Académique Documents

Professionnel Documents

Culture Documents

Foundations For The Future - Removal of Existing Piles

Transféré par

skkongTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Foundations For The Future - Removal of Existing Piles

Transféré par

skkongDroits d'auteur :

Formats disponibles

Foundations for the Future

For the past 50 years civil engineers have been filling the ground under our towns and cities

with, among other things, bored concrete piles. In London Clay in particular, such piles are a

quick, quiet and cost-effective method of supporting ever-taller buildings and structures. But,

unlike the shallower footings of old, today's deep foundations are almost impossible to

remove when the building reaches the end of its life and the site needs to be redeveloped.

The easiest solution-but one that is clearly not sustainable - is to fill up the space in between

with even bigger piles. This article argues that reuse of existing piles is the real answer and

discusses the changes needed in our approach to designing, building and paying for

foundations in the future.

The centres of most large British cities have had rich and varied history. In particular, most of

the centre of London has been continuously occupied since medieval times, with remnants

from previous occupations and many successive phases of development remaining in the

ground.

Generally, up to the 1950s, most buildings were built on shallow foundations and typically had

just one level of basement. Since then, when bored piling and diaphragm walling techniques

became common, buildings have grown taller and basements have grown deeper. Pile loads

have also increased as developers continually seek to fill sites with the largest building

possible and floor spans have lengthened to provide more flexible building layouts.

Most modern buildings now leave behind a set of deep foundations and the foundations for

later buildings have to be installed through this detritus. Generally, the existing piles are of the

bored cast-in-place type as driven piles can seldom be used in such urban situations. This is

certainly the case in the City of London, where the problem of old bored piles is most acute. In

addition to piles and embedded retaining walls, London is also underlain by tunnels and

shafts of London Underground's tube and stations, Mail Rail, British Telecom, London

Electricity, Thames Water and other transport and utility operators. These also take up space

beneath many sites and limit available locations for new foundations.

The volume of ground left available for foundations for new developments is reducing. Sites

on their third set of deep foundations have almost filled the subsoil with little room left for the

installation of new piles. The number of sites now being redeveloped with piles for the third

time or more is fast increasing. As the current set of building stock is demolished when its

useful life ends, in perhaps 30 years time, there will be great difficulty in installing an efficient

set of new piles on many sites.

This article addresses the problems of redeveloping sites that contain a legacy of old bored

cast-in-place reinforced concrete piles, as these are the type of sites most likely to be

encountered in the future. The aim of the article is to highlight the problems that the current

approach to provision of new piles is building up for the future and to provide a framework for

the assessment of concrete piles for reuse.

Old piles-avoid, remove or reuse?

There are three basic options for dealing with old piles when the foundations for a new

building are being planned:

avoid

remove

reuse.

Avoidance

Currently, the easiest option is to avoid all old foundations. In particular situations this can

lead to a need for large transfer structures and larger, high-capacity piles. Where avoidance

of existing foundations is feasible, it allows the redevelopment to proceed but adds to the

detritus in the ground beneath the site to affect future developments.

In the future, as the number of old piles builds up across a site, the option to avoid them will

become increasingly expensive. Continuously adding to the detritus in the ground is not

sustainable.

Removal

Where existing foundations or deep obstructions lie in the way of proposed foundations,

removal is a possibility, even for existing deep piles. Another situation where foundation

removal is sometimes used is in cases where the old foundations penetrate valuable

archaeology and new foundations are constrained to use the same foundation positions.

Removal can be achieved by over-coring and progressive removal of pile lengths from the

ground although, where the piles do not contain full-length reinforcement, removing lengths of

pile from the ground can be difficult. The costs and time-scale required for pile removal

cannot be defined with any certainty because they can be affected by many factors. A further

problem concerns the effects of pile removal on the surrounding ground. The effects of drilling

and soil swelling due to slow pile removal may result in loss of skin friction for subsequent

piles installed at the same location.

Reuse

Reuse of old piles is the third option. Some experience has already been built up on the reuse

of piles such as the timber piles at Tobacco Dock1 and concrete and steel piles on several

other projects.

