Académique Documents

Professionnel Documents

Culture Documents

Truck Loading Example Calcs

Transféré par

mkbijuDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Truck Loading Example Calcs

Transféré par

mkbijuDroits d'auteur :

Formats disponibles

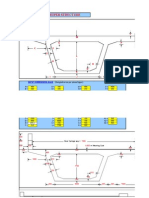

3/ 1el 9e s: o6Pri;

q3/'!A/99 1A:43

-> OYK INCORPORATEDi

NO. 6A 04

3.8,t.2

m

HIGHWAY BNIDGES

H 20.A1 8,000

H 15J4 6,000

32,000 LBS..

21,000 LBS.

LBS.

LBS.

14

'i)(t'

'<

o,'i"

.\

3

.!

W

.

TOTAL

TBUCK

WEIGHT OF

ANO LOAO

3

CLEARANC AND

D LANE

CURB.

!s{r--,,

ae

6'{" 2'{t"

Ftcrr!l.7.6t Srildtrd E thrl!3

.

h 6c d!$S! .{ tiEt'a ,rdr u.l drhoFic d.l d.& (ahdor ErrsEe b*) f.r H lo brdi!3. tr

ulc b.d d 2.,0@

Fl!{lr

6 tk l:L Ldl, d l5.@

Fbds

aci rFed a tui .Frrl y b Bd. rhilEvlt

produ.o rlc

Sui.!

tts, icrrd al t!. 32,0@!ca!d uL d4L

..F!rrl.bd..iF.!!.E16lsofs,i..Ai.Ut.----lbt

I &ot f66 6s ol @t. (Se AnbL

t.74.2.J

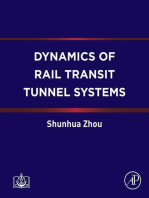

g3/1A/99 16t24

N0.659

3,10, r

22

}TIG!{YAY SIIDGES

HS20.44

HSrS{4

8,@ LBS.

6.m0 LBS,

32,000

24,0m

LBS!

LBS.

COMBINEO WEIGI{T ON THE FIBST TV{O AXLES WHICH

AS FOR THE COFRESPONDING H ?FIUCK

VAFIABLE SPACING

-

14 FEET TO 30 FEST INCLUSIVE.

USEO IS THAT IAIHICII PROBUCES MAXIMUM STRESSES.

ij_

_fE@_._._{o.rwf_

I

-T-

11'4'

3l

IS THE SAME

SPACING TO EIE

EEl't! !.t.?f *!!dtrd ES alarri

.I!

r!. dsi!! of liEld

'16r

!d onbd6P. d.d d..b (elldi{r E$rEc bqEc) bt ns 2! bdi!,

o!. ut lqd d z,m

!oo!.b

q

ls .tt lo& ol 16.@

ro@dt

d.b. rFlql 4 ft.| .Frl E{ bc !!.d,

pli.j.tqlrodE

lh.!r-E .e!.., i!6ddtll !2.lE6"Fqtlul.boB

..Fi

.t$ .t 5isa rE c!rt6 !b. oa !6 *'! b.

r<n':i

b t I b! i6 ie ol 6rn (S.. A'licL

3.24.2.t

s2dm Lss!

OLEANANC AND

"'4"

6',4-

2'4-

\

c

E

o

E

o)

o)

a)

z

0

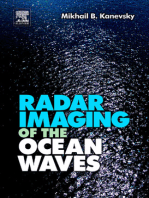

3.44 Slab

area,3'28

0.1

Side

inegative

o.2 0.3 0.4

of square areal/

moment

per

unit width due Figure

loaded

'T!L

:.

F_F_/

to concentrated load versus size of

0.

0.1

c

E

o

E

0,

o

E

o-

=

0.3

Figure 3.

al.ea.3.2t

mc

:0.37P

t.g

'

i

o-2 0.3 0.4

Side of square areal/

posilive moment per unit width under midspan loa

L--oe O

o

0,1

L

41 shb

-t

To'

N_r

l.'**

=)l

rli

i

:;

.t

i

\

\

l,l

tl

I

I

:l

.:

i

I

I

l,

\

I l

li

i

'L

I

I

.ti .t,l

ASSUMPTI ONS 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 1

I. ASSUMPTIONS

Basic Tank Data:

Tank inside diameter = 107.0 ft

Water depth near wall = 30.00 ft (above floor)

Maximum water depth for overload = 31.00 ft (above floor)

Roof placed on top of wall

Distance from floor to top of wall = 31.00 ft

Center-to-center distance between interior roof supports = 21.00 feet

Superimposed roof load = 50.00 psf live load + 200.0 psf soil load

+ H2O truck loading

The corewall is of uniform thickness and poured in place.

Poured in place wall thickness = t

wall

= 10.00 in

Wall edge condition: neoprene pad supports

Prestressing Information:

Circumferential prestressing system: 0.3750" diameter galvanized strand.

Circumferential prestressing machine tolerance = 1.500%

Minimum ultimate strength of circumferential prestressing steel = 240.0 ksi

Prestressing stress loss = 25.00 ksi

Final shotcrete cover depth over prestressing = 1.500 in

Center-to-center distance between layers of prestressing = 0.7500 in

Minimum final circumferential compression for differential temperature and dryness:

Above grade = 200.0 psi

Below grade = 50.0 psi

Prestressing will taper from 200.0 psi to 50.00 psi over 6.000 ft beginning at the

minimum backfill elevation

Vertical prestressing system: Dywidag threadbars

Minimum final vertical compression in corewall = 200.0 psi

Minimum ultimate strength of vertical prestressing steel = 150.0 ksi

Vertical prestressing stress tolerance = 1.500%

Maximum spacing of vertical prestressing = 50.00 in

Soil Information:

Backfill height = h

backfill

= 33.54 ft max. to 31.00 ft. min. (above floor)

Static equivalent liquid backfill pressure = 1192. psf (trapezoidal distribution)

Seismic equivalent liquid backfill pressure = 36.00 psf (inverted triangular distribution)

Backfill soil density = 130.0 pcf

Soil bearing capacity = 6000 psf (Gross) for Columns

= 7000 psf (Gross) for Walls

ASSUMPTI ONS 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 2

Misc. Information:

Concrete strength: core-wall = 4000 psi

shotcrete = 4000 psi

columns = 4000 psi

roof slab = 4000 psi

footings = 3500 psi

floor slab = 3500 psi

sump = 3500 psi

Slopes: center of floor to wall = 1.500% (+ = down, - = up)

center of roof to wall = 1.500% (+ = down, - = up)

Thickness of floor slab = 6.000 in

Steel reinforcement required in floor slab for temperature and drying shrinkage = 0.5000%

Steel reinforcement required in wall footing for temperature and drying shrinkage = 0.5000%

Friction factor between floor and subgrade = 1.500

UBC 97 SEISMIC DESIGN

Effective seismic horizontal acceleration = C

v

x I

R

horiz

x T

Effective seismic vertical acceleration = C

v

x I x B

R

ver

x T

T=[(4 x ( W

S

+W

R

+W

I

) ) / gr k]

1/ 2

Wher e, W

S

= Wei ght of wal l AWWA D110-95, Eq 4-8

= 1610. k ( See Sei smi c Cabl e Desi gn)

W

R

= Wei ght of r oof

= 3662. k ( See Sei smi c Cabl e Desi gn)

W

I

= Wei ght of wat er

= 1. 686e+04 k ( See Sei smi c Cabl e Desi gn)

g = accel er at i on due t o gr avi t y

= 32. 20 f t / sec

2

r = r adi us of t ank at mi d- hei ght of wal l

= 53. 50 f t

k = spr i ng st i f f ness

Wher e, k = 144 [ A x E Cos

2

" + 2 x G x Wx L

p

] AWWA D110-95, Eq 4-9

L

c

x S

c

t x S

p

A = ar ea of st r and

= 0. 8900 i n

2

E = modul us of el ast i ci t y

= 26 x 10

6

psi

" = angl e of st r and

= 45

0

L

c

= l engt h of st r and

= 27. 13 i n

REFERENCES 2.0 MG LESLIE LANE RESERVOIR

REVISED: 11/02/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 3

S

c

= spaci ng bet ween st ands

= 46. 19 i n

G = shear modul us

= 52. 00 psi

W= wi dt h of bear i ng pad

= 6. 000 i n

L

P

= l engt h of bear i ng pad

= 1. 000 i n

t = t hi ckness of bear i ng pad

= 1. 250 i n

S

P

= spaci ng of bear i ng pad

= 1. 000 i n

k= 144 [ 0. 08900 i n

2

x 26 x 10

6

psi x Cos

2

45

0

+ 2 x 52. 00 psi x 6. 000 i n x 1. 000 i n]

27. 13 i n x 46. 19 i n 1. 000 i n x 1. 000 i n

k= 222. 8 k

T=[ ( 4 x ( 1610. k + 3662. k + 1. 686e+04 k) ]

1/ 2

32. 2 f t / s

2

x 53. 50 f t x 222. 8 k

T= 0. 8512

Soil Profile = S

B

Seismic Source Type = A/B

Z = 0.40

Ca = 0.40

Cv = 0.60

I = 1.25

R

hor

= 4.500

R

vert

= 3.00

Nv = 1.0

Na = 1.0

B = 2/3

U

o

= 0.1958 g

V

o

= 0.1958 g

AWWA SEISMIC DESIGN

Effective seismic horizontal acceleration = (Z

H

x I x C)/R

H

Effective seismic vertical acceleration = (Z

V

x I x C)/R

V

Where, Z

H

= 0.4000

Z

V

= 0.2667

I = 1.000

C = 2.750 (conservative)

R

H

= 4.500

R

V

= 3.000

U

o

= 0.2444 g

V

o

= 0.2444 g

Adopt: Effective seismic horizontal acceleration = 0.2444g

Adopt: Effective seismic vertical acceleration = 0.2444g

Seismic spectral velocity = 1.250 ft/sec (at a convective period of 6.792 sec.)

