Académique Documents

Professionnel Documents

Culture Documents

V 3200

Transféré par

Patricio Acuña0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues4 pagesAll Rain Bird pump stations undergo rigorous quality testing at the manufacturing site. Variable speed control provides a smooth automated start and stop of the Pump Station and an extremely quiet low vibration operation. RB Sweden pump Manager software offers the possibility to remotely control the Pump Station from a PC.

Description originale:

Titre original

V-3200

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAll Rain Bird pump stations undergo rigorous quality testing at the manufacturing site. Variable speed control provides a smooth automated start and stop of the Pump Station and an extremely quiet low vibration operation. RB Sweden pump Manager software offers the possibility to remotely control the Pump Station from a PC.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues4 pagesV 3200

Transféré par

Patricio AcuñaAll Rain Bird pump stations undergo rigorous quality testing at the manufacturing site. Variable speed control provides a smooth automated start and stop of the Pump Station and an extremely quiet low vibration operation. RB Sweden pump Manager software offers the possibility to remotely control the Pump Station from a PC.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

TECH SPECS

Vertical Centrifugal Pump Stations

Features

Testing

All Rain Bird pump stations undergo

rigorous quality testing at the

manufacturing site. This includes

operating the completely assembled pump

station at its designed capacity to ensure

that it is fully calibrated.

Variable speed control

All Rain Bird pump stations use electronic

variable speed technology. Variable speed

controlled pump sets maintain a constant

pressure against variable flow. Variable

speed control provides a smooth

automated start and stop of the pump

station and an extremely quiet low

vibration operation.

Remote control from your PC through

RB Sweden Pump Manager Software

The RB Sweden Pump Manager software

offers the possibility to remotely control

the pump station from a PC. The pump

station is connected to the irrigation PC

with Rain Bird 2 x 2.5 mm

2

cable and two

modems or via radio communication. This

also allows for troubleshooting of the

pump station from a remote location.

The possibility to direct link your Pump

Station to your Central Control system

through Smart Pump .

This exclusive software module available

with Rain Bird Site Control, Stratus LT,

StratusII, NimbusII and Cirrus Central

Control systems allows you to link your

Rain Bird pump station directly with the

irrigation central control system. Monitors

and graphs both actual and controlled

flow. Direct and real-time communication

between the pump station and the

irrigation central optimizes your irrigation

cycle by adjusting flow demand according

to actual field conditions.

The most commonly used

line that is suitable for

most applications

Standard configuration allows for

installation of 2 - 6 pumps depending

on duty required.

Operating Range:

Flow range: 20 600 m3/h

5.6 166 l/sec.

88 2640 GPM

Pressure range: 5 13 bar

70 188 PSI

Motors: 4 45 kW

5.3 60 hp

Water temperature

range: 0

o

80

o

C

Air temperature

range: 2

o

40

o

C

Manifold sizes: DN80 DN250

Standard construction include:

Grundfos CR vertical multistage

centrifugal pumps with operating

efficiencies up to 80%

Closed type IP55, high efficiency

EFF1 motors, 3Ph, 400V, 50Hz,

2950rpm

Galvanized steel base frame

Galvanized steel suction and discharge

manifolds

Isolation valve for each pump

Check valve for each pump

Protective thermostat on each pump

prevents motor from running too hot

Pressure transmitter in stainless steel

Hose point connection

Flow meter with electronic signal to

the control cabinet. Allows maximum

flow setting. In the event of this

threshold being exceeded (for example

a pipe burst) the pumps will

automatically shut down

Automatic self-flushing cast-iron Y-

strainer (mesh size 1.5mm) with PLC-

controlled over pressure relief valve.

Screen will be automatically flushed

each time a pump starts and by

customer defined time settings

depending on water quality

Main isolation valve on pump station

outlet with gear handle

Jockey pump included for pump sizes

CR64 and larger

Advanced touch-button user interface

shows actual water flow, operating

conditions and alarms and allows for

easy pressure setting adjustment.

