Académique Documents

Professionnel Documents

Culture Documents

BladeTec HVLS Fans

Transféré par

rijothomasv7770 évaluation0% ont trouvé ce document utile (0 vote)

146 vues12 pagesBladeTec HVLS (High Volume Low Speed) fans for better air flow coverage and human comfort. The sizes varies from 8ft to 24 ft. For more details, visit www.bladetecfans.com

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBladeTec HVLS (High Volume Low Speed) fans for better air flow coverage and human comfort. The sizes varies from 8ft to 24 ft. For more details, visit www.bladetecfans.com

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

146 vues12 pagesBladeTec HVLS Fans

Transféré par

rijothomasv777BladeTec HVLS (High Volume Low Speed) fans for better air flow coverage and human comfort. The sizes varies from 8ft to 24 ft. For more details, visit www.bladetecfans.com

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 12

BladeTec Fans

High Volume, Low Speed Fans (HVLS)

Commercial

Industrial

BladeTec HVLS Fans. The next generation of innovative products from DuctSox Corporation.

For over 30 years, DuctSox has been committed to serving the HVAC community with innovative solutions for air

dispersion needs. From fabric air distribution systems to HVLS fans, DuctSox products have been accepted within

key industry organizations such as ASHRAE, Underwriters Laboratories, International Code Council, and many local

building authorities throughout the world. DuctSox offers the best products, designs, and sales support in our industry.

DuctSox strives to be the leader in the industry through our commitment to quality, service, and innovation. This

commitment has allowed us to expand our product offerings to include BladeTec HVLS Fans.

The BladeTec advantage

Traditional air movement from conventional high RPM beam-mounted or industrial oor fans can be ineffective

and disruptive. Air speeds beyond 3.1 m/s (610 fpm) offer little, if any, added cooling benet. High speed

fans are expensive to operate, several are required for effective cooling, and they cannot destratify air to keep

temperatures consistent from oor to ceiling. BladeTec HVLS Fans are able to deliver a large volume of air (up to

671,000 m

3

/h or 395,000 CFM) to a large space (2,641 m

2

or 28,400 ft

2

) at a relatively low cost.

Increased comfort and productivity

In warmer months/climates, air from a BladeTec fan passes over people to keep them cooler, more comfortable,

and more productive. In cooler months/climates, BladeTec pushes air from the ceiling down to the oor to keep

employees warmer.

Greater energy efciency and cost savings

A large BladeTec fan can lower your energy costs by as much as 30%.

Commercial Fans: Aesthetics and Efciency

BladeTec Commercial fans are designed for smaller spaces from 131,000 m

3

/h

(77,000 CFM) to 158,000 m

3

/h (93,000 CFM). The Commercial fan is a quiet, stylish

fan, suitable for any environment such as retail spaces, health clubs, schools, auto

dealers, government buildings, restaurants, theatres, and many more. The standard

fan includes mill nished aluminum blades with a powder-coated motor frame. When

a custom look is desired, the blades can be polished or painted to any color desired.

Industrial Fans: More air movement. More employee comfort. More energy savings!

With its unique blade design, the BladeTec Industrial fan delivers the most air movement

of any HVLS fan on the market today while providing improved employee comfort at the

most economical start up and operating cost available. BladeTec fans can function as a

standalone product or in conjunction with other methods of maintaining a comfortable

air temperature in any space. With models ranging from 138,000 m

3

/h (81,000 CFM)

to over 671,000 m

3

/h (395,000 CFM), the BladeTec Industrial fans are ideal for use in

large buildings with high ceilings such as distribution centers, manufacturing facilities,

convention centers, stadiums, warehouses, dairy/livestock barns, and airports.

BladeTec. Its all in the Blade!

For improved comfort, efciency, aesthetics, and cost. Get more CFMs per dollar.

3

Uneven temperature zones waste energy and money

BladeTec fans make your HVAC systems more efcient

Reduce energy consumption by 20 to 30%

Eliminate the cold and hot zones

All the comfort, without all the cost

Save money in the warmer months

Moving air is more comfortable

A 1 m/s to 2 m/s (197 fpm to 394 fpm) increase in air

speed delivers the equivalent of a 3C to 7C (5.4F to

12.6F) decrease in room temperature

A BladeTec fan allows you to raise the summer temperature

setting

7% energy savings for every degree (C) you can raise

your setting

Reduce energy consumption by up to 20%

The perfect supplement for your A/C system

Save money in the cooler months

Mix warm air from the ceiling with cooler air below, a

process called destratication

The fan gathers air and pushes it down in a conical shape

until it reaches the oor and then ows out horizontally

Reduce energy consumption by up to 30%

Better fans for better environments

While the money saved by reducing your energy costs can

provide a real return on investment, additional benets

include:

Help eliminate heat stress

Reduced condensation on the oors

Reduced condensation on products and packaging

Improved indoor air quality by dispersing fumes/odors

Improved productivity

Consistent oor-to-ceiling temperatures

Cost Savings,

Improved Environments

Did you know?

