Académique Documents

Professionnel Documents

Culture Documents

Design of Multiloop Controller For

Transféré par

ijscCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of Multiloop Controller For

Transféré par

ijscDroits d'auteur :

Formats disponibles

International Journal on Soft Computing (IJSC) Vol. 5, No.

2, May 2014

DOI: 10.5121/ijsc.2014.5202 11

DESIGN OF MULTILOOP CONTROLLER FOR

THREE TANK PROCESS USING CDMTECHNIQUES

N. Kanagasabai

1

and N. Jaya

2

1,2

Department of Instrumentation Engineering,Annamalai University,

Annamalainagar, 608002, India

ABSTRACT

In this study the controller for three tank multi loop system is designed using coefficient Diagram

method. Coefficient Diagram Method is one of the polynomial methods in control design. The

controller designed by using CDM technique is based on the coefficients of the characteristics

polynomial of the closed loop system according to the convenient performance such as equivalent

time constant, stability indices and stability limit. Controller is designed for the three tank process

by using CDM Techniques; the simulation results show that the proposed control strategies have

good set point tracking and better response capability.

KEYWORDS

Coefficient diagram method, three tank, multiloop, CDM-PI

1. INTRODUCTION

Most of the processes industry in power plants, refinery process, aircrafts and chemical industries

are multivariable or multi-input multi-output (MIMO) and control of these MIMO processes are

more complicated than SISO processes. The strategies are used to design a controller for the Single

input and single output (SISO) process cannot be applied for Multi input and multi output (MIMO)

process because of the more interaction between the two loops. The different methods have been

presented in the literature for control [1] of MIMO process. Proportional-integral-derivative (PID)

or Proportional-Integral (PI) based controllers are used very commonly to control three tank

systems. Generalized synthesis method used to tuning the controller parameters. Generally the two

types of control schemes are available to control the MIMO processes. The first control scheme or

multiloop control scheme, where single loop controller are used to in the form of diagonal matrix is

one.. The second scheme is a [3] multivariable controller known as the centralized controller.

Matrix is not a diagonal one.

In this paper, the Coefficient Diagram Method (CDM) can be used to design a controller for MIMO

process. Now the CDM is well established approach to design a controller, which provides an

outstanding time domain characteristics of closed loop systems. Basically the CDM is based on

pole assignment, which can locate of the closed-loop system are used to obtained the predetermined

values. Although it has been used to demonstrate the design based on CDM. It has some robustness

and is possible to see that of the smooth response without oscillation in change in the model of the

process exists.

2. COEFFICIENT DIAGRAM METHOD

The CDM design procedure is quiet easily understandable, efficient and useful. Therefore, the

coefficients of the CDM controller polynomials which can be determined more easily than the PID

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

12

controller strategies. The CDM design procedure efficient design method (CDM) is possible to

design very good controllers with less effort and easy when compared with the other method, under

the conditions of stability, time domain performance and robustness. The transfer function of the

numerator and denominator of the system are obtained independently according to stability and

response requirements.. Generally the order of the controller designed by CDM is lower than the

order of the plant. when using the PI controller for the first order plant, the order of the controller is

equal to the order of the plant, and for the second order plant, the order of the controller is lower

than the order of the plant equal to one .The parameters are stability index

i

equivalent time

constant and stability limit

i

*

which represent the desired performance. The basic block diagram

of the CDM design for a single-input-single-output system is shown in Fig. 1.Where y is the output

signal, r is the reference signal, u is the controller signal and d is the external disturbance signal.

N(s) and D(s) are to be numerator and Denominator of the plant transfer function. A(s) is the

denominator polynomial of the controller transfer function, F(s) and B(s) are called the reference

numerator and the feedback numerator polynomials of the controller transfer function. The CDM

controller structure they are similar to each other. It has Two Degree of Freedom (2DOF) control

structure because of two numerators in controller transfer function. The system output is given by

d

P(s)

A(s)N(s)

r

P(s)

(s) N(s)F

(s) y + (1)

P(s) =A(s) D(s) +B(s) N(s) =

n

0 i

i

i

s a (2)

Where P(s) is the characteristics polynomial of the closed loop system. The CDM design

parameters with respect to the characteristic polynomial coefficient which are equivalent time

constant , stability index

i

and stability limit

i

are defined as

0

a

1

a

(3a)

1 i ,

1 i

a

1

i

a

2

i

a

i

+

~(n-1),

n

0

(3b)

i

*

=

+ (3c)

