Académique Documents

Professionnel Documents

Culture Documents

Welding of CrMo Steels For Power Generation and Petrochemical Applications

Transféré par

Dries VandezandeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welding of CrMo Steels For Power Generation and Petrochemical Applications

Transféré par

Dries VandezandeDroits d'auteur :

Formats disponibles

BIULETYN INSTYTUTU SPAWALNICTWA No.

2/2013 11

Introduction

Creep and high temperature resistant

CrMo steels have been around for a very long

time and have found use with great success

for applications in the petrochemical, and

respectively in the power generation indus-

try. Typical products for these industries are

boilers, heaters, heat exchangers, reactors,

and hydrocrackers, usually built as heavy

wall pressure vessels.

In a continuous strive for optimizing the

economics in the various process installa-

tions in these industries, the service pres-

sures and/or temperatures have increased.

This implied that the respective base materi-

als either had to be made available in heav-

ier thicknesses or they had to be developed

to meet higher strength and impact tough-

ness requirements. Increased mechanical

properties will reduce or at least restrict the

necessary wall thickness which generates

an additional economical advantage in pro-

duction, handling and installation of heavy

process equipment. An example of a heavy

all pressure vessel is a part of a Hydro

Conversion Unit as shown in Figure 1.

The basic and classic CrMo steels are

alloyed with 0,5%Mo 1%Cr/0,5%Mo

2,25%Cr/1%Mo 5%Cr/1%Mo

9%Cr/1%Mo and 12%Cr/1%Mo. From

these steels further development has taken

place by adding elements such as V, W, Ni, Ti,

Nb, B and/or N to arrive at the new grades of

today such as the T/P22V, T/P23, T/P24, T/

P91, T/P92 and VM 12-SHC. Many of these

new grades have been applied successfully

in industry but the development continues.

Obviously, development of the welding

consumables had to and still must follow the

direction of the base materials with the assur-

ance of meeting the same stringent require-

ments for the process equipment as the base

materials, even more so since the HAZ is

usually also considered part of the weld. Ex-

tensive research and development has taken

place at Bhler Schweisstechnik in Germany

to arrive at a full consumable range for the

new generation of CrMo(V) steels for which

also creep data up to 60 000 hours have been

collected. With increasing alloy level the spe-

cifc welding procedures have to be adjusted

and will call for more precise and strict con-

trol of welding parameters and heat treatment.

Jan Hilkes, Volker Gross

Welding CrMo steels for power generation

and petrochemical applications - past, present and future

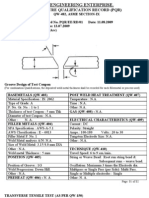

Technical Details of a Hydro Conversion Unit

Base material: 2,25%Cr-1%Mo

Sizes: thickness: 358 mm

length: 21 m

diameter: 5.3 m

total weight: 706 t

Service

conditions:

215.5 bar pressure and max. 454C

Welding

consumables:

SAW: Union S1CrMo2/UV 420TTR

SMAW: Phoenix SH Chromo 2 KS

Fig. 1: Part of Hydro Conversion Unit by ATB, Italy

Jan Hilkes, Volker Gross - Bhler Schweisstechnik Deutschland GmbH, Hamm, Germany

No. 2/2013 12 BIULETYN INSTYTUTU SPAWALNICTWA

Creep resistant CrMo steels

Basic metallurgy for base material

and weldmetal design

Creep resistant steels are steels that can

resist a certain stress at a specifc service

temperature without exceeding a specifed

amount of elongation. The maximum stress

to rupture at a specifc temperature after a

specifc time, e.g. 600C and 105 h, is re-

ferred to as Creep Rupture Stress. For ex-

ample, an engineering design criterion for a

power plant could require a minimal stress

of 100MPa for 105 h at service temperature.

The basic idea is that the vessel remains its

original sizes and shape while in service for

up to 20 to 30 years. Due to the fact that in the

processes used within the Power Generation

and Petrochemical Industry and the many

different service conditions such as pres-

sure, temperature and environment, a wide

variety of CrMo creep resistant steels with

additions of V, W, Ti, Nb, B and/or N have

been developed, while new types are also

still under development. Due to increased

pressures and temperatures, up to 370 bar

and 650C, as for example in components

for Ultra-Super-Critical (USC) steam pow-

er generation plants, CrMo creep resistant

base materials with increased strength are

required to allow wall thicknesses that are

within the range of what fabricators can

handle in their facilities. Also for petro-

chemical applications (P22V), sizes now

up to 350mm are no longer an exception.

An overview of the international standards,

chemical compositions and maximum ser-

vice temperatures of the actual and most

popular CrMo creep resistant steels is given

in Table 1.

Table 1: Overview of the international standards, chemical composition and maximum service temperature

of the actual and most popular CrMo creep resistant steels

CrMo type

INTERNATIONAL STANDARDS TYPICAL CHEMICAL COMPOSITION (wt%) SERVICE

ASTM & ASME DIN/VdTV EN C % Si % Mn % Cr % Mo % Ni % V % W % Nb % other % Temp. C

0.5Mo T/P 1 16 Mo 3 8MoB 5-4 0,16 0,30 0,82 < 0,30 0,32 < 0,30 - - - - < 460

1.25Cr-0.5Mo T/P 11 10 CoMo 5-5 10 CrMo 5-5 0,10 0,32 0,68 1,25 0,50 - - - - - < 545

1,00Cr-0.5Mo T/P 12 13 CrMo 4-5 13 CoMo 4-5 0,13 0,70 0,60 1,00 0,50 - - - - - < 545

1.25Cr-1MoV - 15 CrMoV 5-10 - 0,15 0,30 0,75 1,25 1,05 - 0,26 - - - < 545

T/P 36 15 NiCuMoNb 5 (WB 36) 15 NiCuNb 5 0,15 0,35 0,95 - 0,45 1,12 - - 0,22 Cu: 0,62 < 545

2.25Cr-1Mo T/P 22 10 CrMo 9-10 10 CrMo 9-10 0,10 0,36 0,69 2,20 1,02 - - - - - < 545

2.25Cr-1MoV T/P 22V - - 0,12 0,08 0,50 2,25 1,00 - 0,30 - - - < 545

2.25Cr-MoVW T/P 23 HCM 2S 7CrWVMoNb 9-6 0,08 0,34 0,42 2,32 < 0,30 - 0,02 1,55 0,06 N < 0,010 < 550

2.25Cr-1MoVTiB T/P 24 7CrMoVTiB 10-10 7CrMoVTiB 10-10 0,07 0,28 0,60 2,25 1,04 - 0,24 - -