Running 10 to 20 traditional oor or smaller

ceiling fans can cost 5 to 7 times more to run as

one HVLS fan. Additional benets of HVLS fans

include:

Safer work environments

- Eliminate trip hazards

- Reduce potential for eye injuries

- Reduce noise

Reduce maintenance costs

Free up low voltage power outlets

33C ( 91.4F)

at the ceiling

15C (59F)

on the oor

24.5C (76F)

at the ceiling

24C (75F)

on the oor

4

The BladeTec Commercial HVLS Fan was designed specically for smaller spaces where style and efciency are

important. The unique three-blade design of the Commercial Fan maximizes both. The BladeTec Commercial Fan

can extend air movement up to 18m (60 ft), but is also a quiet solution for environments where noise should be

at a minimum.

The BladeTec Commercial Fan can be used in a variety of commercial environments and is available in three

sizes including 2440mm (8 ft), 3050mm (10 ft), and 3660mm (12 ft).

for commercial applications

Commercial Applications

Ofce Buildings

Health clubs

Schools/universities

Retail

Auto dealers

Lobbies/atriums

Libraries

Religious facilities

Hotels

Theatres

Bars/restaurants

Hospitals

Hundreds of other applications

5

Unique three-blade design

Mill nished aluminum blade with Vortex Tips

Ideal contour and twist for maximum air movement

Upward blade tilt

Increases airow and reach

Extends reach of air movement up to 18m (60 ft) from

the fans center in all directions

Directs air outward from fans center in a conical

shape

Resilient blade/hub connection

Vibration- absorbing material reduces stress to the

hub by up to 75%

Rotationally balanced blade/hub

Used for over 40 plus years in the most demanding

applications worldwide

Designed for over 10 times the force and stress

generated by the BladeTec Commercial Fan

Robust mounting system

Extruded, precision-milled aluminum hub

Three-way motor-to-hub safety connection

Easy-to-use controls

Simple on/off button

Adjustable speed control

Operates in forward or reverse

Fits into standard electrical

housing

Controls up to 4 fans

Optional Zone Controller can

operate up to 18 fans

Commercial Fan Features

DIAMETERS 2440mm (8 ft), 3050mm (10 ft),

3660mm (12 ft)

BLADES Aluminum

BLADE FINISH Mill nished, custom colors optional

# OF BLADES 3

AIRFLOW 2440mm (8 ft) = 131,000 m

3

/h or

77,000 CFM

3050mm (10 ft) = 154,600 m

3

/h

or 91,000 CFM

3660mm (12 ft) = 158,000 m

3

/h

or 93,000 CFM

MOTOR 1 HP

VOLTAGES 230, 380, 400, 460

PHASE 3 phase standard, 1 phase also

available for 230

AMPS 2.9A @ 230V and 400V, 1.7A @

380V and 460V

WATTS 650 to 800

FREQUENCY 50 to 60 Hz

COVERAGE Up to 1017m

2

(11,000 ft

2

)

18m (60 ft) from the fans center in

all directions

DECIBELS 40 to 52 dBA depending on fan

speed (measured 6100mm or 20

ft below and 6100mm or 20 ft

from the fans center)

AIR SPEED Up to 2 m/s (394 fpm) at full

speed

CONTROLS Variable speed

MOUNTING HEIGHTS 3050mm (10 ft) to 9150mm (30

ft), nished oor to bottom of blade

WEIGHT 68 kg (150 lbs)

WARRANTY 3-year parts and 1-year labor

warranty

10-year structural integrity warranty

Lifetime warranty on workmanship

of blades and hub

6

for industrial applications

The BladeTec Industrial HVLS Fan was designed specically for larger spaces where maximizing employee

comfort, air movement, and energy savings are key. The unique three-blade design of the Industrial Fan

maximizes all of these. In addition, it delivers the most air movement of any HVLS fan around. The BladeTec

Industrial Fan can extend its air movement up to 29m (95 ft).

The BladeTec Industrial Fan can be used in a variety of industrial environments and is available in ve sizes:

2440mm (8 ft), 3660mm (12 ft), 4880mm (16 ft), 6100mm (20 ft), and 7320mm (24 ft).

Industrial Applications

Distribution centers

Manufacturing facilities

Warehouses

Athletic facilities

Airports

Convention centers

Stadiums

Arenas

Dairy/Livestock Barns

Hundreds of other applications

7

Industrial Fan Features

Unique three-blade design

Made of strong, durable, lightweight aluminum

Varies in width along entire length of blade

Ideal contour and twist for maximum air movement

Complex jig-formed shape is not possible with

extruded blades

Upward blade tilt

Increases airow and reach

Extends reach of air movement up to 29m (95 ft) from

the fans center in all directions

Directs air outward from fans center in a conical shape

Resilient blade/hub connection

Vibration-absorbing material reduces stress to the

hub by up to 75%

Rotationally balanced blade/hub

Used for over 40 plus years in the most demanding

applications worldwide

Designed for over 10 times the force and stress

generated by the BladeTec Industrial Fan

Robust mounting system

Stabilizing cables, beam clamp and motor housing

Extruded, precision-milled aluminum hub

Three-way motor-to-hub safety connection

Easy-to-use controls

Simple on/off button

Adjustable speed control

Operates in forward or reverse

Fits into standard electrical

housing

Controls up to 4 fans

Optional Zone Controller can

operate up to 18 fans

DIAMETERS 2440mm (8 ft), 3660mm (12 ft),

4880mm (16 ft), 6100mm (20 ft),

7320mm (24 ft)

