Académique Documents

Professionnel Documents

Culture Documents

Jsa - Cable Termination

Transféré par

Santos Rex73%(15)73% ont trouvé ce document utile (15 votes)

8K vues4 pagesjsa cable termination

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentjsa cable termination

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

73%(15)73% ont trouvé ce document utile (15 votes)

8K vues4 pagesJsa - Cable Termination

Transféré par

Santos Rexjsa cable termination

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

1

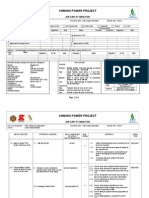

JSA - CABLE TERMINATION

Job Step

No.

Step Description Hazards Control Measure(s)

Responsible

Person

1

Preparing cables Electric shock

Defective hand tools

causing cuts

Test cables with approved test equipment to ensure

that cables are electrically dead

Implement the lock out procedure when required

Lock out procedure to be implemented only by

authorized persons and signed off in the sub-station

permit book

Hazard awareness training by means of toolbox

talks

Supervision by site supervisor

Inspections by safety office

Pre-use inspection by operator

Worn or blunt knife and saw blades must be

replaced before use

Only knives with which the blade can be reversed

into the knife casing will be permitted to be used

Only competent persons are permitted to use

hacksaws and knives for the purpose of stripping

cable

Use the correct technique, always cut away from the

body

Keep hands behind the cutting edges

Use an assistant at all times

Hazard awareness training by means of toolbox

talks

Supervision by foreman

Random inspections by safety officer

Correct P.P.E. to be worn at all times, safety boots,

2

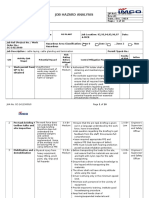

Job Step

No.

Step Description Hazards Control Measure(s)

Responsible

Person

overalls, gloves, safety glasses, hard hat

2

Glanding Cables Sharp edges and

burrs on gland holes

causing cuts

Hand injuries

Poor housekeeping

practices

Use a round file to remove any burrs or sharp edges

Supervision and checks by foreman

Use recommended P.P.E. when handling metal with

rough edges, gloves at all times

Hazard awareness training by means of toolbox

talks

Random inspections by safety officer

Ensure that your hands do not slip when tightening

the cable gland. Use the correct size spanner or gas

pliers on the smaller size glands

Use dedicated gland spanners on the larger size

cable glands. Do not use stilson wrenches or

adjustable spanners

Hazard awareness training by means of toolbox

talks

Supervision by foreman

Random inspections by safety officer

Wear recommended P.P.E. at all times, safety

boots, overalls, gloves, safety glasses, hard hat

Cable off-cuts to be placed in a drum or a suitable

container for disposal

Daily inspections by foreman

Random inspections by the safety officer

3

Pulling of cable on

heights, trenches or

along cable racks

Falling from heights

People working on scaffold to wear safety harness

and it is to be attached to the scaffold, structure or a

lifeline at all times

No-one is allowed to work on the scaffold or

structure in rainy or wet conditions

Ensure that sufficient people are available to handle

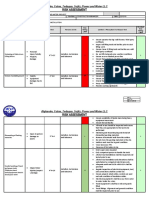

3

Job Step

No.

Step Description Hazards Control Measure(s)

Responsible

Person

Back Injuries

Hand injuries

the cable correctly and safely and to limit any

unnecessary movements on the scaffold

Hazard awareness training by means of toolbox

talks

Routine inspection by supervisor

Random inspections by safety officer

When lifting lengths of heavy cables keep your back

straight and bend your knees

Sufficient people must be available to handle heavy

cables safely

Spread the load. Foreman to space the people

evenly along the cable for ease of handling

On long runs of heavy cables, pull a loop of cable

out onto the ground. Pull the loop out along the

cable route. Repeat this operation as necessary until

the entire length of cable is pulled out along the

cable route

Proper P.P.E. must be worn when cutting cable,

gloves, safety glasses, safety boots, overalls, hard

hat

Only competent persons may use tools for cutting

cable

Hazard awareness training by means of toolbox

talks

Supervision by foreman

Inspections by safety officer

4

Removing cable drum

from cable jacks

Foot injuries

When finished with cable, screw cable jacks down to

lower cable drum to the ground. Do not lift or drop

cable drum to the ground

4

Job Step

No.