N < 0,010

B: 15-70 ppm

Ti: 0,05-0,10

< 550

5Cr-0.5Mo T/P 502 12 CrMo 19-5 - 0,12 0,35 0,65 5,10 0,54 - - - - - < 550

9Cr-1Mo T/P 9 X12 CrMo 9-1 X12 CrMo 9-1 0,12 0,60 0,40 9,00 1,00 - - - - - < 585

9Cr-1Mo mod. T/P 91 X10 CrMoVNb 9-1 X10 CrMoVNb 9-1 0,10 0,36 0,52 8,82 1,02 < 0,40 0,22 - 0,08 N: 30-70 ppm < 585

9Cr-0.5MoWV T/P 911 X11 CrMoWVNb 9-1-1 X11 CrMoWVNb 9-1-1 0,11 0,28 0,54 8,80 1,02 0,25 0,22 1,05 0,08 N: 0,05-0,09 < 625

9Cr-0.5MoWV T/P 92 X10 CrWMoNb 9-2 - 0,10 < 0,50 0,55 8,80 0,52 < 0,40 0,23 1,55 0,08

N: 0,03-0,07

B: 0,001-0,006

< 625

12Cr-0.25Mo

+1.4W1.3Co0.2V

-

X12 CrCoWVNb 11-2-2

(VM 12-SHC) t<10mm

- 0,11 0,45 0,20 11,50 0,23 0,28 0,24 1,40 0,07

Co: 1,30

N: 0,055

B: 0,003

< 650

12Cr-1MoNiV - X20 CrMoV 12-1 X20 CrMoV 11-1 0,20 <0,50 <1,00 12,10 1,05 0,65 0,28 - - - <585

BIULETYN INSTYTUTU SPAWALNICTWA No. 2/2013 13

The creep resistance of a CrMo steel is

based on the formation of stable precipi-

tations such as alloy carbides in a ferritic,

bainitic and/or martensitic microstructure

in the normalised condition. Due to a subse-

quent tempering treatment, a stable micro-

structure with precipitations is generated

that remains stable at the service temper-

ature for which the steel has been devel-

oped. The precipitations formed will block

the grain-boundaries and prevent sliding of

the slip-planes to give the desired creep re-

sistance properties. They should therefore

have the correct shape, be present in the

right amount and be evenly distributed to

obtain a homogeneous structure with homo-

geneous properties. Depending on the al-

loy level and the heat treatment(s), specifc

types of precipitations will be formed in a

specifc amount. The governing parameters

for the heat-treatment are temperature and

time. The variety of precipitations that can

be expected and that are mainly used in the

design of classic and modern creep resistant

CrMo steels are listed in Table 2.

Table 1: Overview of the international standards, chemical composition and maximum service temperature

of the actual and most popular CrMo creep resistant steels

CrMo type

INTERNATIONAL STANDARDS TYPICAL CHEMICAL COMPOSITION (wt%) SERVICE

ASTM & ASME DIN/VdTV EN C % Si % Mn % Cr % Mo % Ni % V % W % Nb % other % Temp. C

0.5Mo T/P 1 16 Mo 3 8MoB 5-4 0,16 0,30 0,82 < 0,30 0,32 < 0,30 - - - - < 460

1.25Cr-0.5Mo T/P 11 10 CoMo 5-5 10 CrMo 5-5 0,10 0,32 0,68 1,25 0,50 - - - - - < 545

1,00Cr-0.5Mo T/P 12 13 CrMo 4-5 13 CoMo 4-5 0,13 0,70 0,60 1,00 0,50 - - - - - < 545

1.25Cr-1MoV - 15 CrMoV 5-10 - 0,15 0,30 0,75 1,25 1,05 - 0,26 - - - < 545

T/P 36 15 NiCuMoNb 5 (WB 36) 15 NiCuNb 5 0,15 0,35 0,95 - 0,45 1,12 - - 0,22 Cu: 0,62 < 545

2.25Cr-1Mo T/P 22 10 CrMo 9-10 10 CrMo 9-10 0,10 0,36 0,69 2,20 1,02 - - - - - < 545

2.25Cr-1MoV T/P 22V - - 0,12 0,08 0,50 2,25 1,00 - 0,30 - - - < 545

2.25Cr-MoVW T/P 23 HCM 2S 7CrWVMoNb 9-6 0,08 0,34 0,42 2,32 < 0,30 - 0,02 1,55 0,06 N < 0,010 < 550

2.25Cr-1MoVTiB T/P 24 7CrMoVTiB 10-10 7CrMoVTiB 10-10 0,07 0,28 0,60 2,25 1,04 - 0,24 - -

N < 0,010

B: 15-70 ppm

Ti: 0,05-0,10

< 550

5Cr-0.5Mo T/P 502 12 CrMo 19-5 - 0,12 0,35 0,65 5,10 0,54 - - - - - < 550

9Cr-1Mo T/P 9 X12 CrMo 9-1 X12 CrMo 9-1 0,12 0,60 0,40 9,00 1,00 - - - - - < 585

9Cr-1Mo mod. T/P 91 X10 CrMoVNb 9-1 X10 CrMoVNb 9-1 0,10 0,36 0,52 8,82 1,02 < 0,40 0,22 - 0,08 N: 30-70 ppm < 585

9Cr-0.5MoWV T/P 911 X11 CrMoWVNb 9-1-1 X11 CrMoWVNb 9-1-1 0,11 0,28 0,54 8,80 1,02 0,25 0,22 1,05 0,08 N: 0,05-0,09 < 625

9Cr-0.5MoWV T/P 92 X10 CrWMoNb 9-2 - 0,10 < 0,50 0,55 8,80 0,52 < 0,40 0,23 1,55 0,08

N: 0,03-0,07

B: 0,001-0,006

< 625

12Cr-0.25Mo

+1.4W1.3Co0.2V

-

X12 CrCoWVNb 11-2-2

(VM 12-SHC) t<10mm

- 0,11 0,45 0,20 11,50 0,23 0,28 0,24 1,40 0,07

Co: 1,30

N: 0,055

B: 0,003

< 650

12Cr-1MoNiV - X20 CrMoV 12-1 X20 CrMoV 11-1 0,20 <0,50 <1,00 12,10 1,05 0,65 0,28 - - - <585

Table 1: Overview of the international standards, chemical composition and maximum service temperature

of the actual and most popular CrMo creep resistant steels (continued)

Table 2: Precipitations that can be found

in creep resistant CrMo steels /1, 2/

Precipitations and possible phases in CrMo steels

Graphite

Epsilon = Fe

2.4

C

Cementite = Fe

3

C

Chi = Fe

2

C

M

2

X M

6

C M

23

C

6

M

7

C

3

Laves

M

5

C

2

Z-phase

Mo

2

C Cr

3

C

NbC NbN VN

No. 2/2013 14 BIULETYN INSTYTUTU SPAWALNICTWA

Heat treatments for CrMo steels and

welded joints

The heat treatments for the base materi-

als are reasonably complex but are required

to obtain the optimal mechanical properties.

