Académique Documents

Professionnel Documents

Culture Documents

Glo Macs

Transféré par

Murugan RajaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Glo Macs

Transféré par

Murugan RajaDroits d'auteur :

Formats disponibles

GLOMACS

Introduction

This program will provide an integrated practical overview of metals and alloys and relating it to

the mechanical and physical characteristics of metals; starting from materials testing and

physical/mechanical properties, through corrosion properties and strength/deformation

principals, and to ferrous and nonferrous alloys and heat treatment.

The course will then include ferrous alloys (plain and alloy steels, Stainless steels and cast irons)

and nonferrous alloys (for corrosion and high temperature applications, such as nickel, cobalt

and titanium based alloys).

The nature of hot and cold working of metals and heat treatment, including annealing,

normalizing, tempering and case hardening will be explained.

The fundamentals of corrosion and corrosion prevention will also be presented in practical terms

with examples to illustrate the key points.

The behavior of metals under various loading conditions (static, dynamic, fracture) will be

presented and related to design methodology and procedures; rules of thumb, standards, and best

industry practices.

Each of the major topics will be presented as individual units, and in the context of the overall

usage of metal components and structures and failure mechanisms, and mechanical integrity.

Objectives

Upon completion of this course, participants will have gained an understanding of the important

principals of engineering involving properties and characteristics of metals and alloys, including

fabrication and heat treatment of commercial steels and non-ferrous alloys.

Participants will acquire sufficient knowledge and skills to independently evaluate possible

metallurgical and design solutions, to recognize crucial metallurgical phenomena and

intelligently discuss their metal problems with design engineers, metallurgists and fabricators.

Training Methodology

The course combines presentations and discussions of topics covered with relevant examples. It

combines knowledge of fundamental principles related to the structure of metals sound

engineering principles, methods, and applicable standards and best industry practices and

enforces learning with Question & Answer sessions to maximize the benefits to the participants.

Videos of relative manufacturing processes of metals will also be included.

Participants will be provided with comprehensive course notes and copies of presentation

material that will be very valuable for detailed study and future reference.

Organizational Impact

The company will be able to specify and select metallic components and other components that are fit-for-purpose without

excessive design margins leading to cost effective facilities.

The company will be able to achieve measurable improvement in mechanical integrity of metal structures and other equipment

through effective interaction between various engineering disciplines, operation and maintenance functions.

Furthermore, an improvement in basic inspection and maintenance may be achieved.

This will also lead to improvement in operating and financial performance, and lead to improvement in loss prevention and safety

performance.

Personal Impact

Upon completion of this course, participants will have gained an understanding of the important principals of metallurgy,

involving properties and characteristics of metals and alloys.

Participants will increase their basic knowledge in related topics such as fabrication and heat treatment of commercial steels

alloys.

Participants will acquire sufficient knowledge and skills to independently evaluate possible metallurgical and design solutions, to

recognize crucial metallurgical selection/design/treatment and intelligently discuss their metal problems with design engineers,

metallurgists and fabricators.

Participant will enhance their knowledge, regarding failure mechanisms, including corrosion.

Participants will enhance their competence and productivity thereby improving their performance level and making additional

value added contributions to their organizations.

Who Should Attend?

This program is intended for those who use or supervise activities requiring the use of metal

parts or structures.

Those with little or no prior formal background who function as:

Supervisors

Engineers

Planners

Inspectors

Designers

Researchers

Investors

and who seek a basic understanding of the practical aspects of metallurgy should find this course

valuable.

SEMINAR OUTLINE

Day 1

Testing and Mechanical Properties of Metals

Tensile tests

Impact tests

Hardness tests

Compression of mechanical properties

The Crystalline Structure of Metals

Bonding in metals

Solidification crystal growth and structures of metals

Defects in metals during solidification

Day 2

Specimen Preparation and Microscopic

Examination

The preparation (Mounting Grinding, Polishing and Etching)

of metal specimens

Metallurgical and Electron Microscopes

Dislocations and Strengthening Mechanisms

in Metals

Edge Dislocation (line imperfections) in crystals

Strengthening of metals by Grain Size Reduction, Solid

Solution and Strain Hardening

Softening of metals by annealing

Comparison of Cold and Hot working of Metals

Day 3

Binary Equilibrium Diagrams

Solubility and cooling curves

Thermal Equilibrium Diagrams (Eutectic Type, Solid Solution

Type and Combination Type)

