Académique Documents

Professionnel Documents

Culture Documents

Method Statement For Fire

Transféré par

Binu GopinathanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Method Statement For Fire

Transféré par

Binu GopinathanDroits d'auteur :

Formats disponibles

THE METHOD STATEMENT OF

MECHANICAL

HANGER AND SUPPORT

INSTALLATION

Page 1

Table of contents

1. Gross References .................................................................Page 3

2. Scope of works......................................................................Page 3

3. Flow of Works Chart..............................................................Page 4

4. Methodology......................................................................Page !2"

. #ools and $%&'p(ent.............................................................Page2)

*. Safety Meas&res...................................................................Page 2)

". +ppend'ces...........................................................................Page 2)

). Pa'nt'ng Safety F're

p'pe,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,Page 2-

1.Gross References

1.1 General Refer to t!e "eneral Re#$%re&ents 'or(sect%on

Refer to the follow'ng worksect'on.

Mechan'cal general re%&'re(ents/ F're protect'on syste(/ hydranl'c syste(/ a'r

handl'ng &'nt and 0ent'lat'on syste(.

1.2 Material:

Mater'al for 1anger and s&pport follow'ng the standards on spec'f'cat'on

+ppro0ed type 2y $ng'neer

To describe mechanical works associated with install hanger and support of mechanical system to

ensure compliance with contract requirements, drawings and technical specification. The design of the

pipe work installation shall be tested and certify strictly in accordance with the requirement specification,

). Sco*e of +or(s

Page 2

Scope of works install hangers and supports of Mechanical System including the uct

works system, Piping fire protection and !ydrandlic system. The scope of work for this method

statement shall include all the Mechanical system.

Page "

,. Flo' of +or(s -Flo' c!art.

Page #

Shop drawings

$%ppro&ed'

Material

%ppro&ed

etermine pipe as per

appro&ed location ( le&el

Marking

)ot appro&ed

*ngineer +s

inspection

Proceed

%ppro&ed

,n-house

,nspection

,nstallation of

pipe

efine position

of support

%ppro&ed

)ot appro&ed

%ppro&ed

/. Met!o0olo"1

/.1. General

#.1.1. The si.e of !angers and supports shall be in compliance with the contract specification,

documents, and appro&ed shop drawings.

#.1.2 !angers and supports of mechanical system shall be fabricated at factory from the

appro&ed and gal&ani.ed steel sheet roll.

#.1." To ensure that all !angers and supports material are fabricated form the appro&ed, worker

Shall take photo picture on the appro&ed material for record, before starting any fabrication process.

/hen the finished parts deli&ery to site, the *ngineer0s shall check the quality and material

used, by the 123 labels together with the e&idence of the photo picture or refer to shop drawing , on the

material been used in the fabrication.

#.1.# 4nly the site engineer0s final appro&ed !angers and supports shall be used for the site

installation works.

#.1.5. 6arious hanger systems and components for system shall be used and shall be

3oordinated with the ceiling work at the 3ontractor option with the appro&al by the Mechanical

engineer.

#.1.7 %ll flanged 8oints shall be pro&ided with suitable gasket as appro&ed type by the *ngineer.

#.1.9 Supports shall be attached to e&ery system using screws or bolt to pre&ent slippage and

noise.

#.1.:./all or o&erhead supports shall be anchored to structure using bolts of suitable type and

adequate si.e or other methods suitable for conditions or materials encountered, only as appro&ed by

the *ngineer.

#.1.;. Supports insulation work will be mentioned on method statement for mechanical system

insulation work.

Page 5

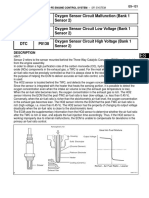

/.). Han"ers an0 S$**orts for 0$c( 'or( s1ste&s

#.2.1 Supports and hangers shall be <-type formed steel angles, shall be as shown in Table 1

The &ibration isolation rod hanger for fans shall be indicated on shop drawings.