Fromequation (3a - 3c), the coefficients a

i

and the target characteristic polynomial P

target

(s) is given

by

a

i

=

0

a

i

Z

0

a

1 i

1 j

j

j i

(4)

P

target(s)

=a

0

(5)

|

|

|

|

,

_

+ +

1 s

n

2 i

i

s) (

1 i

1 j

j i

j

1

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

13

Fig.1: Basic block diagram of CDM

3 .CONTROLLER DESIGN USING CDM

Many of the processes in industry are described as First order process with time delay (FOPTD)

Gp (s) =

s

e

1 s

p

Kp

+

(6)

Where k

p

is process gain is time constant and is time delay. Since the transfer function of the

process is of two polynomials, one is numerator polynomial N(s) of degree m and other is the

denominator polynomial D(s) of degree n where m n, the CDM controller polynomial A(s) and

B(s) of structure shown in Fig 1are represented by

A (s) =

i

q

0 i

i

p

0 i

i

i

S k B(s) and s l

(7)

The controller to be realized for the condition p q must be satisfied. For a better performance the

degree of controller polynomial chosen is important. The controller polynomial for FOPTD process

with numerator Taylors approximation is chosen as

A(s) = s (8a)

B(s) = k

1

s +k

0

(8b)

The determination of the coefficient of the controller polynomial in CDM pole-placement method

is used. The feedback controller is chosen by pole-placement technique then a feed forward

controller is determined so as to match the closed loop system steady-state gain . Hence, a

polynomial depending on the parameters k

i

and l

i

is obtained. Then, a target characteristic

polynomial P

target(s)

is obtained by placing the design parameters into Eqn 5. Equating these two

polynomials is obtained, which is known to be Diophantine equation.

A(s) D(s) + B(s) N(s) = P

target

(s) (9)

Solve these equations the controller coefficient for polynomial A(s) and B(s) is found .The

numerator polynomial F(s) which is defined as pre-filter is chosen to be

F(s) = P(s)/N(s) |

S=0

= P (0)/N (0) (10)

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

14

This way, the value of the error that may occur in the steady-state response of the closed loop

system is reduced to zero. Thus, F(s) is computed by

F(s) = P(s)/N(s) |

S=0 =

1/k

p

(11)

4. CDM-PI CONTROLLER

The transfer function model of conventional PI controller is

G

c

(s) = kc (1+ ) (12)

The controller gain kc and integral time Ti are relevant with polynomial coefficient as k

1

=kc and

k

0

=kc/Ti . By applying the CDM, the values of k1 and K

0

can be calculated as follows:

1) To find the equivalent time constant

2) The stability index

1

= 3,

2

= 4.5 are used.

3) From the Eqn.(2), derive the characteristic polynomial with the PI controller stated in Eqn (12)

and equates to the characteristic polynomial obtained from Eqn(14). Then the parameters k1and K

0

of the PI controller are obtained.

4) Chose the pre-filter B(s) = K

0

and G

f

(s) is feed forward controller

G

f

(s) =

1 s

i

T

1

1 s

1

k

0

k

B(s)

F(s)

+

+

(13)

Fig.2: Equivalent block diagram of CDM

5. THREE TANK PROCESS

The three-tank process taken for study [6] is shown in Fig 2. The controlled variables are the level

of the tank1 (h1) and level of the tank3 (h3)and Manipulated variables are in flow of tank1 (fin1)

and in flow of tank3 (fin3). The steady state operating data of the Three-tank system is given in

Table1. The material balance equation for the above three-tank system is given by

h2) 2g(h1

s1

Az1

s1

fin1

dt

dh1

(14)

h3) 2g(h2

s2

Az3

h2) 2g(h1

s2

AZ1

dt

dh2

+

(15)

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

15

2gh3

s3

Az2

h3) 2g(h2

s3

Az3

s3

fin3

dt

dh3

+ +

(16)

Fig.3: Schematic diagram of three tank process

6. SIMULATION RESULTS AND DISCUSSION

In this work, the coefficient diagram method based control system is considered for the three tank

system under nominal operating conditions. The main objective of this process is to control the

level of Tank1 and Tank3. The coefficient diagram method is designed based on the thorough

knowledge of the three tank process. Also the PI controller parameters for the interacting three tank

process are obtained by utilizing direct synthesis method. The controller parameters of three tank

system are obtained by using direct synthesis method for the closed loop system. The controller

settings for loop1 Kc1=1.24137, Ti1=1336.5 and for loop2 Kc2=1.4589, Ti2=1315.5.The multi

loop CDMPI controller is obtained with time constant =10 and found to be Kc1=2.1720,

Ti1=0.111and timeconstant=15 Kc2=4.1284 Ti2=0.1113 for loop 1 and loop2 respectively.