II. REFERENCES

REFERENCES 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/ 22/ 2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 4

A. Heins, C.P., and Firmage, D.A., Design of Modern Steel Highway Bridges . John

Wiley and Sons, Inc., New York, New York (1979).

B. Park, R., and Gamble, W.L., Reinforced Concrete Slabs. John Wiley and Sons,

Inc., New York, New York (1980).

C. Nuclear Reactors and Earthquakes , Chap. 6 and Appendix F. U.S. Nuclear

Regulatory Commission publication, Division of Technical Information, TID-7024,

National Technical Information Service (1963).

D. Wang, Chu-Kia, and Salmon, Charles G., Reinforced Concrete Design, third edition.

Harper and Row, Publishers, Inc., New York, New York (1979).

E. Peck, Ralph B., Hanson, Walter E., and Thornburn, Thomas H., Foundation

Engineering, second edition. John Wiley and Sons, Inc., New York, New York

(1974).

F. Manual of Steel Construction, Eighth Edition, Chap. 5. American Institute of

Steel Construction, Inc., Chicago, Illinois (1980).

G. Post-Tensioning Manual, Fifth Edition, Chap. 3. Post-Tensioning Institute,

Phoenix, Arizona (1990).

H. ACI Manual of Concrete Practice, Part II. American Concrete Institute, Detroit,

Michigan (1983).

I. Jacobsen, Lydik S., "Impulsive Hydrodynamics of Fluid Inside a Cylindrical Tank

and of Fluid Surrounding a Cylindrical Pier", Bulletin of the Seismological

Society of America, 39:189 (1949).

J. Handbook of Molded and Extruded Rubber, Second Edition. Goodyear Tire and Rubber

Company, Akron, Ohio (1959).

K. AWWA Standard for Wire-Wound Circular Prestressed-Concrete Water Tanks, American

Water Works Association, Denver, Colorado (1995).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 5

III. TANK DESIGN NOMENCLATURE

a side of square area loaded by tire (ft).

a height of Whitney's stress block (in).

A

b

bearing area of vertical prestressing anchorage (in

2

).

A'

b

maximum area of the portion of the concrete anchorage surface for the vertical

prestressing that is geometrically similar to and concentric with the area of the

anchorage (in

2

).

a

bay

plan area of one interior roof bay (ft

2

).

a

bar

area of reinforcing bar or prestressing tendon (in

2

).

alpha

c

ratio of the flexural stiffness of column to flexural stiffness of slab (1).

alpha

ec

ratio of flexural stiffness of equivalent column to flexural stiffness of slab

(1).

alpha

min

minimum alpha

c

to satisfy 1994 UBC, Section (1913.6.10(a)) (1).

A

c

area of concrete in compression for minimum eccentricity (in

2

), area of core

concrete column (in

2

).

A

c,b

area of concrete in compression for balanced condition (in

2

).

A

c,max

area of concrete in compression for maximum eccentricity (in

2

).

A

footing

area of column footing (ft

2

).

A

g

gross cross-sectional area (in

2

).

Ag

column

gross cross-sectional area of column strip (in

2

).

Ag

middle

gross cross-sectional area of middle strip (in

2

).

A

int

area of tank roof supported entirely by interior columns (ft

2

).

A

long

plan area one exterior roof bay at the longest end span (ft

2

).

A

roof

area of tank roof (ft

2

).

A

short

plan area one exterior roof bay at the shortest end span (ft

2

).

As area of reinforcing (in

2

).

As

drag

required area of reinforcing from ACI drag resistance formula (in

2

).

As

max

maximum amount of reinforcing allowed (in

2

).

As

min

minimum amount of reinforcing allowed (in

2

).

A

shear

web area of structural tubing resisting shear (in

2

).

As

seismic

required area of reinforcing for seismic loads (in

2

).

As

temp

required area of reinforcing for temperature effects (in

2

).

A

strand

area of circumferential prestressing strand (in

2

).

As

water

required area of reinforcing for water loads (in

2

).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 6

A

t

tributary area of roof (kips/lineal foot of wall).

A

v

required area of structural tubing for roof shear connection (in

2

).

b width of compression area of concrete section (in).

BD downward drag of backfill on tank wall (plf).

B

d

ratio of maximum factored axial dead load to maximum total factored axial load

(1).

beta

1

factor defined in 1994 UBC, Section (1910.2.7.3).

beta

a

ratio of distributed dead load to distributed live load on roof (1).

b

f

width of flange of structural tubing (in).

b

w

width of compression area for section in bending (in).

C stiffness constant (in

4

).

C

c

compressive force in concrete at minimum eccentricity (kips).

C

c,b

compressive force in concrete for balanced condition (kips).

C

c,max

compressive force in concrete at maximum eccentricity (kips).

C

m

column design constant (1).

Cs

initial

initial compressive stress in tank wall (psi).

Cs

b,e

compressive stress due to seismic backfill pressure

Cs

b,s

compressive stress in wall due to static backfill pressure (psi).

Cs

p

compressive stress in wall due to circumferential prestressing (psi).

d

f

depth to tensile reinforcing for flexure (in).

d

v

depth to tensile reinforcing for shear (in).

d

bar

diameter of reinforcing bar (in).

d

column

diameter of column (in).

delta initial deflection of column (in).

delta

comp

compressive deflection of bearing pad (%).

delta

b

design moment magnification factor (1).

delta

radial

maximum inward wall movement (in).

delta

s

positive moment magnification factor (1).

DL dead load (units as noted).

d

tank

diameter of tank at mid height of wall (ft).

e eccentricity of column axial load (in).

E Modulus of Elasticity (psi).

E

bar

Modulus of Elasticity of prestressing tendon (psi).

e

b

eccentricity of the axial load on the column which corresponds to the point of

transition between the compression controls region and the tension controls

region (in).

e

initial

radial strain in bearing pad due to prestressing (1).

e

max

maximum radial strain in bearing pad (1).

e

min

eccentricity of the axial load on the column which corresponds to the point of

transition between the maximum axial compressive strength controls region and the

compression controls region (in).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 7

e

temp

radial strain in bearing pad due to temperature effects (1).

EL earthquake load (units as noted).

fa allowable tensile force in reinforcing (psi).

F friction factor between floor and subgrade (1).

f'c compressive stress of concrete (psi).

f

cp

permissible compressive stress in concrete at vertical prestressing anchorage

(psi).

F

s

force in reinforcing steel (kips).

F

v

allowable shear stress in structural tubing

fy yield strength of floor reinforcing (psi).

Fy summation of forces in the "Y" direction (lb).

fy yield strength of reinforcing or structural steel (psi).

gamma

backfill

weight density of soil backfill material (pcf).

gamma

concrete

weight density of concrete (pcf).

gamma

equivalent backfill

equivalent liquid density of soil backfill material (pcf).

gamma

f

fraction of column moment transferred to roof slab through flexure (1).

gamma

fluid

weight density of fluid (pcf).

gamma

v

fraction of column moment transferred to roof slab through shear (1).

h

backfill

height of backfill above wall footing (ft).

h

column

side dimension of equivalent square column (in).

H

c

hoop force in wall from convective component of water during seismic excitation

(k/ft).

h

o

elevation of center of impulsive water mass above top of wall footing (ft).

H

i

hoop force in wall from impulsive component of water during seismic excitation

(k/ft).

H

v

hoop force in wall from vertical component of water during seismic excitation

(k/ft).

h

wall

height of tank wall (ft).

h

water

height of normal fluid level above tank floor at wall (ft).

I

gross

moment of inertia of gross cross section (in

4

).

J

c

section property analogous to the polar moment of inertia

k stability factor for frame member (1).

K

column

flexural stiffness of column (k-ft).

K

ec

flexural stiffness of equivalent column (k-ft).

K

slab

stiffness of slab section (k-ft).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 8

K

t

torsional stiffness of slab section (k-ft).

L

2

longer span length from center to center of supports in direction transverse from

direction in which moments are being determined (ft).

L

2

' shorter span length from center to center of supports in direction transverse

from direction in which moments are being determined (ft).

L

column

length of column from top of footing to bottom of drop panel (ft).

L

d

basic tensile development length of reinforcing steel (in).

L

db

basic development length for reinforcing in compression (in).

L

development

required development length of column reinforcing in footing (in).

L

dh

modified tensile or compression development length for standard hooks (in).

L

drop

length of side of square drop panel (ft).

L

e,max

maximum exterior span length from center of column to center of wall (ft).

L

e,min

minimum exterior span length from center of column to center of wall (ft).

L

footing

length of side of square column footing (ft).

L

hb

basic development length for standard hook in tension (in).

L

i,max

maximum interior span length from center to center of column supports (ft).