The requirements for a new building's pile positions and capacities seldom coincide with what

is available from existing pile locations. Where they do coincide, it may be possible to reuse

an old pile cap over an entire pile group.

Mixing old and new piles under new pile caps is possible but consideration should be given to

possible differential settlement of the pile cap under loading. This is due to different pile types

and also different stiffness responses of similar pile types since the older piles will have been

pre-loaded.

Installing new under-reamed piles will be very difficult should the under-ream belling tool hit

an old unmarked pile. The installation of new pile bores through old pile under-reams is also

difficult, because the auger will tend to slip down the under-ream surface. There are several

other requirements that must be met before old piles can be reliably reused. These include:

reliability of information about the existing piles

acceptability of reuse to prospective project funders and future building insurers

confidence in the geotechnical capacity of the piles

ability to ensure that the piles do not become damaged, such that their future

durability might have been impaired

confidence that the pile materials have not significantly deteriorated and will not do so

over their future design life.

The importance of as-built information

The extent and efficiency to which old foundations can be reused depends on the amount of

information that is available. Ideally there will be complete as-built drawings showing the

dimensions of all piles, details of pile reinforcement including its curtailment depth in the pile

and contemporary pile installation records which detail any problems during piling and how

they were resolved. This extent of information is seldom available.

Testing is likely to be destructive and will probably involve exposing and breaking down pile

heads to show dimensions and reinforcement details. Pile length may be proven by integrity

testing but can probably only be confirmed by rotary coring right down to the pile toes.

Integrity testing needs an exposed clear pile head.

For coring to work successfully, the core hole and pile both need to be effectively vertical.

This level of testing is only needed when it is necessary to load the old piles to their previous

capacity.

Proving the depth of reinforcement can be more problematic but may only be of concern in

the upper parts of a pile where it is possible to expose a representative part of the surface.

The depth of reinforcement can be determined by lowering down a core hole in the pile the

probe of a covermeter with an ultra-sensitive antenna and noting where the signal is lost. The

potential separation distance between reinforcement and the covermeter needs to be

considered for the range of verticalities of the pile and core hole and the method should

initially be proven in controlled conditions.

The UK Construction (Design and Management) Regulations require that pile records are

now kept for the life of the building and it is hoped that, in the future, more and better quality

information will be available to assess piles for reuse.

New approach to insurance needed

Building funders increasingly require guarantees that all parts of a building will remain

serviceable over the building's design life, not least due to pressure from future insurers and

occupants - especially those employing other design consultants to pursue a due diligence

search. This is likely to mitigate against allowing 25-year-old reinforced concrete piles being

incorporated into the new works.

A further problem comes down to whether any party is prepared to take responsibility for the

continued performance of reused piles over the new building's design life. In many cases, the

original piling contractor may no longer be in business or may have disposed of the piling

records. Even where the contractor and his records both still exist, the contractor is highly

unlikely to offer a warranty allowing reuse of the piles. The original designer may have been

either the piling contractor or a consultant and is unlikely to accept any responsibility for reuse

of the foundations.

The current consultant can never be completely confident that anomalies or unrecorded

variations in the original piling do not invalidate some of its design assumptions for reuse. The

amount of testing is likely to be prohibitively expensive to prove totally all aspects of the piles

on which the design relies. Such testing will probably involve a lot of destructive testing that

would need a lot of work to put right.

Problems of finding a body to take responsibility for the second life of the piles, as if they were

new, is the main reason for piles not being reused at present. A way around this may be for

the piles to be insured specifically for each new redevelopment, and separately from the rest

of the building. Assessing geotechnical capacity In most situations, soil mechanics theory

shows that the consolidation process that occurs around piles after installation should cause

capacity to increase with time. While the authors are not aware of any load tests that have

been carried out on piles both immediately after installation and subsequently on a similar pile

which has been in place for many years, it is unlikely that such testing would show any loss in

capacity.