BLADES Aluminum

BLADE FINISH Mill nished, custom colors

optional

# OF BLADES 3

AIRFLOW 2440mm (8 ft) = 138,000 m

3

/h or

81,000 CFM

3660mm (12 ft) = 224,000 m

3

/h

or 132,000 CFM

4880mm (16 ft) = 350,000 m

3

/h

or 206,000 CFM

6100mm (20 ft) = 491,000 m

3

/h

or 289,000 CFM

7320mm (24 ft) = 671,000 m

3

/h

or 395,000 CFM

MOTOR 2 HP

VOLTAGES 230, 380, 400, 460, 575

PHASE 3 phase standard, 1 phase also

available for 230

AMPS 6.3A @ 230V, 3.55A @ 380V, 3.6A @

400V, 3.15A @ 460V, 2.5A @ 575V

WATTS 1300 to 1600

FREQUENCY 50 Hz

COVERAGE Up to 2641 m

2

(28,400 ft

2

)

29m (95 ft) from the fan's center

in all directions

DECIBELS 50 to 62 dBA depending on fan

speed (measured 6100mm or 20

ft below and 6100mm or 20 ft

from the fan's center)

AIR SPEED Up to 2.8 m/s (550 fpm) at full

speed

CONTROLS Variable speed

MOUNTING HEIGHTS 4575mm (15 ft) to 24400mm

(80 ft), nished oor to bottom of

blade

WEIGHT 136 kg (300 lbs)

WARRANTY 3-year parts and 1-year labor

warranty

10-year structural integrity warranty

Lifetime warranty on workmanship

of blades and hub

8

Fan Selection Guide

BladeTec fan layout is based on the concept of how air velocities

can produce a perceived range of temperature drops at varying

distances from the center of the fan. To help dene theses ranges,

we have introduced the concept of Areas of Inuence. Figure A

denes the Area of Inuence as four distinct areas (A1, A2, A3,

and A4) using concentric circles to represent average air velocities,

distances, and perceived temperature drop. Each BladeTec model

has its own Area of Inuence. The larger the fan, the larger the Area

of Inuence. Each area of inuence is based on air velocity and

the change in perceived temperature drops from 2.0C (4F) to

8.3C (14.4F). For example, the A1 Area of Inuence is dened

at a distance from the fan center where the velocity is 2.8 m/s

(550 fpm), A2 is 1.3 m/s (250 fpm), A3 is 0.9 m/s (175 fpm), and

A4 is 0.5 m/s (100 fpm). (See Figure A.) The real benet of the

BladeTec selection methodology is a more scientic analysis of the

relationship between fan diameter and perceived temperature change.

The rst step in selecting a fan is understanding what your application needs are.

BladeTec fans can be used for effective cooling only. The air velocity makes the occupants perceive a cooler temperature.

BladeTec fans can be used in combination with traditional air conditioning systems, making cooling more efcient.

BladeTec fans can be used for mixing air vertically from ceiling to oor (typically known as air destratication)

and/or mixing air horizontally from one building area to another.

BladeTec fans can be used for drying oors and product.

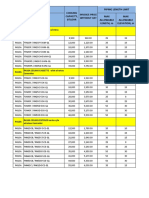

BladeTec fan performance capabilities chart

BladeTec Industrial HVLS Fan

* DeltaET is the perceived temperature drop due to air velocity and is based on data supplied by ASHRAE standard 55-2010.

Note: Industrial fans were tested at a mounting height of 30 ft off grade and Commercial fans were tested at 15 ft off grade.

Area of

Inuence m/s (fpm)

C (F)

DeltaET*

Area of Inuence diameters in meters (ft)

2440mm

(8 ft)

3660mm

(12 ft)

4880mm

(16 ft)

6100mm

(20 ft)

7320mm

(24 ft)

A1

2.8 m/s

(550 fpm)

6 to 8C

(11 to 14F)

2.4m (8 ft) 3.7m (12 ft) 4.9m (16 ft) 6.1m (20 ft) 9.8 (32 ft)

A2

1.3 m/s

(250 fpm)

3 to 5C

(5 to 9F)

4.5m (15 ft) 9.1m (30 ft) 12.2m (40 ft) 13.0m (43 ft) 15.2m (50 ft)

A3

0.9 m/s

(175 fpm)

3 to 4C

(6 to 8F)

6.0m (20 ft) 15.0m (49 ft) 18.0m (60 ft) 30.0m (100 ft) 36.0m (120 ft)

A4

0.5 m/s

(100 fpm)

2 to 3C

(4 to 5F)

45.0m (148 ft) 48.0 (157 ft) 55.4 (182 ft) 57.9m (190 ft) 58.0m (190 ft)

Diameters of coverage Fan diameter

Figure A.