Step Description Hazards Control Measure(s)

Responsible

Person

Persons not involved with lowering the cable drum

are to stand clear

Cable drums must be safely and securely stored

away when finished with

Hazard awareness training by means of toolbox

talks

Supervision by foreman

Inspection by safety officer

Correct P.P.E. to be worn, safety boots, overalls,

gloves, hard hat

NOTE: Everyone performing this work shall sign to confirm their understanding of the work procedure, the hazards and control measures to be

used

Vous aimerez peut-être aussi

- Job Safety Analysis (14) For Cable Laying and PullingDocument4 pagesJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari86% (7)

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- JSA SplicingDocument3 pagesJSA Splicingluis100% (4)

- Cable Laying Safety AnalysisDocument6 pagesCable Laying Safety AnalysisLuqman Osman100% (6)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- JSA FOR Fixing of Light FittingsDocument1 pageJSA FOR Fixing of Light Fittingswahyu nugroho100% (1)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Electrical Isolation JSA SheetDocument1 pageElectrical Isolation JSA SheetLal Dhwoj100% (2)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelPas encore d'évaluation

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- JHA For Cable Laying, Cable Glanding and TerminationDocument12 pagesJHA For Cable Laying, Cable Glanding and TerminationFrancis Enriquez Tan100% (2)

- JSA ElectricalDocument2 pagesJSA Electricalsubhanmusadiq100% (6)

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnPas encore d'évaluation

- JOB HAZARD ANALYSIS - Cable PullingDocument7 pagesJOB HAZARD ANALYSIS - Cable PullingJayson Escamillan100% (2)

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- JHA - General Electrical WorkDocument7 pagesJHA - General Electrical WorkEL Mer98% (48)

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- Job Safety Analysis (JSA) Stringing WorkDocument4 pagesJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- JSA FOR Shakthi ElectricalDocument8 pagesJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Mie Hse Jha 004 - Installation of TransformerDocument5 pagesMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- Safely erect and install electrical equipmentDocument3 pagesSafely erect and install electrical equipmentMon Trang Nguyễn100% (5)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezPas encore d'évaluation

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarPas encore d'évaluation

- Jha For Earth WorkDocument6 pagesJha For Earth Worknik100% (14)

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthPas encore d'évaluation

- JSA For Installation of Fire PumpsDocument2 pagesJSA For Installation of Fire Pumpsperquino oasan100% (3)

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Cable PullingDocument4 pagesCable Pullingmykelrenz90% (10)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshsePas encore d'évaluation

- Risk Assessment For Cable Laying and Raceway InstallationDocument15 pagesRisk Assessment For Cable Laying and Raceway Installationmanikandan100% (3)

- JSA For DuctDocument14 pagesJSA For DuctRakeshkasarla100% (3)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- Job Safety Analysis Template - BatteryDocument2 pagesJob Safety Analysis Template - Batteryvenkateshbitra63% (8)

- Manual Excavation JSADocument1 pageManual Excavation JSATausif Khan100% (2)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaPas encore d'évaluation

- Installation of Earthing System JSADocument4 pagesInstallation of Earthing System JSAAkash Shukla75% (4)

- 08 Cable Termination Risk AssessmentDocument2 pages08 Cable Termination Risk AssessmentBaranidaranRavi72% (18)

- JHA - Installation of Pipe & Support For Fire Protection 1Document7 pagesJHA - Installation of Pipe & Support For Fire Protection 1Ralph Castillo100% (2)

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho83% (6)

- JSA For SealantDocument11 pagesJSA For SealantdipmipPas encore d'évaluation

- MV, HV LV Transformer Installation SafetyDocument6 pagesMV, HV LV Transformer Installation SafetyKiran Bhatt75% (4)

- JSA For Electrical TestingDocument5 pagesJSA For Electrical TestingAchmad Djadjang0% (1)

- Typical JHA FormDocument5 pagesTypical JHA FormNasrullah Jan100% (4)

- Jha Energize Distribution DBDocument1 pageJha Energize Distribution DBAhmad Zahir100% (2)

- GISD - Maintenance Safety RulesDocument15 pagesGISD - Maintenance Safety RulesHarry Wart WartPas encore d'évaluation

- Job Safety Analysis for ElectriciansDocument2 pagesJob Safety Analysis for ElectriciansDeny SafariPas encore d'évaluation

- Risk Assessment No. 45 LIFTING OPERATIONS Rev. 02 20.03.09Document2 pagesRisk Assessment No. 45 LIFTING OPERATIONS Rev. 02 20.03.09Devi Ratna PratiwiPas encore d'évaluation

- SOP Use of A WaterbathDocument3 pagesSOP Use of A WaterbathBenjamin Mutisya MuimiPas encore d'évaluation

- Under Ground Utilities HazardsDocument1 pageUnder Ground Utilities HazardsAnwar MohiuddinPas encore d'évaluation

- Job Safety Analysis Work SheetDocument20 pagesJob Safety Analysis Work SheetBarkat Ullah50% (2)

