Académique Documents

Professionnel Documents

Culture Documents

Air Plant Procedure

Transféré par

Brad FloresCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Air Plant Procedure

Transféré par

Brad FloresDroits d'auteur :

Formats disponibles

74 FDM

/ june 2002

W

hen Barsanti Woodwork

C orp., C hi cago, moved to

i tsnew 54, 000-square-foot

plant i n December 2001, the ti mi ng

wasri ght to upgrade the compressed

ai r system. Everythi ng i sti ed i nto the

compressor, saysG ene Barsanti , the

companyspresi dent. T he compressor

i san i ntegral part of a number of ma-

chi ni ng operati ons, aswell asdust

control, sandi ng and fi ni shi ng process-

es. So a hi gh-capaci ty system wasi nte-

gral to the smooth operati on of the

new plant.

Barsanti producesa wi de range of

hi gh-end archi tectural mi llwork for

many large nati onally known corpora-

ti onsand hasbeen i nvolved i n a num-

ber of hi gh-profi le projectsi n C hi cago

such asthe H arold Washi ngton Li -

brary, the N avy Pi er renovati on and

M i dway Ai rport.

D e p e n d ab ility a m u st

T he bi ggest problem had been

mai ntai ni ng and holdi ng consi stent ai r

pressure, saysBarsanti . H e saysthere

were just too many fluctuati ons. T he

wi de vari ety of materi alsBarsanti

workswi th, especi ally the soli d woods

and exoti c veneers, requi resa consi s-

tency and reli abi li ty i n machi ni ng and

fi ni shi ng.

A Boge 50 hp oi l-flooded rotary

screw ai r compressor waschosen to re-

place at least fi ve smaller uni tsthat

had been used throughout the shop.

T he volume of customi zed commer-

ci al work that Barsanti doescan result

i n a number of sandersbei ng used i n

conjuncti on wi th the fi ni shi ng equi p-

ment, the Bi esse 24 C N C router, a

DM C sander, a recently purchased

K uper veneer spli cer and the Brandt

plant

maintenance

Barsanti Woodworking Corp.

Chicago, Illinois

Annual sales:$8.5 million

Plant size: 54, 000 square feet

Number of employees:60+

Product: High-end architectural

millwork for commercial, residential,

institutional and industrial

p l a n t f a c t s

Air system

improves plant

efficiency

A new air compressor improves all aspects of

the manufacturing process at new

woodworking plant.

Linda O hm

lohm@ chartcomm.com

Th e D M C san d e r b y S C M G ro u p is an e xam p le o f m o d e rn e q u ip m e n t at

B arsan ti th at b e n e fits fro m a stab le air p re ssu re su p p ly. continued

76 FDM

/ june 2002

edgebander. When all thi sequi pment

i sbei ng used at the same ti me, the

compressor hasto be able to handle i t

wi th a hi gh degree of reli abi li ty, says

Barsanti .

Barsanti also wanted to have a sys-

tem that would handle the addi ti onal

machi neryhe i ntendsto purchase i n

the future. Although the Boge compres-

sor ori gi nallyappeared to be a more ex-

pensi ve alternati ve, Barsanti li ked i ts

adaptabi li tyand felt that alone was

worth the pri ce.

T he compressor system consi stsof a

50 hp control uni t, ai r dryer and wet

tank kept i n a separate room wi th the

vacuum equi pment for the C N C

router. A large drytank i skept i n anoth-

er area and holdsthe ai r, so i t i sready

to meet the demandsof the plant.

M anysmall shopsand li ght i ndustri -

al shopsuse a pi ston ai r compressor,

when the power requi red i s25 hp or

less. T he rotaryscrew compressor

makesmore sense for larger power

needs. Both compressorsproduce ai r,

but the pi ston compressor produces

more heat than the rotarytype and

therefore wi ll produce more moi sture i n

the compressed ai r.

M o vin g th e air

M ost systemsuse galvani zed pi pi ng

to move the ai r from the drystorage

tank to the areasai r i sneeded. T he gal-

vani zed pi pe usuallyused requi res

threaded connectorsthat are ei ther

threaded on the job si te or purchased i n

pre-threaded 21-foot secti onsthat can

then be cut to fi t. T hen the pi pesneed

to be coupled together and sealed off

ti ghtly. G alvani zed, or black pi pe, asi t i s

commonlycalled, also hasa rougher

surface that can slow the ai r down and

even redi rect i t, thuscreati ng a pressure

drop i n the plant.