The open loop response of the process is shown in Fig.4.The closed loop response of the three tank

process for a set point change in tank1 from its operating value of 0.7m to 1m is shown in Fig.5 and

its corresponding effect of interaction in tank3 .Fig. 6 shows the closed loop response of tank3 for

a set point change of 0.3 m to1.0 from its operating value and its corresponding effect of interaction

in tank1 and their values are tabulated in Table 2. With same operating conditions, a simulations

runs are carried out for direct synthesis based three tank processes for comparative study. The

simulated servo responses are stored in Fig .7 and Fig 8. The performance indices are calculated in

terms of settling time, Integral Square Error (ISE) and Integral Absolute Error (IAE) and values are

Table.1 Steady state operating parameters of three tank process

h1, h2, h3 in m 0.7,0.5,0.3

fin1 and fin3 in ml/sec 100

Outflow coefficient

(Az1, Az2, Az3)

2.251e-5,3.057e-5

,2.307e-5

Area of tank (S1-S3)in m

2

0.0154

Acceleration due to gravity in

m/sec

2

9.81

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

16

charted in Table 2. From the table it is observed that intelligent fuzzy control system gives

satisfactory performance than the PI controller. The servo and regulatory responses are plotted in

Fig .9 to 12.The servo tracking and regulatory responses are plotted in Fig. 13 to 16. The

performances of these controllers are evaluated and tabulated in Table 6. From the table, it is

clearly indicates that the control augmented the control system is considerably reduced the effect of

load disturbance in the process variable compared to the PI controller.

Fig 4. Open loop Response of the three tank process

Fig5. Closed loop response of three tank process with set Point change

in Tank-1(Conventional PI-Controller)

Fig6. Closed loop response of three tank process With set point change

inTank-3(Conventional PI-Controller)

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

17

Fig7.Closed loop response of three tank process with set point change

in Tank-1(CDM-PI) Controller

Fig8. Closed loop response of three tank process With set point change

in tank-3(CDM-PI) Controller

Fig9. Servo tracking response of three tank process

in Tank-1(Conventional PI-Controller)

Fig10.Servo tracking response of three tank process

in Tank-3(Conventional PI-Controller)

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

18

Fig11. Servo tracking response of three tank process

in Tank-1(CDM-PI) Controller

Fig12 .Servo tracking response of three tank process

in Tank-3(CDM-PI) Controller

Fig13. Servo tracking and Regulatory response of three tank process

in Tank-1Conventional PI-Controller

Fig14. Servo tracking and Regulatory response of three tank process

inTank-3Conventional PI-Controller)

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

19

Fig15. Servo tracking and Regulatory response of three tank process in

Tank1 (CDM-PI) Controller

Fig16. Servo tracking and Regulatory response of three tank process in

Tank-3(CDM-PI) Controller

Table.2 Performance and evaluation of the controllers

Controller

scheme

Controller Parameters

LOOP-1 LOOP-2

ts ISE IAE ts ISE IAE

PI

Controller

2.5 0.01813 0.084 3 0.005283 0.0548

2.25 0.01961 0.108 3.3 0.007632 0.1822

2.75 0.1454 0.204 3.5 0.18759 0.439

2.70 1.4576 0.555 3.0 2.466 0.675

CDM-PI

Controller

0.9 0.001683 0.009099 0.7 0.0001612 0.0001627

0.8 0.002002 0.01281 0.65 0.0003276 0.004079

0.75 0.003767 0.03467 0.8 0.003426 0.004567

0.95 0.7890 0.05678 0.9 0.98675 0.06326

International Journal on Soft Computing (IJSC) Vol. 5, No. 2, May 2014

20

7. CONCLUSION

In this work the Multiloop CDM-PI controller is designed for three tank process and compared with

the conventional PI controller designed by Synthesis tuning method through simulation. The ts,

ISE and IAE are taken as performance indices. The superiority of the CDM-PI control is analyzed

and clearly shows that more potential advantages of using CDM-PI control for a three tank process.