Multi language settings with password

protection.

V-3200 Series

Rain Bird V-3200 Pump Station Specification

The pump station shall be skid mounted and feature vertical multistage centrifugal pumps. The pump station shall

be manufactured by Rain Bird Sweden.

1. General Specifications

1.1. The pump station shall use advanced variable frequency drive and PLC controller technology to maintain a

constant water pressure of ___ bar to a maximum flow of ___ m

3

/h.

1.2. The system shall be completely wired, assembled, and tested prior to shipment. Assembly shall include a

fabricated skid to support all components.

1.3. The complete pump station shall be CE certified for conformance to European Standards. Systems that have

only the sub-assemblies and/or recognized components CE certified for conformance to European Standards

should not be considered equal.

2. Manufacturer Requirements

2.1. The prefabricated pump station shall be a standard product of a single pump station manufacturer. Non stan-

dard, "one of a kind" pump stations shall not be considered equal.

The pump station shall be Rain Bird type V-3200 model _____

2.2. The pump station shall be manufactured by Rain Bird Sweden.

The following shall be provided:

2.2.1. Pump duty performance curves

2.2.2. Complete specification with submittal information on all major components of the pumping system

2.2.3. Pump station drawing including top and elevation views and location and size of all major components

2.2.4. Electrical schematic

2.2.5. CE-approval for the entire pumping system assembly

3. Pump Requirements

3.1. The pump station shall consist of minimum ____ main pumps all with equal performance.

3.2. Pump stations that have main duty pumps in excess of 45 m

3

/h shall include a jockey pump. This pump shall

maintain the system prime during periods of low flow, provide manual watering etc.

3.3. Pumps shall be of the vertical multi-stage centrifugal design. The pump suction/ discharge chamber, motor stool,

and pump shaft coupling shall be constructed of cast iron. The impellers, pump shaft, diffuser chambers, outer

discharge sleeve, impeller seal rings, and seal ring retainers shall be constructed of stainless steel. Optional

materials for the suction/discharge chamber and motor stool liner shall be stainless steel.

3.4. The motors shall be vertical IP55 high efficiency EFF1 motors, 3 phase, 400V, 50Hz, 2900 rpm.

4. Skid Requirements

4.1. The pump station base / skid shall be manufactured out of galvanized steel and designed to support all the

stations components. Anchor plates shall be included to support the frame.

5. Plumbing Requirements

5.1. All fabricated steel pipe work, manifolds and fittings shall be hot dipped galvanized after fabrication and prior to

assembly. No cutting, welding or drilling is permitted after galvanizing.

Surface preparation shall consist of pickling, followed by hot dipped galvanizing.

5.2. No threaded fittings will be permitted except for connections of 50mm nominal diameter or less.

5.3. All items on the pump station including pipe work, manifolds, fittings etc. shall be rated at 16 bar.

6. Pump Station Requirements

The pump station shall include as a minimum but not be limited to:

6.1. Pressure transmitter in stainless steel with build in over pressure security type Danfoss MBS3050.

6.2. Wafer style butterfly isolation valve (per pump) type Danfoss / Socla model Sylax in epoxy coated cast iron and

disc in stainless steel.

6.3. Dual flap check valves (per pump) type Danfoss / Socla in epoxy coated cast iron and plates in stainless steel.

6.4. Y-strainer with a mesh size of 1.5 mm

2

including automatic flushing and PLC-controlled high-pressure relief

valve. The strainer shall be rated at 16 bar. Screen shall be automatically flushed each time a pump starts and /

or by customer defined time settings.

6.5. Glycerin filled pressure gauges, 0 - 16 bar, mounted before and after the Y-strainer.

6.6. Flow meter with signal to the cabinet. The flow meter shall be installed with minimum 5 x pipe diameter before

and minimum 3 x pipe diameter after the flow meter to ensure correct measuring of the flow. The flow meter

shall be ABB type Woltman meter or Siemens MagFlo, electromagnetic rated at 16 bar.