At Barsanti Woodwork air isbrought

to the plant areaswhere itsneeded with

aluminum piping and connectorsfrom

T ransair Products. Although thisalu-

minum piping isinitiallymore expensive

than galvanized piping, it hasa smoother

surface and isnot subject to corrosion.

O ne of the most attracti ve character-

i sti csof the Boge system, accordi ng to

Barsanti , i sthat i t i seasyto bri ng the ai r

anywhere i n the plant. T he T ransai r alu-

mi num pi pi ng, qui ck assemblyand drop

bracketsthat are part of thi ssystem all

work together to make the transfer of ai r

through the plant an easysetup.

T he system waspurchased through

Cochrane, one of Bogesdistributors.

Cochrane worked with Barsanti to dia-

air power

W

h e n air is co m p re sse d , am b i-

e n t air is d rawn in th ro u g h

p re -filte rs an d is sq u e e ze d b y a p is-

to n o r ro tary p u m p to cre ate co m -

p re sse d air. Th is p ro ce ss cre ate s

h e at u p to 1 8 0 F , alth o u g h th e p is-

to n co m p re sso r u su ally p ro d u ce s u p

to 4 0 0 F o f h e at.

B e fo re th e air is d isch arg e d to th e

we t tan k, it g o e s th ro u g h an afte r-

co o le r, sim ilar to a car rad iato r th at

b rin g s th e air te m p e ratu re d o wn to

ab o u t 1 5 d e g re e s ab o ve th e am b ie n t

te m p e ratu re . Th e air is th e n d is-

ch arg e d fro m th e u n it to a we t tan k

th at allo ws all th e m o istu re th at re -

su lte d fro m th e co o lin g p ro ce ss to

d ro p to th e b o tto m o f th e tan k. I n th is

re ce ive r tan k a filte r is b u ilt in th at

trap s an y o il so it can t trave l d o wn -

stre am to th e re frig e ran t air d rye r o r

fu rth e r d o wn th e lin e .

O n ce all th e m o istu re an d o il are

re m o ve d , th e co m p re sse d air m o ve s

to th e re frig e ran t d rye r. Wh e n th e air

le ave s th e d rye r, it trave ls to a larg e

d ry tan k wh e re it waits u n til it is re -

q u ire d in so m e are a o f th e p lan t.

How it works

Ad d in g p ip in g is sim p le . C u t th e ap p ro p riate le n g th o f p ip in g , g rab th e ap p ro p riate Tran sair co n n e cto r o r b racke t, lin e th e

p ie ce s u p an d twist fo r a tig h t, se cu re co n n e ctio n . I t can b e e asily d isco n n e cte d .

FDM

/ june 2002 77

gram the placement of the equipment

and advise the companyof the require-

mentsof the system. However, the plan-

ning and final placement of the pipes

and connectionswasthe work of Scott

Navis, computer specialist at Barsanti.

O verhead pi pesrun throughout the

shop. Addi ng addi ti onal pi pi ng hori -

zontally requi resthe appropri ate

length of pi pi ng and a T ransai r con-

nector. C onnecti ng the pi pi ng to the

connector requi resli ni ng the pi ecesup

and twi sti ng for a ti ght, secure connec-

ti on. I t can be di sconnected easi ly as

well maki ng i t very adaptable.

I f a verti cally dropped li ne i sre-

qui red, a hole i sdri lled on the top of a

hori zontal pi pe runni ng over the area,

a drop bracket i sposi ti oned over the

hole and the pi pe i sconnected to the

bracket. Wi thi n mi nutesthe li ne i si n

place and ready to use. T he ai r travels

up through the hole and i sthen di rect-

ed down to where i tsneeded wi thout

the possi bi li ty of moi sture si nce any

possi ble moi sture would stay at the

bottom of the hori zontal pi pi ng.

T he compressor at Barsanti i stak-

i ng on approxi mately 35 percent of

the ai r needsof the plant. Although

the vacuum table for the C N C router

i staken care of by a separate uni t, the

ai r power provi ded by the Boge com-

pressor i sused to control the tool

change operati on.

T he compressor i salso used to

power the sander and edgebander. Ai r

power i salso used asa blower to clear

dust from all surfaces, for the sprayi ng

and fi ni shi ng operati on and for nu-

meroussmall ai r-powered tools.

