Académique Documents

Professionnel Documents

Culture Documents

Intelligent Solar Tracker System Implemented On 8051 Microcontroller

Transféré par

seventhsensegroup0 évaluation0% ont trouvé ce document utile (0 vote)

125 vues5 pagesSolar energy is becoming increasingly attractive as we

grapple with global climate changes. However, while solar

energy is free, non-polluting, and inexhaustible, solar panels are

fixed. As such, they cannot take advantage of maximum sunlight

as weather conditions and seasons change. A solar panel receives

the most sunlight when it is perpendicular to the sun’s rays, but

the sunlight direction changes regularly with changing seasons

and weather. Currently, most solar panels are fixed, i.e., the

solar array has a fixed orientation to the sky and does not turn to

follow the sun. To increase the unit area illumination of sunlight

on solar panels, we designed a solar tracking electricity

generation system. The design mechanism holds the solar panel

and allows the panel to perform an approximate3-dimensional

(3-D) hemispheroidal rotation to track the sun’s movement

during the day and improve the overall electricity generation.

This system can achieve the maximum illumination and energy

concentration and cut the cost of electricity by requiring fewer

solar panels, therefore, it has great significance for research and

development. The main use of this report is to utilize the

maximum power from the sun. Now a day we are in heavy need

to use the solar power as in the coming days everything we use

might depend on this kind of systems.

Titre original

Intelligent Solar Tracker System Implemented On

8051 Microcontroller

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSolar energy is becoming increasingly attractive as we

grapple with global climate changes. However, while solar

energy is free, non-polluting, and inexhaustible, solar panels are

fixed. As such, they cannot take advantage of maximum sunlight

as weather conditions and seasons change. A solar panel receives

the most sunlight when it is perpendicular to the sun’s rays, but

the sunlight direction changes regularly with changing seasons

and weather. Currently, most solar panels are fixed, i.e., the

solar array has a fixed orientation to the sky and does not turn to

follow the sun. To increase the unit area illumination of sunlight

on solar panels, we designed a solar tracking electricity

generation system. The design mechanism holds the solar panel

and allows the panel to perform an approximate3-dimensional

(3-D) hemispheroidal rotation to track the sun’s movement

during the day and improve the overall electricity generation.

This system can achieve the maximum illumination and energy

concentration and cut the cost of electricity by requiring fewer

solar panels, therefore, it has great significance for research and

development. The main use of this report is to utilize the

maximum power from the sun. Now a day we are in heavy need

to use the solar power as in the coming days everything we use

might depend on this kind of systems.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

125 vues5 pagesIntelligent Solar Tracker System Implemented On 8051 Microcontroller

Transféré par

seventhsensegroupSolar energy is becoming increasingly attractive as we

grapple with global climate changes. However, while solar

energy is free, non-polluting, and inexhaustible, solar panels are

fixed. As such, they cannot take advantage of maximum sunlight

as weather conditions and seasons change. A solar panel receives

the most sunlight when it is perpendicular to the sun’s rays, but

the sunlight direction changes regularly with changing seasons

and weather. Currently, most solar panels are fixed, i.e., the

solar array has a fixed orientation to the sky and does not turn to

follow the sun. To increase the unit area illumination of sunlight

on solar panels, we designed a solar tracking electricity

generation system. The design mechanism holds the solar panel

and allows the panel to perform an approximate3-dimensional

(3-D) hemispheroidal rotation to track the sun’s movement

during the day and improve the overall electricity generation.