Classical research

2

shows that the shaft capacity of bored piles in London Clay increases

over the first 1.2 years after pile installation. More recent research

3

confirms the data for

bored, driven and jacked-in-place piles in London Clay where capacity increased by around

20% in the two months after installation and by a further 15% over the following three years.

Most of the increase was assessed as being due to increases in shaft friction. Similar results

have been observed for driven piles in sand

4

where shaft capacity was seen almost to double

between six months and five years after installation.

Depending on how much information is available, reused piles can be reloaded up to a limit

capacity, possibly related to the originally rated capacity or to the previous maximum load that

the piles have experienced, proven by the load take-down. If it is suspected that the pile

dimensions could vary or that the records are unreliable, a degree of caution is required. In

such a situation, the pile capacity will normally be related to that taken from the load take-

down and often to a fraction of that value, perhaps somewhere between a half and the whole

capacity.

The geotechnical capacity of a pile can be confirmed by load testing a pile to failure.

However, as it is unlikely that the test pile itself will be used again, there should be confidence

that the test pile is representative of the dimensions and likely behaviour of other piles.

Depending on the intensity of new loading, load testing of a sample pile to failure may prove

necessary for reusing a high proportion of the previously rated load capacity.

If there are any doubts about the ground conditions in which the piles were installed, a more

thorough desk study and extra ground investigation may be needed. These may be required

to measure the ground strength to current standards to facilitate modern design practices (for

instance, measurement of undrained strength on U102 samples) or possibly just to define

more reliably the variation in stratigraphy across the site.

Looking out for physical damage

Piles can become damaged during installation (for instance, due to construction problems,

movement of plant, vibrations as adjacent piles are installed) or during the operational life of

the building (for instance, due to heave-induced tension). However, most damage is likely to

be caused in the piles as the first building is demolished. Where piles are to be reused, care

needs to be taken during demolition, particularly when slabs or pile caps are removed above

the piles.

Testing of piles to assess damage is normally carried out using the transient dynamic

response ('soft hammer') test, which can detect cracks in the upper part of the pile, to a depth

equal to perhaps twenty times the diameter

5

. As the testing is non-destructive, a large number

of piles can be tested. Only piles where the pile head is exposed can be tested, so if the pile

cap is also to be reused, proving pile integrity can be difficult. The requirement to wait until the

completion of demolition before proving that the piles are undamaged introduces significant

programme risk.

Assessing steel and concrete deterioration

Before reusing piles, it is necessary to confirm that the pile materials have not deteriorated to

such an extent that their required design life is impaired. Several deleterious processes can

affect the pile concrete and steel reinforcement as shown in the diagram below.

If piles are to be reused, the pile materials must be sampled and a design life reassigned

which obviously needs to be greater than that of the new building that they will support. The

frequency of testing will depend on the details of the original materials and the exposure

conditions to which the piles have been subjected. Additional ground investigation may have

to be carried out if the original investigation did not adequately define the exposure

conditions.

Material standards change, so it may be necessary to demonstrate that materials from, say,

20 years earlier comply fully with current equivalent standards, especially with regard to

concrete durability. Past performance established from observation may, however, provide a

better indication of suitability than strict compliance with standards.

Tests that prove that the materials remain serviceable are set out in the table below.

Materials

Type of

Deterioration

Testing

Concrete

Sulphate attack

Acid attack

Visual Inspection

Petrographic

Chemical analysis

Reinforcing steel

Corrosion

Exposure for visual inspection

Chloride ion content profile

Carbonation depth (if exposed to air)

Cover to reinforcement

Tests to prove that existing piles remain serviceable

Wherever possible and practical, a representative part of the surface of foundations that are

being considered for reuse should be exposed for visual examination and testing.

Unless exposure conditions are likely to change significantly, foundations that exhibit no signs

of 'normal' or thaumasite sulphate attack after several decades are unlikely to suffer such

attack over another few decades of service. However, disturbance of previously undisturbed

ground to expose existing foundations may, in itself, constitute a change in exposure

conditions. In particular, this could be the case if the ground contains sulphides that could

oxidize to sulphates and hence increase the risk of attack as illustrated in the diagram below.

