Académique Documents

Professionnel Documents

Culture Documents

91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PP

Transféré par

Edenson Flores TrujilloDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PP

Transféré par

Edenson Flores TrujilloDroits d'auteur :

Formats disponibles

Modeling Industrial Chemical Processes with MATLAB and

Simulink

By Ahmad Fani Yazdi, HUGO PETERSEN GmbH

Send email to Tony Lennon

Sulfuric acid is used in the manufacture of fertilizers, petrochemical products, synthetic fber, steel, and a wide range of other industrial

materials. Used acid and waste gases are recycled in processing plants that must meet stringent safety and environmental requirements

for working with these chemicals.

HUGO PETERSEN GmbH has a decades-long track record of engineering safe and effcient sulfuric acid and gas cleaning plants. Until

recently, however, our development process was highly labor-intensive. All preliminary design work and process modeling was done

using a complex system of spreadsheets. This manual approach slowed development and introduced the potential for human error.

Model-Based Design with MATLAB

and Simulink

has provided a cost-effective way to simplify and automate our design workfow by

enabling chemical process engineers and controls engineers to work in the same environment. While the chemical process engineers

model the complex thermodynamic and kinetic interactions within the plant, controls engineers model the control algorithms. The plant

and its control system can then be tested in dynamic and steady-state closed-loop simulations.

The new approach is 5 to 10 times faster than the spreadsheet-based approach, and much less susceptible to human error.

Too Complex for Spreadsheets

A typical sulfuric acid plant includes numerous subsystems, such as chemical reactors, heat exchangers, and absorption towers.

Calculating the thermodynamic and kinetic interactions within each subsystem is inherently diffcult. Capturing these processes in

spreadsheets compounded the challenge. Many manual steps were required: The outputs from one subsystem had to be copied to a new

spreadsheet for use as input to the next step in the process, and so on. A single error at one stage could throw off the results for the entire

process. With so many interconnected spreadsheets, it was diffcult to identify and fx such errors.

Creating a Library of Subsystem Models

The frst step in the new workfow was to create a library of reusable modules, one for each subsystem, which the chemical process

engineers could then combine in Simulink system models. To manage the overall complexity of our designs, we defned each module as a

MATLAB class, enabling us to apply object-oriented design patterns to the development of the entire library.

An absorption tower, for example, is defned as a MATLAB class, as are the fuid and gas streams that it takes as input. In the actual

tower, the gas enters at the bottom of a column and is partially absorbed by the liquid, which enters through the top of the tower and

runs down through the column. We modeled the thermodynamic and kinetic processes in MATLAB using the classes we had developed.

The classes perform all the operations that were previously done in spreadsheets, as well as several new calculations that were enabled by

the switch to MATLABfor example, calculation of the heat generated by the absorption of SO

3

in different concentrations of sulfuric

acid. The outputs of the absorption tower model, one gas object and one fuid object, capture the results and are used as input to the next

subsystem in the plant. Our process engineers can use the blocks by simply dragging and dropping them into the Simulink environment,

but they can also study the underlying MATLAB code and develop new MATLAB classes, as well as create new libraries in Simulink.

Simulating Chemical Processes

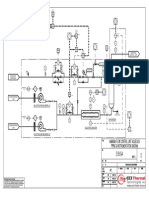

Using a library of MATLAB models for the key plant subsystems, our chemical process engineers can quickly build larger plant designs

in Simulink and simulate them. Several absorption towers, for example, can be connected in Simulink to form a larger absorption unit

(Figure 1).

See more articles and subscribe at mathworks.com/newsletters.

1

Figure 1. An absorption unit for a sulfuric acid plant modeled in Simulink.

Using the subsystem blocks in the library, the engineers can rapidly design and simulate sophisticated new plants, assess changes to

existing plants, or evaluate new processes. For example, they might link two chemical reactors and a static mixer for quench gas (Figure

2). Sensors can be included to monitor temperature, pressure, fow, and other variables throughout the simulation.

Figure 2. A converter comprising two chemical reactors and a static mixer for quench gas.

