Académique Documents

Professionnel Documents

Culture Documents

Computational Heat Transfer ME673 Mini Project 2 Revised

Transféré par

eldwin_dj7216Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Computational Heat Transfer ME673 Mini Project 2 Revised

Transféré par

eldwin_dj7216Droits d'auteur :

Formats disponibles

1

Numerical Heat Transfer ME673

Mini-Project 2

Second Semester 1435

Due date Wednesday April 23

rd

Consider the two-dimensional steady state heat conduction in an isotropic medium,

Defined over the domain .

Subject to the following boundary conditions:

( ) ( )

) ( )

Where,

1. Obtain an expression for evaluating the boundary condition at x=0.

2. Discretize the PDE using a five-point stencil

3. Use Gauss-Seidel iterative scheme to obtain the steady-state temperature distribution.

Use the convergence criteria below. Develop a computer code to do the calculations.

4. Plot temperature contours at steady state.

5. Investigate over-relaxation on convergence acceleration.

Convergence Criteria

Convergence can be assumed when the convergence parameter, p, is less than

.

Where p is defined as,

[

Note: All submitted work should be entirely yours. Include source code in your report.

2

In order to evaluate the boundary condition at x = 0, the following condition is used.

(

(1)

The R.H.S of Eq. (1) will be discretized by using a ghost node/point (a point outside the

domain) as shown in Figure 1. Furhtermore, a second order central difference scheme will be

used on the R.H.S of this equation (see Eq. (2) and Figure 1).

(

(2)

Then, by means of this point, the final difference equation for the boundary condition

can be constructed in conjunction with the five-stencil FDE of the corresponding PDE that

will be developed later. For this reason, the discussion on the expression for the convection

boundary condition will be postponed until the five-point stencil has been developed in the

next discussion/question. It should be mentioned that in this report the index count starts from

(i , j) = (1 , 1) on the lower-left-corner of the domain.

Figure 1: Showing the points and indices used to develope the expression for the convection boundary

condition, Eq. (1). Note: The total number of nodes is only an example.

3

In the next question (question no.2), it is asked to discretize the PDE considered using

a five-point stencil. The PDE is shown below, Eq. (3).

(3)

Figure 2: Showing the points and indices used in developing the FDE of the corresponding

PDE, Eq. (3). Note: The total number of nodes in this figure is only an example.

Based on Figure 2, we will develop the five-point stencil finite difference equation (FDE) as

follows.

(4)

(5)

4

Substitute Eq. (4), and (5) into Eq. (3)

(6)

The truncation error of the FDE, Eq. (6), is O[

]. Collecting and re-arranging terms

we obtain the following.

(7)

In order to simplify, Eq. (7) can be written as shown below.

(8)

where

( )

(9)

Continuing the previous discussion regarding question no.1, i.e., obtaining expression

for evaluation the convection boundary condition, the FDE of Eq. (8) will be utilized together

with Eq. (2). In the following derivation, points and indices in Figure 1 are used.

Solving Eq. (2) for the ghost point,

, Eq. (10) will be obtained.

{(

}

(10)

Now, Eq. (8) will be applied on point (i,j) in Figure 1 in order to get the other equation.

Afterwards, Eq. (10) will be substituted into this equation to get:

5

{(

(11)

After collecting terms and solving for,

, we obtain the final expression, Eq. (12), for

treating the convection boundary condition.

)

(12)

Next, the above equation are written into FORTRAN code to be solved using

Successive Over Relaxation (SOR) method. The code can be seen at the end of this report. In

order to verify the code, a test was conducted by comparing the results of a simple (low

number of segments) mesh with 2x2 segments (Figure 3) obtained by means of the

FORTRAN code with that of manual calculation. The results show a very good agreement

between both calculation methods as can be seen in Table 1.

Figure 3: Schematic of the mesh used for verification of the FORTRAN code

Table 1: Comparison between the results obtained by manual calculation and

FORTRAN code for 2x2 segments mesh

Nodes Manual calculation (C) FORTRAN code (C)

(i,j) = (1,2) 287.9 287.9

(i,j) = (2,2) 172 172

6

In task no.4 and 5, it is required that the temperature contours be plotted and over-

relaxation on convergence acceleration/speed be investigated. We, firstly, will address the

latter, i.e., the effect of relaxation factor, , on the speed of convergence.