Other changes of exposure condition that could be significant include exposure of concrete to

different ground conditions through backfill, increased mobility of groundwater or permanent

exposure of previously buried concrete. Where deterioration of the concrete surface is

observed, it may be possible to estimate the likely rate of future deterioration and form a

judgement as to its significance for the required performance in terms of load capacity and

service life. For piles relying on skin friction for their capacity at working load, the potential

implications for the geotechnical capacity due to surface deterioration need to be considered

carefully.

Choice of testing and interpretation of the resulting information should take careful account of

past and future exposure and operating conditions. For example, corrosion of reinforcement

in a fully embedded pile is unlikely to be significant below about 1m depth owing to the low

oxygen availability. This is likely to be true even where cover is very low or the concrete

contains cracks of width greater than those prescribed by current codes of practice

6

. The

significance of cover and cracking might, however, be quite different in other situations, such

as a piled retaining wall where the reinforced concrete is required to carry sustained bending

moments.

Developing a strategy for testing

Assuming that an acceptable body can be found to take responsibility for the piles, a strategy

for testing is needed to prove that the piles can be relied upon to carry load. The extent of

testing will depend on the amount of original information that is available and how heavily the

piles are to be loaded when compared with their original capacities.

A strategy to show that piles can be reused is likely to take the form outlined in the table

below.

Activity Sampling and

Testing

Assessment Confirmation

Desk study and

invest-igation of

soil and water in

ground

Index testing

Strength testing

Sulphate testing

Compare to

previous results

Pile design

Pile durability

Expose pile head Break down to

expose

reinforcement

Visual

Geometric

Pile dimensions

Pile head

reinforcement

Pile durability

Absence of defects

Concrete integrity

Rotary core pile

to toe

Obtain cylinders Pile to toe level

Material testing Crush cylinders

Petreography

Strength

Evidence of

decline

Load capacity

Pile durability

Load test to geo-

technical failure

Geotechnical

capacity

The diagram below shows material testing schematically.

Basements also need consideration

Basement spaces will be similarly affected as successive generations of basements are built

on the site, although the problems are likely to be less severe. It is seldom feasible in urban

situations to install new retaining walls outside previous walls as buried services have usually

been installed right up to the boundary.

Removal of the original wall is almost never feasible because its retentive action is needed

until completion of the new basement to prevent potentially damaging movements of the

ground outside the site. Therefore each new generation of basement retaining wall has to be

installed inside the original one. This results in a progressive loss of available space.

Conclusion

Over the next twenty years, the presence of old foundations in the ground is going to present

an increasing problem and will ultimately inhibit future developments on many valuable urban

sites. Owners of such sites may find that their foundation costs for future developments will be

very expensive and the foundation constraints may result in a less cost-efficient building on

the site.

Now is the time to make sure that good records are kept which will allow piles being installed

for current projects to be more easily reused in the future. Some developers may find that

independent supervision of piling and maintenance of pile records will allow better

consideration of foundation reuse for later projects on the same site. An alternative approach

that some developers might want to adopt on particularly congested sites is to install sufficient

foundation capacity for the current building and for likely future buildings on the same site.

Such an approach would need to be agreed with prospective building funders and insurers,

which must recognize that such foundations would be an asset for the future developability of

the site.

References

1. MITCHELL J. M., COURTNEY M. and GROSE W. J. Timber Piles at Tobacco Dock,

London. Proceedings of ISSMFE Conference Colloque International Fondations Profondes,

Paris, March 1999.

2. WHITAKER T. and COOKE R.W. An investigation of the shaft and base resistance of large

bored piles in London Clay. Proceedings of a Symposium on Large Bored Piles, 1966, ICE,

London, pp. 7-49.

3. WARDLE I. F., PRICE G. and FREEMAN T.J. Effect of time and maintained load on the

ultimate capacity of piles in stiff clay. In Piling: European Practice and Worldwide Trends

(Sands (ed.)), 1992, pp. 92-99.

4. CHOW F. C., JARDINE R. J., NAUROY J. F. and BRUCY F. Time-related increases in the

shaft capacity of driven piles in sand. Gotechnique, 1997, 47, No. 2, 353-361.

