Académique Documents

Professionnel Documents

Culture Documents

Laser Scan

Transféré par

Chirag ShahCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Laser Scan

Transféré par

Chirag ShahDroits d'auteur :

Formats disponibles

Visual Survey (Laser Scan)

Overview

Applying Fundamental Measurement

Work Process to Dimensional Control

Technologies

Agenda

Explanation of Dimensional Control and the Visual

Survey Technology

Establishing the Fundamentals

Understanding Benefits & Limitations

Recognizing Value & Acceptance

Implementing an Execution Strategy

Planning

Determining Costs

Roles and Responsibilities

Guidelines for the Project Engineer Using the Visual

Survey on the Project

Key Factors To Remember

Establishing the Fundamentals

Review Terminology

Laser Scan Technology (Types)

Understanding Dimensional Control and its

Relationship to the Laser Scan Technology.

Why Use Visual Survey Technology?

What Should Determine the Use of the Visual

Survey Technology?

How Can Value Be Determined By Using the

Visual Survey?

Terminology - Dimensional Control

Dimensional control is a risk mitigation process that

is applied to every project execution task that requires

a dimensional accuracy.

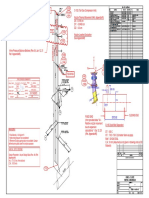

Dimensional Control Illustration

Measure twice; cut once

Terminology - Visual Survey

It is the deliverable that is created from

the culmination of measurement and visual

technologies

It is the Future

Direction of Survey

Other Terminology

Reference Control The Point of Reference Where All

Measurements for Engineering and Construction Will Be

Tied To

Scan Registration - Process in which Laser Scans are

Tied to the Survey Control

Point Cloud - Laser Scan Data from Multiple Scan

Stations in a Defined Volume Space

Segmentation The Process of Separating and Isolating

Groups of Points from the Laser Scan

LASERGen Software Developed by BitWyse Solutions

to Work with the Laser Scan Data. (Used in the Past)

LFM Viewer & LFM Server Software Developed by Z+F

to Work with the Laser Scan Data. (Currently Using)

Laser Scanning Technology

Laser Scan Technologies

LIDAR (Light Detection & Ranging)

Phase Based (AMCW - Amplitude Modulated

Continuous Wave)

Triangulation

Types of Laser Scanning

Aerial

Terrestrial

Dimensional Control and Laser Scanning

The Laser Scanning

Technology is a Dimensional

Control Tool

What is the Relationship?

Laser Scan Technology Benefits

More Accurate Measurement

Information in Less Time than

Traditional Methods

Visual Representation of

Measurement Data

Integrates With Design

Engineering CAD Applications

Consolidates Multiple

Measurement Tasks

Laser Scan Technology Limitations

Extreme Temperatures

Electronic Parts that Freeze

Up or Overheat

Highly Reflective Materials

Mirrors, Water, Polished

Chrome

Steam, Rain, and Fog

Strong Vibrations

Why Use Visual Survey Technologies Over

Traditional Methods of Measuring?

What Factors Determine the Consideration

of Using a Visual Survey Technology?

Costs

Cost Risk in Having Accurate Dimensional Information During

Engineering and Construction

Schedule

Risk to Schedules Impacted by Dimensional Errors that Occur

in Engineering and Construction

Quality

Quality Risks in Engineering from and Constructing to

Existing Conditions

Safety

Exposure Risks Going into Hazardous Environments to

Capture Existing Condition Information, and Re-Work in the

Field Resulting from Dimensional Errors

Execute Better, Faster, Cheaper and Safer

Value of Laser Scan Technology

Safety

Reduced field exposure

Reduced travel

Quality

Accurate as-built data/conditions

3D model in PDS for interference detection

Accurate construction documents

Cost effectiveness

Reduced schedule cycle time for data gathering (80%)

Promotes work sharing to low cost center

Reduce field re-work to less than 1%

Savings ($100 MM Project)

Reduced field data gathering $0.4 MM

Work share opportunities $0.9 MM

Reduced rework $1.0 MM

$2.3 MM

Shortened Project Duration 10%

Laser Scan Technology Acceptance

Sales of terrestrial 3D laser scanners topped $44.8 million in 2004,

according to our latest estimate a growth of 65% over the year before.