Depending on the alloy content a Normalis-

ing, Tempering and Annealing treatment at

various temperatures for several hours with

a controlled cooling rate have to be execut-

ed according strict procedures. The same is

valid for the weldmetal, with increasing al-

loy content the Post Weld Heat Treatment

(PWHT) for welded joints gets more com-

plicated as illustrated in Figure 2.

When in subsequent PWHT, Intermediate

Stress Relieving (ISR) or in service, the ulti-

mate heat treatment temperature of the base

material is exceeded too much and too long,

the precipitations can dissolve again which

causes reduction of the mechanical proper-

ties of the base material. This implies that,

for example, for this reason the maximum

temperature of 760C for P91 in Figure 2

shall not be exceeded. For T/P23 in Figure

2, an Intermediate Stress Relieving is indi-

cated for constructions with different mate-

rial thicknesses. For each application the op-

timum PWHT shall be determined. Further

elaboration will follow in the welding chap-

ter of this paper (Table 4).

Temper Embrittlement

When CrMo base material and the weld

metal is exposed to a temperature range of

400-500C for a very long time there is a

risk of Temper Embrittlement. This type

of embrittlement is caused by trace ele-

ments as P, Sb, Sn and As that migrate to the

grain boundaries and can reduce the duc-

tility in both base material and weldmetal.

To which extent this phenomena will occur

depends merely on temperature and time.

To establish the sensitivity of a material to

temper embrittlement, a Step Cooling (STC)

heat treatment is carried out in the range of

593-316C for a duration of 240 hours. The

difference in transition temperature (impact

properties) from before and after the heat

treatment is a measure for the sensitiveness

to temper embrittlement. A maximum allow-

able shift in transition temperature after step

cooling can be specifed as a requirement for

base material and weldmetal. In order to re-

duce the risk of temper embrittlement, the re-

sponsible trace elements need to be restrict-

ed. Bruscato and Watanabe have developed

formulas to express the tendency of temper

embrittlement /3, 4/.

The formula of Watanabe is only valid for the

base material and is usually restricted to a value

of J < 160 but also requirements for J < 120 or

80 are being specifed by the industry today.

Fig. 2: Temperature cycle and heat control during

welding and PWHT of martensitic steel P91, E911 and

P92 (above) and ferritic/bainitic steel T/P23 (below).

For GTAW joints in <10mm wall thickness T/P 23,

no PWHT is required

Watanabe: J = (Mn + Si) x (P + Sn) x 10

4

elements in wt%

Bruscato: X = (10 P + 5 Sb + 4 Sn + As) / 100 element in wt% and result in ppm

BIULETYN INSTYTUTU SPAWALNICTWA No. 2/2013 15

The Bruscato formula, also referred to as

the X-factor, is valid for both weld metal and

base material. For weldmetal the specifca-

tions are becoming more and more stringent

with increasing wall thickness and desire

for additional assurance of the mechanical

properties. Initially, the required value of the

X-factor was X < 15, but present specifca-

tions already ask for X < 10. An additional

requirement for the Mn and Si content can be

set accordingly: Mn + Si < 1.1%.

Specifcally for SAW where the trace ele-

ments can be picked up from both wire and

fux, the combination should be tested to

comply with the requirements. This means

one source for both wire and fux would be

recommended /5/.

Corrosion: Resistance to Oxidation,

Sulphidation and Hydrogen attack

In addition to the creep resistance and

resistance to embrittlement, CrMo steels

also show increased high temperature oxi-

dation resistance with increasing alloy con-

tent. Comparing the scaling loss for plain

carbon steel and 1%Cr0.5%Mo with that

of 5%Cr0.5%Mo steel at 675C, the scal-

ing loss is reduced from >2.5 mm/y for the

frst two to about 0.1 mm/y for the latter.

This makes these steels also very suitable

for gas-fred furnaces in the petrochemical

industry /6/.

Also sulphidation corrosion resistance in-

creases with increasing alloy content. Com-

paring the corrosion rate of carbon steel with

that of 9%Cr1%Mo steel at 700C, the cor-

rosion rate is reduced from 1.0 to 0.2 mm/y.

Sulphur combines with Chromium to form

Chromium-Sulphides, and hence reduces the

amount of Cr-carbides required for creep re-

sistance. Since most crude oils and other gas-

eous fuels contain either certain amounts of

Sulphur or H2S, suffcient sulphidation cor-

rosion resistance is required for petrochemi-

cal installations.

Another important phenomena is High

Temperature Hydrogen Attack (HTHA), a

formation of Methane from Cementite (Fe

3

C

+ 2H

2

CH

4

+ 3Fe) in the base material un-

der high Hydrogen pressures at high temper-

atures, as for example in heavy wall pressure

vessels for high-temperature, high hydrogen

services in oil refneries. The 2.25%Cr1Mo

and 3%Cr1Mo steels are typical base mate-

rials with good resistance to HTHA in this

application.

Welding and welding consumables

for CrMo steels

In general, creep resistant CrMo-steels are

welded with matching consumables in order

to have a homogeneous welded joint with

about equal mechanical properties. Match-

ing compositions also have the same coeff-

cient of thermal expansion, which prevents

or at least reduces the risk of thermal fatigue

in service. In this respect, the heat affected

zone (HAZ) is a vulnerable area.

In principle, all arc welding processes can

be applied as SMAW. GTAW, GMAW, SAW

and FCAW. For manual processes it is im-

portant to take suffcient measures to protect

the welders from heat, and then it is of ut-

most importance that the preheat as well as

the interpass temperatures are respected and

not reduced to accommodate the welders, as

well as while tacking. With the gas-shielded

processes it is vital to assure proper shield-

ing of the weld. Due to the high preheat, the

gas-shield can be distorted and provide less

protection as required. Special nozzles and

gas cups are available to reduce the problem.

Over the last decades, Bhler Schweiss-

technik Germany has developed a wide range

of welding consumables for welding CrMo

steels for the processes: SMAW, GTAW,

SAW, GMAW and FCAW. A selection table

for the respective welding consumables and

welding processes for creep resistant CrMo

steels can be found in listed in Table 3.