Simulations enable the engineers to visualize key aspects of the process (Figure 3) and help ensure that it complies with environmental

regulations. For example, if the air has not been treated suffciently to meet regulatory standards, this condition is fagged with a red

marker, which indicates that further treatment or other changes to the process may be required.

Figure 3. A sample visualization: plot of oxidation versus temperature for sulfur dioxide processing.

2

Once the chemical process engineers have designed, simulated, and verifed the entire process in Simulink, they use Spreadsheet Link

EX to export the simulation results to a Microsoft

Excel

spreadsheet (Figure 4). This report typically includes the dimensions of the

various subsystems, as well as fow rates, temperatures, and pressures at key points in the process. It is shared with the HUGO

PETERSEN customer who initiated the project, the construction team that will build the plant, and the suppliers who will provide

components. A supplier of blowers, for example, can determine the size and type of blower needed by extracting the relevant fow rate

and gas density from the report.

Figure 4. Spreadsheet showing results from a Simulink simulation of a plant process.

Simulating Control Systems and Plant Startups

To verify the control algorithms, engineers combine the control system model with the plant model and run closed-loop simulations.

These simulations enable both teams to assess the steady-state and dynamic performance of the entire plant. They can simulate startup

and shutdown procedures, as well as faults and hazardous conditions that would be diffcult or unsafe to test on an actual plant.

We continue to use the system model during the plant startup process. If the onsite feld engineers need to know how the plant will

behave under specifc conditions, we run a simulation back at the offce and send them the results. This greatly reduces the risk inherent

in startups because the team knows that the steps they are about to perform will work as expected.

From Ideas to Production

Model-Based Design with MATLAB and Simulink has enabled us to evaluate many design ideas for each project. Because the designs we

create are fexible, we can quickly respond to changing customer requirements. The shared environment has improved communication

between the control and chemical process engineers, making it easy to collaborate to solve problems and optimize performance.

Overall, MATLAB and Simulink have enabled us to cut costs and reduce development time by a factor of 5 to 10. We have designed and

simulated systemsincluding the largest oleum plant in the worldthat were far too complex to handle with our spreadsheet-based

approach. Just as importantly, quality has increased, as we now can fnd and eliminate errors much faster.

This approach has made it easier to demonstrate plants and new design concepts to our customers. We can simulate a model of a

production plant and show that the simulation results match the actual performance of the plant. This gives new customers a great deal

of confdence in our ability to design and deliver a plant to their specifcations.

3

Products Used

MATLAB

Simulink

Spreadsheet Link EX

Learn More

Model-Based Design for Process Automation Systems and

Industrial Controls

Modeling and Advanced Control Strategies for the Process

Industries

See more articles and subscribe at mathworks.com/newsletters.

Published 2012

91988v00

mathworks.com

2012 The MathWorks, Inc. MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See www.mathworks.com/trademarks

for a list of additional trademarks. Other product or brand names may be trademarks or registered trademarks of their respective holders.

4

Vous aimerez peut-être aussi

- Topic 1Document10 pagesTopic 1Swfian ۦۦPas encore d'évaluation

- Modeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideD'EverandModeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuidePas encore d'évaluation

- Assignmaint 1Document4 pagesAssignmaint 1sumitPas encore d'évaluation

- Aspen Hysys SimulationDocument5 pagesAspen Hysys SimulationEngr Mohammad FarhanPas encore d'évaluation

- Gasification Process ModelingDocument6 pagesGasification Process ModelingRebeca Santamaria MedelPas encore d'évaluation

- Modelling of Displacement Compressors Using MATLABDocument10 pagesModelling of Displacement Compressors Using MATLABayub anggoroPas encore d'évaluation

- The Applications of Chemical Engineering Simulation SoftwareDocument9 pagesThe Applications of Chemical Engineering Simulation Softwarekatya ammanuelPas encore d'évaluation

- Modelling of Displacement Compressors Using MATLAB/Simulink SoftwareDocument10 pagesModelling of Displacement Compressors Using MATLAB/Simulink SoftwarerezaPas encore d'évaluation

- 5-1 Introduction:: Chapter Five Process SimulationDocument10 pages5-1 Introduction:: Chapter Five Process SimulationNoon Abdallah AbdalroufPas encore d'évaluation

