Académique Documents

Professionnel Documents

Culture Documents

Probebrochure Rev8

Transféré par

Matheus Torres0 évaluation0% ont trouvé ce document utile (0 vote)

550 vues7 pagesThe document describes the BLD-2000 series bed level detection probes manufactured by Outotec Pty Ltd. The probes consist of a sealed stainless steel tube containing circuit boards and a reed switch relay matrix. A floating cone detects the bed level and activates the reed switches to produce a 4-20 mA signal controlling flocculant dosing pumps based on the measured level. The probes are available in standard sizes and can be customized, with assembly requiring connecting the two sections and protecting connections from contamination.

Description originale:

Titre original

Probebrochure rev8

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document describes the BLD-2000 series bed level detection probes manufactured by Outotec Pty Ltd. The probes consist of a sealed stainless steel tube containing circuit boards and a reed switch relay matrix. A floating cone detects the bed level and activates the reed switches to produce a 4-20 mA signal controlling flocculant dosing pumps based on the measured level. The probes are available in standard sizes and can be customized, with assembly requiring connecting the two sections and protecting connections from contamination.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

550 vues7 pagesProbebrochure Rev8

Transféré par

Matheus TorresThe document describes the BLD-2000 series bed level detection probes manufactured by Outotec Pty Ltd. The probes consist of a sealed stainless steel tube containing circuit boards and a reed switch relay matrix. A floating cone detects the bed level and activates the reed switches to produce a 4-20 mA signal controlling flocculant dosing pumps based on the measured level. The probes are available in standard sizes and can be customized, with assembly requiring connecting the two sections and protecting connections from contamination.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 1 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

OUTOTEC PTY LTD

BED LEVEL DETECTION PROBE BLD-2000 SERIES

The BLD - 2000 series Bed Level Probes are constructed of 316L or 904L Stainless

Steel, and therefore are resistant to corrosion.

They consist of a sealed stainless steel tube and circuit boards with a Reed Switch

Relay Matrix housed inside.

The output is a 0 -10 k-ohm resistance. This is then converted using a resistance

transmitter to produce a 4-20 mA signal.

The 4-20 mA signal is transmitted back to the Control Room, where it is used to

control the speed of the flocculant dosing pumps.

As the Bed Level increases, the pump speed is increased and vice-versa to maintain

a constant level. These levels are important in the control of overflow clarity.

A Derakain Fibreglass cone-shaped float has been designed to promote self-cleaning

and to reduce the build up of solids. The float has a hole through its axis with magnets

along its inner sleeve. The float slides up and down the stainless steel tube probe

whilst floating on the bed. The magnets activate the Reed Switches installed inside

the probe. The Probe has PVC stops, both in the lower and upper positions to prevent

the float from falling out of range.

By filling the cone float with water, it is weighted so it sinks very slowly in a bucket of

Process water. Therefore, it will float on any solids, giving an indication of the Bed

Level.

The probe position is critical to the operation of the Thickener. The ideal location is at

midpoint between the Launder and the Feedwell outer lip. The unit should be at a

level where the bottom of the Probe is level with the bottom of the Deflector Cone.

The units are available in the following standard sizes that suit most applications.

However, any size or range can be built to suit the Clients requirements.

The part numbers and descriptions are as follows:

Model Description Part Number

3.0-316-1.0 3.0m long, SS Gr 316 material, 1.0 m

sensing range.

S.T.BL.3000.1000.316

4.0-316-1.5 4.0m long, SS Gr 316 material, 1.5 m

sensing range.

S.T.BL.4000.1500.316

Standard Derakain Cone Float S.T.BL.CF

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 2 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 3 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

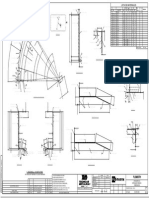

Typical wiring diagrams

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 4 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

ASSEMBLY PROCEDURE

The Bed Level Detection Probe BLD-2000 Series is delivered in a

two-piece configuration. The lower section (with wire attached) contains the

electronics and is Fragile; therefore extra care should be taken when

unpacking this unit. The upper section is a hollow tube.