No. 2/2013 16 BIULETYN INSTYTUTU SPAWALNICTWA

Depending on the alloy level, from only

0.5%Cr to 12%Cr-1%Mo the welding con-

dition regarding preheat (Tp) and interpass

(Ti) temperature as well as the subsequent

temperature cycles during SR, ISR, STC

and PWHTs change drastically. An over-

view with typical guidelines in this regard

for is provided in Table 4. Also see Figure

2 above for examples of complicated heat

treatments. The required heat treatment

Table 3: Selection table for the respective welding consumables and welding processes for creep resistant CrMo steels

CrMo type

BASE MATERIAL WELDING CONSUMABLES FOR CrMo STEELS

ASTM

&

ASME

EN SMAW GTAW GMAW

SAW

FCAW

wire fux

0.5Mo T/P 1 8MoB 5-4

Phoenix SH

Schwarz 3 K

Union I

Mo

Union I

Mo

Union S

2 Mo

UV 420

TT

Union TG

Mo R

1.25Cr-

-0.5Mo

T/P 11

10 CrMo

5-5

Phoenix

Chromo 1

Union I

CrMo

Union I

CrMo

Union S

2 CrMo

UV 420

TT

Union TG

CrMo R

1.00Cr-

-0.5Mo

T/P 12

13 CoMo

4-5

Phoenix

Chromo 1

Union I

CrMo

Union I

CrMo

Union S

2 CrMo

UV 420

TT

Union TG

CrMo R

1.25Cr-

-1MoV

-

15 CrMoV

5-10

Phoenix SH

Kupfer 3 K

- - - - -

- T/P 36

15 NiCuNb

5 (WB 36)

Phoenix SH

Schwarz 3 K Ni

Union I

Mo

Union I

Mo

Union S

3 NiMo 1

UV 420

TT(R)

-

- -

20 MnMo-

Ni 5-5

Phoenix SH

Schwarz 3 K Ni

Union I

MoMn

Union I

MoMn

Union S

3 NiMo 1

UV 420

TT(R)

Union TG

Mo R

2.25Cr-

-1Mo

T/P 22

10 CrMo

9-10

Phoenix SH

Chromo 2 KS

Union I

CrMo 910

Union I

CrMo 910

Union S

1 CrMo 2

UV 420

TTR

Union TG

CrMo 9 10 R

2.25Cr-

-1MoV

T/P

22V

-

Phoenix SH

Chromo 2 V

- -

Union S

1 CrMo 2V

UV 430

TTR-W

-

2.25Cr-

-MoVW

T/P 23

7CrMo-

WVMoNb

9-6

Thermanit

P23

Union I

P23

Union I

P23

Union S

P23

UV 430

TTR-W

UV P23

2.25Cr-

-1MoV

T/P 24

7CrMo-

VTiB

10-10

Thermanit

P24

Union I

P24

Union I

P24

Union S

P24

UV 430

TTR-W

UV P24

5Cr-0.5Mo

T/P

502

12CrMo

19-5

Phoenix

Chromo 5

Union I

CrMo 5

Union I

CrMo 5

Union S1

CrMo 5

Marathon

543

-

9Cr-1Mo T/P 9

X12 CrMo

9-1

Thermanit

Chromo 9 V

Thermanit

MTS 3

Thermanit

MTS 3

Thermanit

MTS 3

Marathon

543

Thermanit

MTS 3 PW

9Cr-1Mo

mod.

T/P 91

X10 CrMo-

VNb 9-1

Thermanit

Chromo 9 V;

Thermanit

Chromo T91

Thermanit

MTS 3

Thermanit

MTS 3

Thermanit

MTS 3

Marathon

543

Thermanit

MTS 3 PW

9Cr-

-0.5Mo-

WV

T/P

911

X11 Cr-

MoWVNb

9-1-1

Thermanit

MTS 911

Thermanit

MTS 911

Thermanit

MTS 911

Thermanit

MTS 911

Marathon

543

-

9Cr-

-0.5Mo-

WV

T/P 92

X10

CrWMoNb

9-2

Thermanit

MTS 616

Thermanit

MTS 616

Thermanit

MTS 616

Thermanit

MTS 616

Marathon

543

-

12Cr-

-0.25Mo

+1.4W1.

3Co0.2V

-

X12 Cr-

CoWVNb

11-2-2

(VM12-

-SHC)

t<10mm

Thermanit

MTS 5 CoT

Thermanit

MTS 5 CoT

- - - -

12Cr-1Mo-

NiV

-

X20 Cr-

MoV 11-1

Thermanit

MTS 4

Thermanit

MTS 4 Si

Thermanit

MTS 4 Si

Thermanit

MTS 4

Marathon

543

-

BIULETYN INSTYTUTU SPAWALNICTWA No. 2/2013 17

depends also on the thickness of the con-

struction and has to be determined by the

fabricator as part of the welding procedure

development. The main factor is to have a

controlled, slow and even heating up and

cooling down to prevent additional stresses

in the welded joint. For heavy thicknesses

this means heating up from as many sides

as possible to get the required heat distribu-

tion in the material. These precautions have

Table 4: Overview of typical guidelines for Preheat & Interpass temperatures and PWHT as SR, ISR and STC

for CrMo steels. Also see Figure 2.

CrMo type

STANDARDS

PREHEAT & INTERPASS TEMPERATURE, PWHT as SR, ISR

and STC GUIDELINES for CrMo STEELS

ASTM &

ASME

EN Tp C Ti C SR h, C ISR h, C PWHT/STC h, C

0.5Mo T/P 1 8MoB 5-4 RT RT

2-4h @

580-630C

1.25Cr-

-0.5Mo

T/P 11 10 CrMo 5-5

200-

250C

> 200C

2-4h @

660-700C

STC depending on

application

1,00Cr-

-0.5Mo

T/P 12 13 CrMo 4-5

200-

250C

> 200C

2-4h @

660-700C

1.25Cr-

-1MoV

15 CrMoV 5-10

200-

250C

> 200C

2-4h @

660-700C

T/P 36

15 NiCuNb 5

(WB 36)

200-

250C

> 200C

2-4h @

580-620C

60h @ 550C +

40h @ 620C

21 MnMoNi 5-5

200-

250C

> 200C

2-4h @

580-620C

2.25Cr-1Mo T/P 22 10 CrMo 9-10

200-

300C

200-

300C

2-4h @

670-720C

2.25Cr-

-1MoV

T/P 22V

200-

300C

200-

250C

1h @

680C

8h @ 705C + STC

+32h @ 705C

2.25Cr-Mo-

VW

T/P 23 7CrWVMoNb 9-6

200-

300C

200-

300C

1h @ 540-

560C*

0.5-4h @ 740C**

2.25Cr-

-1MoV

T/P 24

7CrMoVTiB 10-

10

200-

280C

200-

280C

0.5-4h @ 740C**

5Cr-0.5Mo T/P 502 12 CrMo 19-5

225-

300C

> 225C

2-4h @

730-760C

9Cr-1Mo T/P 9 X12 CrMo 9-1

200-

300C

200-

300C

slow cool

after welding

xh@ 750C

9Cr-1Mo

mod.