- Model Based Systems Engineering For Aircraft Systems - How DoesDocument9 pagesModel Based Systems Engineering For Aircraft Systems - How DoesAlmas QasimPas encore d'évaluation

- Real Time Simulation of Complex Automatic Transmission ModelsDocument20 pagesReal Time Simulation of Complex Automatic Transmission ModelsSudev NairPas encore d'évaluation

- BS09 0652 659Document8 pagesBS09 0652 659Nadia DelibasicPas encore d'évaluation

- Modelling and Dynamic Simulation of Processes With MATLAB'. An Application of A Natural Gas Installation in A Power PlantDocument12 pagesModelling and Dynamic Simulation of Processes With MATLAB'. An Application of A Natural Gas Installation in A Power PlantyacobaschalewPas encore d'évaluation

- Processes: Operator Training Simulator For An Industrial Bioethanol PlantDocument19 pagesProcesses: Operator Training Simulator For An Industrial Bioethanol PlantAL-JABERI SADEQ AMEEN ABDO / UPMPas encore d'évaluation

- Simulation of Plant Scale ManufacturingDocument6 pagesSimulation of Plant Scale ManufacturingTim ChegePas encore d'évaluation

- Rigrous Heat Exchanger SimulationDocument6 pagesRigrous Heat Exchanger SimulationJayakumar PararasuramanPas encore d'évaluation

- The Applications of Engineering Simulation SoftwareDocument10 pagesThe Applications of Engineering Simulation Softwarekatya ammanuelPas encore d'évaluation

- Application of Process Simulation Software METSIMDocument7 pagesApplication of Process Simulation Software METSIMBart FrienderPas encore d'évaluation

- Chemical Engineering Process SimulationD'EverandChemical Engineering Process SimulationÉvaluation : 4 sur 5 étoiles4/5 (13)

- Gridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsDocument8 pagesGridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsIrfan Akbar BarbarossaPas encore d'évaluation

- Industrie 4.0 With MS-Excel?: Chemical EngineeringDocument6 pagesIndustrie 4.0 With MS-Excel?: Chemical EngineeringRyanPas encore d'évaluation

- IPTC-17255-MS RasGas Experience With Production Optimisation System, A Success Story PDFDocument11 pagesIPTC-17255-MS RasGas Experience With Production Optimisation System, A Success Story PDFDenis GontarevPas encore d'évaluation

- A New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkDocument15 pagesA New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkPrashant IngalePas encore d'évaluation

- M.Anas Assigment #2 SimulationDocument10 pagesM.Anas Assigment #2 SimulationMubasher RajputPas encore d'évaluation

- Computer-Controlled Systems: Theory and Design, Third EditionD'EverandComputer-Controlled Systems: Theory and Design, Third EditionÉvaluation : 3 sur 5 étoiles3/5 (4)

- pl4 PDFDocument23 pagespl4 PDFDhairyashil SantrePas encore d'évaluation

- Hydrocarbon Engineering Nov 2004Document4 pagesHydrocarbon Engineering Nov 2004quinteroudinaPas encore d'évaluation

- Hanif Assigment #2 SimulationDocument10 pagesHanif Assigment #2 SimulationMubasher RajputPas encore d'évaluation

- Aspen Plus, Reaction Engineering and DesignDocument45 pagesAspen Plus, Reaction Engineering and Designnikhilgoyal4100% (1)

- Comsol Multiphysics SimulationDocument14 pagesComsol Multiphysics SimulationNaveen Kumar MadasettyPas encore d'évaluation

- Power Plant Simulator For OperatorsDocument2 pagesPower Plant Simulator For Operatorsalbert100% (1)

- 7997-Article Text PDF-16627-3-10-20151223 PDFDocument5 pages7997-Article Text PDF-16627-3-10-20151223 PDFMurali MuthuPas encore d'évaluation

- Individual Design Portfolio Task SheetDocument3 pagesIndividual Design Portfolio Task SheetMax Yee Min JueyPas encore d'évaluation

- Unit-VI-APP HYSYS FLUENT PDFDocument11 pagesUnit-VI-APP HYSYS FLUENT PDFVikas MishraPas encore d'évaluation