A1 = 2.8 m/s (550 fpm)

A2 = 1.3 m/s (250 fpm)

A3 = 0.9 m/s (175 fpm)

A4 = 0.5 m/s (100 fpm)

Perceived cooling degrees

Average air velocity

9

Fan Selection Guide

Figure B. BladeTec Industrial Fans

BladeTec Commercial

HVLS Fan

Fan Layout Examples

Fan layout based on fan diameter and Area of Inuence.

Figure B is another way to look at 7320mm (24 ft), 4878mm (16 ft), and 2440mm (8 ft) BladeTec fans and their

Areas of Inuence. This Figure helps depict how important it is to apply correct BladeTec fan sizes with your

application requirements. You can observe schematically how the Areas of Inuence change by fan diameter.

Example #1

Fitness Center with ceiling heights less than 6100mm

(20 ft), medium to high occupancy

Objective: High air velocity and effective cooling

Solution: Two commercial 2440mm (8 ft) fans with

33% of total area covered by A2 and A3 provides

effective cooling of 3 to 7C (4 to 12F) with the

balance of the area covered by A4 providing effective

cooling of 1.5 to 2.8C (3 to 5F).

A1

A2

A3

A4

7320mm

(24 ft) fan

4878mm

(16 ft) fan

A2

A3

A4

A1 A1

A2

A3

A4

2440mm

(8 ft) fan

2440mm (8 ft) 2440mm (8 ft)

25.9m (85 ft) 7.6m (25 ft)

10.7m

(35 ft)

A2

A3

A4

A2

A3

A4

Area of

Inuence m/s (fpm)

C (F)

DeltaET*

Area of Inuence diameters in meters (ft)

2440mm

(8 ft)

3050mm

(10 ft)

3660mm

(12 ft)

A2

2.0 m/s

(400 fpm)

5 to 7C

(9 to 13F)

2.4m (8 ft) 3.0m (10 ft) 3.7m (12 ft)

A3

0.9 m/s

(175 fpm)

3 to 4C

(6 to 8F)

3.0m (10 ft) 4.6m (15 ft) 6.0m (20 ft)

A4

0.5 m/s

(100 fpm)

2 to 3C

(4 to 5F)

18.0m (60 ft) 24.4m (80 ft) 30.4m (100 ft)

Fan Selection Guide

Example #2

Grocery Store with limited air conditioning

Objective: Provide cooling relief where there is highest

concentration of people

Solution: One 3660mm (12 ft) Commercial fan with A2 and

A3 targeted over the cash register area provides effective

cooling of 3.3 to 7.2C (5 to 13F).

Additional considerations:

An additional fan could also be added over aisle spaces,

but caution should be taken to avoid sensitive air velocity

areas (for example, open case refrigerator cases).

An Industrial fan may also t this application if more air

movement is needed.

Example #3 (2 equivalent spaces with different application requirements)

Industrial Application with low occupancy, warehouse facility

Objective: Limited effective cooling

Solution: Four 7320mm (24 ft) BladeTec Industrial Fans effectively

provide cooling air velocity while providing mixing/destratication for a

majority of the building.

A1 through A4 provide mixing for destratication while A1 through A3

(44% of oor space) provide limited effective cooling of 3 to 8C

(4 to 13F).

Industrial Application with high occupancy, manufacturing facility

Objective: Maximize effective cooling

Solution: Combination of 7320mm (24 ft) and 3660mm (12 ft)

BladeTec Industrial Fans provide effective cooling for a majority of

the building.

A1 through A3 (90%+ of oor space) provide effective cooling of 3

to 8C (4 to 13F).

Other fan layout considerations:

Minimum clearance above fan (both structural/clearance and space for

airow into the fan)

Minimum clearance below fan = 305mm (12 in)

Minimum clearance from fan blade tips = 482mm (19 in)

Obstructions (lighting, sprinklers, access panels, etc.) should be

considered

IMPORTANT!!!

Fan diameter

Min. clearance

dimension at full RPM

2440mm (8 ft) 610mm (2 ft)

3660mm (12 ft) 915mm (3 ft)

4880mm (16 ft) 1220mm (4 ft)

6100mm (20 ft) 1525mm (5 ft)

7315mm (24 ft) 1525mm (5 ft)

A4

Target area,

cash registers

Restrooms Ofces

3660mm

(12 ft) fan

71.3m (234 ft)

61.0m

(200 ft)

Open case refrigerator,

velocity-sensitive area

72.2m

(236 ft,

8 in)

110.4m (362 ft, 2 in)

7320mm (24 ft) fan

A1

A2

A3

A4

72.2m

(236 ft,

8 in)

110.4m (362 ft, 2 in)

Crane with limited clearance above the fan

A1

A2

A3

7320mm (24 ft) fan

ZONE CONTROLLER

ELECTRICAL DISCONNECT

INCOMING

FAN POWER

BUILDING

HEIGHT

MODBUS CABLE

STANDARD FAN

CONTROL BOX

FAN MOTOR

WIRING

MAIN

ELECTRICAL

PANEL

BUILDING

WIDTH

BUILDING

LENGTH

Rotating fan icons provide immediate

visual of fan operation

Fan network may be scheduled to

start/stop twice per day

The BladeTec Zone Controller is a Touch Screen Control Station

designed to coordinate the operation of up to 18 BladeTec high

volume, low speed fans. One centralized control station will

communicate with the standard control box at each fan location

to maximize performance and reduce energy costs.