LL live load (units as noted).

L

n

length of longer clear span in direction in which moments are being determined

(ft).

L

n

' length of shorter clear span in direction in which moments are being determined

(ft).

L

n,e

maximum exterior clear span (ft).

L

n,i

maximum interior clear span (ft).

Ls maximum dimension of floor slab (ft).

L

splice

required length of splice for vertical column reinforcing (in).

M

2b

required bending capacity of column due to distributed loads on roof, from ACI

318R-89, Section 13.6.3.3 (k-ft).

M

c

total required bending capacity of column due to all loads (k-ft).

M

d

required bending capacity of column due to initial deflection (k-ft).

M

f

moment transferred from column to roof slab through flexure (k-ft).

M

footing

design bending moment in wall footing (lb-ft/ft).

M

i

moment in column due to inertia of the column under seismic loads (k-ft).

Mn nominal bending capacity of section (k-ft/ft).

M

n,b

nominal bending capacity of the column at balanced condition (k-ft).

M

n,min

nominal bending capacity of the column at minimum eccentricity (k-ft).

M

o

nominal bending capacity of the column at maximum eccentricity (k-ft).

M

o,c

total factored static moment in roof slab in a cantilever span (k-ft).

M

o,e

total factored static moment in roof slab in an exterior span (k-ft).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 9

M

o,i

total factored static moment in roof slab in an interior span (k-ft).

Mu factored design moment (k-ft/ft).

MUS minimum ultimate stress (psi).

M

v

moment transferred from column to roof slab through shear (k-ft).

M

w

moment in column due to inertia of the water around the column under seismic

loads (k-ft).

n number of seismic cables required per set (ea).

Na

b

neutral axis location for column at balanced condition (in).

Na

max

neutral axis location for column at maximum eccentricity (in).

Na

min

neutral axis location for column at minimum eccentricity (in).

overhang distance from the exterior face of the corewall to the edge of the roof slab

(in).

P

c

critical buckling load on column (k-ft).

P

dt

prestressing force in tank wall for differential temperature and dryness effects

(k/ft).

P

dynamic

prestressing force in the tank wall for hydrodynamic hoop forces (k/ft).

PL point load on roof slab (lbs).

P

n,b

nominal axial capacity of column at balanced condition (kips).

P

ol

prestressing force for hydrostatic overload (k/ft).

P

pad,static

static vertical load on bearing pad (plf).

P

pad,seismic

seismic vertical load on bearing pad (plf).

P

service

total unfactored service load on column footing (kips).

P

sl

prestressing force for hydrostatic service load (k/ft).

P

s,static

static soil load on wall footing (psf).

P

total

total prestressing force required (kips).

P

u

factored axial demand on column (kips).

P

u,static

static structure load on wall footing (psf).

P

v

required vertical prestressing force (k/ft).

P

w,static

static water load on wall footing (psf).

r radius of gyration of column (in).

rho reinforcing ratio (1).

rho

b

reinforcing ratio which produces a balanced strain condition (1).

rho

max

maximum reinforcing ratio (1).

rho

min

minimum reinforcing ratio (1).

rho

s

column spiral reinforcing ratio (1).

rho

water

density of fluid in tank (pcf).

R

u

coefficient of resistance (psi).

s length of prospective failure plane (ft).

S shape factor of bearing pad (1).

stress

allow

allowable compressive stress in bearing pad (psi).

stress

pad

compressive stress in bearing pad (psi).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 10

S

s

strain in reinforcing steel (in/in).

S

y

yield strain of reinforcing steel (in/in).

t

drop

thickness of drop panel slab (in).

t

f

thickness of flange of structural tubing (in).

t

flash coat

thickness of initial coating of shotcrete placed over corewall prior to wrapping

(in).

t

floor

thickness of floor slab (in).

t

footing

thickness of footing (in).

t

pad

thickness of bearing pad (in).

t

roof

thickness of roof slab (in).

t

roof pad

thickness of bearing pad between wall and roof (in).

t

wall

thickness of the tank wall (in).

t

wall,average

average thickness of the tank wall (in).

t

wall,base

thickness of the cast-in-place corewall at the base (in).

t

wall,mid

thickness of the tank wall at midheight (in).

t

wall,top

thickness of the cast-in-place corewall at the top (in).

U total factored load on tank roof (units as noted).

u

o

horizontal acceleration of ground due to seismic excitation (ft/sec

2

).

v roof shear per lineal foot of tank wall (kips/ft).

V total roof shear (kips).

v

1,2

maximum and minimum shear stress in roof slab due to column moment transfer

(psi).

V

c

nominal capacity of concrete section in shear neglecting reinforcing (kips).

Vc

e,circle

nominal shear capacity of roof slab in exterior bay under circular twoway action

neglecting reinforcing (kips).

Vc

e,square

nominal shear capacity of roof slab in exterior bay under square twoway action

neglecting reinforcing (kips).

Vc

e,straight

nominal shear capacity of roof slab in exterior bay under oneway action

neglecting reinforcing (kips).

Vc

i,circle

nominal shear capacity of roof slab in interior bay under circular twoway action

neglecting reinforcing (kips).

Vc

i,square

nominal shear capacity of roof slab in interior bay under square twoway action

neglecting reinforcing (kips).

Vc

i,straight

nominal shear capacity of roof slab in interior bay under oneway action

neglecting reinforcing (kips).

v

connection

roof shear per connection (kips).

V

convective

base shear due to weight of fluid acting convectively on the tank wall (kips).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 11

v

c,square

nominal shear capacity of footing under square twoway action neglecting

reinforcing (psi).

v

c,straight

nominal shear capacity of footing under oneway action neglecting reinforcing

(psi).

V

footing

design shear in wall footing (lb).

V

impulsive

base shear due to weight of fluid acting impulsively on the tank wall (kips).

Vn nominal shear capacity of section (kips/ft).

v

o

vertical acceleration of ground due to seismic excitation (ft/sec

2

).

V

s

volume of spiral reinforcing (in

3

/in).

v

set

required capacity of one set of seismic cables (ft).

V

s,square

nominal shear capacity of reinforcing under square twoway action (kips)

V

s,straight

nominal shear capacity of reinforcing under oneway action (kips)

Vu factored design shear (kips/ft).

Vu

e,circle

factored shear force on roof slab in exterior bay due to circular twoway action

(kips).

Vu

e,square

factored shear force on roof slab in exterior bay due to square twoway action

(kips).

Vu

e,straight

factored shear force on roof slab in exterior bay due to oneway action (kips).

Vu

i,circle

factored shear force on roof slab in interior bay due to circular twoway action

(kips).

Vu

e,square

factored shear force on roof slab in interior bay due to square twoway action

(kips).

Vu

i,straight

factored shear force on roof slab in interior bay due to oneway action (kips).

v

u,square

factored shear stress on footing due to square twoway action (psi).

V

u,square

factored shear force on footing due to square twoway action (kips).

v

u,straight

factored shear stress on footing due to oneway action (psi).

V

u,straight

factored shear force on footing due to oneway action (kips).

w circular frequency of oscillation of fluid surface (rad/sec).

w

pad

total width of bearing pads (in).

W

d

factored distributed dead load on roof for column design (psf).

W

l

factored distributed live load on roof for column design (psf).

W

column

effective weight of columns which is transferred to the roof diaphragm (kips).

W

dead

total dead weight on tank roof (kips).

W

drop

total weight of drop panels (kips).

W

live

total live weight on tank roof (kips).

W

roof

total weight resisted by roof diaphragm (kips).

W

slab

weight of roof slab excluding drop panels (kips).

W

wall

total weight of tank wall (kips).

W

water

total weight of tank contents (kips).

NOMENCLATURE 2.0 MG LESLIE LANE RESERVOIR

DATE: 9/22/2000 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 12

X smaller dimension of rectangular area (in).

X

c

distance from column centerline to centroid of compression area at minimum

eccentricity (in).

X

c,b

distance from column centerline to centroid of compression area for balanced

condition (in).

X

c,max

distance from column centerline to centroid of compression area at maximum

eccentricity (in).

X

roof

location of centroid of roof mass above top of wall footing (ft).

X

s

sum of moment arms for reinforcing in compression at minimum eccentricity (in).

X

s,b

sum of moment arms for reinforcing in compression for balanced condition (in).

X

s,max

sum of moment arms for reinforcing in compression at maximum eccentricity (in).

X

wall

location of centroid of wall mass above top of wall footing (ft).

Y larger dimension of rectangular area (in).

Y

soil

relative location of center of soil pressure from toe of wall footing (1).

Y

wall

relative location of center of bearing pad from toe of wall footing (1).

Y

water

relative location of center of water pressure from toe of wall footing (1).

Y" distance from the base of the wall to the point of investigation (ft).

/0 shear angle of bearing pad (1).

/0 strength reduction factor for concrete design (1).

/0h angular amplitude of free oscillation at the water surface

/0M

o(max)

maximum nominal bending capacity of the column with no axial load and reduced by

the ACI capacity reduction factor (k-ft).

/0P

n(max)

maximum nominal axial capacity of the column with no bending moment and reduced

by the ACI capacity reduction factor (kips).