5. TURNER M. J. Integrity Testing in Piling Practice. CIRIA Report 144, CIRIA, 1997.

6. TYSON J. P. Design of reinforcement in piles. TRL Report 144, Transport Research

Laboratory, Crowthorne,1995.

Reproduced with permission from the Institution of Civil Engineers UK

Vous aimerez peut-être aussi

- Deep FoundatioDocument49 pagesDeep FoundatioSanthosh PurushothamanPas encore d'évaluation

- Under Reamed Piles ComparisonDocument15 pagesUnder Reamed Piles ComparisonMaheswara VarmaPas encore d'évaluation

- Innovation in instrumented test piles using global strain extensometersDocument6 pagesInnovation in instrumented test piles using global strain extensometersG-SamPas encore d'évaluation

- Retaining StructuresDocument15 pagesRetaining StructuresHarold TaylorPas encore d'évaluation

- Terzaghi and PeckDocument7 pagesTerzaghi and PeckRaja Hendra Solihin RambePas encore d'évaluation

- State - of - The - Art - Review - Piles - in - Clay - (Revised - 17th December)Document56 pagesState - of - The - Art - Review - Piles - in - Clay - (Revised - 17th December)ALANG CANDRA MARSUDIANTOPas encore d'évaluation

- Vibroreplacement PDFDocument9 pagesVibroreplacement PDFthadikkaranPas encore d'évaluation

- 3D Tunnel Simulation Using Core Replacement 1.0 IntroductionDocument27 pages3D Tunnel Simulation Using Core Replacement 1.0 IntroductionCarlosMarioVargasMoralesPas encore d'évaluation

- 10.1049 - Ip-C - 19820046 Foundation Uplift ResistanceDocument11 pages10.1049 - Ip-C - 19820046 Foundation Uplift ResistanceJitendraPas encore d'évaluation

- Stress-Strain Relationship For Reinforced Concrete in TensionDocument8 pagesStress-Strain Relationship For Reinforced Concrete in TensionManprit SinghPas encore d'évaluation

- Comparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachDocument7 pagesComparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- EC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFDocument36 pagesEC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFAnPas encore d'évaluation

- Mos Prf111Document7 pagesMos Prf111Nadim527Pas encore d'évaluation

- Design Challenges for Tall Building FoundationsDocument7 pagesDesign Challenges for Tall Building FoundationsJai ThakkarPas encore d'évaluation

- Calculo Soil Nail FHWADocument91 pagesCalculo Soil Nail FHWAdiana cristina arias aldanaPas encore d'évaluation

- Consolidation of Soil For Foundation by Using Sand DrainsDocument7 pagesConsolidation of Soil For Foundation by Using Sand DrainsAulia Nurul AnnisaPas encore d'évaluation

- Q1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionDocument17 pagesQ1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionJhoshep SaavedraPas encore d'évaluation

- 2 Interpretation SBT Full ColourDocument36 pages2 Interpretation SBT Full ColourNaveen SharmaPas encore d'évaluation

- Piled Raft Foundations for Tall BuildingsDocument8 pagesPiled Raft Foundations for Tall Buildingsrenzo1221Pas encore d'évaluation

- FE Modeling of Embedded Cantilever Sheet Pile Retaining WallDocument10 pagesFE Modeling of Embedded Cantilever Sheet Pile Retaining WalllollazzoPas encore d'évaluation

- Pullout Capacity of Model Piles in Sand PDFDocument6 pagesPullout Capacity of Model Piles in Sand PDFJaymin PatilPas encore d'évaluation

- Bearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFDocument22 pagesBearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFAnonymous 8KOUFYqPas encore d'évaluation

- Design and Construction of Anchored and Strutted Sheet Pile WallsDocument37 pagesDesign and Construction of Anchored and Strutted Sheet Pile WallsphamducquangPas encore d'évaluation

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Document11 pagesGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailPas encore d'évaluation