Single location control

The Control Station can control up to 18 BladeTec Fans within one facility

Prevent employees from making adjustments to fan speeds

No need to visit each fan location, which may be great distances apart

Maximize fan performance

Control fan speeds and usage simultaneously or independently

Schedule fans to operate only when needed to save energy

View individual fan settings (On/Off/Reverse + Speed)

Optional ethernet port for network access

Relay input control for easy on/off interface

Customize each fan name to specic building locations

Internal battery retains custom settings in the event of a power failure

Installation exibility

Standard control boxes may be mounted up higher

on walls or columns to minimize costly wiring

and to avoid damage in high trafc areas

RJ-45 plugs used to wire the

network without special tools

BladeTec

Zone Controller

9866 Kapp Court, Peosta, IA, 52068

U.S. Engineering Ofce Phone: 563-588-5340

U.S. Fax: 563-588-5330

Email: bladetec@ductsox.com

www.bladetecfans.com

A Subsidiary of Rite-Hite Holding Corporation

DSBTB0811B 2012 DuctSox Corp.

Our commitment to INNOVATION

provides unique products for many

environments.

Custom engineered air dispersion systems for

open ceiling and nished ceiling applications.

Unique air dispersion systems offer reduced

discharge velocities for critical environments.

Adjustable Fabric Air Dispersion System

Simple and adjustable fabric air dispersion

system assembled with pre-made components

for open ceiling architecture.

Air dispersion systems for food preparation

environments to eliminate drafts and

condensation.

Engineered distribution and dispersion systems

provide uniform temperature and pressure for

raised access oors.

The products in this brochure are covered by one or more of the following U.S. patents: 4,560,315 (RE: 32,968); 4,634,334; 4,692,755; 4,744,121; 4,819,770; 4,843,373;

4,865,507; 4,920,598; 4,995,130; 5,040,258; 5,111,546; 5,212,846; 5,271,183; 5,299,386; 5,311,628; 5,323,503; 5,375,965; 5,440,772; 5,442,825; 5,453,735;

5,531,557; 5,546,623; 5,553,987; 5,582,498; 5,664,930; 5,702,223; 5,762,459 (RE:37,570); 5,882,167; 5,964,572; 6,010,297; 6,052,268; 6,065,172; 6,070,283;

6,074,157; 6,085,375; 6,092,970; 6,106,212; 6,116,839; 6,190,109; 6,220,809; 6,627,016; 6,238,163; 6,322,310; 6,311,352; 6,360,394; 6,368,043, 6,431,819;

6,488,464; 6,497,067; 6,499,169; 6,505,713; 6,524,053; 6,634,049; 6,654,976; 6,676,360; and pending U.S. and foreign patent applications.

Vous aimerez peut-être aussi

- TDA V (Smokespill)Document4 pagesTDA V (Smokespill)Chia Woon LimPas encore d'évaluation

- High Static Ducted DX Split System Technical ManualDocument149 pagesHigh Static Ducted DX Split System Technical ManualsoqhPas encore d'évaluation

- Eurovent Certification Part 1 PDFDocument54 pagesEurovent Certification Part 1 PDFameeri143Pas encore d'évaluation

- Domestic Hot Water Solutions Guide For HospitalsDocument8 pagesDomestic Hot Water Solutions Guide For HospitalsFarhang MotallebiPas encore d'évaluation

- CHROMA Catalog GC - 2012 - en PDFDocument312 pagesCHROMA Catalog GC - 2012 - en PDFy2k_yah77580% (1)

- Prevention of Mould Growth in BuildingsDocument41 pagesPrevention of Mould Growth in BuildingsmaxgyzerPas encore d'évaluation

- Evolution: Elevator TechnologyDocument64 pagesEvolution: Elevator TechnologyStefan HodanPas encore d'évaluation

- Technical Booklet K 2012Document81 pagesTechnical Booklet K 2012Ali GurselPas encore d'évaluation

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocument23 pagesChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinPas encore d'évaluation

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlPas encore d'évaluation

- Calgonpump Catalogue (BSN Shah Alam)Document13 pagesCalgonpump Catalogue (BSN Shah Alam)Zul HafizzPas encore d'évaluation

- Acson Digital Variable Multi Units Application ManualDocument116 pagesAcson Digital Variable Multi Units Application ManualDota NgPas encore d'évaluation

