Académique Documents

Professionnel Documents

Culture Documents

1 - Aitesa Background and Services

Transféré par

xgiorg0 évaluation0% ont trouvé ce document utile (0 vote)

59 vues32 pagesAIT Group is an engineering company founded in 1928 that designs, engineers, installs, and provides maintenance for thermal equipment. It has 3 manufacturing centers and operates in over 120 countries. AITESA, its Spanish subsidiary founded in 1985, is one of the leading engineering companies in Spain that provides services to refineries, petrochemical plants, and other industrial facilities. AITESA specializes in heat recovery steam generators, fired heaters, and other thermal equipment and has experience with projects in sectors such as refinery, chemical, energy, and others.

Description originale:

Titre original

1_Aitesa Background and Services

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAIT Group is an engineering company founded in 1928 that designs, engineers, installs, and provides maintenance for thermal equipment. It has 3 manufacturing centers and operates in over 120 countries. AITESA, its Spanish subsidiary founded in 1985, is one of the leading engineering companies in Spain that provides services to refineries, petrochemical plants, and other industrial facilities. AITESA specializes in heat recovery steam generators, fired heaters, and other thermal equipment and has experience with projects in sectors such as refinery, chemical, energy, and others.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

59 vues32 pages1 - Aitesa Background and Services

Transféré par

xgiorgAIT Group is an engineering company founded in 1928 that designs, engineers, installs, and provides maintenance for thermal equipment. It has 3 manufacturing centers and operates in over 120 countries. AITESA, its Spanish subsidiary founded in 1985, is one of the leading engineering companies in Spain that provides services to refineries, petrochemical plants, and other industrial facilities. AITESA specializes in heat recovery steam generators, fired heaters, and other thermal equipment and has experience with projects in sectors such as refinery, chemical, energy, and others.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 32

We have done great

things in the past.

Nowadays, we are doing

great things for

the future.

Founded in 1928

35,000 references in 120 countries

Turnover of more than 40 M/year

3 manufacturing centers

AIT key information

AIT Group key data:

Core activities:

Design, engineering, installation of thermal equipment

Revamping & maintenance services.

Gasny

Paris

Thonon-Les-Bains

Madrid

Fresnes sur lEscaut

Support of a large Group:

HAMON Group, the international engineering &

contracting company (E.P.C.), as the main shareholder of

AIT, provides full support in the development of AIT

activities.

Proincar

Offices

Sales Representative

Offices

Sales

Air Industrie Thermique Espaa, S.L. (Aitesa) is one of the leading

engineering companies founded in 1985 in Spain, that delivers

engineering, procurement, construction, maintenance and project

management.

The company provide different services including the design and supply

of heat transfer equipment for oil refineries, petrochemical plants,

Cogeneration Plant and other industrial facilities.

The equipment is designed to be highly

efficient and supplied in compliance with the

increasingly strict quality control and

environmental requirements, tailored to each

customers specific needs and process.

Aitesa designs new equipment and revamps old ones such as: fired heaters, existing waste

heat recovery boilers and others. The aim is to minimize losses of thermal energy and improve

the output of existing equipment using steam production systems or combustion air

preheating system depending on customer requirements.

AITESA has a huge experience onto Refinery Sector. It was the aim of the company

when was created and becomes one of the most successful sectors where AITESA has

developed its work.

Waste Heat Recovery Boilers, Furnaces, Heat Recovers and several equipment and

systems has been developed by AITESA in several refineries around the world. Also,

AITESA is the representative in Spain of different solutions for refineries as air

preheaters APH.

New projects for the CEPSA "La Rbida" Refinery - Basic and detail engineering, supply of

necessary equipment such as convection and radiation coils, flue gas ducts, burners, air

preheater, fuel gas battery for air preheating, air and fuel gas fans, heat recovery system and

others, supervision works for Fired-Heaters LV-H1A/LV-H1B/LF-H2, while the LUBRISUR facility

produced 197,000 and 23,000 tons of these products, respectively.