T/P 91

X10 CrMoVNb

9-1

200-

300C

200-

300C

slow cool

after welding

9Cr-0.5Mo-

WV

T/P 911

X11 CrMoWVNb

9-1-1

200-

300C

200-

300C

slow cool

after welding

xh @ 730-780C

9Cr-0.5Mo-

WV

T/P 92

X10 CrWMoNb

9-2

200-

300C

200-

300C

slow cool

after welding

xh @ 730-780C

12Cr-0.25Mo

X12 CrCoWVNb

11-2-2

200-

280C

200-

280C

slow cool

after welding

xh @ 770C

+1.4W1.

3Co0.2V

(VM 12-SHC)

t<10mm

12Cr-1Mo-

NiV

X20 CrMoV 12-1

200-

280C

200-

280C

slow cool

after welding

xh @ 760C

* with great differences in wall thickness

** no PWHT required for GTAW up to wall thickness of 10mm

x depends

on thickness

No. 2/2013 18 BIULETYN INSTYTUTU SPAWALNICTWA

to be taken to safeguard the base material,

the weldmetal and the heat affected zone

(HAZ).Recent developments in P22V, P23,

P24, P92 and VM 12-SHC have

governed more detailed and pre-

cise welding and production pro-

cedures to retain control over the

outcome of the fnal product. Al-

though these materials are not as

forgiving as the basic CrMo steel,

the weldability is excellent when

the correct procedures are fol-

lowed. Depending on the appli-

cation, there can be requirements

for STC and Bruscatos X- factor.

For very heavy wall-thickness in

P22V it could be necessary to ap-

ply intermediate stress relieving treatments

as to reduce the overall stress level before

the fnal heat treatments applied. With the

experience that Bhler Schweisstechnik

Germany has built up over the last decades,

the support that can be provided to the cus-

tomers has become a vital link in the supply

chain in todays business.

As already mentioned, the thicknesses

for a welded part in the power generation

and petrochemical industry keeps increas-

ing and higher tensile strength materials,

with more stringent mechanical properties

and chemical composition, are used to keep

fabrication feasible. This means that the

welding consumables have to be adapted to

follow this trend.

Figure 3 shows a very heavy wall exam-

ple of a pipe connection of a live-steam pipe

of P91 base material in a Power Station.

As indicated the heat treatments includ-

ing preheat and interpass temperature have

to be under strict control to successfully

complete these types of welded joints. The

temperature ranges for the preheat and in-

terpass temperatures given in Table 4 are

to be respected throughout completion of

the joint. For this application, SMAW is

very suitable due to its fexibility and low

investments regarding equipment. In or-

der to increase effciency, higher weldmet-

al deposition per unit of time, develop-

ment is ongoing for FCAW consumables

for CrMo steels. As listed in Table 3, a

number is already available but the range

will be extended upon the demand of the

industry.

Technical Details of the Reactor:

Base

material:

2,25%Cr-1%Mo

thickness: 124, 132 and 153 mm

total weight: about 500 t

Service

conditions:

120 bar pressure and 437C

Welding

consumables:

SAW: Union S1CrMo2/UV 420TTR

SMAW: Phoenix SH Chromo 2 KS

Fig. 4: Heavy wall Reactor in 2.25%Cr-1%Mo

by GODREJ, INDIA

Fig. 3: Weld preparation and fnal weld in a pipe connection

of a live-steam pipe of P91, welded with SMAW

using Thermanit Chromo 9 V

BIULETYN INSTYTUTU SPAWALNICTWA No. 2/2013 19

The SAW consumables range covers all

the CrMo steels available today. GTAW is

mainly used for root welding or automat-

ed welding in demanding industries. The

GMAW range is available but not popular in

the Power Generation industry.

Another practical example is that of a Re-

actor build in 2.25%Cr-1%Mo steel. Figure 4

shows one of a number of these types of heavy

wall pressure vessels produced by Godrej in

India. They have built up excellent and prac-

tical experience to be able to build such units.

When dealing with heavy wall thicknesses,

modern CrMo creep resistant steels and very

stringent specifcations, it is absolutely nec-

essary to build up suffcient experience to

be able to satisfy the demanding engineering

companies as well as the Oil and Power com-

panies, who are the ultimate client.

Parameter control and suggestions for

Best Practice

CrMo(V) weld metal typically shows a

bainitic/martensitic micro structure that re-

spond very sensitively to any kind of heat

put in by means of welding and heat treat-

ment. Furthermore, the high strength in the

as welded condition requires accurate han-

dling in terms of Hydrogen and ISR in order

to avoid cracking due to Hydrogen and/or the

restrained condition of welds in heavy wall

nozzles for example.

To elaborate on some of the infuences,

typical observations in welds made in Cr-

Mo(V) creep resistant steels are illustrated in

the next paragraph.

Figure 5 shows ferrite precipitations in

P11 due to excessive PWHT temperature.

The micrograph in fgure 6 shows Hydrogen

damage due to a improperly applied soaking

treatment, leaving too much residual Hydro-

gen in the weldmetal. Figure 7 shows the ef-

fect of bead-thickness in SMA welds, a shift

of the impact properties to higher tempera-

tures, due to a much courser grain-structure.

Applicable manufacturing parameters,

which include the welding parameters as well

as the quality of the welding equipment and

the skill-level of the welders, become more

important with an increasing initial strength.

The operating window will become small-

er. Therefore suitable control mechanisms

and procedures have to be set up to ensure

the proper application of the required param-

eters. In particular the control of the follow-

ing items shall not be neglected for achiev-

ing successful welds:

Selection of the suitable SAW wire & fux

combination

Proper rebaking of fuxes and electrodes

Verifcation of preheating & interpass

temperatures

Setting of the electrical welding parameters

Weld build-up and beadsequence

Verifcation of the heat treatment temper-

ature.

Almost all issues encountered in CrMo

welds could be related to the non-observance

Fig. 5. Ferrite precipitations in P11 SA welds

Fig. 6. Crack surface due to Hydrogen in P22V SA welds

No. 2/2013 20 BIULETYN INSTYTUTU SPAWALNICTWA

Table 5: Overview of typical applications of CrMo steels in the Power Generation & Petrochemical Industry

CrMo type

BASE MATERIAL INDUSTRIAL APPLICATIONS Service

max. T

in C

ASTM &

ASME

EN POWER GENERATION PETROCHEMICAL

0.5Mo T/P1 8MoB5-4

Pressure vessels; Rp0.2 >

290 MPa, Rm > 500 MPa

Pressure vessels < 460

1.25Cr-

-0.5Mo

T/P11 10CrMo5-5 Steam headers

Heavy Wall Pressure

Vessels, Coke Drums,

< 535

1.00Cr-

-0.5Mo

T/P12 13CoMo4-5

Water walls;

parts of evaporater

Hydrofner Reactors, Catalytic

Reformer Reactors

< 545

1.25Cr-

-1MoV

- 15CrMoV5-10

Main steam pipe; reheater

steam pipe; Rp0.2 > 440

MPa, Rm 590-780 MPa

Heat exchangers < 545

- T/P36

15NiCuNb5

(WB 36)