This system can achieve the maximum illumination and energy

concentration and cut the cost of electricity by requiring fewer

solar panels, therefore, it has great significance for research and

development. The main use of this report is to utilize the

maximum power from the sun. Now a day we are in heavy need

to use the solar power as in the coming days everything we use

might depend on this kind of systems.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9-Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4267

Intelligent Solar Tracker System Implemented On

8051 Microcontroller

Prof. Pooja K. Chhatwani

#1

, Prof. J ayashree S. Somani

#2

#1

Lecturer, Information Technology, Dr. N .P. Hirani Institute of Polytechnic, Pusad

Maharashtra, India

#2

Lecturer, Information Technology, Dr. N .P. Hirani Institute of Polytechnic, Pusad

Maharashtra, India

Abstract Solar energy is becoming increasingly attractive as we

grapple with global climate changes. However, while solar

energy is free, non-polluting, and inexhaustible, solar panels are

fixed. As such, they cannot take advantage of maximum sunlight

as weather conditions and seasons change. A solar panel receives

the most sunlight when it is perpendicular to the suns rays, but

the sunlight direction changes regularly with changing seasons

and weather. Currently, most solar panels are fixed, i.e., the

solar array has a fixed orientation to the sky and does not turn to

follow the sun. To increase the unit area illumination of sunlight

on solar panels, we designed a solar tracking electricity

generation system. The design mechanism holds the solar panel

and allows the panel to perform an approximate3-dimensional

(3-D) hemispheroidal rotation to track the suns movement

during the day and improve the overall electricity generation.

This system can achieve the maximum illumination and energy

concentration and cut the cost of electricity by requiring fewer

solar panels, therefore, it has great significance for research and

development. The main use of this report is to utilize the

maximum power from the sun. Now a day we are in heavy need

to use the solar power as in the coming days everything we use

might depend on this kind of systems.

KeywordsSolar Tracking, Solar Panel, Microcontroller,

Stepper Motor, Analog-to-Digital Converter, Liquid Crystal

Display.

I. INTRODUCTION

Solar energy refers to the utilization of the radiant energy

fromthe sun. Solar power is used interchangeably with solar

energy, but refers more specifically to the conversion of

sunlight into electricity by photovoltaic, concentrating solar

thermal devices, or by an experimental technology such as a

solar chimney or solar pond.

Solar panels are Photovoltaic cells which gives voltage

directly if you place themin sun light. Here if you change the

position of panels the power output will vary. Means, direct

sunrays on solar panel can give good output otherwise there

might be decrease in the value of their outputs. So we have to

track the path where the maximumpower will attain.

Solar panel devices are of two types that collect energy

fromthe sun. One is solar photovoltaic modules which use

solar cells to convert light fromthe sun into electricity and the

other is solar thermal collector which converts the suns

energy to heat water or another fluid such as oil or antifreeze.

In this project we are using the photovoltaic type.

The main aimof the project is to design one systemfor

automated solar tracking system. For this we are using 8051

family microcontroller and two LDR for finding the light

intensity and stepper motor for rotation of the solar panel. We

are implementing one application programusing embedded C

and loading the programinto microcontroller through ISP (in

systemprogrammer) and it will read data fromthe sensors

through ADC MCP3208 and according to the data stepper

motor is rotating. Stepper motor is not directly connected to

microcontroller it is connected through ULN2003.

The main use of this project is to utilize the maximum

power fromthe sun. Now a day we are in heavy need to use

the solar power as in the coming days everything we use

might depend on this kind of systems.

II. SYSTEM ANALYSIS

A. Circuit Operation:

The main aimof the project is to design one systemfor

automated solar tracking system. For this we are using 8051

family microcontroller and two LDR for finding the light

intensity and stepper motor for rotation of the solar panel. We

are implementing one application programusing embedded C

and loading the programinto microcontroller through ISP.

In the following block diagram, when sun rays fall on the

LDR then according to intensity of light, it generates variable

analog output. AT89S52 microcontroller will read data from

the LDR through MCP3208 which is serial ADC used for

converting analog signal to digital one. Oscillator gives the

clock to microcontroller which is necessary for program

execution. In program, AT89S52 microcontroller compares

the output of LDR which is already fetched. Program

generates control signals which are given to stepper motor

driver. Stepper motor is rotating via stepper motor driver

ULN2003.

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9-Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4268

Fig. 1 Schematic representation of Solar Tracking System

B. Hardware:

AT89S52(Microcontroller)

LDR (Light Dependent Resistor)

MCP3208 (Analog-to-Digital Converter)

LCD (Liquid Crystal Display)

ULN2003 (Driver)

Stepper Motor

C. Software:

Embedded C programming

Keil C compiler

III. SELECTION OF HARDWARE

A. Selection of Microcontroller:

As we know that there so many types of micro controller

families that are available in the market.