Whilst the lower section is fully sealed to IP65 standards, it is recommended

that as part of these assembly instructions the Female threaded section be

filled with Silicone or equivalent sealant, and the Male threaded section be

Teflon taped, before connecting the two components - this ensures an

additional seal for the electronic housing section.

ASSEMBLY

1. Remove the cable ties and unroll the cable.

2. Feed the cable through the hollow "upper" tube.

3. When the cable is fed completely through the upper tube, apply Teflon

tape to the threaded male section on the upper tube and screw the two

component parts together.

4. Then fill the threaded female section on the "sensor" tube with silicon

sealant. It is imperative that the join area be sufficiently sealed to reduce

any possibility of contamination to the electronics during operation.

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 5 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 6 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

Outotec Pty Ltd Australian Service Centre

28 Rodborough Rd, Frenchs Forest NSW 2086 Page 7 of 7

Level 2, 1 Walker Street, West Perth WA 6005 www.outotec.com

ABN 7400 3491 165

5. Finally, fit the rubber boot at the top of the upper tube (where the cable

exits). This will stop rain and dust from entering the upper section of the

Probe.

The Probes are tested and calibrated prior to delivery. However, they should be

rechecked upon installation as follows:

* Before lowering the Probe into position, remove the lower bolt, locking nut and

washers.

* Loosen and remove the lower PVC collar.

* Place the weighted Cone Float over the Probe, (pointy end up). If float has not

been weighted with process water, remove the bolt from the bottom and fill with

enough process water so that when in a container of process water, the float

sinks slowly. Refit the bolt.

* Refit the PVC collar, bolt etc.

* Lay the Probe across the bridge handrails and connect the wiring to the control

panel.

* Move the float between the two PVC collars, monitoring the output on the

Control Panel display.

* The output is 4-20 mA and should be displayed as 0 - 100%. If, when fully

raised, the signal drops out of range (i.e. gets to 100% and returns to 0%) then

the PVC collar should be lowered so that the float does not exceed this range.

* There are Span and Zero buttons located on the Resistance Transmitter to

calibrate the 0 - 100% range.

When complete, install the Probe in its correct position ensuring that it is not

positioned lower than the original install - the bottom of the Probe should be level with

the lowest point of the Deflector Cone.

Note: The Cable entry end of the Probes are design to be IP 65 NOT fully

submersible. Any damage caused by submersing, dropping or failure to comply

with assembly procedure is not covered by Warranty.

Probes are manufactured in Australia

Vous aimerez peut-être aussi

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Metal RollingDocument8 pagesMetal Rollingklawsis100% (2)

- Screw Washer A 01Document15 pagesScrew Washer A 01joule357Pas encore d'évaluation

- Maintenance AmckoDocument10 pagesMaintenance AmckoAli Akbar0% (1)

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- TankGard Operation ManualDocument18 pagesTankGard Operation ManualThaibinh NguyenPas encore d'évaluation

- Delkor EspesadorDocument21 pagesDelkor Espesadorrichard gutierrezPas encore d'évaluation

- 628 Glaxo Training CDDocument251 pages628 Glaxo Training CDJuan Manuel Muñoz100% (1)

- PallaDocument16 pagesPallaJuan Alberto Giglio FernándezPas encore d'évaluation

- Complex Tailings Handling ChallengesDocument25 pagesComplex Tailings Handling ChallengescyberminePas encore d'évaluation

- 1.3 Materiales de Caucho para PF Serie 60Document33 pages1.3 Materiales de Caucho para PF Serie 60ronald palomino100% (1)

- Strategies for Instrumentation and Control of ThickenersDocument21 pagesStrategies for Instrumentation and Control of ThickenersPablo OjedaPas encore d'évaluation

- Doe WemcohmsDocument4 pagesDoe Wemcohmsrichard gutierrezPas encore d'évaluation

- 1345 John CraneDocument2 pages1345 John CraneseptixPas encore d'évaluation

- Sihi lph75000Document10 pagesSihi lph75000Hernando SalamancaPas encore d'évaluation

- R0 ModelDocument1 pageR0 ModeltylerdurdanePas encore d'évaluation

- 20.312 D02 Rev 01 Design BriefDocument17 pages20.312 D02 Rev 01 Design BriefSarah PerezPas encore d'évaluation