6.7. A system isolation valve shall be installed on the pump station discharge to isolate the pump station from the

irrigation system. The valve shall be equipped with a 5-position locking lever for dimensions DN80 and smaller

or gear operator for dimensions DN100 and above. The valves shall be rated at 16 bar.

6.8. Hose point connection on the discharge manifold.

6.9. Protective thermostat per pump. These thermostats shall be set to app. 45

o

C to prevent overheating of the

pumps.

7. Electrical Requirements

7.1. Circuit breakers shall always be used (instead of fuses).

7.2. Main switch interlocked with the door shall be included.

7.3. Emergency stop push button shall be mounted in the cabinet front. The push button shall be hard wired outside

the PLC.

7.4. All wires shall be labeled and correspond to the electrical schematic as well as the components.

7.5. Standard industrial components (PLC, operator's panel, frequency converter, contactors, motor protective

switches, circuit breakers, etc.) shall be used.

7.6. Emergency run switches for minimum 2 pumps shall be incorporated for emergency use to run pumps manually

in case of Frequency Converter, PLC or Operators Panel break down.

7.7. Cooling fan to remove heat generated by VFD shall be included or if needed water-cooled heat exchanger. No

water connections shall be made inside the electrical panel.

7.8. Electrical panel shall be rated minimum IP54.

7.9. VFD must be digital, pulse width modulation.

7.10. The operator panel shall be Mitsubishi, E-300 touch button type or optional E-series color touch screen version.

7.11. The PLC shall be Mitsubishi FX2N or FX3N.

7.12. Solid state pressure transmitter in stainless steel with build in over pressure security type Danfoss MBS3050

shall be utilized for pressure measurements.

7.13. Optional. 3-phase control system detecting over- and under voltage, reversal and phase loss shall be installed.

8. Control System Requirements

8.1. The complete instrumentation and control system shall automatically start, stop, and modulate pump speed to

smoothly, efficiently and reliably pump variable flow rates at a constant discharge pressure. Full alarms and

safety features to protect equipment, irrigation piping, and personnel shall be provided.

8.2. Control software shall be parameter driven, fully documented, and allow user to easily change ALL operational

parameters. Standard control features and equipment that need to be included as the minimum are as follows:

8.2.1. Emergency Stop

8.2.2. Low discharge pressure alarm

8.2.3. High discharge pressure alarm

8.2.4. Low water level alarm

8.2.5. Protective thermostat mounted on the pumps

8.2.6. Optional. High / low voltage, phase loss / phase reversal alarm

8.2.7. VFD fault (shutdown VFD pump only and attempts restart)

8.2.8. Flow meter fault

8.2.9. Pressure transmitter fault

8.2.10. Optional. Motor over temperature (PTC resistors)

8.2.11. Selectable functions for Alarms to be auto resetable

8.3. All alarms shall be logged with time and date and be indicated on the operator panel. Pilot light indicators shall

not be acceptable.

8.4. The operator panel shall be able to access all pump information, including but not limited to logging, alarm, and

current status readings. The operator panel shall be able to select and change all pump and pressure settings

while protecting the system from accidental programming errors by password protecting sensitive set up

readings. The operator panel shall have a default screen that shows the following information:

8.4.1. Current pressure, actual and set point (selectable between bar and PSI)

8.4.2. VFD Speed

8.4.3. Actual flow (selectable between m

3

/h, l/sec and GPM)

8.4.4. Fault conditions

8.4.5. Pump selected for VFD operation

8.4.6. Pump operation mode (Of / Standby / Running / Alarm)

8.4.7. Number of pumps operating

8.5. Two distinct set point pressures (normal and elevation 1). The low elevation set point can be tied into a

computerized irrigation system, or directly linked to low elevation satellites. When low elevation satellites are

operating, controls software will automatically and gradually decrease the pressure to the new desired set point.