- Air Terminal CatalogeDocument114 pagesAir Terminal CatalogeRamadan RashadPas encore d'évaluation

- KKM Policies & Procedures On Infection Prevention and Control 2019 PDFDocument305 pagesKKM Policies & Procedures On Infection Prevention and Control 2019 PDFAenz Princess KkmPas encore d'évaluation

- Fire Size Calculation for Smoke Spill SystemsDocument1 pageFire Size Calculation for Smoke Spill SystemsLee SienPas encore d'évaluation

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapPas encore d'évaluation

- FAHU-1 supply unit specificationsDocument2 pagesFAHU-1 supply unit specificationsDuxToyPas encore d'évaluation

- Terminal Housing Box With Hepa FilterDocument4 pagesTerminal Housing Box With Hepa FilterAbd Al-Rahmman Al-qatananiPas encore d'évaluation

- Myanmar Fire Safety Code 2020 (Eng Version) PDFDocument439 pagesMyanmar Fire Safety Code 2020 (Eng Version) PDFThe' Nu AungPas encore d'évaluation

- HvacDocument60 pagesHvacSugi OnoPas encore d'évaluation

- F ChartDocument7 pagesF Charthemal4379Pas encore d'évaluation

- ASHRAE/IESNA Standard 90.1-1999Document69 pagesASHRAE/IESNA Standard 90.1-1999Jônatas SilvaPas encore d'évaluation

- Living Room Heat Loss Calculation in BudapestDocument5 pagesLiving Room Heat Loss Calculation in BudapestJoshua RanjithPas encore d'évaluation

- Ec Axial Fan W3g800gu2501 EngDocument5 pagesEc Axial Fan W3g800gu2501 EngmacmottaPas encore d'évaluation

- Endee Shaw Dew Point Meter Instruction ManualDocument11 pagesEndee Shaw Dew Point Meter Instruction ManualParmeshwar Nath TripathiPas encore d'évaluation

- Romold TrapDocument2 pagesRomold Traprajkumar_chinniah100% (1)

- F 1090 - 87 R97 - Rjewota - PDFDocument4 pagesF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaPas encore d'évaluation

- AAF Product Leaflet AstroFan FFU EN PDFDocument5 pagesAAF Product Leaflet AstroFan FFU EN PDFAlwin WanPas encore d'évaluation

- (1902-22V1906) VX Catalogue PDFDocument51 pages(1902-22V1906) VX Catalogue PDFMinhcong PhanPas encore d'évaluation

- 0405Document27 pages0405miguelin226Pas encore d'évaluation

- Standard 205 10Document20 pagesStandard 205 10Ong Wooi PhengPas encore d'évaluation

- AHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFDocument127 pagesAHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFNitesh SinghPas encore d'évaluation

- Allied Consultants LTD.: XXXX XXXX 1. Input DataDocument4 pagesAllied Consultants LTD.: XXXX XXXX 1. Input DataNelson VargasPas encore d'évaluation

- AS1668 Seminar NotesDocument19 pagesAS1668 Seminar NotesOwen PerrinPas encore d'évaluation

- MS1472-99 - Fire Escape Area With PressurizationDocument64 pagesMS1472-99 - Fire Escape Area With PressurizationBryan Ng Horng HengPas encore d'évaluation

- Water Heater Sizing GuideDocument28 pagesWater Heater Sizing GuidetuzlucayirPas encore d'évaluation

- HVAC Installation Bill of QuantitiesDocument5 pagesHVAC Installation Bill of QuantitiesRajeshPas encore d'évaluation

- Avsu & Alarm & TuDocument41 pagesAvsu & Alarm & Tushahrul aiman100% (2)

- Lift CalculationDocument3 pagesLift CalculationHussain JiffryPas encore d'évaluation

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- FI NotesDocument1 069 pagesFI NotesparadoxendazzlingPas encore d'évaluation

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 pagesASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- Carrier 466Document40 pagesCarrier 466Raul E. SoliPas encore d'évaluation

- SANS 1128 1 2010 (Ed. 2.01)Document29 pagesSANS 1128 1 2010 (Ed. 2.01)Olefile Mark MolokoPas encore d'évaluation

- DAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFDocument3 pagesDAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFIswadi Bin ZulkarnainPas encore d'évaluation

- Example Kitchen Ventilation CalculationDocument4 pagesExample Kitchen Ventilation Calculationwillis0000Pas encore d'évaluation

- Is-10810 - 5 Methods of Test For Cables ResistanceDocument3 pagesIs-10810 - 5 Methods of Test For Cables ResistancepankajnbiPas encore d'évaluation

- LIGHTNING PROTECTION AND EARTHING - Rev 2Document7 pagesLIGHTNING PROTECTION AND EARTHING - Rev 2jiguparmar20094903Pas encore d'évaluation

- Chiller and cooling equipment scheduleDocument53 pagesChiller and cooling equipment scheduleRaju KsnPas encore d'évaluation