Plan the Work, and

Work the Plan

Planning an Execution Strategy

Factors That Determine Using the Visual Survey

or Another Dimensional Control Method

Scope

Determine the Amount of

Information to be Captured

Costs

Determine the Estimated Costs

for Visual Survey and

Traditional Measurement Tasks

Schedule

Determine When to Execute To

Maximize the Value

Safety

Determine the Safety Risks

Risks

Determine Cost Risks

Logistics

Determine Logistical Issues

that May Impact Dimensional

Control Tasks

Planning - When To Execute The Visual

Survey

After All Disciplines Have Defined and

Submitted Their As-Built Dimensional

Requirements

After the Field Execution Plan Has

Been Developed

After the Selected Jacobs Pre-

Qualified Service Provider Has

Fulfilled the Clients Requirements to

Execute Work In Their Facility

After an Understanding of the Project

Scope, Field Execution Schedule, and

Deliverable Requirements and

Schedule Between Jacobs and the

Service Provider

After the Jacobs Field Representative

Who Understands the Project

Requirements, and is Knowledgeable

of the Visual Survey Process has

Been Identified To Go To the Client

Facility To Direct the Visual Survey

Service Provider

Planning How To Execute The Visual

Survey

Establish the Reference Control

The Jacobs Field Representative

Will Locate Scan Station Setups

and Review Scans For Quality

Assurance

Ensure Site Obstructions That May

Interfere with the Visual Survey

Are Removed

Ensure Activities Are Coordinated

With Unit Operators to Minimize

Traffic Where The Visual Survey Is

Being Executed

Ensure Climate and Site

Conditions Meet Acceptable

Conditions for the Laser Scanner

To Operate At Acceptable

Performance

Determining Costs

Planning an Execution Strategy

How to Estimate the Cost of the Visual

Survey

Determine the Number of Scans

Based on Project Discipline

Requirements

Determine Number of Days to

Execute Based on Number of

Scans and Complexity

Determine Expenses Based on

Number of Days and Travel

Location

Determine if the Visual Survey

Will be Executed on One or

More Trips

Factor in Costs for Specialty

Items (i.e. Special Training

Needs, Special Equipment)

Visual Survey Proposal

Summary of Scope

Estimated Number of Scans to

Collect

Estimated Number of Days to

Collect the Information

Estimated Number of Days to

Process the Scan Information

and Generate Deliverables

Cost Breakout for Services and

Expenses

Unit Rates

Required Items That Are To Be Included In

the Service Provider Proposal:

Visual Survey Deliverables

Registered Scan Data

Delivered on Hard Drive That is

Compatible with Jacobs

Software

Electronic Plot Plan Identifying

Scan Station Location

Digital Imagery

Detailed Survey Report

Excel Spreadsheet of All

Surveyed Targets Used to

Register Scan Data

Required Deliverables From the Service

Provider:

Cost Estimate Example to Execute a

Visual Survey

Site 600L x 320W x 100H

400 - Tie-ins

270 - Laser Scan Setups

I Trips to the Facility

8 Days in the Field

3 Service Provider Personnel

1 Jacobs Personnel

Invoiced Amount $85,000 For

Visual Survey Services

(Services and Expenses)

Estimated $10,000 For Jacobs

Personnel (Hours and

Expenses)

Cost Estimate Example to Execute the

Same Project with Traditional Methods

Site 600L x 320W x 100H

400 - Tie-ins

2 - Trips to the Field

10 Days in the Field

10 - Jacobs Personnel

Estimated $110,000 for

Jacobs Personnel (Hours

and Expenses)

Estimated $25,000 for

Additional Survey Services

Project Engineering's Role

Guidelines for the Project Engineer Using the

Visual Survey on the Project

Ensure the Reference Control

for the Project Has Been

Established for the Project

Works With the Project Team to

Determine if the Visual Survey

is a Cost Effective Solution For

the Project

Develop the Cost Estimate for

Implementing the Visual Survey

on the Project

Ensure the Visual Survey is

Added as a Scheduled

Collect All Project Discipline

Requirements to Create the

Visual Survey Cost Estimate

Guidelines for the Project Engineer Using the

Visual Survey on the Project

Work with Sub-Contracts to

Issue a Request for Proposal

from the Service Providers

Coordinate and Plan the

Execution of the Visual Survey

at the Site with the Client To

Ensure No Un-expected

Conflicts Will Occur

Act As the Point of Contact if

Questions Pertaining to the

Project Arise Addressing Visual

Survey Scope

Make Sure All Project

Disciplines are Utilizing the

Visual Survey on the Project

Key Factors to Keep in Mind

Never Assume When it Comes to Dimensional Control

and Survey.

