory of LoggingMudLogggerAUSPas encore d'évaluation

- Evolution of Satellite Meteorology: 1.1 Before SatellitesDocument15 pagesEvolution of Satellite Meteorology: 1.1 Before SatellitesSam LawrencePas encore d'évaluation

- GEOPHYSICSDocument105 pagesGEOPHYSICSRodel Llames VillaosPas encore d'évaluation

- Chapter 1 Introduction To Earth SciencesDocument40 pagesChapter 1 Introduction To Earth SciencesCleevh MabialaPas encore d'évaluation

- Geophysical InvestigationDocument9 pagesGeophysical InvestigationYuvaraj DPas encore d'évaluation

- Geología GeneralDocument38 pagesGeología Generalleonardo guerraPas encore d'évaluation

- Eology in Civil Engineering: (By Riza May S. Cabuga)Document28 pagesEology in Civil Engineering: (By Riza May S. Cabuga)Arah Louise ApostolPas encore d'évaluation

- GeophysicsDocument11 pagesGeophysicsshevtaPas encore d'évaluation

- Lecture03 20110201Document34 pagesLecture03 20110201Jimmy LimPas encore d'évaluation

- 6a.the Age of The EarthDocument62 pages6a.the Age of The Earthmahasiswa biasaPas encore d'évaluation

- Historical Development of The Magnetic Method in ExplorationDocument29 pagesHistorical Development of The Magnetic Method in ExplorationGleizer FerreiraPas encore d'évaluation

- Geology NotesDocument8 pagesGeology NotesLily QuiPas encore d'évaluation

- DR Ambedkar Institute of Technology: Engineering SeismologyDocument32 pagesDR Ambedkar Institute of Technology: Engineering Seismologyhamsalekha KarnaticPas encore d'évaluation

- U-Pb Dating of Mineral Deposits: From Age Constraints To Ore-Forming ProcessesDocument70 pagesU-Pb Dating of Mineral Deposits: From Age Constraints To Ore-Forming ProcessesWilliamsRafaelMataRimacPas encore d'évaluation

- 12.510 Introduction To Seismology: Mit OpencoursewareDocument4 pages12.510 Introduction To Seismology: Mit Opencoursewareanon_814791417Pas encore d'évaluation

- Movement of EarthquakesDocument23 pagesMovement of EarthquakesZyril BestoPas encore d'évaluation

- Earth's Discontinuities.Document10 pagesEarth's Discontinuities.FelipePas encore d'évaluation

- Unit 1 General Geology: 1) Write Notes On LithosphereDocument12 pagesUnit 1 General Geology: 1) Write Notes On LithosphereJegatheeswaran BoompandiPas encore d'évaluation

- Final Climate Change ReportDocument32 pagesFinal Climate Change Reporterin fernandezPas encore d'évaluation

- C1 GeoDocument46 pagesC1 GeoAfiq IrfanPas encore d'évaluation

- Lecture 6 PDFDocument11 pagesLecture 6 PDFsunilaanserPas encore d'évaluation

- Meteorite Impact and Dinosaur ExtinctionDocument25 pagesMeteorite Impact and Dinosaur ExtinctionstepperPas encore d'évaluation

- Answer:CDocument22 pagesAnswer:CmadhubalaPas encore d'évaluation

- Matching FeaturesDocument32 pagesMatching FeaturesHiếu Đức NguyễnPas encore d'évaluation

- Ology in Civil EngineeringDocument95 pagesOlogy in Civil EngineeringPraz Aarash100% (1)

- A3 GeologyDocument5 pagesA3 GeologyRheyland FernandezPas encore d'évaluation

- Mars Pathfinder MissionDocument18 pagesMars Pathfinder MissionHenry Zegarra RodriguezPas encore d'évaluation

- CE6301 Engineering Geology 1Document122 pagesCE6301 Engineering Geology 1Enyen MonsaludPas encore d'évaluation

