Académique Documents

Professionnel Documents

Culture Documents

Elastocool MH1040

Transféré par

TajmirMahmudCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Elastocool MH1040

Transféré par

TajmirMahmudDroits d'auteur :

Formats disponibles

Page 1 of 4

ELASTOCOOL

MH 1040

Technical Data Sheet

Version: 01

Edition: 04/2008

System Description

3 component system for the production of closed cell rigid foams using cylo/iso-pentane (70/30) as

blowing agent.

Application

Elastocool

MH 1040 has been developed particularly for the insulation of refrigerators, deep

freezers and cold room shelves.

Very good flow properties and short demoulding times allow economical production.

Supply Form

The material is supplied as separate components:

1. Elastocool

MH 1040 C-A

Preblended polyol component WITHOUT

blowing agent

2. Cylo/iso-pentane (70/30)

Blowing agent

Has to be added to the polyol

component prior to processing

3. Lupranate M20S / H3610/0 C-B Isocyanate (B component)

Processing

Elastocool

MH 1040 can be processed both on high and low pressure machines. For the dosage

of the blowing agent, appropriate equipment are to be used. The mould temperature should be

between 35C and 45C.

For processing, the Safety Data Sheets and the Technical Information Safety and Precautionary

Measures for the Handling of Polyurethane Systems should be consulted and observed.

Page 2 of 4

ELASTOCOOL

MH 1040

Technical Data Sheet

Receiving Control

The control includes measurement of the cream, string and rise time as well as the free rise

density. Testing of the reaction characteristics is carried out at a material temperature of 20C

using a non-waxed paper cup of 750 cc capacity with a total weighed in quantity of 70g.

Prior to testing Elastocool

MH 1040 C-A must be thoroughly homogenized.

Elastocool

MH 1040 C-A with Cylo/iso-pentane (70/30) and Isocyanate are stirred together

thoroughly at a mixing ratio of 100 : 128 (parts by weight, pbw) for 10 seconds. Mixing is

performed by means of a disc type laboratory stirrer with a diameter of approx. 60 mm at a speed

of approx. 1,300 rpm.

As the reaction characteristics of the mixture using identical raw materials are influenced by the

intensity of mixing, the specified values should be considered as guidance values.

Guide Formulation:

100.0 pbw Elastocool

MH 1040 C-A

13.0 pbw Cylo/iso-pentane (70/30)

144.6 pbw Lupranate M20S / H3610/0 C-B

Mixing ratio: 100 : 128

Packaging Material

Fixed lid drums

Elastocool

MH 1040 C-A : approx. 220 kg contents (blue drum)

Lupranate M20S / H3610/0 C-B : approx. 250 kg contents (red drum)

The appropriate transport classification is to be taken from the shipping documents.

Storage

The components are hygroscopic and should therefore be kept in sealed container when not in

use. The storage temperature should be 15C 25C.

The shelf life is 6 months. In case a longer shelf life is required the polyol component can also be

delivered as a multi-component system.

Page 3 of 4

ELASTOCOOL

MH 1040

Technical Data Sheet

Waste Disposal

Disposing of waste should not be in conflict with national or international regulations. Therefore,

check with your local authorities on how to treat both raw material and production waste.

If you are in doubts or need further clarification, please contact the nearest BASF office for

advice. More information on waste disposal can also be found at the following web page:

www.isopa.org

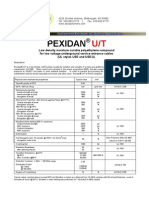

Typical chemical and physical properties

Reactivity

Cup test according to

receiving control

High pressure machine

150 bar

Cream time 9 s 7 s

Gel time (string time) 73 s 55 s

Density (Free Rise) 26.4 kg/m (cup) 23.3 kg/m (core)

Property Standard Value

Core density DIN EN ISO 845 31 kg/m

Compressive stress DIN 53421 0.14 N/mm

Compression DIN 53421 10 %

Closed cell content ISO 4590 93%

Thermal conductivity HESTO 20.0 mW/mK

Property

Polyol-component

without blowing

agent

Polyol-component

with blowing agent

Isocyanate-

component

Density, 20 C 1.09 g/cm 1.02 g/cm 1.24 g/cm

Viscosity, 20 C 5,300 mPas 550 mPas 300 mPas

Page 4 of 4

ELASTOCOOL

MH 1040

Technical Data Sheet

Date of issue : Apr-08/ BPM-ER

= registered trade mark of Elastogran

The statements in this publication are based on our present technical

knowledge and experience. They do not relieve the processor from the

necessity of carrying out his own tests and experiments, since processing

and application of our products can influence results in so many ways;

neither do they imply any legally binding assurance of certain properties or

of suitability for a specific purpose.