AITESA wins supply contract for the Olefins economizer at the REPSOL TARRAGONA plant -

Efficiency improvement, manufacturing and supply of new high pressure economizer for the

Olefins HRSG.

CEPSA-Refinery "Gibraltar"entrusts AITESA to carry out the modifications on the VH-1 vacuum

furnace in order to adapt it to the new additional fuel such es natural gas, convection and heat

recovery system revamping.

Latest success stories in Refinery Sector:

Same as the refinery sector, AITESA has developed a large quantity of

projects onto Petrochemical and Chemical sector. The large experience of

AITESA in carrying out successful projects, give us the necessary expertise to

be the perfect chosen when new solutions must be performed.

Gasification plant for the enhancement of waste polymers and hydrocarbons - Supply of a

heat recovery boiler, a combustion chamber, a heat recovery exchanger and a water

treatment system.

Cepsa Qumica has awarded AITESA the contract for basic and detailed heat recovery

engineering in the H-H 2001 and H-H 2003 furnaces comprising the kerosene hydro

treating unit.

AITESA together with VICHEM commissioned a recovery boiler for gases at the chemical

plant owned by Brazilian company BRASKEM, in the State of Alagoas, in north-eastern

Brazil.

Latest success stories in Chemical Sector:

Based on thermo mechanical expertise, AITESA has been involved in the

performance of a large number of power plants, traditional and renewable

ones.

HRSG and heat exchangers in large plants and, also the development of

medium size power plants with ourselves resources give us a wide capacity

for helping our clients.

AITESA will develop the detailed engineering of a biomass (dual fuel bagasse coal)

power plant of 25 MW in Dominican Republic.

HTF Cleaning System put inp place for ACCIONA Energys Solar Thermal Plant in

Orellana la Vieja AITESA completes assembly of HTF cleaning system.

AITESA wins contract to supply waste heat recovery boiler for 45 MW diesel engine

in fourth phase of Baja California Sur Power Plant in Mexico.

Latest success stories in Energy Sector:

Basic Engineering

Detail Engeneering

Project Management

Purchasing and Outsourcing

Logistics

Quality Assurance

Manufacture, Assembly and Commissioning

Field Assembly Rate Prices

Basic Engineering: Feasibility studies, thermal processes, facilities design, energy audits

and others.

Detail Engineering: Projects, design of equipment and facilities, quality control.

Equipment Supply / facilities fully assembled and commissioned: Turn-key projects,

adapted to the individual requirements of each project. EPC provides a possibility of

concurrent design and manufacture to drastically reduce the facility commissioning

timelines for better customer performance.

Purchasing and Outsourcing: Activate the delivery of equipment and services on time, always

according to the highest standards of quality.

Logistics: Manage the shipment from our suppliers to our workshops and then to the final

destination desired.

Project management: Control and plan the development of different orders involving a complete

team of professionals.

Services

Manufacturing, assembly and commissioning: exercise engineering supervision over performance of works by

the customers specialists and fulfillment of specific requirements and conditions during assembly, initial startup,

diagnostics of complex equipment, and reaching operational parameters, and perform other works to prepare the

equipment for operation.

Quality assurance: Ensure fulfillment of all standards , rules and regulations under current legislation, the most

demanding design codes and customers guidelines.

HRSG

Fired Heaters

Heat Recovery

Systems (HRS)

Air Preheaters

Heat

Exchangers

Economizers Superheaters

Vaporizers

Batteries

Our products

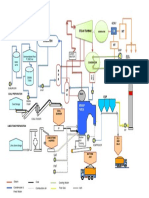

Heat Recovery Steam Generators

Most widely used Heat recovery steam generators or waste heat recovery

units in the combined cycle power plants, petrochemicals, refineries, paper

and pulp manufacturing units, food processing, dairy plants, sugar mills,

cogeneration plants, power producers and others process plants.

Heat Recovery Steam Generators

Waste Heat Recovery Boilers

Natural Circulation Boiler (with vertical tubes);

Forced Circulation Boiler (with horizontal tubes);

Boiler with Cleaning System for Dusty Flue Gas;

HTF for Low and Medium Pressure Closed-Circuit.