Feed water pipe High pressure steam drums < 545

- - 20MnMoNi5-5 Reactor vessels (nuclear) -

2.25Cr-1Mo T/P22 10CrMo9-10

Parts of superheaters;

Rp0.2 > 310 MPa,

Rm 515-690 MPa

Reactors, coke drums,

furnaces, piping

< 535

2.25Cr-

-1MoV

T/P22V -

Rp0.2 > 415 MPa,

Rm 585-760 MPa -->

Hydrocrackers, Heavy Wall

Pressure Vessels

for Hydrogen Service

< 482

2.25Cr-Mo-

VW

T/P23

7CrMo-

WVMoNb9-6

Parts of superheater;

membrane walls

- < 550

2.25Cr-

-1MoV

T/P24

7CrMo-

VTiB10-10

Parts of superheater;

membrane walls

- < 550

5Cr-0.5Mo T/P502 12CrMo19-5 -

Pressure vessels in high tempe-

rature sulfur corrosion, resistan-

ce reactor furnaces and reactors

< 550

9Cr-1Mo T/P9 X12CrMo9-1 -

Reactors, High Temperature

Sulphur corrosion resistance,

furnaces and piping

< 585

9Cr-1Mo

mod.

T/P91

X10CrMo-

VNb9-1

Steam headers,

superheaters for ultra

super critical boilers;

Rp0.2 > 450 MPa,

Rm 630-790 MPa

High pressure steam headers

& piping

< 585

9Cr-0.5Mo-

WV

T/P911

X11CrMo-

WVNb9-1-1

Steam headers,

superheaters

- < 625

9Cr-0.5Mo-

WV

T/P92

X10CrWMo

Nb9-2

Steam headers,

superheaters for Ultra

Super Critical boilers

- < 625

12Cr-

-0.25Mo

+1.4W

1.3Co0.2V

-

X12CrCo-

WVNb11-2-2

(VM12-SHC)

t<10mm

Superheater tubes with

thickness < 10mm

- < 650

12Cr-1Mo-

NiV

-

X20

CrMoV11-1

Steam headers,

superheaters;

Rp0.2 > 500 MPa,

Rm 700-850 MPa

Tubing in H2S environments < 585

High Pressure &

High Temperature

High Pressure, High

Temperature & Corrosion

BIULETYN INSTYTUTU SPAWALNICTWA No. 2/2013 21

of the above mentioned items. Consequent-

ly suitable control mechanisms have to be

developed to ensure proper welds. Quality

assurance becomes a major factor and must

be included in the CrMo welding fabrication.

QA has to be considered as an essential vari-

able, as illustrated with Figure 8.

In conclusion we can state that CrMo

creep resistant steels are widely and success-

fully applied in the Power Generation and

Petrochemical Industries. The development

towards higher service temperatures ask for

new materials, both for base material as for

welding consumables.

To illustrate typical examples of where

the various CrMo materials are applied,

an overview of typical applications of CrMo

steels in the Power Generation and the Petro-

chemical Industry is given in Table 5.

With this paper we intended to provide

an overview of the available materials, the

standards, the consequences and the implica-

tions with regard to welding, heat treatments

and fabrication. When the correct proce-

dures are developed up front and adhered

to throughout the production, projects can be

and have been successfully completed.

References

1. Cole D., Bhadeshia H.K.D.H.: Design

of Creep-Resistant Steel Welds. Re-

search work. University of Cambridge,

Department of Materials Science and

Metallurgy, 1998

2. Bhadeshia H.K.D.H: Design of Creep-Re-

sistant Steels. Proceedings of Ultra-Steel

2000. National Research Institute for

Metals, Tsukuba, Japan 2000, pp. 89-108

3. Bruscato R.: Temper Embrittlement and

Creep Embrittlement of 2.25%Cr - 1%Mo

shielded metal arc weld deposits. Weld-

ing Journal 49 (4), 1973, pp. 148-156

4. Watanabe J. et. al.: Temper Embrittle-

ment of 2.25%Cr - 1%Mo Pressure Vessel

Steel. ASME 29

th

Petroleum Mechan-

ical Engineering Conference, Dallas,

USA, 1974

5. Gross V., Heuser H., Jochum C.:

Schweisstechnische Herausforderung bei

der Verarbeitung von CrMo(V)-Sthlen

fr Hydrocracker. Publication of Bh-

ler Thyssen Schweisstechnik, Germany,

2007

6. Handel Geert van den: Chroom-Molybde-

en staalsoorten. Lastechniek, Nederlands

Instituut voor Lastechniek (NIL), No. 5,

May 2008, pp.10-14

7. Gross V.: Improved toughness in

2.25%Cr - 1%Mo(V) weldmetals for join-

ing heavy walled reactors. Publication

of Bhler Thyssen Schweisstechnik,

Germany, 2006.

8. Fuchs R., Gross V., Heuser H., Jochum

C.: Properties of matching fller metals

for the advanced martensitic steels P911,

P92 and VM12. Proceedings of 5

th

Inter-

national EPRI RRAC Conference, Ala-

bama, USA, June 26-28, 2002

Fig. 7. Infuence of weld build-up on impact toughness Fig. 8: QA to be included to verify required parameters

No. 2/2013 22 BIULETYN INSTYTUTU SPAWALNICTWA

9. Heuser,H, Jochum C.: Neue Schweiss-

zusatzwerkstoffe fr neue Kraftwerks-

sthle. Publication of Bhler Thyssen

Schweisstechnik, Germany, 2004

10. Gross V, Heuser H., Jochum C.: Neuartige

Schweisszustze fr bainitische und mar-

tensitische. Publication of Bhler Thys-

sen Schweisstechnik, Germany, 2005

11. Valaurec, Mannesmann: Seamless boiler

tubes and pipes. Publication of Valaurec

& Mannesmann Tubes, V&M 507-7e

12. Hilkes J., Gross V.: Soldadura de los ace-

ros CrMo para aplicaciones en la Ge-

neracin de Energa y Petroqumica-

- Pasado, Presente & Futuro. CESOL

Conf. Proc. 1

er

Congreso Internacional de

Soldadura y Technologas de Unin (17

as

Journadas Tchnicas), Madrid, Spain,

7-9 October 2008., pp119-124.