Those are:

8051 Family

AVR microcontroller Family

PIC microcontroller Family

ARM Family

Basic 8051 family is enough for our application; hence

we are not concentrating on higher end controller families.

In order to fulfil our application basic that is AT89C51

controller is enough. But still we selected AT89S52 controller

because of inbuilt ISP (in systemprogrammer) option.

There are minimumsix requirements for proper operation

of microcontroller.

Those are:

Power supply section

pull-ups for ports (it is must for PORT0)

Reset circuit

Crystal circuit

ISP circuit (for programdumping)

EA/VPP pin is connected to Vcc.

PORT0 is open collector thats why we are using pull-up

resistor which makes PORT0 as an I/O port. Reset circuit is

used to reset the microcontroller. Crystal circuit is used for the

microcontroller for timing pluses. In this project we are not

using external memory thats why EA/VPP pin in the

microcontroller is connected to Vcc that indicates internal

memory is used for this application.

B. Selection of Driver:

Driver is used increase the strength of signal. In this

application we are using stepper motor to rotate the solar

panel. So to drive the stepper motor we have to increase the

strength of signal. In the market so many ICs are available

but we selected ULN 2003 which is inbuilt 7 NPN transistors.

And the working voltage of this IC is 5 volts which is same as

microcontroller working voltage. And there is no need to

design any other power supply section thats why we selected

this IC in our project.

C. Selection of ADC:

Here in this project we selected MCP3208 ADC. In this

project ADC is used to convert analog voltage sent by the

LDR to digital voltage. We can use parallel ADC (ADC 0804)

but we need more pins to interface that, so to reduce port pins

we can use MCP3208.

D. Selection of LCD:

A liquid crystal display (LCD) is a thin, flat panel used

for electronically displaying information such as text, images,

and moving pictures. Its uses include monitors for computers,

televisions, instrument panels, and other devices ranging from

aircraft cockpit displays, to every-day consumer devices such

as video players, gaming devices, clocks, watches, calculators,

and telephones. Among its major features are its lightweight

construction, its portability, and its ability to be produced in

much larger screen sizes than are practical for the construction

of cathode ray tube (CRT) display technology. Its low

electrical power consumption enables it to be used in battery-

powered electronic equipment. It is an electronically-

modulated optical device made up of any number of pixels

filled with liquid crystals and arrayed in front of a light source

(backlight) or reflector to produce images in colour or

monochrome.

E. Connections to Microcontroller:

Microcontroller has 4 ports and every port has 8 pins we

are connecting all external components to this ports only.

LCD is connected to the PORT0 and ULN2003 is connected

to PORT2 and MCP 3208 which is acting as ADC is

connected to the P1.

F. Connections of Driver IC (ULN 2003):

ULN 2003 has 16 pins in this 1

st

pin is connected to 2.7 pin

and 2

nd

pin is connected to 2.6 and 3

rd

pin is connected to 2.5

and 4

th

pin is connected to 2.4 pin of the microcontroller. And

8

th

pin is connected to ground 9

th

to Vcc and 13

th

to 16

th

pins

are connected to the stepper motor. And other pins are not

connected.

IV. SCHEMATIC DIAGRAM

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9-Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4269

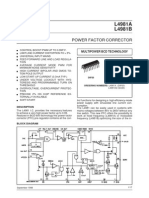

Fig. 2 Microcontroller

Fig. 3 Driver

Fig. 4 ADC Converter

Fig. 5 Light Dependent Resistor

V. POWER SUPPLY SECTION

In-order to work with any components basic requirement is

power supply. In this section there is a requirement of one

voltage level i.e. 5V DC power supply.