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Document5 pagesCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonPas encore d'évaluation

- Vedanta Green Anode Plant Liquid Pitch Stirring ManualDocument47 pagesVedanta Green Anode Plant Liquid Pitch Stirring ManualSubhransu MohapatraPas encore d'évaluation

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoPas encore d'évaluation

- Product Introduction: XCT80 Automobile CraneDocument17 pagesProduct Introduction: XCT80 Automobile CraneErika Justiniano VargasPas encore d'évaluation

- Valu King Screen 1Document3 pagesValu King Screen 1RAUL PEREZ NEGREIROSPas encore d'évaluation

- Control DescriptionDocument10 pagesControl DescriptionTrần Văn PhúcPas encore d'évaluation

- Fxj1070 Parts ListDocument51 pagesFxj1070 Parts ListMario D'AnnunzioPas encore d'évaluation

- 015-80T3-FW8 - Rev 1Document1 page015-80T3-FW8 - Rev 1José Luis TolaPas encore d'évaluation

- Toromocho Project Slurry Sampling Systems SpecificationDocument93 pagesToromocho Project Slurry Sampling Systems SpecificationLuis Valdez espinozaPas encore d'évaluation

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Document12 pagesFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPPas encore d'évaluation

- 600-EQ-014 Operation Manual Stripping Machine PDFDocument90 pages600-EQ-014 Operation Manual Stripping Machine PDFcorasaulPas encore d'évaluation

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Document66 pages15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroPas encore d'évaluation

- Outotec Mineral Processing Solutions: BenefitsDocument12 pagesOutotec Mineral Processing Solutions: BenefitsAndi FaesalPas encore d'évaluation

- 1.2.1 PF Filter PlatesDocument52 pages1.2.1 PF Filter PlatesCristian Pulgar Fabres100% (1)

- Inline Leach Reactor Operators Manual inDocument50 pagesInline Leach Reactor Operators Manual indiksajonaPas encore d'évaluation

- Volumen 1 Number 1Document32 pagesVolumen 1 Number 1dyka_737536Pas encore d'évaluation

- Maelgwyn Imhoflot (Chile)Document0 pageMaelgwyn Imhoflot (Chile)crazymax90Pas encore d'évaluation

- Filtro Marco y PlatosDocument5 pagesFiltro Marco y PlatosCesar LapaPas encore d'évaluation

- Slon Magnetic Separators Applied in TheDocument8 pagesSlon Magnetic Separators Applied in TheMulti DELLPas encore d'évaluation

- Paper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFDocument9 pagesPaper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFcarloscjunoPas encore d'évaluation

- FDP-460A 5F Outdoor Pre-Connectorized Fiber Distribution BoxDocument7 pagesFDP-460A 5F Outdoor Pre-Connectorized Fiber Distribution BoxKentPengPas encore d'évaluation

- Tankcell® Flotation Machine: Bolt ConnectionsDocument6 pagesTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta ArcePas encore d'évaluation

- Celdas de FlotacionDocument4 pagesCeldas de FlotacionRodrigo Zura0% (1)

- 01.01. 1000437900 1000437897 - 1.2Document4 pages01.01. 1000437900 1000437897 - 1.2Javier Ordoñez BarrigaPas encore d'évaluation

- Outotec Oktop Agitator Unit UpgradeDocument2 pagesOutotec Oktop Agitator Unit UpgradegicntPas encore d'évaluation

- 34-27-13 AutoBall Charger 301W Operations MaintenanceDocument28 pages34-27-13 AutoBall Charger 301W Operations Maintenanceerik masongPas encore d'évaluation

- Y JEENDocument1 pageY JEENYousef AlipourPas encore d'évaluation

- Diemme FiltrationDocument8 pagesDiemme FiltrationAbu Fathi Mifth Huda100% (1)

- Low Res Outotec Thickening 18022011Document12 pagesLow Res Outotec Thickening 18022011Juan Alberto Giglio FernándezPas encore d'évaluation