Calculations were done for several segments of mesh with various relaxation factors

() as can be seen in the Table 2. It can be seen clearly from the table that increasing the to

a value of greater than one will increase the convergence speed. This founding is consistent

with the rule that . However, it was also found that there is a limit where

increasing beyond that value will decrerase the convergence speed. This can be seen in the

table for 10x10, 20x20, and 200x200 segments. Hence, an optimum value of exists. Also,

it is found that at the calculation is not converging even up to 500 iterations for 20x20

mesh.

Table 2: The various calculation parameter settings

Next, the contour plot of the temperature is presented with constant omega ( )

but changing the number of segments. From Figure 4 - Figure 7, it can be observed that the

Number of segments Omega No. of iterations

1 95

1.2 65

1.4 41

1.6 21

1.8 52

1 321

1.2 225

1.4 151

1.6 90

1.8 55

1.9 121

2

Still not converge

for 500 iterations

50 x 50 1.6 470

100 x 100 1.6 1528

1.8 2453

1.95 697

1.97 401

1.98 630

1.99 1201

10 x 10

20 x 20

200 x 200

7

trend of the temperature distribution for all number of segments presented are the same. The

difference is only that the least number of segments (10x10) gives coarser temperature

contour. It becomes smoother when the number of segments increased.

Figure 4: Temperature contour plot for mesh of 10x10 segments

Figure 5: Temperature contour plot for mesh of 20x20 segments

8

Figure 6: Temperature contour plot for mesh of 50x50 segments

Figure 7: Temperature contour plot for mesh of 100x100 segments

9

The FORTRAN Code

PROGRAM Steady_2D_heat_equation

IMPLICIT NONE

INTEGER :: i,j,iter,m,n,max_iter

!m is number of segments in x direction

!n is number of segments in y direction grid points

!iter is for iteration number (count from 0)

!max_iter is the possible maximum iteration

REAL, PARAMETER :: h=250.d0, Tamb=300.d0, k=5.d0

!h is the convection HTC (W/m^2.C)

!Tamb is the ambient temperature (C)

!k is the thermal conductivity of the material (W/m.C)

REAL, PARAMETER :: T_bottom = 50.d0, T_right = 200.d0, T_top = 150.d0

!The Ts above are the temp. of boundaries

REAL :: xsize, ysize, p, omega

!xsize is size of the domain in x dir

!ysize is size of the domain in y dir

!omega is the over/under relaxation factor

REAL :: dx, dy, a, b, c

!dx is the size of the segment in x direction

!dy is the size of the segment in y direction

10

DOUBLE PRECISION, ALLOCATABLE :: T(:,:), T_old(:,:)

!T is the temperature (C). It is designated to be

!allocatable, i.e., 2D matrix with adjustable size.

WRITE(*,10,ADVANCE='no')

READ(*,*) xsize

WRITE(*,11,ADVANCE='no')

READ(*,*) ysize

WRITE(*,12,ADVANCE='no')

READ(*,*) m

WRITE(*,13,ADVANCE='no')

READ(*,*) n

WRITE(*,15,ADVANCE='no')

READ(*,*) omega

WRITE(*,14,ADVANCE='no')

READ(*,*) max_iter

WRITE(*,*)

WRITE(*,*) 'The values that you have entered are:'

WRITE(*,*)

WRITE(*,*) 'x =', xsize

WRITE(*,*) 'y =', ysize

WRITE(*,*) 'm =', m

WRITE(*,*) 'n =', n

WRITE(*,*) 'omega =', omega

WRITE(*,*) 'max_iter =', max_iter

WRITE(*,*)

!Calculate dx, dy, a, b, and c

dx = xsize/m

dy = ysize/n

a = 1/(dy*dy)

11

b = 1/(dx*dx)

c = -2*(a + b)

WRITE(*,*) 'Thus, the value of dx, dy, a, b, and c obtained are as follows'

WRITE(*,*)

WRITE(*,*) 'dx=',dx

WRITE(*,*) 'dy=',dy

WRITE(*,*) 'a=',a

WRITE(*,*) 'b=',b

WRITE(*,*) 'c=',c

WRITE(*,*)

WRITE(*,*) 'Where a = 1/dx^2, b = 1/dy^2, and c = -2(a+b)'

