Académique Documents

Professionnel Documents

Culture Documents

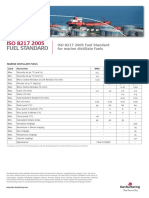

ISO 8217 2010 Fuel Standard For Marine Distillate Fuels

Transféré par

tamailhamDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ISO 8217 2010 Fuel Standard For Marine Distillate Fuels

Transféré par

tamailhamDroits d'auteur :

Formats disponibles

A/S Dan-Bunkering Ltd.

has been leading in the bunker business for more than 3 decades, arranging bunker supplies; fuels, lubricants,

and other related products and services for vessels all over the world. The head ofce is situated in Middelfart with ofces in

Copenhagen, Shanghai, Kaliningrad, Singapore, Monaco, Houston, Beijing, and Dubai with more than 70 dedicated and service-minded

bunker traders ready to guide new and existing clients. A/S Dan-Bunkering Ltd. is part of a professional and nancially strong group

with interests in ship-owning and shipping activities.

ISO 8217 2010 Fuel Standard

for marine distillate fuels

www.dan-bunkering.com

MARINE DISTILLATE FUELS

ISO 8217 2010

FUEL STANDARD

The above is a service for informational purposes only. Dan-Bunkering assumes no responsibility for any errors or omissions.

Limit Parameter DMX DMA DMZ DMB

Max. Viscosity at 40C (mm

2

/s) 5.500 6.000 6.000 11.00

Min. Viscosity at 40C (mm

2

/s) 1.400 2.000 3.000 2.000

Max. Micro Carbon Residue at 10% Residue (% m/m) 0.30 0.30 0.30 -

Max. Density at 15C (kg/m3) - 890.0 890.0 900.0

Max. Micro Carbon Residue (% m/m) - - - 0.30

Max. Sulphur (% m/m) 1.00 1.50 1.50 2.00

Max. Water (% V/V) - - - 0.30

Max. Total sediment by hot ltration (% m/m) - - - 0.10

Max. Ash (% m/m) 0.010 0.010 0.010 0.010

Min. Flash point (0C) 43.0 60.0 60.0 60.0

Max. Pour point in Summer (0C) - 0 0 6

Max. Pour point in Winter (C) - -6 -6 0

Max. Cloud point (C) -16 - - -

Min. Calculated Cetane Index 45 40 40 35

Max. Acid Number (mgKOH/g) 0.5 0.5 0.5 0.5

Max. Oxidation stability (g/m

3

) 25 25 25 25

Max. Lubricity, corrected wear scar diameter (wsd 1.4 at 60C) (um) 520 520 520 520

Max. Hydrogen sulphide (mg/kg) 2.00 2.00 2.00 2.00

Appearance Clear & Bright -

A/S Dan-Bunkering Ltd. has been leading in the bunker business for more than 3 decades, arranging bunker supplies; fuels, lubricants,

and other related products and services for vessels all over the world. The head ofce is situated in Middelfart with ofces in

Copenhagen, Shanghai, Kaliningrad, Singapore, Monaco, Houston, Beijing, and Dubai with more than 70 dedicated and service-minded

bunker traders ready to guide new and existing clients. A/S Dan-Bunkering Ltd. is part of a professional and nancially strong group

with interests in ship-owning and shipping activities.

ISO 8217 2010 Fuel Standard

for marine residual fuels

www.dan-bunkering.com

MARINE RESIDUAL FUELS

Limit Parameter

RMA RMB RMD RME RMG RMK

10 30 80 180 180 380 500 700 380 500 700

Max. Viscosity at 50C (mm

2

/s) 10.00 30.00 80.00 180.0 180.0 380.0 500.0 700.0 380.0 500.0 700.0

Max. Density at 15C (kg/m

3

) 920.0 960.0 975.0 991.0 991.0 1010.0

Max. Micro Carbon Residue (% m/m) 2.50 10.00 14.00 15.00 18.00 20.00

Max. Aluminium + Silicon (mg/kg) 25 40 50 60

Max. Sodium (mg/kg) 50 100 50 100

Max. Ash (% m/m) 0.040 0.070 0.100 0.150

Max. Vanadium (mg/kg) 50 150 350 450

Max. CCAI 850 860 870

Max. Water (% V/V) 0.30 0.50

Max. Pour point (upper) in Summer (C) 6 30

Max. Pour point (upper) in Winter (C) 0 30

Min. Flash point (C) 60.0

Max. Sulphur (% m/m) Statutory requirements

Max. Total Sediment, aged (% m/m) 0.10

Max. Acid Number (mgKOH/g) 2.5

Used lubricating oils (ULO):

Calcium and Zinc; or Calcium and

Phosphorus (mg/kg)

The fuel shall be free from ULO, and shall be considered to contain ULO

when either one of the following conditions is met:

Calcium > 30 and zinc > 15; or Calcium > 30 and phosphorus > 15.