FLAT SLAB 2.0 MG LESLIE LANE RESERVOIR

REVISED: 02/02/2001 ESCONDIDO, CALIFORNIA

LeslieLane.wpf Page 13

IV. FLAT SLAB DESIGN

The flat slab roof and column designs satisfy as a minimum the requirements of the ACI 318-95

and ACI 350-89. The Direct Design Method as outlined in the ACI 318-95, Chapter 19, is

utilized for these designs.

A. Assumptions

Live Loads - Case [1]:

snow = 0.0000 psf

peagravel = 0.0000 psf

soil = 100.0 psf

people = 0.0000 psf

other misc. = 50.00 psf

Live Load = 150.00 psf

Superimposed Dead Loads - Case [1]:

peagravel = 0.0000 psf

soil = 100.0 psf

other misc. = 0.0000 psf

Dead load = 100.0 psf

Roof slab thickness - t

roof

= 12.00 in

Drop panel thickness - t

drop

= 7.500 in

Drop panel size - L

drop

= 7.750 ft x 7.750 ft

Column diameters - d

column

= 24.00 in (Interior)

= 24.00 in (Exterior)

Equivalent square column sizes - h

column

= 21.27 in (Interior)

= 21.27 in (Exterior)

Concrete weight = 150.0 pcf

All reinforcing bars are Grade 60.

Maximum span from center-to-center of supports:

interior bay - L

i,max

= 21.00 ft

exterior bay - L

e,max

= 15.70 ft (to centerline of wall)

Minimum span from center-to-center of supports:

exterior bay - L

e,min

= 10.16 ft (to centerline of wall)

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVISED: 02/02/2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 14

B. Deflection Requirements

The minimum thickness of the two-way flat slab with drop panels will be investigated for

interior and exterior spans as computed from ACI 318-95, Section 9.5.3.2.

basic minimum thickness for exterior span:

t

roof(minimum)

= L

n,e

/33 ACI 318-95, Table 9.5(c)

where, L

n,e

= L

e,max

- (h

column

)/2

L

n,e

= 15.70 ft - (21.27 in x 1 ft) = 14.81 ft

2 x 12 in

t

roof(minimum)

= 14.81 ft x 12 in/ft = 5.387 in

33

basic minimum thickness for interior span:

t

roof(minimum)

= L

n,i

/36 ACI 318-95, Table 9.5 (c)

where, L

n,i

= L

i,max

- h

column

L

n,i

= 21.00 ft - (21.27 in x 1 ft) = 19.23 ft

12 in

t

roof(minimum)

= 19.23 ft x 12 in/ft = 6.409 in

36

In order to reduce the reinforcing requirements and provide a more ductile slab, a

thicker slab will be provided.

ADOPT: t

roof

= 12.00 in

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 15

C. Factored Loads - Load Case [1]

The required capacity of the slab will be calculated in accordance with ACI 350-89,

Sect.(2.6.5) and ACI 318-95, Section (9.2).

The shear load will be carried by the concrete only and does not require the

Environmental Durability Factor per ACI 350.

U1 = 1.40 x DL + 1.70 x LL ACI 350R-89, Sect. (2.6.5)

U2 = 1.05 x DL + 1.28 x LL + 1.40 x EL ACI 350R-89, Sect. (2.6.5)

U3 = 0.90 x DL + 1.43 x EL ACI 350R-89, Sect. (2.6.5)

1. Dead load:

DL = t

roof

x 150 pcf + superimposed dead load

= (12.00 in/12 in/ft) x 150.0 pcf + 100.0 psf

= 250.0 psf

ADOPT: DL = 250.0 psf

DL

drop

= additional dead load at drop panels

= t

drop

x 150.0 pcf

= (7.500 in/12 in/ft) x 150.0 pcf

= 93.75 psf

ADOPT: DL

drop

= 93.75 psf

2. Earthquake load:

EL = v

o

x (DL + LL

soil

)

EL = 0.2444 x (250.0 + 100.0) psf = 85.54 psf

ADOPT: EL = 85.54 psf

3. ACI Factored Load

U1

shear

= 1.40 x 250.0 psf + 1.70 x 150.0 psf = 605.0 psf

U2

shear

= 1.05 x 250.0 psf + 1.28 x 150.0 psf + 1.40 x 85.54 psf = 574.3 psf

U3

shear

= 0.90 x 250.0 psf + 1.43 x 85.54 psf = 347.3 psf

ADOPT: U = 605.0 psf (load case U1)

U1

drop,shear

= 1.40 x 93.75 psf = 131.3 psf

U2

drop,shear

= 1.05 x 93.75 psf + 1.40 x (0.2444 x 93.75 psf) = 130.5 psf

U3

drop,shear

= 0.90 x 93.75 psf + 1.43 x (0.2444 x 93.75 psf) = 117.1 psf

ADOPT: U

drop

= 131.3 psf (load case U1

drop

)

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 16

4. Vehicle Load

The vehi cl e l oads wi l l be cal cul at ed based on t he l oad f act or s f r omACI 318- 95. Fo

a movi ng vehi cl e, t he st at i c l oad wi l l al so be scal ed wi t h an i mpact f act or ( I ) .

Fr omRef er ence 1, t he i mpact f act or s wi l l be 1. 0 and 1. 3 f or st at i onar y and movi ng

vehi cl es r espect i vel y.

Vehi cl e #1: 3. 200e+04 l bs

I = 1. 300 Ref. 1, EQ. (3.1)

VL1

u1

= 1. 7 x I x vehi cl e wei ght

= 1. 7 x 1. 300 x 3. 200e+04 l bs = 7. 072e+04 l bs

VL1

u2

= 1. 28 x vehi cl e wei ght + 1. 40 x ( v

o

x vehi cl e wei ght )

= 1. 28 x 3. 200e+04 l bs + 1. 40 x ( 0. 2444 x 3. 200e+04 l bs)

= 5. 191e+04 l bs

ADOPT: VL = VL1 = 7.072e+04 lbs

5. Wheel Load

Rear wheel l oads wi l l be di st r i but ed as per AASHTO desi gn vehi cl e l oads ( see Fi gur e

3. 1, Ref er ence 1) .

VL1

r ear

= 0. 4 x VL1

= 0. 4 x 7. 072e+04 l bs

= 2. 829e+04 l bs

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 17

D. Shear Requirements - Load Case [1]

The shear st r engt h under wi de- beamact i on i nsi de t he dr op panel and under t wo- way act i on

i nsi de and out si de t he dr op panel wi l l be i nvest i gat ed.

MECHANISM: An i nt er i or bay wi t h a st r ai ght pot ent i al f ai l ur e sur f ace al ong t he f ul l

wi dt h of t he bay and l ocat ed a di st ance d f r om t he edge of t he equi val ent

squar e col umn

Vu

i , st r ai ght

= U x L

i , max

x s

1

+ U

dr op

x L

dr op

x s'

1

+ V1

wher e, s

1

= ( L

i , max

) / 2 - ( h

col umn

/ 2 + d) ACI 318-95 Sect. (11.1.3.1)

s'

1

= ( L

dr op

) / 2 - ( h

col umn

/ 2 + d)

d

= t

r oof

+ t

dr op

- cover - 1. 5 x d

bar

= 12. 00 i n + 7. 500 i n - 2. 000 i n - 1. 5 x 0. 8750 i n

= 16. 19 i n

s

1

= 21. 00 f t / 2 - ( 21. 27 i n/ 2 + 16. 19 i n) / 12 = 8. 265 f t

s'

1

= 7. 750 f t / 2 - ( 21. 27 i n/ 2 + 16. 19 i n) / 12 = 1. 640 f t

Vu

i , st r ai ght

= ( 605. 0psf x 21. 00f t x 8. 265f t + 131. 1psf x 7. 750f t x 1. 640f t + 7. 072e+04

l bs) / ( 1000l bs/ k)

= 177. 4 k

Vc

i , st r ai ght

= 2 x %( f ' c) x b

w

x ( d - t

dr op

) ACI 318-95, EQ. (11-3)

wher e, b

w

= L

i , max

= 21. 00 f t

Vc

i , st r ai ght

= ( 2 x %( 4000psi ) x 21. 00f t x ( 16. 19i n - 7. 500i n) x 12i n/ f t ) / ( 1000l b/ k)

= 276. 9 k

/OVc = 0. 8500 x 276. 9 k = 235. 4 k > Vu

i , st r ai ght

therefore, O.K.

MECHANISM: An ext er i or bay wi t h a st r ai ght pot ent i al f ai l ur e sur f ace al ong t he f ul l

wi dt h of t he bay and l ocat ed a di st ance d f r om t he edge of t he equi val ent

squar e col umn

The shear f or ce i n an ext er i or bay wi l l be scal ed by an addi t i onal f act or f or end

ef f ect s

Vu

e, st r ai ght

= 1. 15 x [ U x L

i , max

x s

2

+ U

dr op

x L

dr op

x s'

1

] + V1

wher e, s

2

= L

e, max

/ 2 - ( h

col umn

/ 2 + d) ACI 318-95, Sect. (11.1.3.1)

d = 16. 19 i n

s

2

= 15. 70 f t / 2 - ( 21. 27 i n/ 2 + 16. 19 i n) / 12 = 5. 615 f t

Vu

e, st r ai ght

= ( 1. 15 x [ 605. 0 psf x 21. 00 f t x 5. 615 f t + 131. 3 psf x 7. 750 f t x

1. 640 f t ] + 7. 072e+04 l bs) / ( 1000 l bs/ k)

= 154. 7 k

Vc

e, st r ai ght

= 2 x %( f ' c) x b

w

x ( d - t

dr op

) ACI 318-89, EQ. (11-3)

b

w

= L

i , max

= 21. 00 f t

Vc

e, st r ai ght

= ( 2 x %( 4000psi ) x 21. 00f t x ( 16. 19i n - 7. 500i n) x 12i n/ f t ) / ( 1000l b/ k)

= 276. 9 k

/OVc = 0. 8500 x 276. 9 k = 235. 4 k > Vu

e, st r ai ght

therefore, O.K.