- Real-Time Simulation of Physical Systems Using Sim PDFDocument14 pagesReal-Time Simulation of Physical Systems Using Sim PDFاسعد البصريPas encore d'évaluation

- Advanced Simulations of Building Energy and Control Systems With An Example of Chilled Water Plant ModelingDocument2 pagesAdvanced Simulations of Building Energy and Control Systems With An Example of Chilled Water Plant ModelingyalllikPas encore d'évaluation

- Wetter DviDocument11 pagesWetter DviRita KimPas encore d'évaluation

- Combined-Cycle Plant Simulation Toolbox For Power Plant SimulatorDocument13 pagesCombined-Cycle Plant Simulation Toolbox For Power Plant Simulatorsor_68mPas encore d'évaluation

- Moshe Article PDFDocument16 pagesMoshe Article PDFicingrockPas encore d'évaluation

- Design of Embedded Controller Using Hybrid Systems For Integrated Building SystemsDocument13 pagesDesign of Embedded Controller Using Hybrid Systems For Integrated Building SystemsCarlos David Paniagua GomezPas encore d'évaluation

- WP Flow Simulation Gas MixingDocument5 pagesWP Flow Simulation Gas MixingpengkritikPas encore d'évaluation

- Intro To LV in S For Control and SimDocument76 pagesIntro To LV in S For Control and SimAdriano NavarroPas encore d'évaluation

- Simulation: Software Used For Chemical Design and SimulationDocument3 pagesSimulation: Software Used For Chemical Design and SimulationMubasher RajputPas encore d'évaluation

- Optimization Mueller-Rochow SynthesisDocument8 pagesOptimization Mueller-Rochow Synthesissahcristine3968Pas encore d'évaluation

- Hydraulics Simulation in MatlabDocument75 pagesHydraulics Simulation in MatlabCarla BarronPas encore d'évaluation

- Assignment 4 Rishab MatlabDocument7 pagesAssignment 4 Rishab MatlabBABAJIPas encore d'évaluation

- Computational Fluid Mechanics Simulation and Computation With Gambit and FluentDocument69 pagesComputational Fluid Mechanics Simulation and Computation With Gambit and FluentYush KumarPas encore d'évaluation

- Comsol Multiphysics 5.1.0.180 (Update2) PDFDocument4 pagesComsol Multiphysics 5.1.0.180 (Update2) PDFsoparjuandegarayPas encore d'évaluation

- 1 IntroductionDocument22 pages1 IntroductionMekoninn HylemariamPas encore d'évaluation

- Integrate Process Simulation and Process Synthesis - DesbloqueadoDocument5 pagesIntegrate Process Simulation and Process Synthesis - DesbloqueadoVictor Heredia MattaPas encore d'évaluation

- HYSYS Simulation of Chemical Process EquipmentsDocument8 pagesHYSYS Simulation of Chemical Process Equipmentshamidrezaee008Pas encore d'évaluation

- Comparing Pressure Flow Solvers For Dinamic SimulationDocument24 pagesComparing Pressure Flow Solvers For Dinamic SimulationEdgar HuancaPas encore d'évaluation

- HydraulicsLibraryTutorial PDFDocument104 pagesHydraulicsLibraryTutorial PDFAnonymous Hy5Ir9QX100% (1)

- Aspen Plus - Module IDocument193 pagesAspen Plus - Module IHafeez Ahmad50% (2)

- Development of Ethyl Acetate Process TechnologyDocument20 pagesDevelopment of Ethyl Acetate Process TechnologyKaycelyn Bacay100% (1)

- Unmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef14/2020-I Chapter 1. Diagrams For Understanding Chemical ProcessesDocument4 pagesUnmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef14/2020-I Chapter 1. Diagrams For Understanding Chemical ProcessesKevin Javier QuispePas encore d'évaluation

- AMOSS: A Bespoke Stochastic Simulation Environment Built On Open Source SoftwareDocument6 pagesAMOSS: A Bespoke Stochastic Simulation Environment Built On Open Source SoftwareMusa MohammadPas encore d'évaluation

- Symbolic Incorporation of External Procedures Into Process Modeling EnvironmentsDocument37 pagesSymbolic Incorporation of External Procedures Into Process Modeling EnvironmentsAMITH OKPas encore d'évaluation