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Effects of Preloading of Struts On Retaining Structures in Deep ExcavationsDocument12 pagesEffects of Preloading of Struts On Retaining Structures in Deep ExcavationsPremnath YadavPas encore d'évaluation

- Shafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDocument6 pagesShafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDavidPas encore d'évaluation

- Structural Seviceability - Floor Vibrations - Ellingwood Tallin PDFDocument18 pagesStructural Seviceability - Floor Vibrations - Ellingwood Tallin PDFLau Kim HwaPas encore d'évaluation

- Guide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupDocument46 pagesGuide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupChhandak BiswasPas encore d'évaluation

- Foundation Design for 5 Tier Carpark Borehole BH 20Document2 pagesFoundation Design for 5 Tier Carpark Borehole BH 20Rio HandokoPas encore d'évaluation

- Pile Dynamic Test PDFDocument69 pagesPile Dynamic Test PDFYosafat JuwonoPas encore d'évaluation

- Young's ModuleDocument12 pagesYoung's Modulelazy catPas encore d'évaluation

- A Parametric Study of Wall Deflections in Deep Excavations With The Installation of Cross Walls PDFDocument11 pagesA Parametric Study of Wall Deflections in Deep Excavations With The Installation of Cross Walls PDFAhmed ArafaPas encore d'évaluation

- Bore Pile DesignDocument2 pagesBore Pile DesignOng George SammyPas encore d'évaluation

- ProtaStructure Suite 2016 Whats NewDocument41 pagesProtaStructure Suite 2016 Whats NewPlacid FabiloPas encore d'évaluation

- Bedding and Fill Heights For Concrete Roadway Pipe and Box CulvertsDocument263 pagesBedding and Fill Heights For Concrete Roadway Pipe and Box CulvertsAnonymous kRIjqBLkPas encore d'évaluation

- King Post Wall Design-1Document10 pagesKing Post Wall Design-1Ibrahim MeharoofPas encore d'évaluation

- CH-2 Caissons and CofferdamsDocument9 pagesCH-2 Caissons and CofferdamsAsegid Bezabih100% (1)

- Cassion FoundationDocument18 pagesCassion FoundationRavi Malik0% (1)

- Soldier Beam Shoring ReportDocument8 pagesSoldier Beam Shoring ReportNarayanan JayachandranPas encore d'évaluation

- Module 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary StressDocument10 pagesModule 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary Stressفردوس سليمانPas encore d'évaluation

- Case Histories On The Use of Helical Piles For Retrofitting and New ConstructionDocument6 pagesCase Histories On The Use of Helical Piles For Retrofitting and New ConstructionLeonardo SanchezPas encore d'évaluation

- Retaining Walls with Geotextile ReinforcementDocument18 pagesRetaining Walls with Geotextile ReinforcementjoverevocalPas encore d'évaluation

- Design of Mechanically Stabilzed Earth Walls (Msew)Document22 pagesDesign of Mechanically Stabilzed Earth Walls (Msew)SUNDARAVELPas encore d'évaluation

- Check Kick-Out Failure Check For Trench For M Deep Trench ExcavationDocument3 pagesCheck Kick-Out Failure Check For Trench For M Deep Trench Excavationhessian123Pas encore d'évaluation

- Evaluation of Shear Strength Parameters of Singapore Marine Clay, 2001 PDFDocument8 pagesEvaluation of Shear Strength Parameters of Singapore Marine Clay, 2001 PDFfreezefreezePas encore d'évaluation

- Behavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersDocument7 pagesBehavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersHasnain BukhariPas encore d'évaluation

- Uplift Capacity of Piles in Two Layered SoilDocument7 pagesUplift Capacity of Piles in Two Layered SoilIAEME PublicationPas encore d'évaluation

- Recent Evolutions in Deep Foundation TechnologiesDocument38 pagesRecent Evolutions in Deep Foundation TechnologiesAnand JadoenathmisierPas encore d'évaluation

- Rock Socketted Piles Chris HaberfieldDocument54 pagesRock Socketted Piles Chris HaberfieldBinSayeedPas encore d'évaluation