Max. Hydrogen sulphide (mg/kg) 2.00

ISO 8217 2010

FUEL STANDARD

The above is a service for informational purposes only. Dan-Bunkering assumes no responsibility for any errors or omissions.

Vous aimerez peut-être aussi

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IID'EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffPas encore d'évaluation

- Iso 8217 Fuel StandardDocument3 pagesIso 8217 Fuel StandardShaaz Anaam0% (1)

- Iso 8217 2005Document2 pagesIso 8217 2005Sara ScaramelliPas encore d'évaluation

- Infineum Marine Fuel Survey 2016Document14 pagesInfineum Marine Fuel Survey 2016Melisa MathiasPas encore d'évaluation

- Iso 8217 2010Document2 pagesIso 8217 2010Flavio MoraesPas encore d'évaluation

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDocument2 pagesISO 8217 2010 Fuel Standard For Marine Distillate FuelsiceburnerPas encore d'évaluation

- Iso 8217 2017 PDFDocument2 pagesIso 8217 2017 PDFAnton100% (2)

- Iso 8217 2017Document2 pagesIso 8217 2017Ahmed BelalPas encore d'évaluation

- Marine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaDocument23 pagesMarine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaRazaq PayapoPas encore d'évaluation

- Technical Aspects of Identifying and Managing Bunker Problems PDFDocument58 pagesTechnical Aspects of Identifying and Managing Bunker Problems PDFMannMannPas encore d'évaluation

- DNV - Qatargas Visit - IsO8217 - 2010Document51 pagesDNV - Qatargas Visit - IsO8217 - 2010hawajePas encore d'évaluation

- Marine Fuel3Document2 pagesMarine Fuel3Finito TheEndPas encore d'évaluation

- International Standard ISO 8217: 1996 British Standard BS MA 100: 1996Document1 pageInternational Standard ISO 8217: 1996 British Standard BS MA 100: 1996Vilius BukysPas encore d'évaluation

- Fuel Iso-8210-2010 - 0Document2 pagesFuel Iso-8210-2010 - 0cupid75Pas encore d'évaluation

- Carlos Types of FuelDocument5 pagesCarlos Types of FuelDaiane LavrattiPas encore d'évaluation

- Iso 8217 2010 Fuel Standard: For Marine Distillate FuelsDocument2 pagesIso 8217 2010 Fuel Standard: For Marine Distillate FuelsMarco MeloniPas encore d'évaluation

- Bunker Specification Page 2Document15 pagesBunker Specification Page 2mohdfadhirul100% (1)

- Marine Fuel Oil ISO 8217:2017: Information On Specifications and TestsDocument2 pagesMarine Fuel Oil ISO 8217:2017: Information On Specifications and TestsnarutorazPas encore d'évaluation

- Iso 8217: 2010 Fuel Standard For Marine Distillate Fuels: Parameter Unit Limit DMX DMA DMZ DMBDocument2 pagesIso 8217: 2010 Fuel Standard For Marine Distillate Fuels: Parameter Unit Limit DMX DMA DMZ DMBHUYQUYENPas encore d'évaluation

- ISO 8217 - 2012 Fuel StandardDocument2 pagesISO 8217 - 2012 Fuel Standardsh_gasimov100% (2)

- SFS SCO Diesel EN590 CIF Only For CAP Terry ZAGOKPROTDocument3 pagesSFS SCO Diesel EN590 CIF Only For CAP Terry ZAGOKPROTDeby Aprilucia Farahdevira100% (1)

- COMPANY PROFILE PT. TAWU INTI BAKU - 2019 VersionDocument22 pagesCOMPANY PROFILE PT. TAWU INTI BAKU - 2019 VersionTeknik MarinaPas encore d'évaluation

- Marine Distillate Fuels (MDF) Marine Residual Fuels (MRF)Document1 pageMarine Distillate Fuels (MDF) Marine Residual Fuels (MRF)ErwinMuellPas encore d'évaluation

- RastovicDocument4 pagesRastovictasosPas encore d'évaluation

- Marine Fuel OilDocument3 pagesMarine Fuel OiltasosPas encore d'évaluation

- International Standard ISO 8217: 1996: NotesDocument1 pageInternational Standard ISO 8217: 1996: NotesVilius BukysPas encore d'évaluation

- Bunker Fuel Oil Specifications2010Document5 pagesBunker Fuel Oil Specifications2010onejako12Pas encore d'évaluation

- DnvWebpage - Iso 8217 2010Document2 pagesDnvWebpage - Iso 8217 2010AutoModi THPas encore d'évaluation

- Rustrans Soft OfferDocument6 pagesRustrans Soft OfferMuhammed AliPas encore d'évaluation