Any proprietary rights should be respected

BASF Polyurethanes (Malaysia) Sdn. Bhd.

(No. Syarikat : 416394-K)

No. 2, Jalan U8/87

Seksyen U8, Bukit Jelutong

40706 Shah Alam,

Selangor Darul Ehsan.

: +(603) 7847 3196, 7847 3197

: +(603) 7847 3192

Vous aimerez peut-être aussi

- Lifting Lug Design B 01Document22 pagesLifting Lug Design B 01bakellyPas encore d'évaluation

- Distillation: Operation and ApplicationsD'EverandDistillation: Operation and ApplicationsAndrzej GorakÉvaluation : 4 sur 5 étoiles4/5 (10)

- Sluice Gate ValveDocument15 pagesSluice Gate ValveRinia DurrsakePas encore d'évaluation

- ESCRDocument3 pagesESCRAvelino Sobrevega Pinuela Jr.Pas encore d'évaluation

- Ismb 600 Splice Design Calculation-R1Document1 pageIsmb 600 Splice Design Calculation-R1Anonymous sfkedkym100% (2)

- Hot BoltingDocument6 pagesHot BoltingNickath Banu100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Flash CalcinationDocument4 pagesFlash CalcinationalulatekPas encore d'évaluation

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.D'EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Évaluation : 4 sur 5 étoiles4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Solvalitt TDSDocument4 pagesSolvalitt TDSphillipskincaidPas encore d'évaluation

- Baltoflake - English (Uk) - Issued.25.03.2010Document4 pagesBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragPas encore d'évaluation

- Interline 850Document4 pagesInterline 850shameelPas encore d'évaluation

- Schill + Seilacher: Solutions - Tailormade - WorldwideDocument3 pagesSchill + Seilacher: Solutions - Tailormade - WorldwideA MahmoodPas encore d'évaluation

- Aluflex - English (Uk) - Issued.06.12.2007Document3 pagesAluflex - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Ethacure 300Document4 pagesEthacure 300sanjiv66669Pas encore d'évaluation

- Super-Clean PET Flake ProcessDocument5 pagesSuper-Clean PET Flake ProcessViktorPas encore d'évaluation

- Chemflake Special - English (Uk) - Issued.08.01.2010Document5 pagesChemflake Special - English (Uk) - Issued.08.01.2010Mohamed FaragPas encore d'évaluation

- TDS - Baltoflake S2000 - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Baltoflake S2000 - English (Uk) - Issued.26.11.2010rezza182Pas encore d'évaluation

- Tds - Antifouling Seaforce 60 - English (Uk) - IssueDocument3 pagesTds - Antifouling Seaforce 60 - English (Uk) - Issuewey5316Pas encore d'évaluation

- Power Fecal™ DNA Isolation Kit: Instruction ManualDocument16 pagesPower Fecal™ DNA Isolation Kit: Instruction ManualJorge Hantar Touma LazoPas encore d'évaluation

- Sikafast - 3131S: Structural Methacrylate AdhesiveDocument4 pagesSikafast - 3131S: Structural Methacrylate Adhesiverobox514Pas encore d'évaluation

- Aqualine 300 TDSDocument2 pagesAqualine 300 TDS8612106535Pas encore d'évaluation

- Pds Hempadur Obm 47150 En-GbDocument2 pagesPds Hempadur Obm 47150 En-GbHuascar Rafael Robles CaceresPas encore d'évaluation

- C18 Spin Column Usage MethodDocument8 pagesC18 Spin Column Usage Methodphd.data19Pas encore d'évaluation

- Pexidan Ut Saco 0510Document2 pagesPexidan Ut Saco 0510Eddy BrentonPas encore d'évaluation

- Futura Matt - English (Uk) - Issued.06.12.2007Document3 pagesFutura Matt - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Trigonox101 PdsDocument3 pagesTrigonox101 PdsPaula RiveraPas encore d'évaluation