- Advanced Geotechnical Analysis CE 444: PLAXIS Assignment ReportDocument16 pagesAdvanced Geotechnical Analysis CE 444: PLAXIS Assignment ReportShikhar SinghPas encore d'évaluation

- Ultimate Lateral StrengthDocument9 pagesUltimate Lateral StrengthAnonymous djb71HriNPas encore d'évaluation

- Burj Khalifa 11 PDFDocument17 pagesBurj Khalifa 11 PDFDenilson Cuya RiveraPas encore d'évaluation

- Foundations-7-Diaphragm WallsDocument69 pagesFoundations-7-Diaphragm WallsElizhabet Flores PaucarPas encore d'évaluation

- Liquefaction of SoilDocument10 pagesLiquefaction of SoilSanthosh SantosPas encore d'évaluation

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsD'EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechPas encore d'évaluation

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980D'EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Pas encore d'évaluation

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- Various Perception Criteria For Occupant ComfortDocument1 pageVarious Perception Criteria For Occupant ComfortskkongPas encore d'évaluation

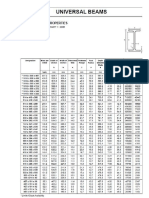

- UB DetailsDocument1 pageUB DetailsskkongPas encore d'évaluation

- Height Requirement For BungalowsDocument1 pageHeight Requirement For BungalowsskkongPas encore d'évaluation

- Moment Rotation CurveDocument1 pageMoment Rotation CurveskkongPas encore d'évaluation

- BS 6472Document1 pageBS 6472skkongPas encore d'évaluation

- Design Check For PEB.Document1 pageDesign Check For PEB.skkongPas encore d'évaluation

- PEB Load CombinationsDocument1 pagePEB Load CombinationsskkongPas encore d'évaluation

- Roofing InstallationDocument1 pageRoofing InstallationskkongPas encore d'évaluation

- PEB Components-1Document1 pagePEB Components-1skkongPas encore d'évaluation

- PEB Building-1Document1 pagePEB Building-1skkongPas encore d'évaluation

- Roof Sheets FixingDocument1 pageRoof Sheets FixingskkongPas encore d'évaluation

- CFD Analysis of Tall BuildingsDocument1 pageCFD Analysis of Tall BuildingsskkongPas encore d'évaluation

- Transformed SectionDocument1 pageTransformed SectionskkongPas encore d'évaluation

- Cruciform Connection DesignDocument1 pageCruciform Connection DesignskkongPas encore d'évaluation

- Data Centre CostDocument1 pageData Centre CostskkongPas encore d'évaluation

- Roof and Wall BracingDocument1 pageRoof and Wall BracingskkongPas encore d'évaluation

- Structural Steel Products'Document1 pageStructural Steel Products'skkongPas encore d'évaluation

- Cantilever Carport 1Document1 pageCantilever Carport 1skkongPas encore d'évaluation

- Cantilever BeamDocument1 pageCantilever BeamskkongPas encore d'évaluation

- Settlement LimitsDocument1 pageSettlement LimitsskkongPas encore d'évaluation

- Slender Residential TowersDocument1 pageSlender Residential TowersskkongPas encore d'évaluation

- RC Beam Section AnalysisDocument1 pageRC Beam Section AnalysisskkongPas encore d'évaluation

- Structural SystemsDocument1 pageStructural SystemsskkongPas encore d'évaluation

- Pad FootingDocument1 pagePad FootingskkongPas encore d'évaluation

- Built Up ColumnsDocument1 pageBuilt Up ColumnsskkongPas encore d'évaluation

- Building Fundamental PeriodsDocument1 pageBuilding Fundamental PeriodsskkongPas encore d'évaluation

- Curtain Wall Assemblies - PPVCDocument1 pageCurtain Wall Assemblies - PPVCskkongPas encore d'évaluation

- Engineering MarketingDocument1 pageEngineering MarketingskkongPas encore d'évaluation

- RC Slab Strength Vs ThicknessDocument1 pageRC Slab Strength Vs ThicknessskkongPas encore d'évaluation