WRITE(*,*)

OPEN (unit = 1 , file = "result_2D_steady_cond")

WRITE(1,*) 'The values that you have entered are:'

WRITE(1,*)

WRITE(1,*) 'x =', xsize

WRITE(1,*) 'y =', ysize

WRITE(1,*) 'm =', m

WRITE(1,*) 'n =', n

WRITE(1,*) 'omega =', omega

WRITE(1,*) 'max_iter =', max_iter

WRITE(1,*)

WRITE(1,*) 'Thus, the value of dx, dy, a, b, and c obtained are as follows'

WRITE(1,*)

WRITE(1,*) 'dx=',dx

WRITE(1,*) 'dy=',dy

WRITE(1,*) 'a=',a

WRITE(1,*) 'b=',b

WRITE(1,*) 'c=',c

WRITE(1,*)

12

WRITE(1,*) 'Where a = 1/dx^2, b = 1/dy^2, and c = -2(a+b)'

WRITE(1,*)

!Allocate the size of T and T_old

ALLOCATE(T(0:m+1,0:n+1))

ALLOCATE(T_old(0:m+1,0:n+1))

!initialize

T(:,:) = 0.d0

T_old(:,:) = 0.d0

!Define the boundary conditions

T(:,1) = T_bottom

T(:,n+1) = T_top

T(m+1,:) = T_right

!Calculate the Temperature distribution

iter = 0 !iteration counter

p = 1 !first guess for p (any number > 1e-5)

DO WHILE (p >= 1.d-5 .AND. iter<max_iter)

T_old(:,:) = T(:,:)

DO j=2,n

DO i=1,m

IF (i==1) THEN

T(i,j) = T(i,j) + omega*((1/(c - 2.d0*b*dx*h/k))*(-2*b*dx*h*Tamb/k -

a*T(i,j-1) - 2.d0*b*T_old(i+1,j)&

& - a*T_old(i,j+1)) - T(i,j))

ELSE

13

T(i,j) = T(i,j) + omega*(1/c*(-a*T(i,j-1) - b*T(i-1,j) - b*T_old(i+1,j) -

b*T_old(i,j+1)) - T(i,j))

ENDIF

ENDDO

ENDDO

p = ABS(MAXVAL(T(1:n,2:m)-T_old(1:n,2:m))/MAXVAL((T(1:n,2:m))))

iter=iter+1

ENDDO

WRITE(1,*)'The temperature distribution:'

WRITE(1,*)

WRITE(1,*)' i=1 i=2 i=3 ...(so on if available)'

DO j=1,n+1

WRITE(1,22,ADVANCE='no') 'j =',j

WRITE(1,22,ADVANCE='no')' '

DO i=1,m+1

WRITE(1,21,ADVANCE='no') T(i,j)

ENDDO

WRITE(1,*)

ENDDO

WRITE(1,*)

WRITE(1,*) 'The residual =', p

WRITE(1,*)

WRITE(1,*) 'Number of iteration =', iter

10 FORMAT('The size of the domain in x direction, x = ')

14

11 FORMAT('The size of the domain in y direction, y = ')

12 FORMAT('The number of segments in x direction, m = ')

13 FORMAT('The number of segments in y direction, n = ')

14 FORMAT('Maximum iteration, max_iter = ')

15 FORMAT('Over/under relaxation factor, omega = ')

21 FORMAT(F6.1)

!FORMAT no.21 is to let the value using this format to be Real decimal form (for 'F') and

!the last digit is written at the 6th space (for '6') and consist of 1 decimal number after point

(for .1)

22 FORMAT(A3,I4)

END PROGRAM Steady_2D_heat_equation

Vous aimerez peut-être aussi

- UNIVERSE Pelatihan GuruDocument5 pagesUNIVERSE Pelatihan Gurueldwin_dj7216Pas encore d'évaluation

- Rexroth IndraMotion MLC02VRS DiagnosticsDocument174 pagesRexroth IndraMotion MLC02VRS Diagnosticseldwin_dj7216Pas encore d'évaluation

- Orthographic Projection TaskDocument1 pageOrthographic Projection Taskeldwin_dj7216Pas encore d'évaluation

- Presentation1.pptx Ahda Coba2Document1 pagePresentation1.pptx Ahda Coba2eldwin_dj7216Pas encore d'évaluation