Now the aimis to design the power supply section which

converts 230V AC in to 5V DC. Since 230V AC is too high to

reduce it to directly 5V DC, therefore we need a step-down

transformer that reduces the line voltage to certain voltage that

will help us to convert it in to a 5V DC. Considering the

efficiency factor of the bridge rectifier, we came to a

conclusion to choose a transformer, whose secondary voltage

is 3 to 4 V higher than the required voltage i.e. 5V. For this

application 0-9V transformers is used, since it is easily

available in the market.

The output of the transformer is 9V AC; it feed to rectifier

that converts AC to pulsating DC. As we all know that there

are 3 kinds of rectifiers that are:

Half wave rectifier

Full wave rectifier

Bridge rectifier

Here we short listed to use Bridge rectifier, because half

wave rectifier has we less in efficiency. Even though the

efficiency of full wave and bridge rectifier are the same, since

there is no requirement for any negative voltage for our

application, we gone with bridge rectifier.

Since the output voltage of the rectifier is pulsating DC, in

order to convert it into pure DC we use a high value

(1000UF/1500UF) of capacitor in parallel that acts as a filter.

The most easy way to regulate this voltage is by using a 7805

voltage regulator, whose output voltage is constant 5V DC

irrespective of any fluctuation in line voltage.

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9-Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4270

Fig. 6 Power Supply

VI. FLOW CHART

Fig. 7 Flowchart of Solar Tracking System

VII. CODE IMPLEMENTATION

A. Kiel-C Compiler:

Many companies provide the 8051 assembler, some of

themprovide shareware version of their product on the Web,

Kiel is one of them. We can download them from their

Websites. However, the size of code for these shareware

versions is limited and we have to consider which assembler

is suitable for our application.

B. Kiel U Vision2:

This is an IDE (Integrated Development Environment)

that helps you write, compile, and debug embedded programs.

It encapsulates the following components:

A project manager

A make facility

Tool configuration

Editor

A powerful debugger

To get start here are some several example programs

1) Building an application in U vision2: To build

(compile, assemble, and link) an application in uVision2, you

must:

Select ProjectOpen Project

(For example, \C166\EXAMPLES\HELLO\HELLO.UV2)

Select Project - Rebuild all target files or Build target.

UVision2 compiles, assembles, and links the files in your

project.

2) Creating Your Own Application In Uvision2:To

create a new project in uVision2, you must:

Select Project - New Project.

Select a directory and enter the name of the project file.

Select Project - Select Device and select an 8051, 251, or

C16x/ST10 device fromthe device

Database

Create source files to add to the project.

Select Project - Targets, Groups, and Files. Add/Files,

select Source Group1, and add the source files to the

project.

Select Project - Options and set the tool options. Note

when you select the target device fromthe Device

Database all-special options are set automatically. You

only need to configure the memory map of your target

hardware. Default memory model settings are optimal for

most.

Fig. 8 IDE Window

Applications:

Select Project - Rebuild all target files or build target.

3) Debugging An Application In Uvision2:

To debug an application created using uVision2, you must:

Select Debug - Start/Stop Debug Session.

Use the Step toolbar buttons to single-step through your

program. You may enter G, main in the Output Window to

execute to the main C function.

Open the Serial Window using the Serial #1

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9-Sep 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4271

Button on the toolbar.

Debug your programusing standard options.

Like Step, Go, Break, and so on.

A. CONCLUSION

In this design, we used Atmel 8051 microcontroller. This

design represents a new systemdesign technology, and Keil C

- Compiler helped us see the powerful design technologies of

software and hardware systems. Most traditional circuit

designs are composed of hardware components building on a

printed circuit board (PCB), we used same. If errors are found

or the system needs to be improved or upgraded, the PCB

must be redesigned. Adjusting and modifying the PCB is very

inconvenient and increased the design cost and development

period. This implementation has great future scope because

the Sun is important source of energy which available in free

of cost. As todays world need greater amount of energy it can

be satisfy by our project use.

REFERENCES

[1]. Muhammad Ali Mazidi and J anice Gillispie Mazidi, The 8051

Microcontroller and Embedded Systems by, Pearson Education

[2]. Kenneth J ayala, 8051 Microcontroller Architecture, programming and

application.