- Safety Procedures and PPE RequirementsDocument38 pagesSafety Procedures and PPE RequirementsAmin UllahPas encore d'évaluation

- +1 Free Buy 6 Pc. Fried ChickenDocument1 page+1 Free Buy 6 Pc. Fried ChickenSantos RexPas encore d'évaluation

- Tech - Top100 12.31.20Document2 pagesTech - Top100 12.31.20Santos RexPas encore d'évaluation

- Daily vehicle checklistDocument1 pageDaily vehicle checklistSantos Rex100% (2)

- Smoke DetectorDocument1 pageSmoke DetectorSantos Rex100% (1)

- Driving Policy Signed ApprovedDocument1 pageDriving Policy Signed ApprovedSantos RexPas encore d'évaluation

- NearMiss ExampleDocument1 pageNearMiss ExampleSantos Rex67% (3)

- SAFETY Statistics AprDocument1 pageSAFETY Statistics AprSantos RexPas encore d'évaluation

- Outstanding Balances For A Specific Company: Bpname HoldingsDocument3 pagesOutstanding Balances For A Specific Company: Bpname HoldingsSantos RexPas encore d'évaluation

- GS Neotek Driving Policy and Driver ManagementDocument1 pageGS Neotek Driving Policy and Driver ManagementSantos RexPas encore d'évaluation

- Incident/Accident Records: Uo1 Project Rabigh Phase IiDocument3 pagesIncident/Accident Records: Uo1 Project Rabigh Phase IiSantos RexPas encore d'évaluation

- Safety Harness Inspection ChecklistDocument1 pageSafety Harness Inspection ChecklistSantos RexPas encore d'évaluation

- Fire ExtinguisherDocument1 pageFire ExtinguisherSantos Rex83% (6)

- Scaffold RegisterDocument2 pagesScaffold RegisterSantos Rex100% (3)

- 34A. Compressed Gas CylindersDocument2 pages34A. Compressed Gas CylindersSantos RexPas encore d'évaluation

- Ma'aden Ammonia Plant JSA for Painting WorkDocument2 pagesMa'aden Ammonia Plant JSA for Painting WorkSantos Rex100% (1)

- Maaden-JSA - Piping Erection 1Document1 pageMaaden-JSA - Piping Erection 1Santos RexPas encore d'évaluation

- Jsa - Cutting and WeldingDocument2 pagesJsa - Cutting and WeldingSantos Rex50% (2)

- Near Miss Temple FormDocument1 pageNear Miss Temple FormSantos RexPas encore d'évaluation

- Deep ExcavationDocument1 pageDeep ExcavationSantos RexPas encore d'évaluation

- Material StorageDocument1 pageMaterial StorageSantos RexPas encore d'évaluation

- Engine Oil MSDSDocument7 pagesEngine Oil MSDSSantos RexPas encore d'évaluation

- Air DryingDocument1 pageAir DryingSantos RexPas encore d'évaluation

- Emergency Response Drill Scenarios 1Document10 pagesEmergency Response Drill Scenarios 1Arfiyunanto Malika50% (4)

- Confined SpacesDocument36 pagesConfined SpacesSantos RexPas encore d'évaluation

- Hempel's Galvosil 1578919840 En-UsDocument10 pagesHempel's Galvosil 1578919840 En-UsSantos RexPas encore d'évaluation

- Protecting Your HearingDocument3 pagesProtecting Your HearingSantos RexPas encore d'évaluation

- OSHA and You As A SupervisorDocument28 pagesOSHA and You As A SupervisorSreedhar Patnaik.MPas encore d'évaluation

- Emergency Response Drill Scenarios 1Document10 pagesEmergency Response Drill Scenarios 1Arfiyunanto Malika50% (4)

- G.i.6 - 004 Near Miss Reporting ProcessDocument5 pagesG.i.6 - 004 Near Miss Reporting ProcessSantos Rex100% (2)

- Magnetic Leakage FieldDocument13 pagesMagnetic Leakage FieldNjkt CADPas encore d'évaluation

- OPM - VHU0K73K0XU - TNR Installation and Instruction - OPM - VHU0K73K0XU - PDF&filename GE - UPS - OPM - VHU - 0K7 - 3K0 - XUS - V011Document25 pagesOPM - VHU0K73K0XU - TNR Installation and Instruction - OPM - VHU0K73K0XU - PDF&filename GE - UPS - OPM - VHU - 0K7 - 3K0 - XUS - V011Khách Sạn Hoàng PhốPas encore d'évaluation