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDocument12 pages2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216Pas encore d'évaluation

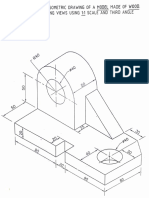

- Isometric drawing of a wood model with front, top and right side viewsDocument1 pageIsometric drawing of a wood model with front, top and right side viewseldwin_dj7216Pas encore d'évaluation

- High School Chemistry Grade 10-12Document486 pagesHigh School Chemistry Grade 10-12Todd95% (39)

- Pressure Loss Experiment Gunt Hamburg HM 150.29Document2 pagesPressure Loss Experiment Gunt Hamburg HM 150.29eldwin_dj7216Pas encore d'évaluation

- Penberthy EductorDocument16 pagesPenberthy EductorVikk SuriyaPas encore d'évaluation

- Kaeser ASD Series Rotary Screw Compressors with SIGMA PROFILE TechnologyDocument11 pagesKaeser ASD Series Rotary Screw Compressors with SIGMA PROFILE Technologyeldwin_dj7216Pas encore d'évaluation

- Northvale Steam Ejector Basics. 1Document16 pagesNorthvale Steam Ejector Basics. 1eldwin_dj7216Pas encore d'évaluation

- GEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFDocument8 pagesGEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFeldwin_dj7216Pas encore d'évaluation

- Equation Editor MainDocument24 pagesEquation Editor Mainmywol1931Pas encore d'évaluation

- 2014 Al-Leathy Thermal Energy Storage Tank Design Concepts For Use With A Solid Particle Receiver-Based Solar Power TowerDocument16 pages2014 Al-Leathy Thermal Energy Storage Tank Design Concepts For Use With A Solid Particle Receiver-Based Solar Power Towereldwin_dj7216Pas encore d'évaluation

- Modeling of Transient Cyclic Behavior of A Solid Particle Thermal Energy Storage Bin For Central ReceiverDocument10 pagesModeling of Transient Cyclic Behavior of A Solid Particle Thermal Energy Storage Bin For Central Receivereldwin_dj7216Pas encore d'évaluation

- 2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow FieldsDocument6 pages2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow Fieldseldwin_dj7216Pas encore d'évaluation

- Greater Boston Math Olympiad, 6th Grade, SolutionsDocument3 pagesGreater Boston Math Olympiad, 6th Grade, SolutionsRajiv KabadPas encore d'évaluation

- Comparison of Turbulence Models On 2D Backward Facing StepDocument16 pagesComparison of Turbulence Models On 2D Backward Facing Stepeldwin_dj7216Pas encore d'évaluation

- 2D Airfoil Meshing Tutorial in ICEM CFDDocument11 pages2D Airfoil Meshing Tutorial in ICEM CFDsvkindiaPas encore d'évaluation

- Radiative Heat Transfer ProblemsDocument10 pagesRadiative Heat Transfer Problemseldwin_dj7216Pas encore d'évaluation

- ELDWIN Report On Supersonic Wind TunnelDocument9 pagesELDWIN Report On Supersonic Wind Tunneleldwin_dj7216Pas encore d'évaluation

- Advanced CFD Project 1Document14 pagesAdvanced CFD Project 1eldwin_dj7216Pas encore d'évaluation

- Lid Driven Cavity Flow OK Final EldwinDocument33 pagesLid Driven Cavity Flow OK Final Eldwineldwin_dj7216Pas encore d'évaluation

- Heat Transfer PHD Qualifying ExamDocument13 pagesHeat Transfer PHD Qualifying Exameldwin_dj7216Pas encore d'évaluation

- ELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching SurfaceDocument15 pagesELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching Surfaceeldwin_dj7216Pas encore d'évaluation

- 7.18.MNF2011 Full Paper ELDWIN PublishedDocument8 pages7.18.MNF2011 Full Paper ELDWIN Publishedeldwin_dj7216Pas encore d'évaluation

- 2010 Uit Congress Estimation of Effectiveness of Using Nanofluids Flowing Inside A Circular Tube For Heat Transfer ApplicationsDocument1 page2010 Uit Congress Estimation of Effectiveness of Using Nanofluids Flowing Inside A Circular Tube For Heat Transfer Applicationseldwin_dj7216Pas encore d'évaluation