The control technique has a good set point tracking without any offset with better settling time. The

comparison of these above two controllers clearly shows that CDM-PI controller is superior

resulting in smoother controller output without oscillations which would like increase the actuator

life.

8. REFERENCES

[1] S.Abraham Lincon., D.Sivakumar., J.Prakash State and Fault Parameter Estimation Applied To

Three-Tank Bench Mark Relying On Augmented State Kalman Filter., ICGSTACSE Journal, Volume

7, Issue 1, May 2007.

[2] M.Zhaung and D.P. Atherton (1994), PID controller design for TITO system, IEEP process controls

Theory Appl., Vol. 141 no.2pp 111-120.

[3] A. Niderlinski (1971), A heuristic approach to the design of linear multivariable integrating control

system, Automatica, vol.7, 691-701.

[4] P.J. Cawthrop (1987), Continuous-Time self-Tuning Control, Vol.1-Design, Research Studies

Press, Letchworth, UK.

[5] Q.G. Wang, B. Zou, T.H. Lee andQ. Bi (1996), Auto tuning of multivariable PID controllers from

decentralized relay feedback, Automatica, vol.33, no.3, pp49-55.

[6] S. Majhi (2001), "SISO controller for TITO systems", presented at the Int. Can on Energy. Automation

and information Tech.

[7] S.Skogestad, I.Postlehwaite (1996), Multivariable Feedback Control Analysis and Design, John

Wiley & Sons Chichester.

[8] S.Manbe (1998), Coefficient Diagram Method, Proceedings of the 14th IFAC Symposium on

Automatic Control in Aerospace, Seoul.

[9] KAstrom and T. Hagglund (1995), PID Controllers: Theory Design and Tuning, Instrument Society

of America, 2nd Edition.

[10] I. Kaya (1995), Auto tuning of a new PI-PD Smith predictor based on time domain specifications,

ISA Transactions, vol.42 no.4, pp. 559-575.

[11] S.Manabe (1994), A low cost inverted pendulum system for control system education, Proc. of the

3rd IFAC Symp. On advances in control Education, Tokyo.

[12] A.Desbiens, A. Pomerlau and D. Hodouin (1996), Frequency based tuning of SISO controller for

two by-two processes, IEE Proc. Control Theory Appl., Vol .143, pp 49-55.

[13] M.Senthilkumar and S. Abraham Lincon (2012), Design of stabilizing PI controller for coupled tank

MIMO process, International Journal of Engineering Research and Development, Vol.3 no. 10: pp.

4755.

[14] S.E Hamamci, I. Kaya and M.Koksal (2001), Improving performance for a class of processes using

coefficient diagram method, presented at the 9th Mediterran conference on control, Dubrovnik.

[15] S.E. Hamamci (2004), Simple polynomial controller design by the coefficient diagram

method,WSEAS Trans. on Circuits and Systems, v.3, no.4, pp.951-956.

[16] S.E. Hamamci and M. Koksal (2003), Robust controller design for TITO systems with Coefficient

Diagram Method s, CCA 2003 IEEE Conference on Control Applications.

[17] W.L Luyben (1986),Simple methods for tuning SISO controllers in multivariable systems, Ind. Eng.

Chem. Process Des. Dev.25 654-660.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Tyranny of Edward TufteDocument142 pagesThe Tyranny of Edward TufteGabi Schaffzin67% (6)

- What Is TrustworthinessDocument12 pagesWhat Is Trustworthinesswwccff100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Introduction To Holy Fire III Reiki: by Illiam Ee andDocument17 pagesIntroduction To Holy Fire III Reiki: by Illiam Ee andAlberto100% (1)

- American English vs. British EnglishDocument14 pagesAmerican English vs. British EnglishGermán Calvo MartínezPas encore d'évaluation

- Morph Practice NewDocument4 pagesMorph Practice NewBùi Quang TrânPas encore d'évaluation

- Rudolf Steiner - Cosmosophy Volume I GA 207Document99 pagesRudolf Steiner - Cosmosophy Volume I GA 207Raul Popescu100% (1)

- How To Write A Reflective EssayDocument2 pagesHow To Write A Reflective EssayMeha Raj100% (1)

- Organization Culture and Employee MotivationDocument68 pagesOrganization Culture and Employee MotivationSamuel Davis100% (2)