- 00000937Document9 pages00000937hardy7047Pas encore d'évaluation

- Axial AXBDocument20 pagesAxial AXBhoseyliauPas encore d'évaluation

- AHRI 880 Performance Rating of Air TerminalsDocument16 pagesAHRI 880 Performance Rating of Air TerminalsDumitru Cristina100% (1)

- TDA-F Series: Smokespill Axial FanDocument4 pagesTDA-F Series: Smokespill Axial Fanjames_chan2178Pas encore d'évaluation

- Nuaire Commercial Useful InfoDocument10 pagesNuaire Commercial Useful InfoYaser AkarPas encore d'évaluation

- Cooling Load Rule of Thumb PDFDocument36 pagesCooling Load Rule of Thumb PDFmaungPas encore d'évaluation

- Perkins Fans&BlowersDocument12 pagesPerkins Fans&BlowersPranay KharbePas encore d'évaluation

- C20D WindJet Air ProductsDocument28 pagesC20D WindJet Air Productscepong89Pas encore d'évaluation

- Airfoil Fan: AFHS Product DescriptionDocument16 pagesAirfoil Fan: AFHS Product Descriptionpowersp1394Pas encore d'évaluation

- BAFcatalog v31003Document40 pagesBAFcatalog v31003myoldtoastPas encore d'évaluation

- Armstrong Booster PumpsDocument4 pagesArmstrong Booster Pumpsrijothomasv777Pas encore d'évaluation

- Cas-White Chemical Resistant and Anti SlipDocument28 pagesCas-White Chemical Resistant and Anti SlipAnonymous llBSa7Pas encore d'évaluation

- Armstrong Design Envelope PumpsDocument20 pagesArmstrong Design Envelope Pumpsrijothomasv777Pas encore d'évaluation

- Intelligent Fluid Management SystemDocument8 pagesIntelligent Fluid Management Systemrijothomasv777Pas encore d'évaluation

- LabSox Brochure-Mar2015-web-6pg PDFDocument6 pagesLabSox Brochure-Mar2015-web-6pg PDFrijothomasv777Pas encore d'évaluation

- VLT - HVAC - Basic - Drive Brochure - Hospital Alor SetarDocument8 pagesVLT - HVAC - Basic - Drive Brochure - Hospital Alor SetarNorsyafiqah RoziPas encore d'évaluation

- 35 11 SG FTV BrochureDocument8 pages35 11 SG FTV Brochuresyed aliPas encore d'évaluation

- Armstrong Close-Coupled Pump (Monobloc)Document4 pagesArmstrong Close-Coupled Pump (Monobloc)rijothomasv777Pas encore d'évaluation

- Armstrong Vertical In-Line PumpsDocument6 pagesArmstrong Vertical In-Line Pumpsrijothomasv777Pas encore d'évaluation

- High Performance Axial Fans: Model RA - Standard and High TemperatureDocument8 pagesHigh Performance Axial Fans: Model RA - Standard and High Temperaturerijothomasv777Pas encore d'évaluation

- Armstrong Fluid Technology - Complete Product Offering.Document40 pagesArmstrong Fluid Technology - Complete Product Offering.rijothomasv777Pas encore d'évaluation

- Siemens PICV ValvesDocument8 pagesSiemens PICV Valvesrijothomasv777Pas encore d'évaluation

- Danfoss-Fc 051 CatalogDocument8 pagesDanfoss-Fc 051 Catalogrijothomasv777Pas encore d'évaluation

- Now Purity, Coolness & Freshness Flow Into Your WorldDocument2 pagesNow Purity, Coolness & Freshness Flow Into Your Worldrijothomasv777Pas encore d'évaluation

- EasyFlex Spring HangerDocument2 pagesEasyFlex Spring Hangerrijothomasv777Pas encore d'évaluation

- Coatings For Extreme Applications: Perma-Z Hi-Pro-ZDocument4 pagesCoatings For Extreme Applications: Perma-Z Hi-Pro-Zrijothomasv777Pas encore d'évaluation

- STV General Information: Threshold Amount Rs Deduction Amount Rs Deduction Amount RsDocument3 pagesSTV General Information: Threshold Amount Rs Deduction Amount Rs Deduction Amount Rsrijothomasv777Pas encore d'évaluation

- Tabla de Frame Motores Baldor IEC y NEMADocument2 pagesTabla de Frame Motores Baldor IEC y NEMAenicolas2100% (1)

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationEngJtonuiPas encore d'évaluation

- HVLS FansDocument4 pagesHVLS Fansrijothomasv777Pas encore d'évaluation

- Atex Eng PDFDocument1 pageAtex Eng PDFEPas encore d'évaluation

- VRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010Document2 pagesVRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010rijothomasv777Pas encore d'évaluation

- Bluestar Organisation StructureDocument1 pageBluestar Organisation Structurerijothomasv777Pas encore d'évaluation

- Blue Star's History as an Air Conditioning LeaderDocument2 pagesBlue Star's History as an Air Conditioning Leaderrijothomasv777Pas encore d'évaluation

- VRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010Document2 pagesVRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010rijothomasv777Pas encore d'évaluation