Barsanti saysthat the compressor

hasworked very effecti vely to provi de

all the power needsof the plant.

continued

Altendorf America

Altendorf sliding table saw

Brandt edgebander

616/698-8456

www.altendorfamerica.com

Biesse America

Rover 24 CNC router

704/357-3131

www.biesseamerica.com

Boge America

Compressor system

770/448-5995

www.boge.com

SCM Group USA Inc.

DM C sander

770/813-8818

www.scmgroup-usa.com

Stiles Machinery

K uper veneer splicer

616/698-7500

www.stilesmachinery.com

Transair

Air distribution system

www.transair.legris.com

For more information on these

products visit fdmonline.comor

contact the company directly.

78 FDM

/ june 2002

When the compressor wasfi rst put

i nto acti on, i t wasset at 100 psi . Ex-

peri mentati on and experi ence led the

company to change the setti ng to 97

psi , a more effi ci ent use of the system.

C urrently the plant setup works to

move parts through the plant effi -

ci ently, says Barsanti , but that can

change qui ckly. H e says that a sys-

tem li ke the Boge makes movi ng the

pi pi ng an easy part of any plant re-

desi gn or modi fi cati on, whi ch makes

thi s adaptable system i deal for hi s

company. L

air power

Afte r th e air g o e s th ro u g h a p artial co o lin g in th e co m p re sso r u n it, it is th e n

d isch arg e d to a we t tan k th at allo ws all th e m o istu re th at re su lte d fro m th e

co o lin g p ro ce ss to d ro p to th e b o tto m o f th e tan k. I n th is re ce ive r tan k a filte r is

b u ilt in th at trap s an y o il. I t th e n g o e s to th e re frig e ran t air d rye r, rig h t, th at

re m o ve s th e re m ain in g m o istu re .

A B o g e 5 0 h p o il-flo o d e d ro tary

scre w air co m p re sso r was ch o se n to

m e e t th e air p o we r n e e d s fo r B arsan ti

Wo o d wo rkin g . E ve ryth in g starts h e re

with th e co m p re sso r co n tro l u n it th at

take s th e am b ie n t air an d p ro d u ce s

co m p re sse d air.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- West Systems Fiberglass Boat Repair & MaintenanceDocument91 pagesWest Systems Fiberglass Boat Repair & MaintenanceDonát Nagy100% (2)

- Demoversion IWE 2011Document47 pagesDemoversion IWE 2011Burag HamparyanPas encore d'évaluation

- CIS2103-202220-Group Project - FinalDocument13 pagesCIS2103-202220-Group Project - FinalMd. HedaitullahPas encore d'évaluation

- X Ay TFF XMST 3 N Avx YDocument8 pagesX Ay TFF XMST 3 N Avx YRV SATYANARAYANAPas encore d'évaluation

- Method Statement For LVAC Panel TestingDocument9 pagesMethod Statement For LVAC Panel TestingPandrayar MaruthuPas encore d'évaluation

- Piping SDocument20 pagesPiping SBrad FloresPas encore d'évaluation

- FORM 2 Research Proposal 2009Document16 pagesFORM 2 Research Proposal 2009Brad FloresPas encore d'évaluation

- Pipe Fitting Work GuideDocument3 pagesPipe Fitting Work GuideBrad FloresPas encore d'évaluation

- Finishing A Basement Bathroom - Part 9: Liberty Sewage PumpDocument15 pagesFinishing A Basement Bathroom - Part 9: Liberty Sewage PumpBrad FloresPas encore d'évaluation

- Component Pipa BranzeningDocument3 pagesComponent Pipa BranzeningBrad FloresPas encore d'évaluation

- Automotive Blade-Type Fuses ATC: 32 Volts DC, 1 To 40 AmpsDocument1 pageAutomotive Blade-Type Fuses ATC: 32 Volts DC, 1 To 40 AmpsBrad FloresPas encore d'évaluation

- Component Pipa BranzeningDocument3 pagesComponent Pipa BranzeningBrad FloresPas encore d'évaluation

- Comparative Study On Solar Collector's Configuration For An Ejector Refrigeration CycleDocument17 pagesComparative Study On Solar Collector's Configuration For An Ejector Refrigeration CycleJonathan Martin LimbongPas encore d'évaluation