- Assessment 2 - Designing Teaching and LearningDocument21 pagesAssessment 2 - Designing Teaching and Learningapi-357575377Pas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)ijscPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)Document2 pagesInternational Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)ijscaiPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- ISSN: 2320-7493 (Online) 2320 - 8449 (Print)Document2 pagesISSN: 2320-7493 (Online) 2320 - 8449 (Print)Alejandro CarverPas encore d'évaluation

- IJSCDocument2 pagesIJSCijscPas encore d'évaluation

- IJSCDocument2 pagesIJSCijscPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal of Peer-To-Peer Networks (IJP2P)Document2 pagesInternational Journal of Peer-To-Peer Networks (IJP2P)Aircc KarlonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- International Journal On Soft Computing (IJSC)Document1 pageInternational Journal On Soft Computing (IJSC)Matthew JohnsonPas encore d'évaluation

- QFT Ideas From Google DocsDocument2 pagesQFT Ideas From Google Docsapi-137669263Pas encore d'évaluation

- NatureDocument1 pageNatureDaisy Rose TangonanPas encore d'évaluation

- Lay Denial of Knowledge For Justified True BeliefsDocument10 pagesLay Denial of Knowledge For Justified True BeliefsJuan Camilo Osorio AlcaldePas encore d'évaluation

- Breath Yogananda PDFDocument8 pagesBreath Yogananda PDFIñaki RoldósPas encore d'évaluation

- Research AssignDocument2 pagesResearch AssignKit ViescaPas encore d'évaluation

- Topic Sentence Lesson PlanDocument6 pagesTopic Sentence Lesson Planapi-397089431100% (1)

- Rationale For GiftedDocument5 pagesRationale For Giftedapi-266088524Pas encore d'évaluation

- DST in Psychology PDFDocument3 pagesDST in Psychology PDFwernsicklePas encore d'évaluation

- Qualia: IntrospectionDocument16 pagesQualia: IntrospectionRafael RoaPas encore d'évaluation

- Comprehension Strategies For Reading Historical FictionDocument10 pagesComprehension Strategies For Reading Historical Fictionapi-251249268Pas encore d'évaluation

- Population Vs SampleDocument5 pagesPopulation Vs Sampleronald bantuganPas encore d'évaluation

- Glossary of Words Used in ISO 9000-2015 and ISO 9001-2015Document5 pagesGlossary of Words Used in ISO 9000-2015 and ISO 9001-2015alfredorozalenPas encore d'évaluation

- Pebc Lesson Plan DocumentDocument4 pagesPebc Lesson Plan Documentapi-309521519Pas encore d'évaluation

- Lesson Plan - LANG FOCUS - Unit 15 E11Document13 pagesLesson Plan - LANG FOCUS - Unit 15 E11Ngọc BíchPas encore d'évaluation

- Airbus BBA Candidate Report 11032843Document6 pagesAirbus BBA Candidate Report 11032843Bahareh MaghaniPas encore d'évaluation

- Semi-Supervised Learning Via Regularized Boosting Working On Multiple Semi-Supervised AssumptionsDocument15 pagesSemi-Supervised Learning Via Regularized Boosting Working On Multiple Semi-Supervised AssumptionsDrishti BeoharPas encore d'évaluation

- The Impact of Video Lessons On The Academic Performance of Senior High School Students at Arellano University - Jose Rizal CampusDocument6 pagesThe Impact of Video Lessons On The Academic Performance of Senior High School Students at Arellano University - Jose Rizal CampusJohn Lloyd TomacaPas encore d'évaluation

- Distributed Situation Awareness in Pilotage Operations: Implications and ChallengesDocument5 pagesDistributed Situation Awareness in Pilotage Operations: Implications and ChallengesHarel Santos RosaciaPas encore d'évaluation

- Conditional Sentences in EnglishDocument3 pagesConditional Sentences in EnglishJorge PinargotePas encore d'évaluation

- The Bremen-Groningen Online Workshops On Multimodality 2020 - 2021Document6 pagesThe Bremen-Groningen Online Workshops On Multimodality 2020 - 2021cecirenniePas encore d'évaluation

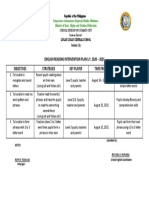

- English Reading Intervention Plan S.Y. 2020 - 2021 Objectives Strategies Key Player Time Frame Expected OutputDocument1 pageEnglish Reading Intervention Plan S.Y. 2020 - 2021 Objectives Strategies Key Player Time Frame Expected OutputMaribel A. BustilloPas encore d'évaluation