- EMC 3273 E-Cat MechDocument4 pagesEMC 3273 E-Cat Mechrichard gutierrezPas encore d'évaluation

- Csp703-Sluicepipe 1: Detail ADocument1 pageCsp703-Sluicepipe 1: Detail AKarlyCharlisPas encore d'évaluation

- Unidad Hidráulica PF1019Document2 pagesUnidad Hidráulica PF1019Juan Carlos Lopez TorresPas encore d'évaluation

- CMP2015 - Assessing Vertimill Ultrafine Grinding PerformanceDocument7 pagesCMP2015 - Assessing Vertimill Ultrafine Grinding PerformancerodrigoPas encore d'évaluation

- Operating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnDocument41 pagesOperating & Maintenance Manual Mini Pilot Plant System - Compact Lab ColumnDiego Carhuaz VasquezPas encore d'évaluation

- 015-80T4-FW6 - Rev 1Document1 page015-80T4-FW6 - Rev 1José Luis TolaPas encore d'évaluation

- White Paper On Conveyor Belt CapacityDocument3 pagesWhite Paper On Conveyor Belt Capacityhimangshu mandal100% (1)

- CIP CIL Interstage Screening SolutionsDocument4 pagesCIP CIL Interstage Screening SolutionsevalenciaPas encore d'évaluation

- 4 NewThickener PDFDocument3 pages4 NewThickener PDFRogerio CannoniPas encore d'évaluation

- Vibrating Screen Details and SpecsDocument3 pagesVibrating Screen Details and SpecsRaphael PalaciosPas encore d'évaluation

- CCS InterconnectionDocument16 pagesCCS InterconnectionAtiq Ur RehmanPas encore d'évaluation

- Flotation Advances PDFDocument7 pagesFlotation Advances PDFvictrburgosPas encore d'évaluation

- Pebble Crusher Specific EnergyDocument10 pagesPebble Crusher Specific Energy12milehillPas encore d'évaluation

- Manual Instructuni - SITA ROTATIVA - T.R. 40-75 PDFDocument141 pagesManual Instructuni - SITA ROTATIVA - T.R. 40-75 PDFRoxana AnteaPas encore d'évaluation

- Uranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102Document4 pagesUranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102arsaniosePas encore d'évaluation

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaPas encore d'évaluation

- Vdocuments - MX Probebrochure Rev8Document7 pagesVdocuments - MX Probebrochure Rev8SebastianPas encore d'évaluation

- Es 03895 1 R1Document1 pageEs 03895 1 R1jr_satish6965Pas encore d'évaluation

- Rosemount 3051 Press. FieldBusDocument20 pagesRosemount 3051 Press. FieldBusQuynhtnPas encore d'évaluation

- Rosemount 1195 Integral Orifice Primary Element: Quick Installation GuideDocument16 pagesRosemount 1195 Integral Orifice Primary Element: Quick Installation GuideJosé Carlos Batista SilvaPas encore d'évaluation

- Install and Maintain Synchronized Telescopic CylinderDocument23 pagesInstall and Maintain Synchronized Telescopic CylinderMohamed SemedaPas encore d'évaluation

- Quebrar Senha de PlanilhaDocument1 pageQuebrar Senha de PlanilhaFelipe Yudi NakataPas encore d'évaluation

- MSS SP-83-2001Document12 pagesMSS SP-83-2001Matheus TorresPas encore d'évaluation

- Add02 0371.1Document5 pagesAdd02 0371.1sihamyoussefPas encore d'évaluation

- Din 8074Document18 pagesDin 8074Matheus TorresPas encore d'évaluation

- ASME B1.20.1 NPT Threaded EndsDocument13 pagesASME B1.20.1 NPT Threaded EndsMatheus TorresPas encore d'évaluation

- Rules For The Design of Hoisting Appliances - Booklet 1Document23 pagesRules For The Design of Hoisting Appliances - Booklet 1Matheus TorresPas encore d'évaluation

- Rules For The Design of Hoisting Appliances - Booklet 8Document14 pagesRules For The Design of Hoisting Appliances - Booklet 8Matheus TorresPas encore d'évaluation