- Cheat Empire 2Document1 pageCheat Empire 2Brad FloresPas encore d'évaluation

- FuseDocument3 pagesFuseBrad FloresPas encore d'évaluation

- 01 Intro 3Document0 page01 Intro 3api-237613744Pas encore d'évaluation

- Fine Tuning FirefoxDocument5 pagesFine Tuning FirefoxBrad FloresPas encore d'évaluation

- PH Measurement TechniqueDocument5 pagesPH Measurement TechniquevahidPas encore d'évaluation

- RIE 2013 Dumping and AD DutiesDocument21 pagesRIE 2013 Dumping and AD Dutiessm jahedPas encore d'évaluation

- Demecio Flores-Martinez Petition For Review of Enforcement of Removal OrderDocument9 pagesDemecio Flores-Martinez Petition For Review of Enforcement of Removal OrderBreitbart NewsPas encore d'évaluation

- The General Agreement On Trade in Services An IntroductionDocument22 pagesThe General Agreement On Trade in Services An IntroductionakyregisterPas encore d'évaluation

- Reason Document 0n Rev.3Document58 pagesReason Document 0n Rev.3d bhPas encore d'évaluation

- JAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesDocument51 pagesJAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesVaibhav PachauleePas encore d'évaluation

- Which Delivery Method Is Best Suitable For Your Construction Project?Document13 pagesWhich Delivery Method Is Best Suitable For Your Construction Project?H-Tex EnterprisesPas encore d'évaluation

- AGE-WELL Annual Report 2021-2022Document31 pagesAGE-WELL Annual Report 2021-2022Alexandra DaniellePas encore d'évaluation

- EPA - Regulatory Impact AnalysisDocument822 pagesEPA - Regulatory Impact AnalysisSugarcaneBlogPas encore d'évaluation

- MACROECONOMICSDocument95 pagesMACROECONOMICSClaudine Jeanne NillamaPas encore d'évaluation

- Fifeville Plan: Building A Connected CommunityDocument92 pagesFifeville Plan: Building A Connected CommunityAl DiPas encore d'évaluation

- Aggregate Demand and Supply: A ReviewDocument36 pagesAggregate Demand and Supply: A ReviewYovan DharmawanPas encore d'évaluation

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1Pas encore d'évaluation

- Recent Advances in Mobile Robotics - TopalovDocument464 pagesRecent Advances in Mobile Robotics - TopalovBruno MacedoPas encore d'évaluation

- ESA 7.6 Configuration GuideDocument460 pagesESA 7.6 Configuration GuideaitelPas encore d'évaluation

- Cis285 Unit 7Document62 pagesCis285 Unit 7kirat5690Pas encore d'évaluation

- Hydraulic-Fracture Design: Optimization Under Uncertainty: Risk AnalysisDocument4 pagesHydraulic-Fracture Design: Optimization Under Uncertainty: Risk Analysisoppai.gaijinPas encore d'évaluation

- Mom Luby and The Social WorkerDocument1 pageMom Luby and The Social WorkerqtissskrazyPas encore d'évaluation

- Lessee Information StatementDocument1 pageLessee Information Statementmja.carilloPas encore d'évaluation

- Igbt Irg 4p254sDocument9 pagesIgbt Irg 4p254sMilagros Mendieta VegaPas encore d'évaluation

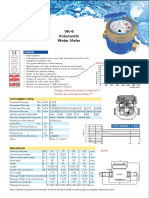

- Baylan: VK-6 Volumetric Water MeterDocument1 pageBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaPas encore d'évaluation

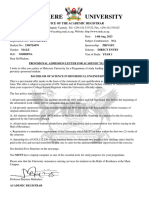

- Makerere University: Office of The Academic RegistrarDocument2 pagesMakerere University: Office of The Academic RegistrarOPETO ISAACPas encore d'évaluation

- MEETING OF THE BOARD OF GOVERNORS Committee on University Governance April 17, 2024Document8 pagesMEETING OF THE BOARD OF GOVERNORS Committee on University Governance April 17, 2024Jamie BouletPas encore d'évaluation

- Group Assignment: Consumer Buying Behaviour Towards ChipsDocument3 pagesGroup Assignment: Consumer Buying Behaviour Towards ChipsvikasPas encore d'évaluation

- Tutorial 2 EOPDocument3 pagesTutorial 2 EOPammarPas encore d'évaluation