[3]. SyedArsalan, Sun TrackingSystemwith Microcontroller 8051,

International Journal of Scientific & Engineering Research., Volume 4,

Issue 6, J une2013

[4]. J . Huang, C. Y. Chen, C. H. Chang, T. C. Kuo, Solar Tracking Fuzzy

Control System Design using FPGA, Proceedings of the World

Congress on Engineering 2009 Vol I WCE 2009, J uly 1 - 3, 2009,

London, U.K.

[5]. Mostefa Ghassoul, Design of an Automatic Solar Tracking Systemto

Maximize Energy Extraction, International Journal of Emerging

Technology and Advanced Engineering, Volume 3,Issue 5,May 2013

[6]. Nur Mohmmad, Tarequl Karim, The Design and Implementation of

Hybrid Automatic Solar Tracking System , International Journal Of

Electical & Power Engineering, Volume 6, Issue 3-2012

Vous aimerez peut-être aussi

- Grid Connected Converters: Modeling, Stability and ControlD'EverandGrid Connected Converters: Modeling, Stability and ControlPas encore d'évaluation

- Power Electronics Converters and their Control for Renewable Energy ApplicationsD'EverandPower Electronics Converters and their Control for Renewable Energy ApplicationsArezki FekikPas encore d'évaluation

- Design and Development of Single Axis Solar Tracking System Using C8051F120 (CYGNAL) MicrocontrollerDocument8 pagesDesign and Development of Single Axis Solar Tracking System Using C8051F120 (CYGNAL) MicrocontrollerarcherselevatorsPas encore d'évaluation

- Solar TrackerDocument16 pagesSolar TrackergalaxyPas encore d'évaluation

- Solar Micro ControllerDocument18 pagesSolar Micro ControllerElangovanPas encore d'évaluation

- Pe Final Ex SS 2010-2011Document8 pagesPe Final Ex SS 2010-2011Saif Uddin100% (1)

- (REPORT) - Automatic Sun Tracking SystemDocument14 pages(REPORT) - Automatic Sun Tracking SystemPrashant Kumar100% (1)

- Energy ManagementDocument55 pagesEnergy ManagementNjitnumPas encore d'évaluation

- Testingcommissioning Blogspot QaDocument6 pagesTestingcommissioning Blogspot QaratheeshkumardPas encore d'évaluation

- Solar System CompleteDocument16 pagesSolar System CompleteAlok JainPas encore d'évaluation

- Solar Rooftop Power Generation System by Using IOT (Arduino & Blynk)Document4 pagesSolar Rooftop Power Generation System by Using IOT (Arduino & Blynk)International Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- My NotesDocument87 pagesMy NotesjaimanPas encore d'évaluation

- Arduino Solar Tracker Using LDR and Servo MotorDocument9 pagesArduino Solar Tracker Using LDR and Servo MotorAvnish SharmaPas encore d'évaluation

- Primary-Side Transformer ProtectionDocument15 pagesPrimary-Side Transformer ProtectionRicarno Sei'koPas encore d'évaluation

- 87 CT Class ExplanationDocument11 pages87 CT Class ExplanationdskymaximusPas encore d'évaluation

- Basic Structure of A Power SystemDocument9 pagesBasic Structure of A Power Systembiruke6Pas encore d'évaluation

- Hybrid Power Generation by Solar - WindDocument27 pagesHybrid Power Generation by Solar - WindUday Wankar100% (1)

- Abstract On UPSDocument4 pagesAbstract On UPSUday ShankarPas encore d'évaluation

- Microcontroller Based Solar Charger: A Project Report OnDocument51 pagesMicrocontroller Based Solar Charger: A Project Report Oniwantinthatve67% (3)

- Chapter - 1 1.1 OverviewDocument21 pagesChapter - 1 1.1 OverviewTirumalarao PechettyPas encore d'évaluation

- EE6504 Electrical Machines-II PDFDocument233 pagesEE6504 Electrical Machines-II PDFkumar m100% (1)