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresPas encore d'évaluation

- Filtro JohnsonDocument20 pagesFiltro JohnsonMatheus TorresPas encore d'évaluation

- Distribution of Lateral Pressure Due To Surcharge With DepthDocument18 pagesDistribution of Lateral Pressure Due To Surcharge With DepthuhopePas encore d'évaluation

- ToolpostDocument2 pagesToolpostMawan BentzPas encore d'évaluation

- Bendix SR-2 Trailer Spring Brake Valve: DescriptionDocument6 pagesBendix SR-2 Trailer Spring Brake Valve: DescriptionSteven FryePas encore d'évaluation

- LG Inverter Single Split Scac-1Document12 pagesLG Inverter Single Split Scac-1Rupesh DangolPas encore d'évaluation

- Force Assignment (Measurement Lab)Document12 pagesForce Assignment (Measurement Lab)Mostafa Ahmed ZeinPas encore d'évaluation

- Catalog Numbers (AMPS)Document2 pagesCatalog Numbers (AMPS)api-289140720Pas encore d'évaluation

- Guide To Oxygen Delivery SystemDocument3 pagesGuide To Oxygen Delivery Systemsheirlyazhari56530% (1)

- Ab 12Document199 pagesAb 12PauloPas encore d'évaluation

- Atasheet: Model: ETH-SP-G2Document3 pagesAtasheet: Model: ETH-SP-G2Zelaya DudPas encore d'évaluation

- Electric/ffy Jraulic Two-Speed Se/f-Tailing Winch Winch ServiceDocument4 pagesElectric/ffy Jraulic Two-Speed Se/f-Tailing Winch Winch ServicefabPas encore d'évaluation

- Forecast Stock 0802Document392 pagesForecast Stock 0802api-3802780Pas encore d'évaluation

- tp99124 PDFDocument20 pagestp99124 PDFDieselkPas encore d'évaluation

- Edoc - Pub - Canon mp750 780 Service ManualDocument132 pagesEdoc - Pub - Canon mp750 780 Service ManualKarim KarimmPas encore d'évaluation

- How to calculate conduit fillDocument2 pagesHow to calculate conduit fillYousif_AbdalhalimPas encore d'évaluation

- Power Supply WiringDocument1 pagePower Supply WiringsundaygboroPas encore d'évaluation

- Making Stright and Crossover Cables and Crimping PDFDocument11 pagesMaking Stright and Crossover Cables and Crimping PDFRAVI KUMAR LANKEPas encore d'évaluation

- Cummins Annunciator ManualDocument29 pagesCummins Annunciator ManualChris MaytumPas encore d'évaluation

- EM Series Electromantle Heating Key FeaturesDocument1 pageEM Series Electromantle Heating Key FeaturesAmmar GamalPas encore d'évaluation

- AVS BV Product CatalogDocument644 pagesAVS BV Product CatalogCRIS SEDANTOPas encore d'évaluation

- FS-2000D-3900DN-4000DN SM Uk 00Document142 pagesFS-2000D-3900DN-4000DN SM Uk 00connectingeurope8479Pas encore d'évaluation

- Skid Installation PDFDocument1 pageSkid Installation PDFruhul01Pas encore d'évaluation

- RMV-142D Data Sheet 4921240128 UKDocument8 pagesRMV-142D Data Sheet 4921240128 UKAlexPas encore d'évaluation

- Expansor de BridaDocument12 pagesExpansor de BridajlermaPas encore d'évaluation

- BJ-Q1 Range Quarter-Turn Intelligent Electric Valve Actuator GuideDocument20 pagesBJ-Q1 Range Quarter-Turn Intelligent Electric Valve Actuator GuideRudi AlfadliPas encore d'évaluation

- Method Statement For PPMCM of Electrical SystemsDocument7 pagesMethod Statement For PPMCM of Electrical Systemsnasir habibPas encore d'évaluation

- Dortronics W5286-P23DAXE1 Pneumatic Button DsDocument2 pagesDortronics W5286-P23DAXE1 Pneumatic Button Dsbloper2Pas encore d'évaluation

- SCV Series Screw CompressorDocument2 pagesSCV Series Screw CompressorCali MelendezPas encore d'évaluation