- Manual Batch Records Mix Design ExcelDocument2 pagesManual Batch Records Mix Design ExcelIswantoPas encore d'évaluation

- ENCH607-ENPE625 Assignment-03 Fall 2020Document3 pagesENCH607-ENPE625 Assignment-03 Fall 2020Ghost RiderPas encore d'évaluation

- Fuel Oil SpecificationDocument7 pagesFuel Oil Specificationmichael_forraPas encore d'évaluation

- MC 30Document3 pagesMC 30kalina11042007Pas encore d'évaluation

- Bardahl XTC 5w30Document2 pagesBardahl XTC 5w30Feri FebriantoPas encore d'évaluation

- PI 015013 Agrisynth LSP 10w 40 enDocument2 pagesPI 015013 Agrisynth LSP 10w 40 enMabarf MenanaPas encore d'évaluation

- CPCB Effluent Discharge StandardsDocument9 pagesCPCB Effluent Discharge StandardsPavan Tamiri100% (1)

- Exxonmobil Marine Fuel OilDocument1 pageExxonmobil Marine Fuel OilPrinceSadhotraPas encore d'évaluation

- Pub Iso8217 Fuels SpecsDocument4 pagesPub Iso8217 Fuels SpecsARGONAFTISPas encore d'évaluation

- Presentation Transformer OilDocument44 pagesPresentation Transformer Oilravi_bagga2000100% (3)

- Fuel Lub #1Document141 pagesFuel Lub #1Hasan CosalevPas encore d'évaluation

- ASTM 6751 - 02: Astm ASTM 6751 Typical Biodiesel Test Description Test Method Biodiesel Soy & YGDocument1 pageASTM 6751 - 02: Astm ASTM 6751 Typical Biodiesel Test Description Test Method Biodiesel Soy & YGSergio Rodrigues BarbedoPas encore d'évaluation

- 7th International İstanbul Bunker Conference Chris Fisher PDFDocument39 pages7th International İstanbul Bunker Conference Chris Fisher PDFBatul KhuzemaPas encore d'évaluation

- High Speed DieselDocument1 pageHigh Speed DieselDika KiraPas encore d'évaluation

- Momentive RTV 630 TDS 2019Document7 pagesMomentive RTV 630 TDS 2019crushergaming1804Pas encore d'évaluation

- The Design of Rotary Kiln With Cyclonic Heat ExchangersDocument33 pagesThe Design of Rotary Kiln With Cyclonic Heat ExchangersAuliverKayMHPas encore d'évaluation

- Metalshield MC - 80NI1 SUITEDocument1 pageMetalshield MC - 80NI1 SUITEH_DEBIANEPas encore d'évaluation

- Zic Supervis AwDocument2 pagesZic Supervis AwMohammed Abdul GhafoorPas encore d'évaluation

- AlnovolDocument18 pagesAlnovolcasual12Pas encore d'évaluation

- Screenshot 2019-12-28 at 4.13.33 PMDocument10 pagesScreenshot 2019-12-28 at 4.13.33 PMDave Acang100% (1)

- Iso 8217 2010Document4 pagesIso 8217 2010Chamika Dilshan WickramawardenaPas encore d'évaluation

- Corning Fused Silica 7980Document4 pagesCorning Fused Silica 7980Mandi IndarsPas encore d'évaluation

- ASTM MethodsDocument9 pagesASTM MethodsLe Nguyen Phuc ThienPas encore d'évaluation

- 001TDS Bannoh 1500 QDDocument2 pages001TDS Bannoh 1500 QDali maulanaPas encore d'évaluation

- Ultra Mag enDocument8 pagesUltra Mag enAdmir TalicPas encore d'évaluation

- Silica For Adhesives BrochureDocument1 pageSilica For Adhesives BrochureSami KocahanPas encore d'évaluation

- Exxonmobil Marine Distillate Fuels PDFDocument2 pagesExxonmobil Marine Distillate Fuels PDFAntonPas encore d'évaluation

- Standar Mutu Biofuel: Pusat Penelitian Surfaktan Dan Bioenergi LPPM - IpbDocument37 pagesStandar Mutu Biofuel: Pusat Penelitian Surfaktan Dan Bioenergi LPPM - IpbMa'ruf NurwantaraPas encore d'évaluation

- List of Products Manufactured by Naftan OJSC: Aromatic HydrocarbonsDocument36 pagesList of Products Manufactured by Naftan OJSC: Aromatic HydrocarbonsAnonymous HoCqhQjPPas encore d'évaluation

- Corrosion and Fouling Control in Desalination IndustryD'EverandCorrosion and Fouling Control in Desalination IndustryPas encore d'évaluation

- Sebu6400-05 - Cat Gas EngineDocument48 pagesSebu6400-05 - Cat Gas EnginetamailhamPas encore d'évaluation