Table 1 Han"ers an0 S$**orts Sc!e0$le - Refer to AS /)2/.

uct Si.e

<argest

imension

$mm'

Si.e of <-type

formed steel

angle

$minimum'

$mm'

!anger rods

diameter

$minimum'

$mm'

!anger

Ma=imum

spacing for

>lange ?oint

$mm'

!anger

Ma=imum

spacing for

T3 ?oint

$mm'

@p to ;AA "A = "A = " :mm ",AAAmm 15AAmm

;A1 to 17AA #A = #A = " 1Amm ",AAAmm 15AAmm

17A1 to 22AA #A = #A = " 12mm 2,#AAmm -

4&er 2,2AA 5A = 5A = " 12mm 2,#AAmm -

W

Insertion

Anchor bolt

(Appro type

by the ICE)

Hanger

rod-galvanize

is use

area normal

L to L!"#

$%& $!& $&

'oo( use rod

Ino) or rod Hot

div galvanize

W * %+

L - type (ormed steel angle

W - Include the thic,ness o( insulation

F%"$re 1 Sect%on of Han"ers an0 S$**orts

(Detail refer to drawing SRF-DT-500)

)oteB a' !angers and supports details please refer to appro&ed shop drawings.

Page 7

F%"$re ) Deta%ls of Han"ers an0 S$**orts of D$ct 'or( for R%ser

-Deta%l refer to Table HS.2 of MOS !an"er s$**ort.

(SEE TO FILE AUTOCAD)

/.).). F%3 S$**ort

#.2.2.1. 3heck length of duct round and weight according to Table 12-1,12-2.

#.2.2. %ccording to Table ", select the Steel angle and %nchor bolt. Steel angle must be fabricated at

factory.

Page 9

#.2.". >i= support must be fi=ed to slab or beam.

#.2.2.#. Spacing of >i= support by steel angle shall be 15AAmm and below, or refer to shop drawing

appro&ed.

F%"$re 4 Sect%on of F%3 s$**ort

(Detail refer to table HS.5))

)oteB

>i= supports details please refer to appro&ed shop drawings.

Table. ) S%5e of Steel An"le an0 Anc!or 6olt

-refer to AS /)2/.

Steel angle length - < Steel angle Si.e$minimum'

%nchor Colt si.e Slab $mm'

@p to 1AAA <-"AD"AD2.5

MD8

@p to 17AA <-5AD5AD".A

MD10

@p to 22AA <-5AD5AD#.A

MD12

4&er 22AA <-5AD5AD5

MD12

)oteB >i= supports details please refer to appro&ed shop drawings.

/.)., Plen$& C!a&ber

Plenum Chamber Thickness:

- Thickness for gal&ani.ed steel sheet shall be as shown in Shop drawing appro&ed

/.)., Re%nforc%n"

- Eequirements for Si.e of <-type formed steel angle reinforcing shall be as shown in Table #.

Page :

Duct including

insulation

Anchor bolt (Approved type by the engineer)

L-type formed steel angle

Beam

Table /. S%5e of L7t1*e for&e0 steel an"le Re%nforc%n"

)otes

- ,nstallation details shall be indicated on shop drawings.

- etails of plenum chamber shall be indicated on the shop drawings.

Page ;

<argest imension of

Plenum 3hamber $mm'

Si.e of <-type formed

steel angle

Si.e $minimum'

$mm'

Ma=imum Spacing

$mm'

@p to 1AAA <-"AD"AD2.5 15AA

@p to 17AA <-5AD5AD".A 15AA

@p to 22AA <-5AD5AD#.A 15AA

4&er 22AA <-5AD5AD5 15AA

4.. Pi!e "an#ers an$ su!!%r& '%r s(s&em

- Piping or equipment supported by wire, plumber0s tape, rope or other means or arrangements shall not

be permitted.