- Concresssive 1350Document4 pagesConcresssive 1350krimchand1825Pas encore d'évaluation

- Lusin Alro OL 141: Special Silicone-Free Release AgentDocument1 pageLusin Alro OL 141: Special Silicone-Free Release AgentImeblaPas encore d'évaluation

- JotunBitum Ballastic BlackDocument3 pagesJotunBitum Ballastic BlackMekhmanPas encore d'évaluation

- Korethan H.B. UH279 (Two-Component) : Physical PropertiesDocument2 pagesKorethan H.B. UH279 (Two-Component) : Physical PropertiesTrịnh Minh KhoaPas encore d'évaluation

- Elastopor H 2130-38 Material CertificateDocument3 pagesElastopor H 2130-38 Material Certificatejithinjose860% (2)

- ALUFLEX - English (Uk) - Issued.28.11.2005Document3 pagesALUFLEX - English (Uk) - Issued.28.11.2005wey5316Pas encore d'évaluation

- Interthane 990: Product DescriptionDocument4 pagesInterthane 990: Product Descriptionsorion61Pas encore d'évaluation

- Tds - Antifouling Seaforce 90 - English (Uk) - IssueDocument3 pagesTds - Antifouling Seaforce 90 - English (Uk) - Issuewey5316Pas encore d'évaluation

- CPE7012-B REX Coursework Brief 2020Document13 pagesCPE7012-B REX Coursework Brief 2020Prashant PrashantPas encore d'évaluation

- TDS - Tankguard HB - English (Uk) - Issued.06.12.2007Document3 pagesTDS - Tankguard HB - English (Uk) - Issued.06.12.2007AckmonPas encore d'évaluation

- HYSOL® FP4323 (ES4323) : Technical Data SheetDocument2 pagesHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemPas encore d'évaluation

- All DatasheetsDocument485 pagesAll Datasheetssflynn79Pas encore d'évaluation

- SeaQuantum Classic - English (Uk) - Issued.06.12.2007Document3 pagesSeaQuantum Classic - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- KCC DataSheet EH3150 (Eng)Document2 pagesKCC DataSheet EH3150 (Eng)Trịnh Minh KhoaPas encore d'évaluation

- Chem FlakeDocument5 pagesChem Flakejay2kay5793Pas encore d'évaluation

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Document4 pagesTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316Pas encore d'évaluation

- Elastollan Processing Recommendations PDFDocument28 pagesElastollan Processing Recommendations PDFNicolae MariusPas encore d'évaluation

- Elan-Tron MC4260 W4260 IngDocument4 pagesElan-Tron MC4260 W4260 IngZdzisław LatoPas encore d'évaluation

- Pds Ipd Sikafast3121 Us MW 3.22.12Document4 pagesPds Ipd Sikafast3121 Us MW 3.22.12robox514Pas encore d'évaluation

- Internationa Paint MSDSDocument4 pagesInternationa Paint MSDStsoheil100% (1)

- Stonproof CT5 Product Data - en - USDocument2 pagesStonproof CT5 Product Data - en - USVentas ExpertisPas encore d'évaluation

- Tds - Alkydprimer - Issued.31.08.2005Document4 pagesTds - Alkydprimer - Issued.31.08.2005wey5316Pas encore d'évaluation

- D45 Inchisa Elastospray LWP 1672 10 Ed04 enDocument8 pagesD45 Inchisa Elastospray LWP 1672 10 Ed04 enMangalagiu BogdanPas encore d'évaluation

- Agilent Metacarb 87H Organic Acids Column H Form User Manual Part No. A5214Document7 pagesAgilent Metacarb 87H Organic Acids Column H Form User Manual Part No. A5214Maira ChinchillaPas encore d'évaluation

- TDS - Jotacote 410 - Issued.06.12.2007 - 2Document3 pagesTDS - Jotacote 410 - Issued.06.12.2007 - 2musaismail8863Pas encore d'évaluation

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Document4 pagesTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkPas encore d'évaluation

- Penguard Primer PDFDocument4 pagesPenguard Primer PDFheri_prasetyadi7715Pas encore d'évaluation

- Tankguard ARDocument4 pagesTankguard ARSherif Abdelhameed100% (1)