We are specialized in Waste Heat Recovery Boilers / Heat Recovery Steam

Generators with or without afterburner:

An example of HRSG

CEPSA, S.A.

Heat recovery boiler of F.C.C. (Fluid catalytic cracking) unit.

Production of 32.500 Kg/h at 50 bar and 435 C

THE VICHEM GROUP

Heat recovery boiler behind Incinerator.

Production of 7.300 kg/h at 18 bar and 210 C

PAPEL ARALAR

Heat recovery boiler behind Siemens gas engine of 15 MW for pulp and paper mill.

High pressure production of 20.200 kg/h at 40 bar and 400 C.

Low pressure production of 2.500 kg/h at 7 bar and 165 C.

REPSOL, S.A.

Design and supply of two Heat Recovery Steam Generators behind

Incinerator for REPSOL Refinery at Cartagena.

Unit production of 6.300 Kg/h at 45 bar and 500 C

ABENER

Heat recovery boiler behind 45 MWe flue oil engine. Production:

16.500 kg/h of saturated steam at 265 C and 8 bar, Baja California Sur,

Mxico

COLUMBIAN CARBON, S.A.

Heat Recovery Steam Generator and combustion chamber of off-gas.

Production of 63.000 Kg/h at 76 bar and 525 C

Paseo de la Castellana Str., 184 11th floor

28046 Madrid (Spain)

Phone.: +34 91 350 16 87

Fax: +34 91 350 16 10

aitesa@aitesa.es

www.aitesa.es

altesa

Vous aimerez peut-être aussi

- Orc English 20180507 PDFDocument8 pagesOrc English 20180507 PDFMudabbir Shan AhmedPas encore d'évaluation

- !!!1MW Fengyu ProposalDocument12 pages!!!1MW Fengyu ProposalUmer_Altaf_5934100% (1)

- IRENA-ETSAP Tech Brief E21 Biomass Co-Firing - 005 PDFDocument28 pagesIRENA-ETSAP Tech Brief E21 Biomass Co-Firing - 005 PDF조민기100% (1)

- Electric Motorcycle Charging Station Powered by SoDocument11 pagesElectric Motorcycle Charging Station Powered by SoAbass BILAPas encore d'évaluation

- Automobile Industry: InnovationDocument5 pagesAutomobile Industry: InnovationYash DhanukaPas encore d'évaluation

- Utilization of Oil Palm Empty Fruit Bunches As Solid Materials'Document19 pagesUtilization of Oil Palm Empty Fruit Bunches As Solid Materials'ilayarasan100% (1)

- Quantitative Relationships Between Key Performance Indicators For SupportingDocument10 pagesQuantitative Relationships Between Key Performance Indicators For Supportingjihanebk0% (1)

- ADB Financed Electric Vehicle Design in The PhilippinesDocument9 pagesADB Financed Electric Vehicle Design in The PhilippinesJerry EsquivelPas encore d'évaluation

- Battery Industry in Poland and The CEE Region 1684823232-2023-05-23-06 27 24Document69 pagesBattery Industry in Poland and The CEE Region 1684823232-2023-05-23-06 27 24Tomasz KarczewskiPas encore d'évaluation

- Reporter: April 2021 - E-MagazineDocument25 pagesReporter: April 2021 - E-MagazineBasudev Saha100% (1)

- Biomass Syngas Generator 68Document1 pageBiomass Syngas Generator 68Pankaj KamblePas encore d'évaluation

- MKTG AuditDocument31 pagesMKTG AuditVishal Singh100% (1)

- Complete EFB Pellet Plant - Customized Biopellet Line PDFDocument4 pagesComplete EFB Pellet Plant - Customized Biopellet Line PDFPuri PurwantariPas encore d'évaluation

- Universitas Pamulang Viktor Tangsel 186.2 KWP REC SMA Proposal v0.1Document29 pagesUniversitas Pamulang Viktor Tangsel 186.2 KWP REC SMA Proposal v0.1Zakky Ghifari Arfiansyah100% (1)