- Pipe or equipment supported by &al&es or other line accessories shall not be permitted.

a' 6ertical piping shall be supported as followsB

i' EisersB Steel angle support to rest at least on refer to shop drawing appro&ed

ii' 3opper pipeB Steel angle support with rubber and refer to shop

b' !ori.ontal piping shall be supported as followsB

Pipes shall be attached to or supported from structure using hangers and de&ices as specified or

appro&ed.

c' !anger and >i= support spacing shall be as the following Table 5.

Table 2 Han"er an0 F%3 s$**ort s*ac%n"

15 2 25 !2 " 5 #5 $ 1 125 15 2 25 !

%ang

&pacing

'arbon

&teel (ipe

2) m or less !) m or less

(olyvinyl

chloride

pipe

1)5 m or less 1)2 m or less

'opper

pipe

1)5 m or less 1)5 m or less

*i+

&upport

&pacing

'arbon

&teel (ipe

,,,

&pan by span

or less

1)5m or &ho- on &hop

Dra-ing

(olyvinyl

chloride

pipe

,,,

&pan by span

or less

&pan by span or less

1)5m or &ho- on &hop 1)5m

or Dra-ing

'opper

pipe

,,,

&pan by span or

less

&pan by span or less

1)5m or &ho- on &hop

Dra-ing

d' <ow temperature pipe insulation shall be required for refrigerant lines and chilled water lines at

points of support between pipe and hanger using rebar sheet or wood appro&ed.

e' 3opper pipe isolation shall be required for each point of contact with hangers or other ferrous

materials.

f' !anger rods

i' !anger rod si.e shall be as the following Table 7B

Table 8 Han"er ro0 s%5e -Ite& 6 of S*ect%on.

&upported pipe (mm) .od diameter (mm)

/2 #

2 to /1 1

1 to 12 12

012 to 215 1#

0215 to !25 2

Page 1A

Diameter

2ype

3ver !25 2"

Table 19 U bolt S%5e -S*ect%on.

D%a&eter P%*e U bolt S%5e

17mm F "#mm 7mm

#2mm F ;Amm :mm

4&er ;Amm 1Amm

>rom 15A - 25A 25=2mm

/./.,. A00%t%onal S$**ort

%t changes of direction in either &ertical or hori.ontal and point near the &al&e, additional support

shall be pro&ided. !owe&er it may be omitted when coincidental with required standard spacing

location.

Page 11

F%"$re :. A00%t%onal s$**ort

/././. F%3 S$**ort

1. 3heck the pipe weight, number and support spacing $Table 5'.

2. %ccording to Table ;, select the Steel angle and %nchor bolt.

". The method of fi=ing for ,nsulated pipe is in accordance with Section:.:.

Page 12

&upport

4alve si5e is Less than 1mm

&upport near valve

#mm and above

&upport near branch

"56

4alve si5e is 1mm and above

#mm and above

!77 or belo-

&upport near branch

&upport near bent &upport near bent

&upport near bent

&upport

&upport

&upport

&upport

&upport

&upport

!77 or belo- !77 or belo-

&upport

-I-E -I-E

-I-E C./ "0 A12LE WEL3

!

3E/AIL

3E/AIL

WEL3

Figure 10 : Example for connect pipe over 65mm

-for C!%ller 'ater *%*e.

Table : S%5e of Steel An"le an0 Anc!or 6olt

)oteB Steel angle and bolts shall be indicated on shop drawings.