- Emflon PFRW Filter Cartridges: For Sterile Filtration of GasesDocument3 pagesEmflon PFRW Filter Cartridges: For Sterile Filtration of GasesRichard BakerPas encore d'évaluation

- Hardtop AsDocument4 pagesHardtop AsulusoynPas encore d'évaluation

- Ultraconductive Coating: Conductive Coating For LSPDocument3 pagesUltraconductive Coating: Conductive Coating For LSPfaradaiPas encore d'évaluation

- Instructions For Use: Blotting / Transfer ManifoldsDocument3 pagesInstructions For Use: Blotting / Transfer ManifoldsIsah MohammedPas encore d'évaluation

- Search P "Aromatic+Polyester"&Ei UTF 8&Fl 0&Fr FP Tab WeDocument11 pagesSearch P "Aromatic+Polyester"&Ei UTF 8&Fl 0&Fr FP Tab WeA MahmoodPas encore d'évaluation

- PD05P XXX XXX B enDocument8 pagesPD05P XXX XXX B enkarthik_mohankumarPas encore d'évaluation

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryD'EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryPas encore d'évaluation

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraPas encore d'évaluation

- Orifice Test ExperimentDocument4 pagesOrifice Test ExperimentEmmanuel MulayiPas encore d'évaluation

- Monitoring Pekerjaan Dan MaterialDocument3 pagesMonitoring Pekerjaan Dan MaterialHarits Angga KusumaPas encore d'évaluation

- IS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete BlocksDocument21 pagesIS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete Blocksmanish_shashikantPas encore d'évaluation

- LP in Periodic Table of ElementsDocument7 pagesLP in Periodic Table of ElementsShyra May GalendezPas encore d'évaluation

- Kovan Grandeur BrochureDocument14 pagesKovan Grandeur BrochureMax KohPas encore d'évaluation

- Hinge: Door HingesDocument4 pagesHinge: Door HingesWee Yong KeePas encore d'évaluation

- Air Cond Instructor Guide Lesson PlanDocument29 pagesAir Cond Instructor Guide Lesson PlanWilliam Kibbe100% (1)

- 4 App Physics 22EL Q I VDocument17 pages4 App Physics 22EL Q I VRizwan MPas encore d'évaluation

- Hardie Plank Installation GuideDocument1 pageHardie Plank Installation GuideBrandon VieceliPas encore d'évaluation

- 100 Questions For IEEDocument18 pages100 Questions For IEEmusleh19Pas encore d'évaluation

- Sabiana FC CRCDocument23 pagesSabiana FC CRCIgor SpasovicPas encore d'évaluation

- PVDF PolyvinyldenfluorideDocument2 pagesPVDF Polyvinyldenfluoridehudi_leksonoPas encore d'évaluation

- 10 - Ravichandran Et AlDocument13 pages10 - Ravichandran Et AlAdam Al AufaPas encore d'évaluation

- Duracrete FichaDocument2 pagesDuracrete FichavankarpPas encore d'évaluation

- Definitions and Nomenclature in Exergy Analysis and ExergoeconomicsDocument5 pagesDefinitions and Nomenclature in Exergy Analysis and ExergoeconomicsGhassen KhalilPas encore d'évaluation

- Price List EcoLum Price List March 2023 IssueDocument12 pagesPrice List EcoLum Price List March 2023 IssueGrace Mecate VillanuevaPas encore d'évaluation

- SLD of MDB-3 Last Update For Print-ModelDocument1 pageSLD of MDB-3 Last Update For Print-ModelSharif 087Pas encore d'évaluation

- Template - USJ DME Front Page For Practical ReportsDocument11 pagesTemplate - USJ DME Front Page For Practical ReportsUshmikaPas encore d'évaluation

- The House in 1970Document20 pagesThe House in 1970SRPas encore d'évaluation

- Wooden Doors CatalogueDocument25 pagesWooden Doors CatalogueGayan IndunilPas encore d'évaluation

- Columns and StrutsDocument10 pagesColumns and StrutsamitsagaPas encore d'évaluation

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoPas encore d'évaluation

- Performance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFDocument14 pagesPerformance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFsandeeppandey0789Pas encore d'évaluation

- Steel Framing For Service YardDocument1 pageSteel Framing For Service YardNana BarimaPas encore d'évaluation