- Solar Based Home Automation SystemDocument7 pagesSolar Based Home Automation SystemHamza MunibPas encore d'évaluation

- F/i Converter mA/V Output Analog Based 2-Wire Transmitter Head Mounting Transmitter 2-Wire Transmitter Lqʨhoghqforvxuh MODEL 6420 620S HTB230 311Document3 pagesF/i Converter mA/V Output Analog Based 2-Wire Transmitter Head Mounting Transmitter 2-Wire Transmitter Lqʨhoghqforvxuh MODEL 6420 620S HTB230 311azkalPas encore d'évaluation

- M.g.say ch01Document5 pagesM.g.say ch01prabhjot singh150% (2)

- Solar EnergyDocument30 pagesSolar EnergyJatin Sharma cse 20Pas encore d'évaluation

- Design and Contruction of Automatic Phase Selector PDFDocument51 pagesDesign and Contruction of Automatic Phase Selector PDFKadiri IbrahimPas encore d'évaluation

- (Experiment 3) BJT - Common Emiter Amplifier PDFDocument9 pages(Experiment 3) BJT - Common Emiter Amplifier PDFArik JuniarPas encore d'évaluation

- Laser Security System: Bachelor of Techonology IN Electronics and Communication EngineeringDocument17 pagesLaser Security System: Bachelor of Techonology IN Electronics and Communication Engineering4H9. Aaleem skPas encore d'évaluation

- Projects Titles For Protection - W2017Document3 pagesProjects Titles For Protection - W2017Ahmad AbunassarPas encore d'évaluation

- Assignment 2Document2 pagesAssignment 2ksajjPas encore d'évaluation

- Chapter On1 and Two-1Document25 pagesChapter On1 and Two-1Roqeebat OdunayoPas encore d'évaluation

- Unit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityDocument18 pagesUnit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityMathumathi TPas encore d'évaluation

- LED Flasher Circuit ExplanationDocument5 pagesLED Flasher Circuit ExplanationBharathPas encore d'évaluation

- Advancements in Inverter TechnologyDocument9 pagesAdvancements in Inverter TechnologyAyush KumarPas encore d'évaluation

- 16 Unit15Document45 pages16 Unit15ZULUPas encore d'évaluation

- PSOC-Lecture NotesDocument130 pagesPSOC-Lecture NotesHemaChandar PPas encore d'évaluation

- EE-455 Electrical PowerSystem Protection - F2013Document61 pagesEE-455 Electrical PowerSystem Protection - F2013Patel DipenPas encore d'évaluation

- Protection and Monitoring of Three Phase Induction Motor From Over Voltage, Under Voltage, Single Phasing, Phase Reversal, and Overheating ReviewDocument4 pagesProtection and Monitoring of Three Phase Induction Motor From Over Voltage, Under Voltage, Single Phasing, Phase Reversal, and Overheating ReviewAnonymous CUPykm6DZPas encore d'évaluation

- Fault Detection On Radial Power Distribution Systems Using Fuzzy LogicDocument8 pagesFault Detection On Radial Power Distribution Systems Using Fuzzy LogicDa DebebePas encore d'évaluation

- Over Voltage ProtectionDocument15 pagesOver Voltage ProtectionSridharan MPas encore d'évaluation

- Last PDF of Project ReportDocument18 pagesLast PDF of Project ReportRAVINA MANGAL100% (1)

- Fault Detection On Radial Power DistributionDocument15 pagesFault Detection On Radial Power DistributionJuan CarlosPas encore d'évaluation

- Design Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsDocument12 pagesDesign Calculations For Buck-Boost Converters: Michael Green Advanced Low Power SolutionsnandhakumarmePas encore d'évaluation

- 1.single Phase AC To DC Fully Controlled Converter PDFDocument10 pages1.single Phase AC To DC Fully Controlled Converter PDFAshwin RaghavanPas encore d'évaluation

- Construction of An Automatic Change Over Switch (3.7kva)Document10 pagesConstruction of An Automatic Change Over Switch (3.7kva)AlexOdarteyBannermanPas encore d'évaluation