- Small HVAC System GuideDocument96 pagesSmall HVAC System GuideMalcolm ChanPas encore d'évaluation

- Patch Cord LC-Duplex PC - LC-Duplex PC, Beige/heather Violet, OM4, Bm/3, F8 2.0x4.1mm, 3 MDocument3 pagesPatch Cord LC-Duplex PC - LC-Duplex PC, Beige/heather Violet, OM4, Bm/3, F8 2.0x4.1mm, 3 MAbdelaaziz ALLALIPas encore d'évaluation

- Intro Letter For Chemietron For Aristo Pharma MumbaiDocument2 pagesIntro Letter For Chemietron For Aristo Pharma MumbaiOm Prakash SinghPas encore d'évaluation

- BT1 Leaflet Telephone Interface (PD-081 Iss 6)Document5 pagesBT1 Leaflet Telephone Interface (PD-081 Iss 6)Angelo IonPas encore d'évaluation

- Structural Analysis ReportDocument31 pagesStructural Analysis ReportjesusgameboyPas encore d'évaluation

- Sa 7927Document2 pagesSa 7927aahil ahmadPas encore d'évaluation

- C5 Galaxy Pilot GuideDocument18 pagesC5 Galaxy Pilot Guidebbarry138Pas encore d'évaluation

- Manual: Active Response On Windows: Documentation DownloadsDocument2 pagesManual: Active Response On Windows: Documentation DownloadsDevin FifieldPas encore d'évaluation

- Covid Full Catalog 2016Document96 pagesCovid Full Catalog 2016Camilo Alejandro PalaciosPas encore d'évaluation

- Intro To Power Quality: Prepared By: Theo Laughner, PE April 19, 2017Document45 pagesIntro To Power Quality: Prepared By: Theo Laughner, PE April 19, 2017Ulap KumoPas encore d'évaluation

- LG - 42pq10r Plasma TVDocument25 pagesLG - 42pq10r Plasma TVCristian ChanampaPas encore d'évaluation

- 3Ph 3wire CTPT Trivector Meter With PPMB For 11KV Boundary Metering 24.09.10 PDFDocument14 pages3Ph 3wire CTPT Trivector Meter With PPMB For 11KV Boundary Metering 24.09.10 PDFStephen BridgesPas encore d'évaluation

- Comap InteliDrive EM User Guide v.1.0Document56 pagesComap InteliDrive EM User Guide v.1.0edcooPas encore d'évaluation

- Bombs For Airfcraft Pt.2Document160 pagesBombs For Airfcraft Pt.2117kitchener100% (1)

- PC Replacement PolicyDocument3 pagesPC Replacement PolicyChristopher GuestPas encore d'évaluation

- IRC5-MultiMove Application Manual 3HAC021272-001 - RevBDocument116 pagesIRC5-MultiMove Application Manual 3HAC021272-001 - RevBmartinimartiiniPas encore d'évaluation

- Wimax 802.16E Indoor Iad: Key FeaturesDocument2 pagesWimax 802.16E Indoor Iad: Key Featuresmehedi2636Pas encore d'évaluation

- BSCE EXCAVATION FILLING GRADINGDocument16 pagesBSCE EXCAVATION FILLING GRADINGMark AvanzadoPas encore d'évaluation

- Professional Engineer Summary StatementDocument4 pagesProfessional Engineer Summary StatementfastwritenamePas encore d'évaluation

- Radio Air Interface v300 PDFDocument42 pagesRadio Air Interface v300 PDFtetrapoltestPas encore d'évaluation

- Smart Zoning CiscoDocument3 pagesSmart Zoning Ciscousa_sPas encore d'évaluation

- International CV Wiring Diagrams PDFDocument1 039 pagesInternational CV Wiring Diagrams PDFiskandarmustafa100% (1)

- Leadership Quality ManagementDocument8 pagesLeadership Quality Managementselinasimpson361Pas encore d'évaluation

- Wargame Texture Editing GuideDocument13 pagesWargame Texture Editing GuideLatwPIATPas encore d'évaluation

- TB6588FG Usage Considerations: 1. Absolute Maximum RatingsDocument10 pagesTB6588FG Usage Considerations: 1. Absolute Maximum RatingsElton RibeiroPas encore d'évaluation

- John Deere Manual Tecnico PDFDocument389 pagesJohn Deere Manual Tecnico PDFjesus93% (28)

- 1400 Kva MitsubishiDocument4 pages1400 Kva MitsubishiAbid LakhaniPas encore d'évaluation

- IKEA's Global Sourcing ChallengesDocument7 pagesIKEA's Global Sourcing ChallengesdrnavaPas encore d'évaluation

- Fund Mech Eng SiemensDocument150 pagesFund Mech Eng SiemensRafael Pacheco100% (2)

- Mildly Flammable RefrigerantsDocument19 pagesMildly Flammable RefrigerantshazelbuddyPas encore d'évaluation

- Two Step Cluster AnalysisDocument10 pagesTwo Step Cluster AnalysisRex Rieta VillavelezPas encore d'évaluation