- Failure Studies in Materials - ch8Document47 pagesFailure Studies in Materials - ch8tamailhamPas encore d'évaluation

- Facility Design GuidelinesDocument418 pagesFacility Design GuidelinestamailhamPas encore d'évaluation

- Power Calculations For Pelton TurbinesDocument19 pagesPower Calculations For Pelton TurbinestamailhamPas encore d'évaluation

- Performance Analysis of SSFC For Power Quality Improvement in Wind Smart GridDocument4 pagesPerformance Analysis of SSFC For Power Quality Improvement in Wind Smart GriderpublicationPas encore d'évaluation

- Microgrid ThesisDocument163 pagesMicrogrid ThesisAshik AhmedPas encore d'évaluation

- Briggs & Stratton Model 091200 Illustrated Parts ListDocument20 pagesBriggs & Stratton Model 091200 Illustrated Parts Listb0beiiiPas encore d'évaluation

- Effizienzhausplus Elektromobil en Aufl1Document17 pagesEffizienzhausplus Elektromobil en Aufl1Wessel SimonsPas encore d'évaluation

- Step-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferDocument7 pagesStep-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferLuciano PereiraPas encore d'évaluation

- Physics Investigatory Project Class 12Document28 pagesPhysics Investigatory Project Class 12sumeet yadav0% (1)

- NIBE BrochureDocument36 pagesNIBE Brochurembreuer7484Pas encore d'évaluation

- Formula For Calculating Btu For A Room MetricDocument2 pagesFormula For Calculating Btu For A Room MetricRoland CepedaPas encore d'évaluation

- Lecture 7 Integration of Renewable Energy SourcesDocument48 pagesLecture 7 Integration of Renewable Energy Sourcesas2899142Pas encore d'évaluation

- Solar Water Pump Project ReportDocument45 pagesSolar Water Pump Project ReportDaya BindPas encore d'évaluation

- Home Energy Self AuditDocument9 pagesHome Energy Self AuditJorge RodriguezPas encore d'évaluation

- Amelia 2020 IOP Conf. Ser. Mater. Sci. Eng. 767 012052Document11 pagesAmelia 2020 IOP Conf. Ser. Mater. Sci. Eng. 767 012052ecom mPas encore d'évaluation

- NLB 225 Series F PumpDocument2 pagesNLB 225 Series F Pumpjromero_rpgPas encore d'évaluation

- 9 Non Conventional Power Plant BDocument3 pages9 Non Conventional Power Plant BJillian PadillaPas encore d'évaluation

- Pollen Collection E-BrochureDocument51 pagesPollen Collection E-BrochureĶĦĬåň ŴƏï ĜöħPas encore d'évaluation

- Upstream ChinaFocusS PDFDocument19 pagesUpstream ChinaFocusS PDFLow AlysPas encore d'évaluation

- 8016Document20 pages8016Zaanaa ZaanPas encore d'évaluation

- Lmop PartnersDocument1 035 pagesLmop PartnersEnggSolutionsPas encore d'évaluation

- What Is Sustainability in ConstructionDocument2 pagesWhat Is Sustainability in ConstructionLakmal DissanayakePas encore d'évaluation

- A Guide To Solar PV SystemsDocument24 pagesA Guide To Solar PV Systemserkamlakar2234100% (1)

- Lecture RadiationDocument16 pagesLecture Radiationzakibrant23Pas encore d'évaluation

- Start-Up Costs of Thermal Power Plants in Markets With Increasing Shares of Variable Renewable GenerationDocument6 pagesStart-Up Costs of Thermal Power Plants in Markets With Increasing Shares of Variable Renewable GenerationIkenna OnyegbaduePas encore d'évaluation

- Visco MeterDocument1 pageVisco MetercellPas encore d'évaluation

- Cep DerDocument4 pagesCep DerarshadPas encore d'évaluation

- TEN100: Test 02 - Study GuideDocument4 pagesTEN100: Test 02 - Study GuidenhstechnologyPas encore d'évaluation

- The President Post English Edition Januari 2018Document16 pagesThe President Post English Edition Januari 2018The President PostPas encore d'évaluation

- Nit 132 KVDocument386 pagesNit 132 KVamrit90320100% (2)

- Architecture Ebook Outstanding Wood Buildings - CWCDocument28 pagesArchitecture Ebook Outstanding Wood Buildings - CWCAc Arquitetos Associados50% (2)

- Voltage Regulation On Micro GridDocument61 pagesVoltage Regulation On Micro GridkarthikPas encore d'évaluation

- TECHNICAL DATA Cogeneration Unit IET BIO 520 V01 - 50Document7 pagesTECHNICAL DATA Cogeneration Unit IET BIO 520 V01 - 50Elias RizkPas encore d'évaluation