8eight

(9g)

&teel Angle Length &i5e of &teel Angle and Anchor Bolt

L % &teel angle &i5e(minimum)

Anchor Bolt &i5e(minimum)

&lab 8all

#

5

1 L-5:5:5)5 ;1:!:2 ;1:!:2

15 L-#!:#!:5)5 ;1:!:2 -

1

1 L-#!:#!:5)5 ;1:!:2 ;1:!:2

15 L-#!:#!:5)5 ;1:!:" -

12

5

1 L-1:1:#)5 ;1:!:" ;1:!:2

15 <12:"$:" ;1:!:" -

1

1 L-15:15:5)5 ;1:!:" ;1:!:2

15 <15:"$:" ;2":!:" -

2"

1

1

<12:"$:"

;1:!:" ;1:!:2

15 ;1:!:" -

15

1 ;1:!:" ;1:!:2

15 ;1:!:" -

!#

1

1

<15:"$:"

;1:!:" ;1:!:2

15 ;1:!:" -

15

1 ;1:!:" ;1:!:2

15 ;2":!:" -

/./.2 Sett%n" of Floor Dra%n an0 Clean o$t

Setting of >loor rain and 3lean out shall be followed as under >igures.

Page 1"

(Fire stopping will be supply late)

F%"$re 1) Sett%n" of Clean o$t T1*e A

(Fire stopping will be supply late)

F%"$re 12 Deta%l of *%*e *enetrat%on for 'ater *roof

Page 1#

'ap

&lab

'oncrete

(4' pipe &teel panel

'ut pipe

*inishing -or9

(Architectural -or9)

'lean out ('3A)

(rocess 1)

1) =nstall pipe and steel panel)

2) *ill concrete)

(rocess 2)

1) *inishing -or9 by Architectural -or9)

2) 'ut pipe)

(rocess !)

=nstall '3A ( upper part ))

'ap

&lab

'oncrete

(4' pipe &teel panel

8ater proofing

(Architectural -or9)

'ut pipe

*inishing -or9

(Architectural -or9)

'onnect &anitary

*i+tures

(rocess 1)

1) =nstall pipe and steel panel)

2) *ill concrete) ;a9e slope

for -ater proofing)

!) 8ater proofing

( Architectural -or9 )

(rocess 2)

1) *inishing -or9 by Architectural -or9)

2) 'ut pipe)

(rocess !)

1) =nstall >?uipment)

2) Apply sealing compound)

&ealing

compound

Page 15

4.4.).*e&h%$%l%#ies:

- >or all sprinkler piping installation either wall or ceiling area.

- /ork will be e=ecuted by fi=ing anchor bolt into concrete structure or brick wall with appro&ed

bracket support and dimension according to appro&ed shop drawing

- %ll brackets supports shall be factory-fabricated and hot dipped gal&ani.ed to ?,S !:7#1 Standard

prior to deli&ery to site for installation.

- eli&er pipes and fittings to designated area of site work. 3heck and ensure sufficient quantity for

area installation.

- %ll supports shall be fabricated at workshop factory shall be appro&ed type based on sample

submitted and appro&ed by the *ngineer.

- ,nstalled supports will be checked by the *ngineer.

- %ll bolt and nuts accessories shall be appro&ed brand2 types by the *ngineer based on submission

and appro&ed.

- <ocate position of pipe installation as according to shop drawing.

- Siamese fire department connection shall be as per appro&ed drawing location easily be

approached by fire engines for emergency fire fitting. Type of connection shall be compatible

with hose fitting used by the local fire department and based on 6ietnamese standard.

a' Pipe shaft area B

- 3arry pipe by manual labor to location. 3hain block may be used to lift bigger pipe for

installation.

b' 4n ceiling area B

- 3arry pipe to designated area of installationB for bigger pipe, chain block shall be used to hoist

pipe to ceiling area.

- Pipe shall be cleaned before installation.

- Pipe shall be ad8usted to fi= location as according to appro&ed shop drawing indicated and

according to the construction schedule.

- Mark and determine the location of pipe support.

- ,nstalled pipe shall be pressure tested and inspected by the *ngineer for appro&al.

- Shall be cleaned system before pressure test 2 leak test.

4.4.+ *arkin# an$ cu&&in#.

Page 17

7 %ll pipes si.e diameter 15Amm and smaller shall be cut by electric powered, circular machine

with abrasi&e wheel. Metallic wheel cutters shall not be permitted.