- Types and Applications of Common HVAC SystemsDocument39 pagesTypes and Applications of Common HVAC SystemsNur Atiqah NabilaPas encore d'évaluation

- AutoMeter Sport Comp InstallationDocument2 pagesAutoMeter Sport Comp Installationxeron7126Pas encore d'évaluation

- UTPDocument14 pagesUTPJohn Carlo C. EnriquezPas encore d'évaluation

- Tle-Computer Systems SERVICING (Grade 10) : First Quarter - Module 2 Components of Computer System Hardware ToolsDocument10 pagesTle-Computer Systems SERVICING (Grade 10) : First Quarter - Module 2 Components of Computer System Hardware ToolsRowel P. Raña Jr.Pas encore d'évaluation

- Comfort 220.2, 250.2, 252.2, 250.2 Speed: Operating InstructionsDocument40 pagesComfort 220.2, 250.2, 252.2, 250.2 Speed: Operating InstructionsBojan RakicPas encore d'évaluation

- VITO LT Selction GuideDocument6 pagesVITO LT Selction GuideThái NgọcPas encore d'évaluation

- Safety tips for home electrical wiringDocument2 pagesSafety tips for home electrical wiringSatria Yudha WirawanPas encore d'évaluation

- Electrical & Power Control System OverviewDocument74 pagesElectrical & Power Control System OverviewA_triniPas encore d'évaluation

- Wirtgen W 2000 DatasheetDocument8 pagesWirtgen W 2000 DatasheetBeltazor HellboyPas encore d'évaluation

- GPS100 Aviation Kit Installation Manual: Communication & NavigationDocument27 pagesGPS100 Aviation Kit Installation Manual: Communication & Navigation19600702Pas encore d'évaluation

- Dimmer Dove Dm1224 ManualDocument5 pagesDimmer Dove Dm1224 ManualKader SmailiPas encore d'évaluation

- Modelos de ColimadoresDocument8 pagesModelos de ColimadoreslauraPas encore d'évaluation

- Barrel Conversion Kit: Operator InstructionsDocument10 pagesBarrel Conversion Kit: Operator Instructionsmikeabramson316Pas encore d'évaluation

- Elevators Testing ReportDocument6 pagesElevators Testing ReportMUHAIDEEN KANI ABDUL AZEEZPas encore d'évaluation

- FF Series (50hz) PDFDocument5 pagesFF Series (50hz) PDFTin Htun MyintPas encore d'évaluation

- Elevador Rotary LiftDocument120 pagesElevador Rotary LiftMiguel Eliezer SequeiraPas encore d'évaluation

- Pocket Guide For Medical Electrical InstallationsDocument16 pagesPocket Guide For Medical Electrical InstallationsDhairyasheel PatilPas encore d'évaluation

- Materials: Opw 199asv Anti-Siphon ValveDocument1 pageMaterials: Opw 199asv Anti-Siphon ValveSuhasPas encore d'évaluation

- TC5X Configuration & Accessories GuideDocument17 pagesTC5X Configuration & Accessories GuideYesica SantamariaPas encore d'évaluation

- Den Jet Accessory Catalog 2018Document52 pagesDen Jet Accessory Catalog 2018RusmansyahPas encore d'évaluation

- Dgs Approved Fire FightingDocument4 pagesDgs Approved Fire FightingDBSPas encore d'évaluation

- Mobile Incoming Call IndictorDocument13 pagesMobile Incoming Call IndictorVadnala AishwaryaPas encore d'évaluation

- Cat DP150 Forklift Service Manual 1Document209 pagesCat DP150 Forklift Service Manual 1diego100% (1)

- ECL 82, Tube ECL82 Válvula ECL 82 ID415, Triode-Beam PowerDocument1 pageECL 82, Tube ECL82 Válvula ECL 82 ID415, Triode-Beam PowerEduardo Alberto HenriquezPas encore d'évaluation

- Hydr Aulic: Syst emDocument13 pagesHydr Aulic: Syst emAzriel Varrand KhaleviPas encore d'évaluation

- Challenger 874-1074-1274 Rogator Liquid System Parts Manual (PDF, Eng, 40 MB)Document908 pagesChallenger 874-1074-1274 Rogator Liquid System Parts Manual (PDF, Eng, 40 MB)abdul KadirPas encore d'évaluation

- MTG ADocument152 pagesMTG Akuren kaPas encore d'évaluation

- Converteam Drive 1200 HP: Cable Interconnection Top Drive Drilling System Cable Interconnection Top Drive Drilling SystemDocument1 pageConverteam Drive 1200 HP: Cable Interconnection Top Drive Drilling System Cable Interconnection Top Drive Drilling SystemZinou ZizouPas encore d'évaluation