When finished, the low set point will be increased back to normal.

8.6. Software shall be included to automatically and gradually ramp-up irrigation system pressure to the desired

operating pressure (e.g., 0.1 bar every five seconds) without exceeding design pressure. This ramp-up time

shall be fully adjustable by the operator.

8.7. Optional feature: Automatic alternation of VFD driven pump. This shall be accomplished by incorporating dual

mechanically and electrically interlocked contactors.

8.8. Real-time clock calendar shall allow operator panel to internally provide all date and time functions used above.

8.9. Full manual operation capability with screen speed control for manually adjusting VFD speed.

8.10. Pump station shall be able to communicate with remote software, compatible with Rain Bird Smart Pump.

8.11. Operators panel shall display sequential pump station alarms with date and time.

9. Optional Monitoring Software Requirements

9.1. Monitoring software must be integrated with Rain Bird Smart Pump

TM

software.

9.2. Software shall display the current operation status. When the station is running, the display shall show the set

point pressure, actual pressure, flow, and pump speed.

9.3. Software shall display alarms recorded in memory and displayed with related detail information on the alarm

time and date of.

9.4. Software shall display individual pump run times.

9.5. The software shall have the capability to show historical flow - and pressure curves.

10. System Operation Requirements

10.1. If Jockey pump is installed it shall cycle on and off as required to maintain irrigation system pressure during non-

irrigation times. If the Jockey pump cannot maintain the desired pressure the system shall go to normal irrigation

mode.

When the system pressure drops then the VFD shall start the first pump and will gradually ramp the pressure up

to the desired pressure regardless of flow. As the flow rate increases the pump speed shall be modulated to hold

a constant discharge pressure regardless of flow. As the flow rate increases and the VFD pump can no longer

maintain pressure while at maximum speed, the next sequential pump shall be started. As the flow continues to

increase, pumps shall be started sequentially until all pumps are running. As the flow begins to decrease, pumps

shall be turned off sequentially until a single VFD pump is operating. When a no-flow / over-set point pressure

condition occurs, the VFD pump shall be turned off.

11. Testing Requirements

11.1. The complete Pump Station shall be fully assembled and tested to capacity. Calibrations required shall be

performed during this factory test. Only minor adjustment needs to be done during start up. All electrical

calibration / control settings shall be recorded in the operation manual test section.

11.2. The complete pumping system shall operate without undue vibration throughout the range of operating

conditions. The unit shall be given a running test of normal start and stop conditions under load.

12. Training Requirements

12.1. The pump station manufacturer shall provide training for the end user on proper operation of the pump station.

The training shall be performed on the actual installed equipment after such time as installation, startup and

calibration have been completed.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

Rain Bird Europe S.A.R.L.

900, rue Ampre

B.P. 72000

13792 Aix-en-Provence Cedex 3

FRANCE

Phone: (33) 4 42 24 44 61

Fax: (33) 4 42 24 24 72

Rain Bird France

900, rue Ampre

B.P. 72000

13792 Aix-en-Provence Cedex 3

FRANCE

Phone: (33) 4 42 24 44 61

Fax: (33) 4 42 24 24 72

Rain Bird Turkey

stiklal Mahallesi

Alemda Caddesi, No 262

81240 mraniye stanbul

TURKEY

Phone: (90) 216 443 75 23

Fax: (90) 216 461 74 52

Rain Bird Iberica S.A.