- 1 Evidence For Earth's Crust, Mantle & CoreDocument12 pages1 Evidence For Earth's Crust, Mantle & CoreNaga NagendraPas encore d'évaluation

- Well LoggingDocument25 pagesWell LoggingMohd Wirawan PutraPas encore d'évaluation

- The Science of Geology What Is Geology?Document24 pagesThe Science of Geology What Is Geology?Zekariyas AbushaPas encore d'évaluation

- Chapter 1 GeologyDocument48 pagesChapter 1 GeologylovryantadenaamilingacadsPas encore d'évaluation

- ERD Lecture 2 Measurement of Earthquake.Document27 pagesERD Lecture 2 Measurement of Earthquake.sujan pokhrelPas encore d'évaluation

- IntSoilDyn Ch2 SeisAndEqsDocument88 pagesIntSoilDyn Ch2 SeisAndEqsSelcuk ZenginPas encore d'évaluation

- New Microsoft Office Word DocumentDocument39 pagesNew Microsoft Office Word DocumentsudhanshudeshmukhPas encore d'évaluation

- Earthquake Causes and OccurrencesDocument17 pagesEarthquake Causes and OccurrencesNILRATAN SARKARPas encore d'évaluation

- PalaentologyDocument6 pagesPalaentologySefatPas encore d'évaluation

- Ertq Ang FaultDocument5 pagesErtq Ang FaultMaricris OrendainPas encore d'évaluation

- Introduction To Seismology: Lupei ZhuDocument22 pagesIntroduction To Seismology: Lupei ZhuHaider ShahPas encore d'évaluation

- Geology Module 1Document15 pagesGeology Module 1Yashawanth ChavanPas encore d'évaluation

- 02 ExplorationDocument50 pages02 ExplorationYernar TiyntayevPas encore d'évaluation

- History of EarthDocument3 pagesHistory of EarthChristy AsendientePas encore d'évaluation

- Geophysics and Earthquakes: GY 111 Lecture Note SeriesDocument12 pagesGeophysics and Earthquakes: GY 111 Lecture Note SeriesKuldeepKaushikPas encore d'évaluation

- Water Supply and Urban Drainage PDFDocument243 pagesWater Supply and Urban Drainage PDFNâtty Abebe100% (4)

- Bilgin N. Et Al. (2005) - From Research To Practice Development of Rapid Excavation Technologies 2Document8 pagesBilgin N. Et Al. (2005) - From Research To Practice Development of Rapid Excavation Technologies 2Andres Mujica MorovicPas encore d'évaluation

- Drilling-Workover Rig Maintenance and Preventative Maintenance Scheduling PDFDocument2 pagesDrilling-Workover Rig Maintenance and Preventative Maintenance Scheduling PDFandrePas encore d'évaluation

- Drilling & Completion CommitteeDocument194 pagesDrilling & Completion Committeeemba2015100% (1)

- 250P Series Core BarrelDocument4 pages250P Series Core BarrelJuan Miguel RobledoPas encore d'évaluation

- BADHRA-7 DIR Geological & Drilling Well ProgramDocument180 pagesBADHRA-7 DIR Geological & Drilling Well ProgramBhagwal TravelsPas encore d'évaluation

- ENI - Drilling Procedures ManualDocument234 pagesENI - Drilling Procedures Manualirma_alby100% (8)

- Use of Slotted Casing PMT For Deep Foundation Design-Case StudyDocument9 pagesUse of Slotted Casing PMT For Deep Foundation Design-Case StudySiencia No Enjinaria DitPas encore d'évaluation

- Introduction of The StudyDocument72 pagesIntroduction of The StudyAbdul MalikPas encore d'évaluation

- Spe 135910 MSDocument6 pagesSpe 135910 MSmohamedabbas_us3813Pas encore d'évaluation

- Trenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeDocument24 pagesTrenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeFrancico Javier Ondo BiteguePas encore d'évaluation

- Code of Safe Drilling PracticesDocument25 pagesCode of Safe Drilling PracticesCostas Sachpazis0% (1)