- Dip and Rally TrendDocument1 pageDip and Rally TrendskkongPas encore d'évaluation

- Role of Destiny in Shakespearean TragediesDocument19 pagesRole of Destiny in Shakespearean TragediesInzmamul Haque100% (2)

- ESL S9 W3 P14-15 Project Challenge Part 2Document27 pagesESL S9 W3 P14-15 Project Challenge Part 2Emma Catherine BurkePas encore d'évaluation

- Akhila-Rasamrta-Murtih Prasrmara-Ruci-Ruddha-Taraka-PalihDocument44 pagesAkhila-Rasamrta-Murtih Prasrmara-Ruci-Ruddha-Taraka-PalihSauri ChaitanyaPas encore d'évaluation

- Case Study For Engineering ProblemDocument37 pagesCase Study For Engineering ProblemAfiq AfifePas encore d'évaluation

- (1964) AC 763 Help: House of Lords Chandler and OthersDocument22 pages(1964) AC 763 Help: House of Lords Chandler and OthersShehzad HaiderPas encore d'évaluation

- Essay Language TestingDocument6 pagesEssay Language TestingSabrina OktariniPas encore d'évaluation

- RLE107MCF - REVISED Case Study (OB - CENTERED) (Henderson A - Group 1)Document37 pagesRLE107MCF - REVISED Case Study (OB - CENTERED) (Henderson A - Group 1)Abigail RegaladoPas encore d'évaluation

- Women &literatureDocument54 pagesWomen &literatureAicha ZianePas encore d'évaluation

- Benchmark Evidence BasedDocument11 pagesBenchmark Evidence BasedPeterPas encore d'évaluation

- Go Int 6 Unit 2 Extension TestDocument4 pagesGo Int 6 Unit 2 Extension TestMiguel Anabalón TorresPas encore d'évaluation

- Assignment 1Document3 pagesAssignment 1Rabia Ahmad100% (1)

- An Exploratory Study of Personal Calendar UseDocument23 pagesAn Exploratory Study of Personal Calendar UseManas Tungare100% (1)

- National Competency Based Teachers StandardDocument34 pagesNational Competency Based Teachers Standarddanebantilan100% (3)

- Environmental Sanitation LessonDocument4 pagesEnvironmental Sanitation LessonMARIS GRACE CARVAJALPas encore d'évaluation

- Aspen FLARENET Getting StartedDocument62 pagesAspen FLARENET Getting StartedAde Nurisman100% (7)

- ProgDocument16 pagesProgRenon MadariPas encore d'évaluation

- Activity 13Document13 pagesActivity 13Lielannie CarasiPas encore d'évaluation

- Civet CoffeeDocument8 pagesCivet CoffeeAn NhiênPas encore d'évaluation

- 5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)Document2 pages5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)humberto Nascimento100% (1)

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocument26 pagesReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaPas encore d'évaluation

- Group 2Document3 pagesGroup 2sharmisthahalder21Pas encore d'évaluation

- Introduction To ErgonomicsDocument16 pagesIntroduction To Ergonomicsnatrix029Pas encore d'évaluation

- Practice Test 4: Explorer's Rainforest Trip and Blind AdventurerDocument6 pagesPractice Test 4: Explorer's Rainforest Trip and Blind AdventurerKhang Nguyen TienPas encore d'évaluation

- Interpretative Translation Theory EvaluationDocument13 pagesInterpretative Translation Theory EvaluationAnastasia MangoPas encore d'évaluation

- Virgil AeneidDocument367 pagesVirgil Aeneidlastoic100% (1)

- DeVry ACCT 505 Final Exam 2Document12 pagesDeVry ACCT 505 Final Exam 2devryfinalexamscomPas encore d'évaluation

- Philo 12Document2 pagesPhilo 12Rachel LaganPas encore d'évaluation

- The Directors Six SensesDocument31 pagesThe Directors Six SensesMichael Wiese Productions93% (14)

- Geographic Location SystemsDocument16 pagesGeographic Location SystemsSyed Jabed Miadad AliPas encore d'évaluation