- Power Line Fault DetectionDocument4 pagesPower Line Fault DetectionVishnu JoshiPas encore d'évaluation

- EEE 805 Assignment Questions For Chapter 20Document11 pagesEEE 805 Assignment Questions For Chapter 20ayeniPas encore d'évaluation

- Protective Relaying For Transmission and Distribution LinesDocument18 pagesProtective Relaying For Transmission and Distribution LinesSheraz AhmedPas encore d'évaluation

- Chapter 3Document46 pagesChapter 3Tewodros ShegawPas encore d'évaluation

- Power System Protection PDFDocument12 pagesPower System Protection PDFBala MPas encore d'évaluation

- Switchgear and Protection 3Document4 pagesSwitchgear and Protection 3vimal067Pas encore d'évaluation

- Over Under Voltage and Over Current Protection SystemDocument8 pagesOver Under Voltage and Over Current Protection SystemHassan AliPas encore d'évaluation

- Real-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkDocument12 pagesReal-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkIJRASETPublicationsPas encore d'évaluation

- chp7 3 Economic Dispatch PDFDocument11 pageschp7 3 Economic Dispatch PDFdo3llah100% (1)

- Two-Stage Micro-Grid Inverter With High PDFDocument10 pagesTwo-Stage Micro-Grid Inverter With High PDFacostaricciPas encore d'évaluation

- Static RelaysDocument11 pagesStatic RelaysBharathwaj SreedharPas encore d'évaluation

- Voltage Profile Improvement Using SVCDocument10 pagesVoltage Profile Improvement Using SVCkubera uPas encore d'évaluation

- How Does A PID Controller Work - Structure & Tuning MethodsDocument12 pagesHow Does A PID Controller Work - Structure & Tuning Methodsmurugan1984Pas encore d'évaluation

- Power System ContingenciesDocument31 pagesPower System ContingenciesSal ExcelPas encore d'évaluation

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsD'EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsPas encore d'évaluation

- Fabrication of High Speed Indication and Automatic Pneumatic Braking SystemDocument7 pagesFabrication of High Speed Indication and Automatic Pneumatic Braking Systemseventhsensegroup0% (1)

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupPas encore d'évaluation

- Implementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationDocument6 pagesImplementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationseventhsensegroupPas encore d'évaluation

- FPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorDocument4 pagesFPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorseventhsensegroupPas encore d'évaluation

- Ijett V5N1P103Document4 pagesIjett V5N1P103Yosy NanaPas encore d'évaluation

- Non-Linear Static Analysis of Multi-Storied BuildingDocument5 pagesNon-Linear Static Analysis of Multi-Storied Buildingseventhsensegroup100% (1)

- An Efficient and Empirical Model of Distributed ClusteringDocument5 pagesAn Efficient and Empirical Model of Distributed ClusteringseventhsensegroupPas encore d'évaluation

- Design and Implementation of Multiple Output Switch Mode Power SupplyDocument6 pagesDesign and Implementation of Multiple Output Switch Mode Power SupplyseventhsensegroupPas encore d'évaluation

- Ijett V4i10p158Document6 pagesIjett V4i10p158pradeepjoshi007Pas encore d'évaluation

- Experimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineDocument5 pagesExperimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineseventhsensegroupPas encore d'évaluation

- Analysis of The Fixed Window Functions in The Fractional Fourier DomainDocument7 pagesAnalysis of The Fixed Window Functions in The Fractional Fourier DomainseventhsensegroupPas encore d'évaluation

- ServiceManual H15Document93 pagesServiceManual H15MohamedPas encore d'évaluation

- Electronic Circuits Lab Manual 13-12-11 PDFDocument54 pagesElectronic Circuits Lab Manual 13-12-11 PDFREMALLI KeerthiPas encore d'évaluation

- Pre Board EeDocument119 pagesPre Board EeJohn Lloyd Santos75% (4)

- Tube DistortionIzerDocument1 pageTube DistortionIzerBAMF100% (1)

- Project ReportDocument67 pagesProject ReportDivyanshu DkPas encore d'évaluation