- ABSIM - Modular Simulation of Advanced Absorption SystemsDocument13 pagesABSIM - Modular Simulation of Advanced Absorption Systemsamirdz76Pas encore d'évaluation

- SPE 136126 Realising Opportunities Using Integrated Production Modelling in Occidental of Sultanate of OmanDocument19 pagesSPE 136126 Realising Opportunities Using Integrated Production Modelling in Occidental of Sultanate of OmanMahfoud AMMOURPas encore d'évaluation

- Inferential Control System of Distillation Compositions Using Dynamic Partial Least Squares RegressionDocument10 pagesInferential Control System of Distillation Compositions Using Dynamic Partial Least Squares RegressionEdenson Flores TrujilloPas encore d'évaluation

- Urea Infrastructure Project: Power Utility - North CarolinaDocument1 pageUrea Infrastructure Project: Power Utility - North CarolinaEdenson Flores TrujilloPas encore d'évaluation

- HHO GeneratorDocument35 pagesHHO GeneratorANVPas encore d'évaluation

- Batch DistillationDocument197 pagesBatch DistillationKrishanu SahaPas encore d'évaluation

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaPas encore d'évaluation

- Inferential Control: Lack of MeasurementDocument11 pagesInferential Control: Lack of MeasurementEman El DsoukyPas encore d'évaluation

- Ammonia Vaporization DrawingsDocument3 pagesAmmonia Vaporization DrawingsEdenson Flores TrujilloPas encore d'évaluation

- Ammonia Handling Manual PDFDocument14 pagesAmmonia Handling Manual PDFEdenson Flores TrujilloPas encore d'évaluation

- 04 Carbon Dioxide Absorption Into Aqueous Blends ofDocument15 pages04 Carbon Dioxide Absorption Into Aqueous Blends ofEdenson Flores TrujilloPas encore d'évaluation

- Diaz, ControlDocument179 pagesDiaz, ControlEdenson Flores TrujilloPas encore d'évaluation

- Computer Programming DR - Zaidoon - PDF Part 2Document104 pagesComputer Programming DR - Zaidoon - PDF Part 2Carlos Salas LatosPas encore d'évaluation

- Antennas - 2014 PDFDocument34 pagesAntennas - 2014 PDFEdenson Flores TrujilloPas encore d'évaluation

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaPas encore d'évaluation

- 04 Carbon Dioxide Absorption Into Aqueous Blends ofDocument15 pages04 Carbon Dioxide Absorption Into Aqueous Blends ofEdenson Flores TrujilloPas encore d'évaluation

- 1ammonium Nitrate IndustrialDocument2 pages1ammonium Nitrate IndustrialEdenson Flores TrujilloPas encore d'évaluation

- Aspen-Hysys Simulation of Sulfuric Acid PlantDocument3 pagesAspen-Hysys Simulation of Sulfuric Acid PlantacckypenrynPas encore d'évaluation

- 1ammonium Nitrate IndustrialDocument2 pages1ammonium Nitrate IndustrialEdenson Flores TrujilloPas encore d'évaluation

- Divisor de Frecuencia de 50MHz A 1Hz para Parpadeo de LEDDocument2 pagesDivisor de Frecuencia de 50MHz A 1Hz para Parpadeo de LEDepievegaPas encore d'évaluation

- Simzlab Eula - TXT 8/10/08 11:51 PMDocument6 pagesSimzlab Eula - TXT 8/10/08 11:51 PMpeteryu1028Pas encore d'évaluation

- journalTechV10N2 Aticle11Document9 pagesjournalTechV10N2 Aticle11dhavaleshPas encore d'évaluation

- RFCC Process Technology Manual PDFDocument779 pagesRFCC Process Technology Manual PDFSagar Srinivas100% (8)

- Ecre CD-CH10Document30 pagesEcre CD-CH10nickmarinov1Pas encore d'évaluation

- Is Oxidative Coupling The Royal Road For The Valorization of Methane To Olefines?Document50 pagesIs Oxidative Coupling The Royal Road For The Valorization of Methane To Olefines?anon_936836736Pas encore d'évaluation