The More Effort in the Planning Will Return the Most Value

in the Deliverable.

Challenge Yourself and Others to Use this Technology to

Your Advantage.

The Work Process Should Always Drive the Technology,

and NOT the Technology Driving the Work Process.

There is Only One Thing That Is for Certain, Change is

Inevitable.

The Dimensional Control Process Will Be Used on a

Project, But the Methods of How It Will Be Executed Will

Be Determined By Project

Questions?

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Diary of Anne Frank PacketDocument24 pagesThe Diary of Anne Frank Packetcnakazaki1957Pas encore d'évaluation

- Piping Stress AnalysisDocument52 pagesPiping Stress Analysispatdumont100% (6)

- Prodelin 1385Document33 pagesProdelin 1385bebebrenda100% (1)

- Sketch Skirt Data: Vessel Skirt Average Temperature Calculation Calculations and SketchesDocument2 pagesSketch Skirt Data: Vessel Skirt Average Temperature Calculation Calculations and SketchesChirag ShahPas encore d'évaluation

- Trade Notice 36 Particulars of Mundra LPG Terminal PVT LTD MLTPLDocument2 pagesTrade Notice 36 Particulars of Mundra LPG Terminal PVT LTD MLTPLChirag ShahPas encore d'évaluation

- Ph4 Si 1004 Var r2 Stress IsometricsDocument106 pagesPh4 Si 1004 Var r2 Stress IsometricsChirag ShahPas encore d'évaluation

- Ph4-Si-1004-Var-R2 - Stress Input ReportDocument217 pagesPh4-Si-1004-Var-R2 - Stress Input ReportChirag ShahPas encore d'évaluation

- SafeNet MobilePASS+ Setup Guide For AndroidDocument12 pagesSafeNet MobilePASS+ Setup Guide For AndroidChirag ShahPas encore d'évaluation

- PH4-SI-1004-VAR-R2 - Nozzle N5 1 To N5 12 of Equipment 25-2501Document10 pagesPH4-SI-1004-VAR-R2 - Nozzle N5 1 To N5 12 of Equipment 25-2501Chirag ShahPas encore d'évaluation

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Document12 pagesPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahPas encore d'évaluation

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Document12 pagesPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahPas encore d'évaluation

- PH4-SI-1004-VAR-R2 - Trunnion at Node151Document10 pagesPH4-SI-1004-VAR-R2 - Trunnion at Node151Chirag ShahPas encore d'évaluation

- C2Document16 pagesC2Chirag ShahPas encore d'évaluation

- Piping Engineering Piping Engineering Piping Engineering Piping EngineeringDocument12 pagesPiping Engineering Piping Engineering Piping Engineering Piping EngineeringChirag ShahPas encore d'évaluation

- Application DomicileDocument1 pageApplication DomicileAbhinav JhaPas encore d'évaluation

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Document12 pagesPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahPas encore d'évaluation

- R2Document12 pagesR2Chirag ShahPas encore d'évaluation

- Write XDocument1 pageWrite XChirag ShahPas encore d'évaluation

- GID Engineering Feedback SummaryDocument4 pagesGID Engineering Feedback SummaryChirag ShahPas encore d'évaluation

- 2562 10968 1 PBDocument21 pages2562 10968 1 PBFaiz AizPas encore d'évaluation

- C-102 Stress Sketches (RevB - Jan 30 - 21)Document6 pagesC-102 Stress Sketches (RevB - Jan 30 - 21)Chirag ShahPas encore d'évaluation

- Two Step Verification FAQDocument8 pagesTwo Step Verification FAQChirag ShahPas encore d'évaluation

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadPas encore d'évaluation

- Jacobs - Positive Mental Health Programme - Health and Wellbeing Initiative of The YearDocument9 pagesJacobs - Positive Mental Health Programme - Health and Wellbeing Initiative of The YearChirag ShahPas encore d'évaluation

- New Ration Card Form 64Document3 pagesNew Ration Card Form 64Chirag ShahPas encore d'évaluation

- Spans 3 FT Rise - Steel - SCH 40and160Document1 pageSpans 3 FT Rise - Steel - SCH 40and160Chirag ShahPas encore d'évaluation