- LT Spice Basic Simulation ExerciseDocument6 pagesLT Spice Basic Simulation ExerciseJoshua OrlandaPas encore d'évaluation

- All Electric ShipDocument88 pagesAll Electric ShipOladokun Sulaiman Olanrewaju100% (10)

- Aoc E2795vh LCD MonitorDocument80 pagesAoc E2795vh LCD MonitorJerzy LisowskiPas encore d'évaluation

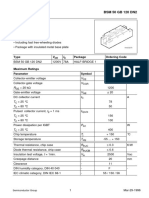

- L4981ADocument17 pagesL4981AMcu CdiiPas encore d'évaluation

- BSM50GB120DN2Document4 pagesBSM50GB120DN2مجید تولاییPas encore d'évaluation

- Baderia Global Group of Institutions, Jabalpur: "Wdp4 Locomotive"Document40 pagesBaderia Global Group of Institutions, Jabalpur: "Wdp4 Locomotive"James StephenPas encore d'évaluation

- Optimizing With eGaN FETsDocument6 pagesOptimizing With eGaN FETskhsniperPas encore d'évaluation

- Miller Tig BookDocument88 pagesMiller Tig BookJon Proce100% (1)

- Static Excitation System Stage-I. 2docDocument28 pagesStatic Excitation System Stage-I. 2docraghavendran raghu100% (1)

- QSL9-G3: Emissions Compliance: EU Stage IIIA at 50 HZ EPA NSPS Stationary Emergency Tier 3Document10 pagesQSL9-G3: Emissions Compliance: EU Stage IIIA at 50 HZ EPA NSPS Stationary Emergency Tier 3mohsen_cumminsPas encore d'évaluation

- Fast Rectifiers ES1F-ES1JDocument5 pagesFast Rectifiers ES1F-ES1Jdhanabal GPas encore d'évaluation

- KX-NS500 KX-NS520 Series: Hybrid IP-PBXDocument26 pagesKX-NS500 KX-NS520 Series: Hybrid IP-PBXRami Assaf100% (1)

- Dsa 00107859Document22 pagesDsa 00107859gbaetaPas encore d'évaluation

- A Review On Charging Infrastructure For Electric Transit Buses - India - 2021Document13 pagesA Review On Charging Infrastructure For Electric Transit Buses - India - 2021Ivana BlackPas encore d'évaluation

- Power Electronics PPT by HEMANTDocument9 pagesPower Electronics PPT by HEMANTshadan alamPas encore d'évaluation

- Manual VFD Bomba para Lodos NovDocument1 440 pagesManual VFD Bomba para Lodos Novkiko20000Pas encore d'évaluation

- 50 Watt Small Homemade InverterDocument25 pages50 Watt Small Homemade InverterMarlon CarinoPas encore d'évaluation

- Statement of Needs - SampleDocument88 pagesStatement of Needs - SampleThana bPas encore d'évaluation

- 2 JOB SHEET-Elecro-Pneumatics 2Document26 pages2 JOB SHEET-Elecro-Pneumatics 2ardiyantoPas encore d'évaluation

- Philadelphia University Student Name: Faculty of Engineering Student NumberDocument2 pagesPhiladelphia University Student Name: Faculty of Engineering Student NumberSaif UddinPas encore d'évaluation

- Carbon Arc Cutting PDFDocument44 pagesCarbon Arc Cutting PDFIlkin hasanov100% (1)

- Project Report Electronic Number LockDocument13 pagesProject Report Electronic Number Locksushmadasari1067% (3)

- Brochure Marine Solutions 2015Document206 pagesBrochure Marine Solutions 2015ana0% (1)

- Fisa Tehnica Sursa de Alimentare MeanWell NDR-240-24Document4 pagesFisa Tehnica Sursa de Alimentare MeanWell NDR-240-24Nicolae BucurPas encore d'évaluation

- ECAT 7 Past Papers PakLearningSpotDocument10 pagesECAT 7 Past Papers PakLearningSpotwww.mukkarram321Pas encore d'évaluation