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 18

MECHANISM: An i nt er i or bay wi t h a ci r cul ar pot ent i al f ai l ur e sur f ace l ocat ed a di st ance

d/ 2 f r omt he f ace of t he col umn:

Vu

i , ci r cl e

= U x [ L

i , max

2

- x ( s

3

/ 2)

2

] + U

dr op

x [ L

dr op

2

- B x ( s

3

/ 2)

2

] + V1

ACI 318-95, Sect. (11.12)

wher e, s

3

= d

col umn

+ d

= ( 24. 00 i n + 16. 19 i n) / ( 12 i n/ f t ) = 3. 349 f t

Vu

i , ci r cl e

= ( 605. 0 psf x [ ( 21. 00 f t )

2

- B x ( 3. 349 f t / 2)

2

] + 131. 1 psf x [ ( 7. 750 f t )

2

- B x ( 3. 349 f t / 2)

2

] + 7. 072e+04l bs) / ( 1000 l bs/ k)

= 338. 9 k

Vc

i , ci r cl e

= 4 x %( f ' c) x b

o

x d ACI 318-95, EQ. (11-38)

wher e, b

o

= B x s

3

= x 3. 349 f t = 10. 52 f t

Vc

i , ci r cl e

= 4 x %( 4000 psi ) x 10. 52 f t x 16. 19 i n x 12 i n/ f t / ( 1000 l bs/ k)

= 517. 0 k

/OVc = 0. 8500 x 517. 0 k = 439. 5 k > Vu

i , ci r cl e

therefore, O.K.

MECHANISM: An ext er i or bay wi t h a ci r cul ar pot ent i al f ai l ur e sur f ace l ocat ed a di st ance

d/ 2 f r omt he f ace of an edge col umn:

Vu

e, ci r cl e

= 1. 15 x [ U x [ L

i , max

x ( L

i , max

+ L

e, max

) / 2 - B x ( s

3

/ 2)

2

] + U

dr op

x

[ L

dr op

2

- B x ( s

3

/ 2)

2

] ] + V1 ACI 318-95, Sect. (11.12)

Vu

e, ci r cl e

= ( 1. 15 x [ 605. 0 psf x [ 21. 00 f t x( 21. 00 f t + 16. 19 f t ) / 2 - B x( 3. 349 f t / 2)

2

]

+ 131. 3 psf x [ ( 7. 750 f t )

2

- B x ( 3. 349 f t / 2)

2

] ] + 7. 072e+04 l bs) / ( 1000

l bs/ k)

= 340. 4 k

Vc

e, ci r cl e

= 4 x %( f ' c) x b

o

x d ACI 318-95, EQ. (11-38)

wher e, b

o

= B x s

4

= B x 3. 349 f t = 10. 52 f t

Vc

e, ci r cl e

= 4 x %( 4000 psi ) x 10. 52 f t x 16. 19 i n x 12 i n/ f t / ( 1000 l bs/ k)

= 517. 0 k

/OVc = 0. 8500 x 517. 0 k = 439. 5 k > Vu

e, ci r cl e

therefore, O.K.

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 19

MECHANISM: An i nt er i or bay wi t h a squar e pot ent i al f ai l ur e sur f ace l ocat ed a di st ance

( d - t

dr op

) / 2 f r omt he edge of t he dr op panel

Vu

i , squar e

= U x ( L

i , max

2

- ( L

dr op

+ d - t

dr op

)

2

) + V1 ACI 318-95, Sect. (11.12)

( 605. 0 psf x ( ( 21. 00 f t )

2

- ( 7. 750 f t + ( 16. 19 i n - 7. 500 i n) /

( 12 i n/ f t ) )

2

] + 7. 072e+04 l bs) x 0. 001 k/ l b

= 294. 1 k

Vc

i , squar e

= 4 x %( f ' c) x b

o

x ( d - t

dr op

) ACI 318-95, EQ. (11-38)

wher e, b

o

= 4 x ( L

dr op

+ ( d - t

dr op

) / 12)

= 4 x ( 7. 750 f t + ( 16. 19 i n - 7. 500 i n) / ( 12 i n/ f t ) )

= 33. 90 f t

Vc

i , squar e

= 4 x %( 4000 psi ) x 33. 90 f t x ( 16. 19 i n - 7. 500 i n) x 12 i n/ f t / ( 1000 l bs/ k)

= 893. 9 k

/OVc = 0. 8500 x 893. 9 k = 759. 9 k > Vu

i , squar e

therefore, O.K.

MECHANISM: An ext er i or bay wi t h a squar e pot ent i al f ai l ur e sur f ace l ocat ed a di st ance

( d - t

dr op

) / 2 f r omt he edge of t he dr op panel

Vu

e, squar e

= 1. 15 x U x [ L

i , max

x ( L

e, max

+ L

i , max

) / 2 - ( L

dr op

+ d - t

dr op

)

2

) + V1

ACI 318-95, Sect. (11.12)

= ( ( 1. 15 x 605. 0 psf x [ 21. 00 f t x ( 16. 19 f t + 21. 00 f t ) / 2 - ( 7. 750 f t +

( 16. 19 i n - 7. 500 i n) / ( 12 i n/ f t ) )

2

] ) + 7. 072e+04 l bs) / ( 1000 l bs/ k)

= 288. 9 k

Vc

e, squar e

= 4 x %( f ' c) x b

o

x ( d - t

dr op

) ACI 318-95, EQ. (11-38)

wher e, b

o

= 4 x ( L

dr op

+ ( d - t

dr op

) / 12)

= 4 x ( 7. 750 f t + ( 16. 19 i n - 7. 500 i n) / ( 12 i n/ f t ) )

= 33. 90 f t

Vc

e, squar e

= 4 x %( 4000 psi ) x 33. 90 f t x ( 16. 19 i n - 7. 500 i n) x 12 i n/ f t / ( 1000 l bs/ k)

= 893. 9 k

/OVc

e, squar e

= 0. 8500 x 893. 9 k = 759. 9 k > Vu

e, squar e

therefore O.K.

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 20

E. Moments in Roof Slab - Load Case [1]

The moments in the roof slab will be due to distributed loads and point loads. The

design for bending due to distributed loads will be based on the ACI 318-95 Direct Design

Method and ACI 350-89, Section 2.6.5.a. The moments caused by point loads (if required)

will be calculated separately and superimposed upon the distributed load moments.

1. Factored load moments due to distributed loads:

U1

moment

= 1.30 x U1

shear

= 1.30 x 605.0 psf = 786.5 psf

U2

moment

= 1.30 x U2

shear

= 1.30 x 574.3 psf = 746.5 psf

U3

moment

= 1.30 x U3

shear

= 1.30 x 347.3 psf = 451.5 psf

ADOPT: U = 786.5 psf (load case 1)

U1

drop,moment

= 1.30 x U1

drop,shear

= 1.30 x 131.3 psf = 170.6 psf

U2

drop,moment

= 1.30 x U2

drop,shear

= 1.30 x 130.5 psf = 169.7 psf

U3

drop,moment

= 1.30 x U3

drop,shear

= 1.30 x 117.2 psf = 152.3 psf

ADOPT: U

drop

= 170.6 psf (load case 1)

M

o,i

= total factored static moment in an interior span per ACI 350-89,

Sect.2.6.5.a.

M

o,i

= (U x L

2

x L

n,i

2

)/8 + U

drop

x L

drop

x (L

drop

- h

column

)

2

/8

ACI 318-95, EQ. (13-3)

where, L

2

= L

i,max

= 21.00 ft CRSI Handbook-82, Sect. 10

M

o,i

= 786.5 psf x 21.00 ft x (19.23 ft)

2

/(8 x 1000 lb/k) + 170.6 psf x

7.750 ft x (7.750 ft - 21.27 in/12 in/ft)

2

/(8 x 1000 lb/k)

= 769.2 k-ft

M

o,e

= total factored static moment in an exterior span

M

o,e

= (U x L

2

x L

n,e

2

)/8 + U

drop

x L

drop

x (L

drop

- h

column

)

2

/8

ACI 318-95, EQ. (13-3)

where, L

2

= L

i,max

= 21.00 ft CRSI Handbook-82, Sect. 10

M

o,e

= (786.5 psf x 21.00 ft x (14.81 ft)

2

/(8 x 1000 lb/k) + 170.6 psf

x 7.750 ft x(7.750 ft - 21.27 in/12 in/ft)

2

/(8 x 1000 lb/k)

= 459.0 k-ft

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 21

2. Service load moments due to distributed loads:

M

o,i

= total service load static moment in an interior span

M

o,i

= ((DL + LL) x L

2

x L

n,i

2

)/8 + DL

drop

x L

drop

x (L

drop

- h

column

)

2

/8

ACI 318-95, EQ. (13-3)

where, L

2

= L

i,max

= 21.00 ft CRSI Handbook-82, Sect. 10

M

o,i

= (250.0 psf + 150.0 psf) x 21.00 ft x (19.23 ft)

2

/(8 x 1000 lb/k)

+ 93.75 psf x 7.750 ft x (7.750 ft - 21.27 in/12 in/ft)

2

/(8 x 1000 lb/k)

= 391.4 k-ft

M

o,e

= total service load static moment in an exterior span

M

o,e

= ((DL + LL) x L

2

x L

n,e

2

)/8 + DL

drop

x L

drop

x (L

drop

- h

column

)

2

/8

ACI 318-95, EQ. (13-3)

where, L

2

= L

i,max

= 21.00 ft CRSI Handbook-82, Sect. 10

M

o,e

= (250.0 psf + 150.0 psf) x 21.00 ft x (14.81 ft)

2

/(8 x 1000 lb/k)

+ 93.75 psf x 7.750 ft x (7.750 ft - 21.27 in/12 in/ft)

2

/(8 x 1000 lb/k)

= 233.5 k-ft

Longitudinal Distribution of Total Factored Static Moment:

The total factored static moment in an INTERIOR span shall be distributed

longitudinally based on ACI 318-95, Sect. (13.6.3.2).