Ferrous Alloys

Definitions and classifications and some uses of

ferrous alloys including;

Carbon steels

Alloy steels

Stainless steels

Cast irons

Fabrication of Metals

A selection of metal fabrication methods,

including;

Forming

Casting

Welding

Day 4

Heat Treatment of Plain Carbon Steel

Hardening of carbon steel (by quenching)

Annealing

Normalizing

Tempering

Austempering

Surface treatments

Heat affected zone (HAZ) in welding

Non-Ferrous Alloys

Nickel and cobalt

Titanium alloys

Day 5

Corrosion in Metals

The electrochemical cell

Types of electrochemical corrosion

Pitting

Crevice

Stress corrosion

Hydrogen induced, etc.

Protection against Electrochemical Corrosion and

Inspection

Coatings

Internal

External

Polymers

Galvanizing, etc.

Inhibitors, Types and usage

Cathodic protection, Impressed current, Sacrificial

Inspection

Standards

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

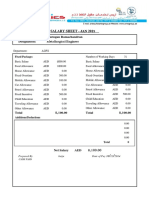

- Salary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerDocument1 pageSalary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerMurugan RajaPas encore d'évaluation

- Eticket RMTN6JA54Z362Document1 pageEticket RMTN6JA54Z362Murugan RajaPas encore d'évaluation

- Details of UKAS Recalibration Due of Mechanical Test EquipmentsDocument1 pageDetails of UKAS Recalibration Due of Mechanical Test EquipmentsMurugan RajaPas encore d'évaluation

- Subject: Requisition of Advance For Home ConstructionDocument1 pageSubject: Requisition of Advance For Home ConstructionMurugan RajaPas encore d'évaluation

- By Laws - 26 Février 2013Document17 pagesBy Laws - 26 Février 2013Murugan RajaPas encore d'évaluation

- Confirmation - Your Booking Confirmation and Reference - FlydubaiDocument2 pagesConfirmation - Your Booking Confirmation and Reference - FlydubaiMurugan Raja67% (9)

- Waslab PrintDocument1 pageWaslab PrintMurugan RajaPas encore d'évaluation

- JafzaDocument6 pagesJafzaMurugan RajaPas encore d'évaluation

- ARIES Marine Sample Testing of Different QualitiesDocument1 pageARIES Marine Sample Testing of Different QualitiesMurugan RajaPas encore d'évaluation

- Ref No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentDocument2 pagesRef No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentMurugan RajaPas encore d'évaluation

- UAE Power Plant ListDocument2 pagesUAE Power Plant ListMurugan Raja0% (1)

- RA - Angle GrinderDocument4 pagesRA - Angle GrinderMurugan RajaPas encore d'évaluation

- Middle East Technologies (Fze) : SL - Number: 35808 P.O.Box: 9352 SHJ Phone: 06-5572971 Fax: 065572972 E-MailDocument2 pagesMiddle East Technologies (Fze) : SL - Number: 35808 P.O.Box: 9352 SHJ Phone: 06-5572971 Fax: 065572972 E-MailMurugan RajaPas encore d'évaluation

- Mechanical PropertiesDocument21 pagesMechanical PropertiesMurugan RajaPas encore d'évaluation

- Corrosion Pit EvaluationDocument1 pageCorrosion Pit EvaluationMurugan RajaPas encore d'évaluation

- GLIER QSP ManagementrequirementsDocument72 pagesGLIER QSP ManagementrequirementsMurugan RajaPas encore d'évaluation

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistMurugan RajaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Astm b425Document5 pagesAstm b425singaravelan narayanasamyPas encore d'évaluation

- Ko Large Bore PistonsDocument0 pageKo Large Bore PistonsvshalimovPas encore d'évaluation

- ASTM-A227 Spring SteelDocument4 pagesASTM-A227 Spring SteelLalo CastañedaPas encore d'évaluation

- Mil DTL 12560KDocument52 pagesMil DTL 12560KGökhan ÇiçekPas encore d'évaluation