7 >or pipes with outside diameter 15Amm and greater shall be cut by 4=yacetylene torch.

7 %fter cutting, edges of pipe shall be grinded forming an angle of "A

A

. Eefer to >igure 1A

4.4., Cu& a h%le &% -%in smaller !i!e:

>or steel pipe connect to steel pipe that is two times smaller than diameter of main pipe

7 3ut a hole on main pipe by using o=yacetylene torch to create a hole.

7 @se grinder machine to smoothen the edges and burrs of the cut hole before 8oining the main pipe

and the smaller pipe together forming a ;A

A

3

7 Seam of 8oining shall be welded in three passes.

7 uring work not in progress, the opening of hole shall be temporary capped to pre&ent entry of

foreign ob8ect.

- Take out gal&ani.e for >ire protection

- >or flange weld, spot weld at 1 point, then connect flange surface perpendicular to pipe and spot

weld at "-# points prior to full welding and after that take down floor weld complete for >ire

protection pipe. )ote that seam of weld in outside face shall not be out off flange face.

- Eemo&e water, oil and paint off completed weld.

- /eld at "-# points on seam, then roll pipe to continue welding from up and down.

- 3ompleted weld shall be clean by using wire brush and prime paint.

,nspection of weld. Eefer to >igure 1A

- /eld seam shall be checked &isually.

- /eld 8oint will be thicker than edge of pipe ma=imum "mm.

- /eld defects shall be remoed and repaired under the *ngineer0s super&ision.

a. Screwed threaded connection.

- Pipe will be threaded by using the threading machine ?,S CA2A" Standard with automatic thread

defining dimension.

- %dd suitable oil onto the cutting part or filling oil regularly onto cutting part of threading

machine. /hen oil changes color due to mi=ing with water, change new oil.

- 3hange threading teeth when pitches are not threading in regular manner due to wear and tear.

- 3heck length and surface of pitches &isually and ad8ust selection of threading range by hand.

- Eemo&e oil and dust on pitches, inside and outside pipe prior to start threading.

Page 19

b. Tightening threaded pipe and fitting.

- %pply teflon sealing tape around the threaded pipe.

- Screw pipe and fitting by hand, and then use pipe wrench to tighten slowly till pipe and fitting

firmly tighten.

- %fter tighten screw connection, co&er odd pitches with primer paint and mark of pipe wrench.

- Pressure test shall be carried out after area pipe work completed and 8ointed area paint dry up.

d. Sprinkler heads installation and co&erage.

- % sprinkler head shall be installed at e&ery part of a ceiling di&ided by beam, etc. pro8ected A.#m

abo&e from the surface of installation for the said heads. !owe&er, this shall not apply in case the

mutual central distance of the said beams does not e=ceed 1.:m or less.

- ,n case there should be 1.2 m abo&e of width and length for air duct, shelf etc, a sprinkler head

shall be installed at the bottom surface of the said duct etc.

- % distance between the deflector of sprinkler heads and the surface of installation for the said

heads, shall be A."m below.

- Sprinkler heads shall be so installed that the spindle thereof is perpendicular to the surface to

which the said head is fitted.

- )othing shall be either installed or placed in the section within the distance of A.#5 m from the

deflector of a sprinkler head, and A."m below of hori.ontal direction, or installation refer to Spec

#.#.; Support installation

a. >or ceiling support. Eefer to Section on ceiling $file %utocad'

- rill a hole and insert anchor bolt into concrete structure according to construction working

schedule and appro&ed shop-drawing.

- >i= threaded rod support into insert anchor bolt and fi= 3-channel into location before laying pipe

onto the bracket support.

- 3heck the le&el of bracket support to ensure the pipe work ha&e been done as according to the

appro&ed shop drawings and location.

S$**ort !an"er s%5es on ce%l%n"

Page 1:

S$**orte0 *%*e -&&. Ro0 0%a&eter -&&.