Based on the ACI 318-95, Sect. (13.6.3.3), the total factored static moment in

an EXTERIOR span shall be distributed longitudinally based on the support

condition at the exterior edge of the slab. Due to the fact that the length of

the end span varies depending on which column line is analyzed, the support

condition will fall under one of two categories. For moderate to long end spans,

the support condition for the exterior span is most accurately represented by

Column (1) of Sect. 13.6.3.3. For short end spans, the support condition for the

first interior span is most accurately represented by Column (3) of Sect.

13.6.3.3. Both cases will be completely investigated in the calculations which

follow.

Transverse Distribution of Factored Moment:

The transverse distribution of the negative moment in interior spans, negative

moment in exterior spans, and positive moment shall be as prescribed by the ACI

318-95, Sect. (13.6.4).

FLAT SLAB 2. 0 MG LESLI E LANE

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 22

3. Moments due to vehicle load:

The moment s due t o t he wheel l oad on t he sl ab wi l l be cal cul at ed based on t he

di scussi on i n Ref er ence 2, Sect . 3. 5. 2, concer ni ng concent r at ed l oads on sl abs.

Ref er ence 2 appl i es speci f i cal l y t o one l oad appl i ed t o t he sl ab. I t i s assumed t hat

t he one wheel l oad i s appl i ed at t he poi nt whi ch causes maxi mummoment i n t he sl ab

f or posi t i ve or negat i ve moment s. These poi nt s ar e 0. 50L and 0. 25L r espect i vel y.

Based on t hi s assumpt i on, t he second wheel shoul d be at l east 7 f t f r omt he f i r st .

The f act t hat t he second wheel wi l l be l ocat ed no l ess t han 7 f t f r omt he poi nt whi ch

causes maxi mumposi t i ve moment wi l l ef f ect i vel y r educe t he posi t i ve moment caused by

t he second wheel t o apr oxi mat el y one t hi r d of t hat caused by t he wheel whi ch i s

l ocat ed at 0. 50L.

The negat i ve moment wi l l not be ef f ect ed near l y as much by t he l ocat i on of t he wheel

l oad. Ther ef or e, t he conser vat i ve way t o anal i ze f or t he negat i ve moment caused by

t wo wheel l oads wi l l be t o doubl e t he moment caused by one wheel l oad.

M

v, c, i , neg

= negat i ve moment caused by vehi cl e l oad on col umn st r i p i n an i nt er i or span

M

v, m, i , neg

= negat i ve moment caused by vehi cl e l oad on mi ddl e st r i p i n an i nt er i or span

M

v, i , pos

= posi t i ve moment caused by vehi cl e l oad on any st r i p i n an i nt er i or span

M

v, c, e, neg

= negat i ve moment caused by vehi cl e l oad on col umn st r i p i n an ext er i or span

M

v, m, e, neg

= negat i ve moment caused by vehi cl e l oad on col umn st r i p i n an ext er i or span

M

v, e, pos

= posi t i ve moment caused by vehi cl e l oad on col umn st r i p i n an ext er i or span

a. Vehicle #1

a1 = %( VL1

r ear

/ ( t i r e pr essur e) )

a1 = %( 2. 829e+04 l bs/ 40. 00 psi ) x 1 f t / 12 i n = 2. 216 f t

For an I nt er i or span:

a1/ L

i , max

= 2. 216 f t / 21. 00 f t = 0. 1055

assumi ng al pha

1

= bet a

t

= 0,

M1

v, c, i , neg

/ VL1

r ear

= 0. 360 Ref. 2, Fig. (3.44)

M1

v, c, i , neg

= 2 x ( M1

v, c, i , neg

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 2 x ( 0. 360 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 213. 9 k- f t

assumi ng al pha

1

= bet a

t

= i nf i ni t y,

M1

v, m, i , neg

/ VL1

r ear

= 0. 231 Ref. 2, Fig. (3.44)

M1

v, m, i , neg

= 2 x ( M1

v, m, i , neg

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 2 x ( 0. 231 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 137. 2 k- f t

FLAT SLAB 2. 0 MG LESLI E LANE

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 23

assumi ng al pha

1

= bet a

t

= 0,

M1

v, i , pos

/ VL1

r ear

= 0. 210 Ref. 2, Fig. (3.43)

M1

v, i , pos

= 1. 333 x ( M1

v, i , pos

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 1. 333 x ( 0. 210 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 83. 15 k- f t

For an Ext er i or span:

a1/ L

e, max

= 2. 216 f t / 15. 70 = 0. 1412

assumi ng al pha

1

= bet a

t

= 0,

M1

v, c, e, neg

/ VL1

r ear

= 0. 350 Ref. 2, Fig. (3.44)

M1

v, c, e, neg

= 2 x ( M1

v, c, e, neg

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 2 x ( 0. 350 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 207. 9 k- f t

assumi ng al pha

1

= bet a

t

= i nf i ni t y,

M1

v, m, e, neg

/ VL1

r ear

= 0. 230 Ref. 2, Fig. (3.44)

M1

v, m, e, neg

= 2 x ( M1

v, m, e, neg

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 2 x ( 0. 230 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 136. 6 k- f t

assumi ng al pha

1

= bet a

t

= 0,

M1

v, e, pos

/ VL1

r ear

= 0. 185 Ref. 2, Fig. (3.43)

M1

v, e, pos

= 1. 333 x ( M1

v, e, pos

/ VL1

r ear

x VL1

r ear

) x L

2

/ 2

= 1. 333 x ( 0. 185 x 2. 829e+04 l b) x 21. 00 f t / 2 x 0. 001 k/ l b

= 73. 25 k- f t

b. TABLE 1. Summary of Moments due to vehicle load:

Ser vi ce Load

Locat i on Fact or ed Load Moment ( k- f t ) Moment

M

v, c, e, neg

M1

v, c, e, neg

x 1. 3 = 266. 4 M1

v, c, e, neg

/ 1. 7 = 122. 3

M

v, m, e, neg

M1

v, m. e, neg

x 1. 3 = 173. 8 M1

v, m. e, neg

/ 1. 7 = 80. 35

M

v, e, pos

M1

v, e, pos

x 1. 3 = 87. 50 M1

v, e, pos

/ 1. 7 = 43. 09

M

v, c, i , neg

M1

v, c, i , neg

x 1. 3 = 278. 1 M1

v, c, i , neg

/ 1. 7 = 125. 8

M

v, m, i , neg

M1

v, m, i , neg

x 1. 3 = 178. 1 M1

v, m, i , neg

/ 1. 7 = 80. 71

M

v, i , pos

M1

v, i , pos

x 1. 3 = 108. 1 M1

v, i , pos

/ 1. 7 = 48. 92

FLAT SLAB 2. 0 MG LESLI E LANE

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 24

F. Moment Summary

TABLE 2. Summary of Moments in Slab (worst case)