Pol. Ind. Prado del Espino

C/ Forjadores, Parc. 6, M18, S1

28660 Boadilla del Monte, Madrid

ESPANA

Phone: (34) 91 632 48 10

Fax: (34) 91 632 46 45

Rain Bird Deutschland GmbH

Siedlerstrae 46

71126 Gufelden Nebringen

DEUTSCHLAND

Phone: (49) 07032 99010

Fax: (49) 07032 990111

Rain Bird Sverige A.B

Fleningevgen 315

260 35 dkra

SWEDEN

Phone: (46) 042 25 04 80

Fax: (46) 042 20 40 65

Registered Trademark of Rain Bird Corporation

2005 Rain Bird Corporation 02/05

http://www.rainbird.fr

e-mail:rbe@rainbird.fr

Vous aimerez peut-être aussi

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Instruction Manual HFU-TorayDocument35 pagesInstruction Manual HFU-TorayPatricio AcuñaPas encore d'évaluation

- ROT Rotary Control Valves OverviewDocument8 pagesROT Rotary Control Valves OverviewPatricio AcuñaPas encore d'évaluation

- Dow UF General Design GuidelinesDocument2 pagesDow UF General Design GuidelinesPatricio AcuñaPas encore d'évaluation

- Tabla de Carga LTM 1400 TY 140tonDocument4 pagesTabla de Carga LTM 1400 TY 140tonPatricio AcuñaPas encore d'évaluation

- 01 231023 Curso Online Karin BäpplerDocument66 pages01 231023 Curso Online Karin BäpplerPatricio AcuñaPas encore d'évaluation

- Special Solutions: For Industry and Plant EngineeringDocument32 pagesSpecial Solutions: For Industry and Plant EngineeringPatricio AcuñaPas encore d'évaluation

- Bermingham Lead BrochureDocument8 pagesBermingham Lead BrochurePatricio AcuñaPas encore d'évaluation

- Neodren EnglishDocument13 pagesNeodren EnglishPatricio AcuñaPas encore d'évaluation

- Check Valve Nozzle Non - SlamDocument16 pagesCheck Valve Nozzle Non - SlamPatricio AcuñaPas encore d'évaluation

- AE20/BE20: SeriesDocument7 pagesAE20/BE20: SeriesPatricio Acuña0% (1)

- Westfall 2800 Static Mixer PDFDocument8 pagesWestfall 2800 Static Mixer PDFPatricio AcuñaPas encore d'évaluation

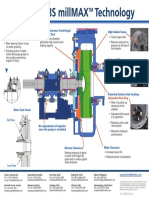

- 00millMAXSlurryPumpJuly2016Cutaway PDFDocument1 page00millMAXSlurryPumpJuly2016Cutaway PDFPatricio AcuñaPas encore d'évaluation

- Dhatec Overview Presentation - Roadshow Compreesed VersionDocument31 pagesDhatec Overview Presentation - Roadshow Compreesed VersionPatricio AcuñaPas encore d'évaluation

- ABB Instrumentation: Pipeline Booster Station Control SystemsDocument6 pagesABB Instrumentation: Pipeline Booster Station Control SystemsPatricio AcuñaPas encore d'évaluation

- 00 Mill MAXSlurry Pump July 2016 CutawayDocument1 page00 Mill MAXSlurry Pump July 2016 CutawayPatricio Acuña100% (1)

- Development of Api Grade Linepipe Steels at Saudi Iron & Steel Company, HadeedDocument9 pagesDevelopment of Api Grade Linepipe Steels at Saudi Iron & Steel Company, HadeedPatricio AcuñaPas encore d'évaluation

- Ms Adminguide v8 5 PDFDocument490 pagesMs Adminguide v8 5 PDFPatricio AcuñaPas encore d'évaluation

- BS en 341 2011 PDFDocument26 pagesBS en 341 2011 PDFPatricio AcuñaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Granlund Software Help: RiuskaDocument14 pagesGranlund Software Help: RiuskaObi-Wan KenobiPas encore d'évaluation

- The Death of Science.Document1 pageThe Death of Science.sam iam / Salvatore Gerard MichealPas encore d'évaluation

- 050 Meteorology (JAA ATPL Theory)Document700 pages050 Meteorology (JAA ATPL Theory)Sarah Schroeder100% (2)

- Power Generation Using Forearm Gym EquipmentDocument7 pagesPower Generation Using Forearm Gym EquipmentIJRASETPublicationsPas encore d'évaluation