- CV Mutasem, Crane, Rigger Trainer and Lifting InspectorDocument4 pagesCV Mutasem, Crane, Rigger Trainer and Lifting InspectorMo'tasem SerdanehPas encore d'évaluation

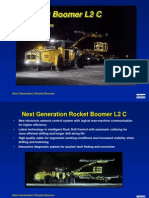

- Rocket Boomer L2 C: Next GenerationDocument63 pagesRocket Boomer L2 C: Next GenerationArturo Pedro Salgado Medina100% (2)

- Winch Operation Lift PLan v0Document14 pagesWinch Operation Lift PLan v0Raza Aidan100% (1)

- PeWeTe PresentationDocument11 pagesPeWeTe PresentationVladimir GaevoyPas encore d'évaluation

- TAT Spec SheetDocument2 pagesTAT Spec SheetLegend AnbuPas encore d'évaluation

- Tesco ProfileDocument28 pagesTesco ProfileShonaUsmanPas encore d'évaluation

- BOP and Its Parts: Hydrulic RepairDocument7 pagesBOP and Its Parts: Hydrulic RepairShashidhar KasturiPas encore d'évaluation

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineRemmy Torres VegaPas encore d'évaluation

- DCM KellerDocument8 pagesDCM KellerHumza MubarikPas encore d'évaluation

- Introduction To Underbalanced DrillingDocument51 pagesIntroduction To Underbalanced DrillingSlim.BPas encore d'évaluation

- Factual Report Seabed CPTs and Geotechnical BoreholesDocument39 pagesFactual Report Seabed CPTs and Geotechnical BoreholesMortezaPas encore d'évaluation

- Rig Components - Definitions: 1. Gin PoleDocument70 pagesRig Components - Definitions: 1. Gin PoleHarpreetk87Pas encore d'évaluation

- AnnualReport2016 17Document60 pagesAnnualReport2016 17zebxxyeqPas encore d'évaluation

- Company-Profile PT - DUNGGIO DRILLING PDFDocument24 pagesCompany-Profile PT - DUNGGIO DRILLING PDFGugun GunawanPas encore d'évaluation

- Duplex Drilling MethodDocument48 pagesDuplex Drilling MethoddilaksanPas encore d'évaluation

- Ongc Presentation TrainingDocument33 pagesOngc Presentation Trainingalok sahuPas encore d'évaluation

- Dp1500i t4 Specification Sheet EnglishDocument3 pagesDp1500i t4 Specification Sheet EnglishMahamadou IssoufouPas encore d'évaluation

- L PDFDocument5 pagesL PDFRafael SantosPas encore d'évaluation

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseD'EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseÉvaluation : 3.5 sur 5 étoiles3.5/5 (69)

- The Comfort of Crows: A Backyard YearD'EverandThe Comfort of Crows: A Backyard YearÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincD'EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincÉvaluation : 3.5 sur 5 étoiles3.5/5 (137)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- Water to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesD'EverandWater to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesÉvaluation : 4 sur 5 étoiles4/5 (21)

- Smokejumper: A Memoir by One of America's Most Select Airborne FirefightersD'EverandSmokejumper: A Memoir by One of America's Most Select Airborne FirefightersPas encore d'évaluation

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (81)

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- The Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterD'EverandThe Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterPas encore d'évaluation

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterD'EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterÉvaluation : 5 sur 5 étoiles5/5 (3)

- The Weather Machine: A Journey Inside the ForecastD'EverandThe Weather Machine: A Journey Inside the ForecastÉvaluation : 3.5 sur 5 étoiles3.5/5 (31)

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Packing for Mars: The Curious Science of Life in the VoidD'EverandPacking for Mars: The Curious Science of Life in the VoidÉvaluation : 4 sur 5 étoiles4/5 (1396)

- Pale Blue Dot: A Vision of the Human Future in SpaceD'EverandPale Blue Dot: A Vision of the Human Future in SpaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (588)