- Batch ReactorDocument28 pagesBatch ReactorNur Afifah IIPas encore d'évaluation

- CP Marlin Book Chapters 1 - 2Document44 pagesCP Marlin Book Chapters 1 - 2David pollitoPas encore d'évaluation

- Intensifying Multiphase Reactions and Reactors: Strategies and ExamplesDocument16 pagesIntensifying Multiphase Reactions and Reactors: Strategies and ExamplesMuhammad Arsalan AshrafPas encore d'évaluation

- Temperature Control of Fluidized Bed Reactor PDFDocument8 pagesTemperature Control of Fluidized Bed Reactor PDFJacob SchmidtPas encore d'évaluation

- SWECs External 9 Apr 2021Document230 pagesSWECs External 9 Apr 2021Fisah WanPas encore d'évaluation

- 2010 BT Chem 01,02 PDFDocument8 pages2010 BT Chem 01,02 PDFAtif MehfoozPas encore d'évaluation

- Reactor Design IIDocument68 pagesReactor Design IIKORAMA KIEN0% (1)

- Project AramDocument13 pagesProject AramAram Nasih MuhammadPas encore d'évaluation

- Alat & Mesin Pengolahan Industri Hilir: Pertemuan 2# Teknik Kimia - Politeknik LPP Saptyaji HarnowoDocument20 pagesAlat & Mesin Pengolahan Industri Hilir: Pertemuan 2# Teknik Kimia - Politeknik LPP Saptyaji HarnowoJeri AlexPas encore d'évaluation

- Global Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry CatalystDocument7 pagesGlobal Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry Catalystkrishna_nimeshPas encore d'évaluation

- KineticsDocument1 pageKineticsWinsletJoyDauagPas encore d'évaluation

- Articulo 04Document9 pagesArticulo 04Alexis GoicocheaPas encore d'évaluation

- Residence - Time DistributionDocument9 pagesResidence - Time DistributionNik Nur Izzatul IkmalPas encore d'évaluation

- LECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene OxideDocument7 pagesLECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene Oxideمحمود محمدPas encore d'évaluation

- All About EnginesDocument1 pageAll About EnginesMandi BozoPas encore d'évaluation

- MBBR Wastewater Treatment Processes: Harlan H. Bengtson, PHD, P.EDocument48 pagesMBBR Wastewater Treatment Processes: Harlan H. Bengtson, PHD, P.ELouay Mansour100% (2)

- Dehydration of 2 3-Butanediol To Mek.3Document11 pagesDehydration of 2 3-Butanediol To Mek.3hidayahPas encore d'évaluation

- Simulation of The Industrial Fixed Bed Catalytic RDocument6 pagesSimulation of The Industrial Fixed Bed Catalytic RSebasstian GomezPas encore d'évaluation

- Ch. 1 Enviromental EngineeringDocument25 pagesCh. 1 Enviromental Engineeringbob100% (6)

- CPP Lab 1 MuahDocument16 pagesCPP Lab 1 Muahelynnmasrof100% (1)

- Thermo Catalytic Degradation of Low Dens PDFDocument11 pagesThermo Catalytic Degradation of Low Dens PDFDANIELA FERNANDES DA CUNHAPas encore d'évaluation

- Sulfonation of by So3Document4 pagesSulfonation of by So3International Journal of Advance Research and Innovative Ideas in EducationPas encore d'évaluation

- Chapter 1 - Reaction Kinetics of HeterogenousDocument68 pagesChapter 1 - Reaction Kinetics of HeterogenousFhan Sani SeowPas encore d'évaluation

- Kinetics of Ethane PyrolysisDocument11 pagesKinetics of Ethane PyrolysisErika ScheelePas encore d'évaluation

- Refinery Process DescriptionDocument24 pagesRefinery Process DescriptionjeyalaksPas encore d'évaluation

- A Project Report On Linear Alkyl Benzene (L.A.B.) : Pritesh S. Chauhan (CH-09)Document131 pagesA Project Report On Linear Alkyl Benzene (L.A.B.) : Pritesh S. Chauhan (CH-09)Navjyot Singh100% (1)