- Recovering Palm Oil From Empty Fruit Bunch Liquor PDFDocument4 pagesRecovering Palm Oil From Empty Fruit Bunch Liquor PDFAldino Chandra SiePas encore d'évaluation

- Indonesia Webinar 3 (JCOAL) - 1Document17 pagesIndonesia Webinar 3 (JCOAL) - 1Budi Setyawan100% (1)

- 1.0tph palm fruite crushing mill-印尼 PDFDocument5 pages1.0tph palm fruite crushing mill-印尼 PDFAgus AriyantoPas encore d'évaluation

- Engine SeatingDocument34 pagesEngine SeatingRuby Shaji100% (1)

- Rechargeable Lithium Battery (Estimated Life)Document2 pagesRechargeable Lithium Battery (Estimated Life)MegumiPas encore d'évaluation

- Low Rank Coal UtilizationDocument22 pagesLow Rank Coal Utilizationarjmandquest100% (1)

- Charging Station For E-Vehicles Using Solar With IoTDocument6 pagesCharging Station For E-Vehicles Using Solar With IoTIJRASETPublications100% (1)

- Meditech Oxygen ConcentratorDocument4 pagesMeditech Oxygen ConcentratorelmarwamedPas encore d'évaluation

- Techno FixDocument36 pagesTechno Fixbinta100% (1)

- Battery-2030 Roadmap Version2.0Document82 pagesBattery-2030 Roadmap Version2.0Rodrigo Vieira100% (1)

- Tesla EcosystemDocument13 pagesTesla EcosystemAbhishek Goel100% (1)

- EFB PelletDocument1 pageEFB PelletmuhammadnainPas encore d'évaluation

- AWING Group Presentation 2019 07Document19 pagesAWING Group Presentation 2019 07Ananda Setiyo IvannantoPas encore d'évaluation

- Climate Change & Carbon Market-Issues & RecomaditionsDocument10 pagesClimate Change & Carbon Market-Issues & Recomaditionsrathneshkumar100% (2)

- 30 Full Turnkey CapabilitiesDocument12 pages30 Full Turnkey CapabilitiesMahazan Ab. GhaniPas encore d'évaluation

- Biogas As Vehicle FuelDocument51 pagesBiogas As Vehicle FuelSuzana KrstanovićPas encore d'évaluation

- 27 May 2016 Pre-Feasibility Project Report BMWDocument53 pages27 May 2016 Pre-Feasibility Project Report BMWVishal V Bhagwat100% (2)

- Application of Technology ForDocument27 pagesApplication of Technology ForHotib PerwiraPas encore d'évaluation

- Integration of Power Plant and Amine Scrubbing To Reduce CO2 Capture CostsDocument26 pagesIntegration of Power Plant and Amine Scrubbing To Reduce CO2 Capture CostsshubhamPas encore d'évaluation

- Pre Feasibility PDFDocument90 pagesPre Feasibility PDFSulaksha WimalasenaPas encore d'évaluation

- PV CalculatorDocument18 pagesPV CalculatorHaroon RasheedPas encore d'évaluation

- CP - PT Valindo TP - Pltu TembilahanDocument38 pagesCP - PT Valindo TP - Pltu TembilahanDangol100% (1)

- Skema Proses Produksi PLTU Pelabuhan Tarahan 2x8 MWDocument1 pageSkema Proses Produksi PLTU Pelabuhan Tarahan 2x8 MWapurnomoPas encore d'évaluation

- Palm Oil Fresh Fruit Bunches To Palm Kernel ExpellerDocument4 pagesPalm Oil Fresh Fruit Bunches To Palm Kernel ExpellerSafwan Ghafar100% (1)

- The Future of Nickel: A Class Act: Basic Materials November 2017Document16 pagesThe Future of Nickel: A Class Act: Basic Materials November 2017Ιωάννης ΖαφειράτοςPas encore d'évaluation

- ATW Pricelist 2021Document14 pagesATW Pricelist 2021Erlangga Bayu100% (1)

- Ge 36 Brochure NewDocument4 pagesGe 36 Brochure NewAnaApcarianPas encore d'évaluation