5A and smaller A:

5A-1AA 1A

125 through 2AA 17

25A and larger 2#

b. >or support on wall and pipe shaft. Eefer to >igure Eiser $file %uto3ad'

- Mark sure ( fabricate support and then Gal&ani.e for le&el C", C2, C1, Eoof, Eiser

- 3heck support by plump-line to ensure bracket support are in a &ertical straight line

- >i= bracket support onto wall and fastened with nuts to get support in position.

- Mark the location of pipe support as according to appro&ed shop drawing.

- ri&e a hole into wall of concrete structure or brick wall.

- rill an anchor bolt into drilled hole.

- >i= bracket support onto wall and fastened with nuts to get support in position.

#.#.1A Prime paint and identification of pipe

7 3ompleted pipe will be prime paint by the appro&ed color code.

7 Symbol of identification of pipe will be suitable to diameter of pipe.

7 irection of arrow denote the way of water flow

Sc!e0$le of letter%n" s%5es

-or refer to s*ect%on.

4utside diameter of pipe or

co&ering $mm'

Si.e of stencil

letter $mm'

Minimum length of flow

arrow $mm'

2A to #A incl. 12 7A

5A to 1AA incl. 25 1AA

125 to 195 incl. 5A 125

2AA and larger 95 15A

Sc!e0$le of !an"er s$**ort s*ac%n"

Page 1;

<ocation

Pipe

2Amm

diameter or

less

25mm to

#Amm

diameter

5Amm to

:Amm

diameter

1AAmm

diameter or

more

Steel pipe

2.Amm 2.Amm 2.Amm ".Amm

2 Mac!%ner1 ; Tools

- Power hacksaw

- 3ircular cutting machine with abrasi&e wheel

- Pipe clamp

- Plump-line

- Power drill.

- 3hain block.

- Threading machine.

- Scaffolding

- Pipe wrench

- Spanner

- !ammer

- /ater le&el ruler

8. Safet1 Meas$res

- Temporary barricade and warning sign shall be set up at area of site work

- %ny worker works at the height of 2m and abo&e shall wear safety belt.

- /orkers shall be trained about safety condition.

- Machineries, equipments and staging should be inspected by safety super&isor prior to work

- % safety forms signed by workers and briefing before work will be pro&ided to control the safety

working condition $forms enclosed'.

4. A**en0%3

7 <eaking test record.

7 %&ailable for ,nspection $%>,'

7 ,nspection Eecord $,E'

<. Pan%t%n" sefet1 f%re *%*e

Step 1B 3arry pipe to location area installation, properti floor at work area to be done.

Step 2B 3lean pipe

Page 2A

Step "B Painting ,ron-Mould safety and $Creak-Hinc if need' by Grey color

Step #B Painting one undercoat by Eed color

Step 5B Painting complete safety by Eed color F 1

ST

Step 7B Painting complete safety by Eed color F 2

)

Step 9B 3heck after instal finish

Page 21

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Expt 8.7 Finding The Formula of Copper OxideDocument2 pagesExpt 8.7 Finding The Formula of Copper OxideIra Munirah0% (2)

- Manual de Operación Mantenimiento y Partes P375WCU P250WCUDocument160 pagesManual de Operación Mantenimiento y Partes P375WCU P250WCUPercy Cárdenas100% (2)

- FMC Flowline Products & Services Catalog PDFDocument80 pagesFMC Flowline Products & Services Catalog PDFsekead67% (3)

- 66cc 80cc Grubee SkyHawk GT5 Bike Engine Kit Installation ManualDocument14 pages66cc 80cc Grubee SkyHawk GT5 Bike Engine Kit Installation Manualpauliedata100% (1)

- Getting Started PPGsDocument28 pagesGetting Started PPGsBinu GopinathanPas encore d'évaluation

- LiNK PPG - ToolkitDocument20 pagesLiNK PPG - ToolkitBinu GopinathanPas encore d'évaluation