13. Hilkes J., Gross V.: Het lassen van CrMo

stalen voor de Energieopwekking en de

Petrochemische Industrie - Verleden,

Heden en Toekomst. Dutsch & Belgium

Welding Institute, NIL/BIL Lassymposi-

um, Eindhoven, The Netherlands, 26/26

November 2008

Vous aimerez peut-être aussi

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD'EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinPas encore d'évaluation

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringgogotigPas encore d'évaluation

- Welding of Ferritic Creep-Resistant SteelsDocument3 pagesWelding of Ferritic Creep-Resistant Steelssn200709Pas encore d'évaluation

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 pagesLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraPas encore d'évaluation

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pages02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- T 91 WeldingDocument12 pagesT 91 WeldingMohammad KhaliquzzamaPas encore d'évaluation

- Metrode P92TP Welding ConsumablesDocument23 pagesMetrode P92TP Welding Consumablespipedown456Pas encore d'évaluation

- Review of Type IV Cracking of Weldments in 9Document64 pagesReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajPas encore d'évaluation

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Pas encore d'évaluation

- Temper Embrittlement - J and X FactorDocument2 pagesTemper Embrittlement - J and X Factorgovimano100% (2)

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Document7 pagesComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- Effect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base MetalDocument8 pagesEffect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base Metalshrikant tambePas encore d'évaluation

- Thermal CuttingDocument32 pagesThermal CuttingoviemePas encore d'évaluation

- MSM Marketing SDN BHD: MIG Welding Electrodes !Document3 pagesMSM Marketing SDN BHD: MIG Welding Electrodes !namasralPas encore d'évaluation

- Reformer Component Management After An Overheating Incident That Resulted in Tube FailuresDocument12 pagesReformer Component Management After An Overheating Incident That Resulted in Tube FailuresGrootPas encore d'évaluation

- Corrosion of Carbon SteelDocument3 pagesCorrosion of Carbon Steelvandanak_mechPas encore d'évaluation

- Fabrication and Processing of Grade 91 MaterialDocument376 pagesFabrication and Processing of Grade 91 MaterialVinoth Rajendra100% (2)

- Arcelormittal Pressure VesselDocument12 pagesArcelormittal Pressure VesselAnonymous UoHUagPas encore d'évaluation

- Metrode Welding Consumables For P92 and T23 Creep Resisting SteelsDocument17 pagesMetrode Welding Consumables For P92 and T23 Creep Resisting SteelsClaudia MmsPas encore d'évaluation

- Ferrite Limitation For SS316LDocument12 pagesFerrite Limitation For SS316LAntonio PerezPas encore d'évaluation

- Zero Defect in P91-Report-2005Document20 pagesZero Defect in P91-Report-2005sbmmla100% (1)

- PED 2014-68-EU Guidelines EN PDFDocument218 pagesPED 2014-68-EU Guidelines EN PDFMali MedoPas encore d'évaluation

- Dissimilar Welds in Refinery Services - B JackDocument18 pagesDissimilar Welds in Refinery Services - B JackSayiram GovindasamyPas encore d'évaluation

- Controlling Hydrogen-Induced Cracking: Entering The Weld PoolDocument3 pagesControlling Hydrogen-Induced Cracking: Entering The Weld PoolHoangPas encore d'évaluation

- Api 5l Test PressrureDocument2 pagesApi 5l Test PressrureSıddık SarıcalarPas encore d'évaluation

- Phase Transformation in Metals: Dr. Aneela WakeelDocument29 pagesPhase Transformation in Metals: Dr. Aneela WakeelmazharPas encore d'évaluation

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniPas encore d'évaluation

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulPas encore d'évaluation

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesSyed Furqan Rehmani0% (2)

- 1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Document10 pages1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Filipe RenanPas encore d'évaluation

- Definition of Buttering From ASME Section IXDocument2 pagesDefinition of Buttering From ASME Section IXsanket100% (3)

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDocument5 pages625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhitePas encore d'évaluation

- Ferrite Measurement in Austenitic and Duplex Stainless SteelDocument87 pagesFerrite Measurement in Austenitic and Duplex Stainless Steelafnene1Pas encore d'évaluation

- SAW Flux StorageDocument2 pagesSAW Flux StorageTrung Tinh HoPas encore d'évaluation

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinPas encore d'évaluation

- En 12451 1999Document24 pagesEn 12451 1999victoraghiPas encore d'évaluation

- NSSW Welding Handbook Web PDFDocument334 pagesNSSW Welding Handbook Web PDFTran Chi Binh DDC100% (1)

- QW 442 A Number PDFDocument1 pageQW 442 A Number PDFMadidj_2014Pas encore d'évaluation

- Welding Studies On WB36 For Feed Water PipingDocument17 pagesWelding Studies On WB36 For Feed Water PipingAnonymous gr5Pr9AVPas encore d'évaluation

- p91 PWHTDocument4 pagesp91 PWHTDipenchauhan100% (2)

- Procedure For: J164 (Rev 11/02)Document21 pagesProcedure For: J164 (Rev 11/02)tomcanPas encore d'évaluation

- Life Assessment of High Temperature HeadersDocument31 pagesLife Assessment of High Temperature HeadersAnonymous UoHUag100% (1)

- SST (GMAW) Welding Process PDFDocument4 pagesSST (GMAW) Welding Process PDFmudrijasm100% (1)

- Special Alloys and Overmatched Welding Products SolveDocument14 pagesSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryPas encore d'évaluation

- ArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Document2 pagesArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Vinoth Kumar PothuvudaiPas encore d'évaluation

- DegassingDocument11 pagesDegassingMKOZERDEMPas encore d'évaluation

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyPas encore d'évaluation

- Standard: I.S. CEN/TR 14549:2004Document7 pagesStandard: I.S. CEN/TR 14549:2004Cengiz KARAKOSEPas encore d'évaluation

- Case Studies in Engineering Failure Analysis: S.M.R. Ziaei, A.H. Kokabi, M. Nasr-EsfehaniDocument12 pagesCase Studies in Engineering Failure Analysis: S.M.R. Ziaei, A.H. Kokabi, M. Nasr-Esfehanipinkan25Pas encore d'évaluation

- Welding Catalogue PDFDocument292 pagesWelding Catalogue PDFvudinhnambrPas encore d'évaluation

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceD'EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferencePas encore d'évaluation

- Advances in Research on the Strength and Fracture of Materials: An OverviewD'EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinPas encore d'évaluation

- Fracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsD'EverandFracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsJ. C. RadonPas encore d'évaluation

- ABC To Welding - InterpassDocument1 pageABC To Welding - InterpassDries VandezandePas encore d'évaluation

- Gas Safety Replacement RecommendationsDocument2 pagesGas Safety Replacement RecommendationsDries VandezandePas encore d'évaluation

- ExtractPage40 41D PDFDocument21 pagesExtractPage40 41D PDFDries VandezandePas encore d'évaluation

- ExtractPage35 36c PDFDocument8 pagesExtractPage35 36c PDFDries VandezandePas encore d'évaluation

- ESAB ExtractPage32-33DDocument17 pagesESAB ExtractPage32-33DDries VandezandePas encore d'évaluation

- ESAB ExtractPage34-35DDocument16 pagesESAB ExtractPage34-35DDries VandezandePas encore d'évaluation