- JMST Journal EldwinDocument10 pagesJMST Journal Eldwineldwin_dj7216Pas encore d'évaluation

- Mathematics Extension 2 HSC LevelDocument250 pagesMathematics Extension 2 HSC LevelkalstarPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter 5Document14 pagesChapter 5bhavyaPas encore d'évaluation

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocument13 pagesExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerPas encore d'évaluation

- Data Communication & Computer NetworksDocument32 pagesData Communication & Computer NetworksMuhammad NadeemPas encore d'évaluation

- A Review On Promethee and Analytic Hierarchy Process With Its ApplicationDocument7 pagesA Review On Promethee and Analytic Hierarchy Process With Its Applicationkherrouf YOUNESPas encore d'évaluation

- Mobile GIS Platforms and Applications with ArcGISDocument28 pagesMobile GIS Platforms and Applications with ArcGISZachary Perkins100% (1)

- Lecture Notes in Computational Science and EngineeringDocument434 pagesLecture Notes in Computational Science and Engineeringmuhammad nurulPas encore d'évaluation

- Manage expenses and group contributions with Expense ManagerDocument29 pagesManage expenses and group contributions with Expense ManagerPt Kamal SharmaPas encore d'évaluation

- SP 5500 V5.1 1.0Document17 pagesSP 5500 V5.1 1.0Rama Tenis CopecPas encore d'évaluation

- h2 PR Final Key SP 13Document3 pagesh2 PR Final Key SP 13George ConstantinouPas encore d'évaluation

- Cs8080 - Irt - Notes AllDocument281 pagesCs8080 - Irt - Notes Allmukeshmsd2Pas encore d'évaluation

- Staad FoundationDocument25 pagesStaad FoundationAnonymous nwByj9L100% (2)

- Clinical Microscopy ReviewerDocument31 pagesClinical Microscopy ReviewerbokbokbokPas encore d'évaluation

- Mole Conversions Extra Practice Answer KeyDocument1 pageMole Conversions Extra Practice Answer Keyapi-376281962Pas encore d'évaluation

- MOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doDocument2 pagesMOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doĐặng Trung AnhPas encore d'évaluation

- Hadoop HiveDocument61 pagesHadoop HivemustaqPas encore d'évaluation

- Hospital Management System: A Project Report OnDocument24 pagesHospital Management System: A Project Report OnRama GayariPas encore d'évaluation

- C34 January 2014 (IAL)Document44 pagesC34 January 2014 (IAL)SandyDavidPas encore d'évaluation

- Foundations On Friction Creep Piles in Soft ClaysDocument11 pagesFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihPas encore d'évaluation

- Synopsis On Mobile TrackingDocument11 pagesSynopsis On Mobile Trackingcooolhoney885Pas encore d'évaluation

- Lecture Antenna MiniaturizationDocument34 pagesLecture Antenna MiniaturizationJuhi GargPas encore d'évaluation

- Problem Solving 1 Arithmetic SequenceDocument62 pagesProblem Solving 1 Arithmetic SequenceCitrus National High SchoolPas encore d'évaluation

- Line Tension and Pole StrengthDocument34 pagesLine Tension and Pole StrengthDon BunPas encore d'évaluation

- The Chemistry of Gemstone Colours 2016Document1 pageThe Chemistry of Gemstone Colours 2016Lukau João PedroPas encore d'évaluation

- Limiting Reagents 1Document17 pagesLimiting Reagents 1Aldrin Jay Patungan100% (1)

- EEE415 Digital Image Processing: Frequency Domain FilteringDocument50 pagesEEE415 Digital Image Processing: Frequency Domain FilteringFAISAL NAWABPas encore d'évaluation

- 978402applied Math Test Paper - Xi Set 2 - Sem 2Document4 pages978402applied Math Test Paper - Xi Set 2 - Sem 2MehulPas encore d'évaluation

- Instantaneous Waterhammer EquationDocument10 pagesInstantaneous Waterhammer EquationkiranPas encore d'évaluation

- Assignment 2Document6 pagesAssignment 2Umar ZahidPas encore d'évaluation

- Engineering Graphics (046) Marking Scheme: Sample Question Paper (2017-18)Document8 pagesEngineering Graphics (046) Marking Scheme: Sample Question Paper (2017-18)RaghuSrinivasanPas encore d'évaluation