- Abha Private Hospital - KSA: 1. Project DescriptionDocument6 pagesAbha Private Hospital - KSA: 1. Project DescriptionOsama AlsherifPas encore d'évaluation

- Inorganic Qualitative AnalysisDocument9 pagesInorganic Qualitative AnalysisShireen SuhailPas encore d'évaluation

- COMPUTER PROGRA-WPS OfficeDocument5 pagesCOMPUTER PROGRA-WPS OfficeGurpreet KumarPas encore d'évaluation

- Petrel 2013 Property Modeling Course: Module 2: Data PreparationDocument15 pagesPetrel 2013 Property Modeling Course: Module 2: Data PreparationJaninne Campo100% (1)

- Icm U1d7 Simplifying Exponential Expressions 1Document2 pagesIcm U1d7 Simplifying Exponential Expressions 1kazamPas encore d'évaluation

- Repulsive Force FieldDocument7 pagesRepulsive Force FieldSoundararajan SeeranganPas encore d'évaluation

- 2595 Olive OilDocument18 pages2595 Olive OilclionpoorPas encore d'évaluation

- Macromolecules Study Guide Key 1Document5 pagesMacromolecules Study Guide Key 1api-330218302Pas encore d'évaluation

- Hydraulics Multiple Choice Questions and Answers - Set 26 - Engineering, Competitive Exams and Jobs PDFDocument9 pagesHydraulics Multiple Choice Questions and Answers - Set 26 - Engineering, Competitive Exams and Jobs PDFl8o8r8d8s8i8v8Pas encore d'évaluation

- HSR 1.63 (For HYSYS V10.0)Document4 pagesHSR 1.63 (For HYSYS V10.0)Ba Jun Thối0% (1)

- Tutorial Sheet 2213Document2 pagesTutorial Sheet 2213Mithilesh GuruPas encore d'évaluation

- Engineering Drawing II (For Diploma in Engineering) : December 2019Document9 pagesEngineering Drawing II (For Diploma in Engineering) : December 2019Kamalnath GPas encore d'évaluation

- Padhle Akshay Maths 33 DaysDocument263 pagesPadhle Akshay Maths 33 DaysShamik BhattacharjeePas encore d'évaluation

- SPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideDocument4 pagesSPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideRoxy RoxaPas encore d'évaluation

- Simulation of Antenna Radiation Pattern-HornDocument5 pagesSimulation of Antenna Radiation Pattern-Hornbenny_181163% (8)

- Chapter 5 Final A5 EditDocument8 pagesChapter 5 Final A5 EditkINGPas encore d'évaluation

- 3 Paramater Untuk Men-Synchron-Kan Komunikasi: Set 2 For Modbus CommunicationDocument5 pages3 Paramater Untuk Men-Synchron-Kan Komunikasi: Set 2 For Modbus CommunicationAhmad FathurachmanPas encore d'évaluation

- Unit I. Bascis of Manufacturing ProcessesDocument30 pagesUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECEPas encore d'évaluation

- Technical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsDocument1 pageTechnical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsAhmadPas encore d'évaluation

- Super Had CCD IIDocument2 pagesSuper Had CCD IIMohd Safian ZakariaPas encore d'évaluation

- Oracle Database: Performance Tuning Guide 12c Release 1 (12.1)Document340 pagesOracle Database: Performance Tuning Guide 12c Release 1 (12.1)sanjayid1980Pas encore d'évaluation

- Switchgear and Controlgear AssembliesDocument4 pagesSwitchgear and Controlgear AssembliesJon LopezPas encore d'évaluation

- Technical ReportDocument32 pagesTechnical ReportKenneth Dwight BojaPas encore d'évaluation

- STPM Trial 2009 Che Q&A (Johor)Document43 pagesSTPM Trial 2009 Che Q&A (Johor)SimPor100% (1)

- General Handout - MathematicsDocument7 pagesGeneral Handout - MathematicsRaven St. LouisPas encore d'évaluation