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13h100% (1)

- ESAB ExtractPage35-36DDocument16 pagesESAB ExtractPage35-36DDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument4 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandePas encore d'évaluation

- ESAB ExtractPage15-16cDocument9 pagesESAB ExtractPage15-16cDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument2 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandePas encore d'évaluation

- ESAB ExtractPage20-21cDocument8 pagesESAB ExtractPage20-21cDries VandezandePas encore d'évaluation

- ESAB ExtractPage39-40DDocument17 pagesESAB ExtractPage39-40DDries VandezandePas encore d'évaluation

- Regulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDocument4 pagesRegulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDries VandezandePas encore d'évaluation

- ESAB ExtractPage23-24cDocument8 pagesESAB ExtractPage23-24cDries VandezandePas encore d'évaluation

- ESAB ExtractPage17-18cDocument9 pagesESAB ExtractPage17-18cDries VandezandePas encore d'évaluation

- Regulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDocument1 pageRegulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDries VandezandePas encore d'évaluation

- ESAB ExtractPage29-30cDocument9 pagesESAB ExtractPage29-30cDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument2 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandePas encore d'évaluation

- Regulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDocument1 pageRegulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDries VandezandePas encore d'évaluation

- ExtractPage23 24B PDFDocument4 pagesExtractPage23 24B PDFDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series KitsDocument1 pageOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series KitsDries VandezandePas encore d'évaluation

- Regulators Edge Series RegulatorsDocument4 pagesRegulators Edge Series RegulatorsDries VandezandePas encore d'évaluation

- ExtractPage38 39c PDFDocument8 pagesExtractPage38 39c PDFDries VandezandePas encore d'évaluation

- ExtractPage35 36c PDFDocument8 pagesExtractPage35 36c PDFDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument2 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandePas encore d'évaluation

- ExtractPage33 34c PDFDocument8 pagesExtractPage33 34c PDFDries VandezandePas encore d'évaluation

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument4 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandePas encore d'évaluation

- Gas Safety Replacement RecommendationsDocument2 pagesGas Safety Replacement RecommendationsDries VandezandePas encore d'évaluation

- ExtractPage40 41c PDFDocument12 pagesExtractPage40 41c PDFDries VandezandePas encore d'évaluation

- Wire Arc Additive Manufacturing of ER 4043 Aluminum Alloy: Evaluation of Bead Profile, Microstructure, and Wear BehaviorDocument14 pagesWire Arc Additive Manufacturing of ER 4043 Aluminum Alloy: Evaluation of Bead Profile, Microstructure, and Wear Behaviorvasundhara singhPas encore d'évaluation

- Inverter Controlled Mig Welding-Machine YD-400GT3 Operating ManualDocument53 pagesInverter Controlled Mig Welding-Machine YD-400GT3 Operating ManualsunhuynhPas encore d'évaluation

- Advances in Welding Technologies For Process Development (2019)Document311 pagesAdvances in Welding Technologies For Process Development (2019)Vijay KumarPas encore d'évaluation

- Service Bulletin 8-12-109hDocument16 pagesService Bulletin 8-12-109hexergicPas encore d'évaluation

- d1.1 Fcaw Unlimited Test Plate ConfigurationDocument77 pagesd1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- Saep 321Document25 pagesSaep 321AbdullahPas encore d'évaluation

- GMW 14057-2012Document11 pagesGMW 14057-2012JUAN CARLOS MURILLO LARROTAPas encore d'évaluation

- BT Price List 1stmay2018Document24 pagesBT Price List 1stmay2018Jayant JadhavPas encore d'évaluation

- Auto MIG 250XL Operating ManualDocument36 pagesAuto MIG 250XL Operating Manualsachinkumar7091904964Pas encore d'évaluation

- Saieed Marichamy PresentationDocument26 pagesSaieed Marichamy PresentationIrfan MarichamyPas encore d'évaluation

- Mig ReportDocument14 pagesMig ReportDhana KumaranPas encore d'évaluation

- Hensley SpecBook Ch07Document92 pagesHensley SpecBook Ch07RENE ACEBEYPas encore d'évaluation

- Welder (GMAW - GTAW) - CTS2.0 - NSQF-3Document32 pagesWelder (GMAW - GTAW) - CTS2.0 - NSQF-3sanjeevPas encore d'évaluation

- Catalogue Soldamatic IE ENDocument11 pagesCatalogue Soldamatic IE ENCaleb ReisPas encore d'évaluation

- 1554.1-2011 Structural Steel Welding - Part 1. Welding of Steel StrucutresDocument8 pages1554.1-2011 Structural Steel Welding - Part 1. Welding of Steel Strucutreskaramullahrasheed50% (2)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- MIG Welding ProcessDocument12 pagesMIG Welding ProcessHimanshu RaoPas encore d'évaluation

- Health and Safety in WeldingDocument46 pagesHealth and Safety in Weldingegn2007Pas encore d'évaluation

- Servo Magazine 01 2005Document84 pagesServo Magazine 01 2005dangtq8467% (3)

- Welding ProcessDocument137 pagesWelding ProcessIlhamPas encore d'évaluation

- Welding ElectrodeDocument6 pagesWelding ElectrodeKapil PudasainiPas encore d'évaluation

- 49283991-DNV-OS-C401-2009-10 Fab and Testing Offshore Structure PDFDocument46 pages49283991-DNV-OS-C401-2009-10 Fab and Testing Offshore Structure PDFtriyuliantoPas encore d'évaluation

- Flux Core Arc WeldingDocument8 pagesFlux Core Arc Weldingamirhazwan100% (1)

- API 577 Key Points - Chapter 5Document4 pagesAPI 577 Key Points - Chapter 5muhammadazharPas encore d'évaluation

- Flux Cored ARC Welding (FCAW)Document26 pagesFlux Cored ARC Welding (FCAW)Ad Man GeTigPas encore d'évaluation

- Ed529207 PDFDocument214 pagesEd529207 PDFchandranPas encore d'évaluation

- Welding Qualifications GDSS.505-1: Subj CTDocument25 pagesWelding Qualifications GDSS.505-1: Subj CTOPAZOSCPas encore d'évaluation

- Water StopsDocument12 pagesWater Stopstss13723Pas encore d'évaluation

- Hastelloy B 3 RTW Filler Metal: Product DescriptionDocument2 pagesHastelloy B 3 RTW Filler Metal: Product DescriptionedrPas encore d'évaluation

- Comparison Between Smaw and Gmaw-Stt Plus Fcaw-G Welding of Api 5L X80 Tubes For Pipeline FabricationDocument8 pagesComparison Between Smaw and Gmaw-Stt Plus Fcaw-G Welding of Api 5L X80 Tubes For Pipeline FabricationJaimeCasanova Junior100% (1)