Fact or ed Load Ser vi ce Load

Locat i on Equat i on f or Moment Moment Moment

Ext er i or Col umn 0. 75 x 0. 75 x M

o, e, ext er i or

+ M

v, c, e, neg

= 528. 5 f t - k 253. 6 f t - k

St r i p - Top or 0. 26 x 1. 00 x M

o, i , ext er i or

+ M

v, c, e, neg

= 470. 3 f t - k 224. 0 f t - k

Ext er i or Col umn 0. 63 x 0. 60 x M

o, e, ext er i or

+ M

v, e, pos

= 268. 7 f t - k 131. 3 f t - k

St r i p - Bot t om

Ext er i or Mi ddl e 0. 75 x 0. 25 x M

o, e, ext er i or

+ M

v, m, e, neg

= 263. 7 f t - k 124. 2 f t - k

St r i p - Top or 0. 26 x 0. 00 x M

o, i , ext er i or

+ M

v, m, e, neg

= 177. 6 f t - k 80. 37 f t - k

Ext er i or Mi ddl e 0. 63 x 0. 40 x M

o, e, ext er i or

+ M

v, e, pos

= 210. 9 f t - k 101. 9 f t - k

St r i p - Bot t om

Fi r st I nt er i or 0. 70 x 0. 75 x M

o, i , i nt er i or

+ M

v, c, i , neg

= 681. 8 f t - k 331. 3 f t - k

Col umn St r i p - Top 0. 65 x 0. 75 x M

o, i , i nt er i or

+ M

v, c, i , neg

= 653. 0 f t - k 316. 6 f t - k

Fi r st I nt er i or 0. 52 x 0. 60 x M

o, i , i nt er i or

+ M

v, i , pos

= 348. 1 f t - k 171. 0 f t - k

Col umn St r i p - Bot t om

Fi r st I nt er i or 0. 70 x 0. 25 x M

o, i , i nt er i or

+ M

v, m, i , neg

= 313. 0 f t - k 149. 2 f t - k

Mi ddl e St r i p - Top or 0. 65 x 0. 25 x M

o, i , i nt er i or

+ M

v, m, i , neg

= 303. 4 f t - k 144. 3 f t - k

Fi r st I nt er i or 0. 52 x 0. 40 x M

o, i , i nt er i or

+ M

v, i , pos

= 268. 1 f t - k 130. 3 f t - k

Mi ddl e St r i p - Bot t om

I nt er i or Col umn 0. 65 x 0. 75 x M

o, i , i nt er i or

+ M

v, c, i , neg

= 653. 0 f t - k 316. 6 f t - k

St r i p - Top

I nt er i or Col umn 0. 35 x 0. 60 x M

o, i , i nt er i or

+ M

v, i , pos

= 269. 6 f t - k 131. 1 f t - k

St r i p - Bot t om

I nt er i or Mi ddl e 0. 65 x 0. 25 x M

o, i , i nt er i or

+ M

v, m, i , neg

= 303. 4 f t - k 144. 3 f t - k

St r i p - Top

I nt er i or Mi ddl e 0. 35 x 0. 40 x M

o, i , i nt er i or

+ M

v, i , pos

= 215. 8 f t - k 103. 7 f t - k

St r i p - Bot t om

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 25

G. Flexural Design

A. Method for determining required reinforcing:

The required area of tension reinforcing within each strip was determined by the

following procedure:

Mu # /0Mn

/0Mn = /0 x As x fy x (d - a/2)

where, As = rho x b x d

a = As x fy = rho x d x fy

0.85 x f'c x b 0.85 x f'c

/0Mu = /0 x rho x b x d x fy x (d - rho x d x fy ) Ref. 4, EQ. (3.6.3)

2 x 0.85 x f'c

by defining the following:

m = fy Ref. 4, EQ. (3.6.4a)

0.85 x f'c

and substituting Ref. 4, EQ. (3.6.3) and (3.6.4a) into the above,

R

u

= rho x fy x (1 - 0.5 x rho x m)

rho = 1(1 - %(1 - 2 x m x R

u

)) Ref. 4, EQ. (3.6.5)

m

fy

As

required

= rho x b x d

B. Maximum reinforcement ratio:

rho

max

= 0.75 x rho

b

ACI 318-95, Sect. (10.3.3)

where, rho

b

= the reinforcing ratio producing a balanced strain condition

rho

b

= 0.85 x f'c x beta

1

x 87000 Ref. 4, EQ. (3.5.4)

fy 87000 + fy

rho

max

= 0.75 x 0.85 x 4000 psi x 0.8500 x 87000 = 0.02138

60000 psi 87000 + 60000

C. Minimum reinforcement ratio:

rho

min

= 0.0018 ACI 318-95, Sect. (7.12.2.1)

As

min

= rho

min

x Ag

for column strips reinforcing at drop panels, Ag = b x t

roof

+ L

drop

x t

drop

Ag = 126.0 in x 12.00 in + 7.750 ft x 12 in/ft x 7.500 in = 2210. sqin

As

min

= 0.0018 x 2210. sqin = 3.977 sqin

for all other strips, Ag = b x t

roof

Ag = 126.0 in x 12.00 in = 1512. sqin

As

min

= 0.0018 x 1512. sqin = 2.722 sqin

D. Calculation of Z values:

At service loads, we assume a linear stress strain relationship. In addition, for

a linear stress strain relationship, the location of the neutral axis coincides with

FLAT SLAB 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 26

the location of the center of gravity of the section. Therefore, solving for the

distance to the neutral axis, x,

(A

c

)(x) = (A

t

)(d - x) + (A

t

')(d' - x)

where: A

c

= 1/2 (b)(x)

b = width of section

x = distance to neutral axis

A

t

= equivalent concrete area of tension steel

= (n)(A

s

)

A

t

'= equivalent concrete area of additional tension steel (the

additional steel is typically in compression, however here

it is in tension)

= (n)(A

s

')

n = modular ratio = E

s

/E

c

= 8.044

manipulating the equation

(1/2)(b)(x)

2

+ n(A

s

+ A

s

')(x) - n[(A

s

)(d) + (A

s

')(d')] = 0

therefore

x = -n(A

s

+ A

s

') + %[(n(A

s

+ A

s

'))

2

+ (2)(b)(n)[(A

s

)(d) + (A

s

')(d')]]

b

The service load moments is:

M

service

= (j)(A

s

)(f

s

) + (j')(A

s

')(f

s

')

where, j = moment arm for tension steel

= d - x/3

j'= moment arm for additional tension steel

= d' - x/3

from strain compatibility,

f

s

f

s

'

=

d - x d' - x

therefore,

f

s

' = f

s

(d' - x)/(d - x)

substituting and solving for f

s

,

f

s

= M

service

/[(d - x/3)(A

s

) + (d' - x/3)[(d' - x)/(d - x)](A

s

')]

Z = f

s

3

%[(2)(d

c

)

2

(spacing)] ACI 318-95, EQ. (10-5)

Z # 115 k/in ACI 350-89, Sect. (2.6.6)

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 27

E. Reinforcing

TABLE 2. Reinforcement Parameters and Provisions

Location b d As bar # of As

(n) (in) rho required size bars provided spacing

Exterior Column 93.00 16.19 0.005043 7.593 7 16 9.600 7.875

Strip - Top

Exterior Column 126.0 8.688 0.006672 7.304 7 16 9.600 7.875

Strip - Bottom

Exterior Middle 126.0 8.875 0.006247 6.988 6 16 7.040 7.875

Strip - Top

Exterior Middle 126.0 8.875 0.004937 5.521 6 16 7.040 7.875

Strip - Bottom

First Interior 93.00 16.19 0.006602 9.939 7 20 12.00 6.300

Column Strip -

Top

First Interior 126.0 8.688 0.008820 9.655 7 20 12.00 6.300

Column Strip -

Bottom

First Interior 126.0 8.875 0.007505 8.393 6 20 8.800 6.300

Middle Strip -

Top

First Interior 126.0 8.875 0.006359 7.111 6 20 8.800 6.300

Middle Strip -

Bottom

Interior Column 93.00 16.19 0.006305 9.492 7 20 12.00 6.300

Strip - Top

Interior Column 126.0 8.688 0.006696 7.330 7 20 12.00 6.300

Strip - Bottom

Interior Middle 126.0 8.875 0.007258 8.116 6 20 8.800 6.300

Strip - Top

Interior Middle 126.0 8.875 0.005057 5.655 6 20 8.800 6.300

Strip - Bottom

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 28

F. Check for flexural crack control

TABLE 3. Reinforcement Parameters and Provisions

Location b d d

c

* d' A

s

A

s

' x fs Z

(in) (in) (in) (in) spacing provided provided (in) (ksi) (k/in)

Exterior Column 93.00 16.19 2.438 10.81 7.875 9.600 12.00 5.399 15.83 71.85

Strip - Top

Exterior Column 126.0 8.688 2.438 3.313 7.875 9.600 6.000 2.770 20.79 94.38

Strip - Bottom

Exterior Middle 126.0 8.875 2.375 3.125 7.875 7.040 8.800 2.526 25.50 113.8

Strip - Top

Exterior Middle 126.0 8.875 2.375 3.125 7.875 7.040 4.400 2.474 21.21 94.62

Strip - Bottom

First Interior 93.00 16.19 2.438 10.81 6.300 12.00 12.00 5.693 17.77 74.91

Column Strip -

Top

First Interior 126.0 8.688 2.438 3.313 6. 300 12. 00 6. 000 2.994 22.06 92.96

Column Strip

Bottom

First Interior 126.0 8.875 2.375 3.125 6.300 8.800 8.800 2.716 25.07 103.8

Middle Strip -

Top

First Interior 126.0 8.875 2.375 3.125 6.300 8.800 4.400 2.684 22.05 91.34

Middle Strip -

Bottom

Interior Column 93.00 16.19 2.438 10.81 6.300 12.00 12.00 5.693 16.99 71.59

Strip - Top

Interior Column 126.0 8.688 2.438 3.313 6.300 12.00 6.000 2.994 16.91 71.26

Strip - Bottom

Interior Middle 126.0 8.875 2.375 3.125 6.300 8.800 8.800 2.716 24.25 100.4

Strip - Top

Interior Middle 126.0 8.875 2.375 3.125 6.300 8.800 4.400 2.684 17.55 72.68

Strip - Bottom

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 29

H. Flexural Capacity

The capacity of each design strip can be calculated based on the formula below:

Capacity = /0 x T x (d - a/2)

where, T = tensile force in reinforcing

= As

provided

x fy

d = depth to reinforcing from Table 2

a = height of compressive stress block in concrete

= As

provided

x fy

0.85 x f'c x b

Capacity = /0 x As

provided

x fy x (d - ( As

provided

x fy))

1.7 x f'c x b

TABLE 3. Flexural Capacity of Roof Design Strips in Bending

Location Capacity (ft-k)

Exterior Column Strip - Top 660.0

Exterior Column Strip - Bottom 364.3

Exterior Middle Strip - Top 265.5

Exterior Middle Strip - Bottom 265.5

First Interior Column Strip - Top 812.6

First Interior Column Strip - Bottom 423.8

First Interior Middle Strip - Top 327.1

First Interior Middle Strip - Bottom 327.1

Interior Column Strip - Top 812.6

Interior Column Strip - Bottom 423.8

Interior Middle Strip - Top 327.1

Interior Middle Strip - Bottom 327.1

V. COLUMN DESIGN

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 30

A. Stiffness Calculations

1. Slab Stiffness

E = 57,000 x %(4000) = 3.605e+06 psi

I

gross

= 1/12 x L

i,max

x t

roof

3

= 1/12 x 21.00 ft x 12 in/ft x (12.00 in)

3

= 3.629e+04 in

4

K

slab

= 4 x E x I

gross

/L

i,max

= 4 x 3.605e+06 psi x 3.629e+04 in

4

= 1.730e+05 ft-k

21.00 ft x (12 in/ft)

2

x 1000 lb/k

2. Torsional Stiffness of Roof Slab at Columns

C = (1 - 0.63 x X) x X

3

x Y ACI 318-95, Sect.(13.0)

Y 3

where, for roof slab: X = t

slab

= 12.00 in

Y = h

column

= 21.27 in

for drop panel: X = minimum(C1,C2)

Y = maximum(C1,C2)

where,

C1 = t

slab

+ t

drop

= 12.00 in + 7.500 in = 19.50 in

C2 = h

column

= 21.27 in

Therefore,

X = 19.50 in

Y = 21.27 in

C

slab

= (1 - 0.63 x 12.00 in) x (12.00 in)

3

x 21.27 in = 7897. in

4

21.27 in 3

C

drop

= (1 - 0.63 x 19.50 in) x (19.50 in)

3

x 21.27 in = 2.221e+04 in

4

21.27 in 3

K

t

= torsional stiffness of slab section

= [L

i,max

x ((1 - Y/L

i,max

)

5

+ (1 - L

drop

/L

i,max

)

5

x (1/C

slab

- 1/C

drop

))]

-1

20 E x C

drop

E

= [21.00 x ( (1 - 21.27 in x 1 ft/12 in)

5

+ (1 - 7.750 ft)

5

x ( 1 - 1 ))]

-1

20 21.00 ft 21.00 ft 7897. 2.221e+04

3.605e+06 psi x 2.221e+04 in

4

3.605e+06 psi

= 9.245e+10 in

2

-lb/ft x 1 ft

2

/144 in

2

x 0.001 k/lb = 6.420e+05 ft-k

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

REVI SED: 02/ 02/ 2001 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 31

3. Column Stiffness

E = 57000 x %(fc) = 57000 x %(4000 psi) = 3.605e+06 psi

L

column

= distance from top of the floor to top of wall + t

roof pad

- t

drop

-t

column footing

= 31.00 ft + (0.5000 in - 7.500 in - 15.00 in)/12 in/ft

= 29.17 ft

I

gross

= B/4 x (d

column

/2)

4

= B/4 x (24.00/2)

4

= 1.629e+04 in

4

K

column

= 4 x E x I

gross

/L

column

= 4 x 3.605e+06 psi x 1.629e+04 in

4

29.17 ft x (12 in/ft)

2

x 1000 lb/k

= 5.592e+04 ft-k

K

ec

= (K

column

-1

+ K

t

-1

)

-1

= ((5.592e+04 ft-k)

-1

+ (6.420e+05 ft-k)

-1

)

-1

= 5.144e+04 ft-k

alpha

ec

= K

ec

/K

slab

= (5.144e+04)/(1.730e+05) = 0.2972

B. Column Loads

Length designations are as follows:

L

n

= longer clear span in direction moments are being determined

L

2

= transverse span

L

n

'= shorter clear span in direction moments are being determined

L

2

'= shorter transverse span

r = radius of gyration

= 0.25 x d

column

The column will be assumed to be braced against sidesway. Under seismic loading, the

roof-wall shear connection allows 0.1250 in of movement in any direction which will be

treated as an initial displacement of the column-roof joint. All moments caused by

seismic loading would logically be multiplied by delta

s

and all static moments would be

multiplied by delta

b

(ACI 318-95, EQ. (10-9)). However, due to the small magnitude of

the lateral deflection (0.1250 in) and for simplicity, all calculated moments will be

conservatively magnified by delta

b

.

k = 1.00 (assuming a braced frame)

for interior columns,

A

bay

= L

i,max

2

for exterior columns,

A

bay

= L

i,max

x (L

e

+ L

i,max

)/2

Slenderness = k x L

column

/r

Since Slenderness > 22, moment magnification will be calculated for each case.

Since Slenderness < 100, approximate methods may be used to evaluate slenderness

effects (ACI 318-95, Sect. (10.11.5)).

column weight = B x (d

column

/2)

2

x L

column

x 150.0 pcf

column weight + drop panel weight = column weight + [(L

drop

)

2

x t

drop

x 150.00 pcf]

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 32

TABLE 4. Column Design Variables Consistent for All Load Cases

exterior exterior

column at column at

interior longest shortest

column end span end span

L

n

(ft) 19.23 19.23 19.23

L

2

(ft) 21.00 21.00 21.00

L

n

' (ft) 19.23 11.92 6.773

L

2

' (ft) 21.00 21.00 21.00

d

column

(in) 24.00 24.00 24.00

r

gyration

(in) 6.000 6.000 6.000

k 1.000 1.000 1.000

L

i,max

(ft) 21.00 21.00 21.00

L

e

(ft) 0 12.81 7.659

A

bay

(ft

2

) 441.0 355.0 300.9

L

column

(ft) 29.17 29.17 29.17

sl ender ness 58. 33 58. 33 58. 33

column weight (lbs) 1.374e+04 1.374e+04 1.374e+04

column + drop (lbs) 1.938+04 1.938e+04 1.938e+04

Dead load:

DL = distributed dead load on column

For soil and gravel treated as Live Loads,

DL = roof weight + other dead load

For soil and gravel treated as Dead Loads,

DL = roof weight + other dead load + soil dead load + gravel dead load

Live load:

LL = distributed live load on column

For soil and gravel treated as Live Loads,

LL = live loads + soil live load + gravel live load

For soil and gravel treated as Dead Loads,

LL = live loads

Earthquake load - for SEISMIC cases only:

EL = distributed earthquake load on column

= v

o

x DL

Factored loads:

for static cases,

W

d

= 1.3 x 1.4 x DL

W

L

= 1.3 x 1.7 x LL

for seismic cases,

W

d

= 1.3 x 1.05 x DL

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R

DATE: 9/ 22/ 2000 ESCONDI DO, CALI FORNI A

LeslieLane.wpf Page 33

W

L

= 1.3 x 1.28 x LL + 1.3 x 1.40 x EL

Axial load on column:

for static cases,

P

u

= ((W

d

+ W

L

)/1.3) x A

bay

+ 1.4 x (column weight + drop panel) + VL1

for seismic cases,

P

u

= ((W

d

+ W

L

)/1.3)x A

bay

+(1.05 + 1.40 x v

o

)x(column weight + drop panel)+ VL1

P

u

//0 = P

u

/0.7500

Flexural load on column:

Since columns form part of two or more intersecting lateral-force-resisting

systems, the effects of the two orthogonal direction moments (M

2b,x,

and M

2b,y

)will

be combined using the square root of the sum of the squares (SRSS) method.

Conservatively we will assume that the moments generated on the columns by the

gravity loads and moment magnifiers are the same in both directions.

M

2b,x

= ADOSS (See Appendix)

M

2b,min

= 1.3 x Pu (0.6 + 0.03 x d

column

) / 12.00 in/ft ACI 318-95, Eq. (10-15)

M

2b

= /(M

2b,x

2

+ M

2b,y

2

)

wher e M

2b, x

= M

2b, y

= maxi mumval ue f r omM

2b, x1

, M

2b, x2

, and M

2b, mi n

Assuming both ends of the columns are constrained against rotation, the moment

due to the imposed deflection during seismic loading will be calculated using

load factors from ACI 318-95, Sect. (9.2): (1.1 x 1.7 x 0.75 = 1.4), and ACI

350R-95, Sect. (2.6.5a):(1.30)

M

d

= 1.3 x 1.4 x 12 x E x I x delta x L

column

= 1.3 x 1.4 x 6 x E x I x delta

2 x L

column

3

L

column

2

M

i

= Moment caused by the inertia of the column in an earthquake assuming both

ends of the column are constrained against rotation.

= 1.3 x 1.4 x column weight x L

column

x u

o

/12

The force caused by the water accelerating against the column in an earthquake

will be calculated based on Reference 10.

COLUMN DESI GN 2. 0 MG LESLI E LANE RESERVOI R