- OxygenDocument31 pagesOxygenOanh HuynhPas encore d'évaluation

- Implementation of 100% Electric Vehicle in Bali With The Supply of Potential Independent Solar EnergyDocument6 pagesImplementation of 100% Electric Vehicle in Bali With The Supply of Potential Independent Solar EnergyInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Nuclear Battery: Presented by SivananthanDocument17 pagesNuclear Battery: Presented by SivananthankamaleshmanojiPas encore d'évaluation

- 0141 - 4kWp To 6kWp Solar Photovoltaic Power Plants - CREDADocument19 pages0141 - 4kWp To 6kWp Solar Photovoltaic Power Plants - CREDAPranavateja Chilukuri100% (1)

- The KDV Technology PDFDocument14 pagesThe KDV Technology PDFGerardo Noguera100% (1)

- Multi Nozzle, Dual Pump, Wheel Driven, Pull Type Agricultural SprayerDocument6 pagesMulti Nozzle, Dual Pump, Wheel Driven, Pull Type Agricultural SprayerCharbel GhanemPas encore d'évaluation

- Axial Fan 7028 PDFDocument9 pagesAxial Fan 7028 PDFHuyPas encore d'évaluation

- Palm Oil BiomassDocument7 pagesPalm Oil Biomassnhalieza1067Pas encore d'évaluation

- Converting Biogas To CNG For Vehicle Fuel: September 30, 2013 Chris Voell, Eastern Sales ManagerDocument51 pagesConverting Biogas To CNG For Vehicle Fuel: September 30, 2013 Chris Voell, Eastern Sales ManagerStalinraja DPas encore d'évaluation

- Presentation Mida Biomass Conference 2015 MpobDocument28 pagesPresentation Mida Biomass Conference 2015 MpobZulkifli Zainal Rampak100% (1)

- SOP For Feasibility Study-Rev2Document3 pagesSOP For Feasibility Study-Rev2Obaid BilgaramiPas encore d'évaluation

- Marketing Stratergy of Hero HondaDocument103 pagesMarketing Stratergy of Hero HondaparulankitPas encore d'évaluation

- Day 2 Solar 2 Developing The First Grid Connected Solar PV in Indonesia Abraham MoseDocument20 pagesDay 2 Solar 2 Developing The First Grid Connected Solar PV in Indonesia Abraham MoseMuammar ZainuddinPas encore d'évaluation

- 3s Steam BoilerDocument13 pages3s Steam BoilertahirPas encore d'évaluation

- Heat Pipe Heat Exchanger-An Energy Recovery Solution-Sales BrochureDocument12 pagesHeat Pipe Heat Exchanger-An Energy Recovery Solution-Sales Brochure조기현Pas encore d'évaluation

- Energy Solutions Heat RecoveryDocument4 pagesEnergy Solutions Heat RecoveryyaserbadrPas encore d'évaluation

- Agasti Corporate BrochureDocument10 pagesAgasti Corporate BrochureYogesh KumarPas encore d'évaluation

- Uhde Brochures PDF en 18Document32 pagesUhde Brochures PDF en 18geocottonPas encore d'évaluation

- Modular Hydrogen Plants: Hydro-ChemDocument12 pagesModular Hydrogen Plants: Hydro-ChemFahryPurnamaPas encore d'évaluation

- Flow Induced Vibration in BoilersDocument20 pagesFlow Induced Vibration in BoilersxgiorgPas encore d'évaluation

- Flow Induced Vibration by Robert D. Blevins - 2nd EdDocument254 pagesFlow Induced Vibration by Robert D. Blevins - 2nd Eddemonlist100% (14)

- C12200Document3 pagesC12200xgiorg100% (1)

- Sa-En 10028-2Document2 pagesSa-En 10028-2xgiorg100% (2)

- ManualDocument21 pagesManualMohd Naser100% (1)

- NATCO Glymine Gas SweeteningDocument2 pagesNATCO Glymine Gas Sweetening2009tamerPas encore d'évaluation