- FAMECADocument8 pagesFAMECADhimaz ZiroPas encore d'évaluation

- Practice Examination API 1104Document9 pagesPractice Examination API 1104Percy Morales RamirezPas encore d'évaluation

- Direct Black 22 - HPLC Determination Four Textile Dyes and Studying Their Degradation Using Spectrophotometric TechniqDocument110 pagesDirect Black 22 - HPLC Determination Four Textile Dyes and Studying Their Degradation Using Spectrophotometric TechniqREACH_ColoursPas encore d'évaluation

- Construction of Covered Court, Brgy. Veterans Village, Quezon CityDocument8 pagesConstruction of Covered Court, Brgy. Veterans Village, Quezon CityIan JamesPas encore d'évaluation

- Guidelines For Rationalised Use of High Performance ConductorsDocument163 pagesGuidelines For Rationalised Use of High Performance ConductorsRajeev KumarPas encore d'évaluation

- BS 7371-1-2009 General RequirementsDocument24 pagesBS 7371-1-2009 General RequirementsmoorthyxPas encore d'évaluation

- LamelerDocument5 pagesLamelerPrasetyaOne NugraHantoePas encore d'évaluation

- 215R 74Document24 pages215R 74Catalin BoroianuPas encore d'évaluation

- Safe-Lec 2 & Hevi-Bar II CatalogDocument68 pagesSafe-Lec 2 & Hevi-Bar II Catalogcj7man80Pas encore d'évaluation

- Coudoint Edgewound ResistorsDocument25 pagesCoudoint Edgewound ResistorsPetar PetrovicPas encore d'évaluation

- High Hardness & Toughness New General-Purpose Cold Die SteelDocument2 pagesHigh Hardness & Toughness New General-Purpose Cold Die SteelSinan YıldızPas encore d'évaluation

- A Comparative Thermal and Structural Analysis of Different Disc Brake MaterialsDocument6 pagesA Comparative Thermal and Structural Analysis of Different Disc Brake MaterialsTJPRC PublicationsPas encore d'évaluation

- MSS SP-6 (2001)Document6 pagesMSS SP-6 (2001)Vijay KumarPas encore d'évaluation

- Astm A510 6 PDFDocument7 pagesAstm A510 6 PDFNafiou KamelPas encore d'évaluation

- Bend Tonnage CalculationDocument2 pagesBend Tonnage CalculationLingarajan RamasamyPas encore d'évaluation

- Bahru Stainless Product Catalogue (5th Rev, 10 Feb 2017)Document35 pagesBahru Stainless Product Catalogue (5th Rev, 10 Feb 2017)JonPas encore d'évaluation

- KF Ball FloatingThreadedGroovedDocument20 pagesKF Ball FloatingThreadedGroovedBhupatiPas encore d'évaluation

- Portable Intermediate Flush Deck Stanchion: Standard Specification ForDocument4 pagesPortable Intermediate Flush Deck Stanchion: Standard Specification ForEduardoPas encore d'évaluation

- Cases 1Document26 pagesCases 1yagayPas encore d'évaluation

- Holophane Outdoor Substation Series Brochure 8-79Document2 pagesHolophane Outdoor Substation Series Brochure 8-79Alan MastersPas encore d'évaluation

- Selective Dissolution of Austenite in 304 by Bacterial ActivityDocument3 pagesSelective Dissolution of Austenite in 304 by Bacterial ActivityDavid Andres Cañas SuarezPas encore d'évaluation

- 1 - 2015 Enimex Ball ValvesDocument55 pages1 - 2015 Enimex Ball ValvesNoytsias KostantinosPas encore d'évaluation

- Lotherme Electrodes Cement Plant Application: Mining DepartmentDocument2 pagesLotherme Electrodes Cement Plant Application: Mining DepartmentGyanaranjan2011Pas encore d'évaluation

- Strainer Screen & Mesh Selection GuideDocument4 pagesStrainer Screen & Mesh Selection Guidelenasko0% (1)

- PDMDocument58 pagesPDMapi-251473627Pas encore d'évaluation

- Lab ReportDocument21 pagesLab ReportMuhammad YasirPas encore d'évaluation