- Appointment Booking To Ambulatory Care Division: PurposeDocument1 pageAppointment Booking To Ambulatory Care Division: PurposeBinu GopinathanPas encore d'évaluation

- Machester - Not Detailed - Reference Material OnlyDocument13 pagesMachester - Not Detailed - Reference Material OnlyBinu GopinathanPas encore d'évaluation

- EFuel ReportDocument52 pagesEFuel ReportMassimiliano ZocchiPas encore d'évaluation

- Basic Preventive Maintenance Check List For ReciprocatingDocument4 pagesBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- Nava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileDocument8 pagesNava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileashifPas encore d'évaluation

- Mapúa University: Shop Practice No. 9Document5 pagesMapúa University: Shop Practice No. 9marisonPas encore d'évaluation

- General Catalogue: Compressors & Condensing UnitsDocument88 pagesGeneral Catalogue: Compressors & Condensing UnitsJader Leon100% (1)

- CFD of CombustionDocument7 pagesCFD of CombustionGulshan Kumar SinhaPas encore d'évaluation

- Investigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantDocument5 pagesInvestigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantKR PAPas encore d'évaluation

- Draft CRE Regulations 2019-pdf452019102100AM PDFDocument118 pagesDraft CRE Regulations 2019-pdf452019102100AM PDFPurna AcharyaPas encore d'évaluation

- World Lecture Hall: Useful Links For EngineersDocument9 pagesWorld Lecture Hall: Useful Links For Engineerssandi1111Pas encore d'évaluation

- Self Cleaning Hydro ScreensDocument4 pagesSelf Cleaning Hydro ScreenssavuPas encore d'évaluation

- Rammed EarthDocument10 pagesRammed EarthAnugraha KrishnanPas encore d'évaluation

- HO2 Sensor InfoDocument24 pagesHO2 Sensor InfoÇağrı SivrikayaPas encore d'évaluation

- Pages From Chapter 17-11Document10 pagesPages From Chapter 17-11taPas encore d'évaluation

- Detailed CalculationsDocument14 pagesDetailed CalculationsrozPas encore d'évaluation

- 5456 de Filter PressDocument6 pages5456 de Filter PressmbhadelPas encore d'évaluation

- York YFM Fan-Coil UnitsDocument16 pagesYork YFM Fan-Coil UnitsInviairPas encore d'évaluation

- MB Precast Concrete Buildings Dec07Document20 pagesMB Precast Concrete Buildings Dec07magdyamdbPas encore d'évaluation

- Green Hotels and Sustainable Hotel Operations in India: ResearchgateDocument7 pagesGreen Hotels and Sustainable Hotel Operations in India: ResearchgateSanika AgrawalPas encore d'évaluation

- Theogarajan SlidesDocument78 pagesTheogarajan SlidesMikaela MennenPas encore d'évaluation

- Instrumentation AssignmentDocument5 pagesInstrumentation AssignmentShreyee PalPas encore d'évaluation

- Esm-48100u2 v100r022c91 User ManualDocument49 pagesEsm-48100u2 v100r022c91 User ManualBiniVincentPas encore d'évaluation

- TM 9 4935 601 14 3&PDocument137 pagesTM 9 4935 601 14 3&Pkhaerul jannahPas encore d'évaluation

- Southwark Schools For The FutureDocument59 pagesSouthwark Schools For The FuturewilliamsaminPas encore d'évaluation

- ENGINEERING DATA VRV III System-Daikin PDFDocument746 pagesENGINEERING DATA VRV III System-Daikin PDFĐỗ Xuân QuânPas encore d'évaluation

- PHYSICS/FILIPINODocument2 pagesPHYSICS/FILIPINOMaLou Temblique EscartinPas encore d'évaluation

- W22 Homework #8 AnwsersDocument4 pagesW22 Homework #8 Anwsersiamayesha725Pas encore d'évaluation