- XXL Size Recovery Boilers WhitepaperDocument11 pagesXXL Size Recovery Boilers WhitepaperMario MeloPas encore d'évaluation

- Vitomax HS Technical DataDocument26 pagesVitomax HS Technical DataamirokhovatPas encore d'évaluation

- Mechanical Data Sheet: Philippine Economic Zone AuthorityDocument3 pagesMechanical Data Sheet: Philippine Economic Zone Authorityjhay lagmanPas encore d'évaluation

- 2012 York Tech Guide - VA AirDocument36 pages2012 York Tech Guide - VA AirAndrea LemusPas encore d'évaluation

- Inv Eu 3.6 5 KW 48v 1p ManualDocument51 pagesInv Eu 3.6 5 KW 48v 1p ManualMauricio Oropeza CabreraPas encore d'évaluation

- 20kva 60HZ Silent Yangdong DIESEL GENERATOR 2022.8.17Document7 pages20kva 60HZ Silent Yangdong DIESEL GENERATOR 2022.8.17Cordova Yaranga JuanPas encore d'évaluation

- H11 Espl Comm Rev01Document4 pagesH11 Espl Comm Rev01Norberto NorbertoPas encore d'évaluation

- Thermal Engineering-II LESSON PLANDocument7 pagesThermal Engineering-II LESSON PLANdipsankar chatterjeePas encore d'évaluation

- Tech - Interview QuestionDocument20 pagesTech - Interview Questionrautrajeshv100% (1)

- DSR Ktps Sat-Thu 19-02-2024Document2 pagesDSR Ktps Sat-Thu 19-02-2024amit kumarPas encore d'évaluation

- Nuclear Powered Aircraft CarrierDocument12 pagesNuclear Powered Aircraft CarrierSahilMagotraPas encore d'évaluation

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- 1 s2.0 S0360319920336818 MainDocument12 pages1 s2.0 S0360319920336818 MainLarissa Moreira dos SantosPas encore d'évaluation

- Birla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Document2 pagesBirla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Vashistha GargPas encore d'évaluation

- Hydraulic FoundationsDocument41 pagesHydraulic FoundationsJay PandyaPas encore d'évaluation

- Comparing Nuclear Accident Risks With Those From Other Energy SourcesDocument47 pagesComparing Nuclear Accident Risks With Those From Other Energy SourcesDana AmangeldiPas encore d'évaluation

- 12-Circulating Water Systems PDFDocument32 pages12-Circulating Water Systems PDFAbah JamalPas encore d'évaluation

- CHE10710 NitrogenDocument32 pagesCHE10710 NitrogenFA Ay100% (1)

- The 48 Laws of Power-5Document10 pagesThe 48 Laws of Power-5probiggy007Pas encore d'évaluation

- Waste Heat RecoveryDocument25 pagesWaste Heat RecoveryJoeb DsouzaPas encore d'évaluation

- Pollution Less EngineDocument10 pagesPollution Less Enginemicmech67% (6)

- A Brief Analysis of The Physical Require-2Document3 pagesA Brief Analysis of The Physical Require-2Alok KumarPas encore d'évaluation

- Stirling Engine DesignDocument304 pagesStirling Engine Designkocrucq100% (1)

- Fire Fighting Pumps & SystemsDocument4 pagesFire Fighting Pumps & SystemsLaxmanDungraniPas encore d'évaluation

- Dickey - Halley Future of Field Installations UTC PowerDocument18 pagesDickey - Halley Future of Field Installations UTC PowerHasan NoahPas encore d'évaluation

- BNB 31403 Electrical & Energy SupplyDocument18 pagesBNB 31403 Electrical & Energy SupplyAidi RedzaPas encore d'évaluation

- List of Indian & Iec Codes For Hazardous AreaDocument4 pagesList of Indian & Iec Codes For Hazardous AreaShirishPas encore d'évaluation

- Scotch Yoke Actuator Selecting Tool: Valve Tag SDV-3003Document1 pageScotch Yoke Actuator Selecting Tool: Valve Tag SDV-3003Javier LopezPas encore d'évaluation