- Calculation of Strut StiffnessDocument1 pageCalculation of Strut Stiffnesskeroro18Pas encore d'évaluation

- WBeDistrict Domicile Certificate Application FormDocument4 pagesWBeDistrict Domicile Certificate Application FormHimaniPas encore d'évaluation

- Worley quiz questions and answersDocument2 pagesWorley quiz questions and answersChirag ShahPas encore d'évaluation

- Rubber Expansion Joints Engineering GuideDocument12 pagesRubber Expansion Joints Engineering GuideChirag ShahPas encore d'évaluation

- Behringer IndustrialDocument36 pagesBehringer IndustrialChirag ShahPas encore d'évaluation

- L P 10Document13 pagesL P 10Bình Minh HoàngPas encore d'évaluation

- Philip Larkin: The Art of Poetry 30Document32 pagesPhilip Larkin: The Art of Poetry 30Telmo RodriguesPas encore d'évaluation

- Youre The Inspiration CRDDocument3 pagesYoure The Inspiration CRDjonjammyPas encore d'évaluation

- Videocon ProjectDocument54 pagesVideocon ProjectDeepak AryaPas encore d'évaluation

- IonosondeDocument3 pagesIonosondeFaizan GoharPas encore d'évaluation

- Cefoxitin and Ketorolac Edited!!Document3 pagesCefoxitin and Ketorolac Edited!!Bryan Cruz VisarraPas encore d'évaluation

- Symasym BBDocument37 pagesSymasym BBChandraRizkyPas encore d'évaluation

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Document104 pagesOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaPas encore d'évaluation

- Judges - God's War Against HumanismDocument347 pagesJudges - God's War Against HumanismgypsylanternPas encore d'évaluation

- Delhi Mumbai Award Status Mar 23Document11 pagesDelhi Mumbai Award Status Mar 23Manoj DoshiPas encore d'évaluation

- S 212 Pre Course WorkDocument5 pagesS 212 Pre Course Workafiwierot100% (2)

- Ifatsea Atsep Brochure 2019 PDFDocument4 pagesIfatsea Atsep Brochure 2019 PDFCondor GuatonPas encore d'évaluation

- J-Garlic in CheeseDocument12 pagesJ-Garlic in CheeseMary GinetaPas encore d'évaluation

- Clustering Social Network GraphsDocument12 pagesClustering Social Network GraphsRáhùl SréédhãrPas encore d'évaluation

- CE ProblemDocument5 pagesCE ProblemJho FPas encore d'évaluation

- The Pathogenic Basis of Malaria: InsightDocument7 pagesThe Pathogenic Basis of Malaria: InsightRaena SepryanaPas encore d'évaluation

- Soft StarterDocument6 pagesSoft StarterEric Maglinte TolosaPas encore d'évaluation

- Alfa Romeo Giulia Range and Quadrifoglio PricelistDocument15 pagesAlfa Romeo Giulia Range and Quadrifoglio PricelistdanielPas encore d'évaluation

- Business Plan1Document38 pagesBusiness Plan1Gwendolyn PansoyPas encore d'évaluation

- Writing A Formal Letter To The PresidentDocument1 pageWriting A Formal Letter To The PresidentPiaAnaisPas encore d'évaluation

- AMB4520R0v06: Antenna SpecificationsDocument2 pagesAMB4520R0v06: Antenna SpecificationsЕвгений ГрязевPas encore d'évaluation

- 740 (Q50, V40, Awa 4Document10 pages740 (Q50, V40, Awa 4rawat2583Pas encore d'évaluation

- LM385Document14 pagesLM385vandocardosoPas encore d'évaluation

- Journal Sleep Walking 1Document7 pagesJournal Sleep Walking 1Kita SemuaPas encore d'évaluation

- Chapter 4. Quality Service and Standards TrainingDocument40 pagesChapter 4. Quality Service and Standards TrainingJia Mae Sapico ApantiPas encore d'évaluation

- FeatureSelectionAccepted IEEE Review PDFDocument20 pagesFeatureSelectionAccepted IEEE Review PDFrvsamy80Pas encore d'évaluation

- Financial Services : An OverviewDocument15 pagesFinancial Services : An OverviewAnirudh JainPas encore d'évaluation

- 4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Document3 pages4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Tarannum Yogesh DobriyalPas encore d'évaluation