Académique Documents

Professionnel Documents

Culture Documents

Stiffened Plate With Circular Opening

Transféré par

Marco MorrisCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stiffened Plate With Circular Opening

Transféré par

Marco MorrisDroits d'auteur :

Formats disponibles

PLEASE SCROLL DOWN FOR ARTICLE

This article was downloaded by: [ABM Utvikling STM / SSH packages]

On: 21 July 2009

Access details: Access Details: [subscription number 792960683]

Publisher Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

Ships and Offshore Structures

Publication details, including instructions for authors and subscription information:

http://www.informaworld.com/smpp/title~content=t778188387

Interaction curves for stiffened panel with circular opening under axial and

lateral loads

M. Suneel Kumar

a

; P. Alagusundaramoorthy

b

; R. Sundaravadivelu

c

a

Department of Civil Engineering, College of Engineering, Sri Venkateswara University, Tirupati, India

b

Department of Civil Engineering, IITMadras, Chennai, India

c

Department of Ocean Engineering, IITMadras,

Chennai, India

First Published:June2009

To cite this Article Kumar, M. Suneel, Alagusundaramoorthy, P. and Sundaravadivelu, R.(2009)'Interaction curves for stiffened panel

with circular opening under axial and lateral loads',Ships and Offshore Structures,4:2,133 143

To link to this Article: DOI: 10.1080/17445300902746420

URL: http://dx.doi.org/10.1080/17445300902746420

Full terms and conditions of use: http://www.informaworld.com/terms-and-conditions-of-access.pdf

This article may be used for research, teaching and private study purposes. Any substantial or

systematic reproduction, re-distribution, re-selling, loan or sub-licensing, systematic supply or

distribution in any form to anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representation that the contents

will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses

should be independently verified with primary sources. The publisher shall not be liable for any loss,

actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly

or indirectly in connection with or arising out of the use of this material.

Ships and Offshore Structures

Vol. 4, No. 2, 2009, 133143

Interaction curves for stiffened panel with circular opening under axial and lateral loads

M. Suneel Kumar

a

, P. Alagusundaramoorthy

b

and R. Sundaravadivelu

c

a

Department of Civil Engineering, College of Engineering, Sri Venkateswara University, Tirupati 517 502, India;

b

Department of Civil

Engineering, IITMadras, Chennai 600 036, India;

c

Department of Ocean Engineering, IITMadras, Chennai 600 036, India

(Received 22 October 2008; nal version received 14 January 2009)

Stiffened panels in ships and offshore oil platforms are provided with circular openings for repair, access and maintenance.

This paper presents the numerical study carried out on the ultimate strength of stiffened panel with central circular opening

subjected to axial load, lateral load and a combination of axial and lateral loads. Ultimate strength of the panel was evaluated

considering both geometric and material non-linearities using FEA software ANSYS. Plates of varied widths and open

section unequal angle stiffeners covering plate and column slenderness ratios in the practical range of 1.04.5 and 0.321.00,

respectively, keeping the opening ratio equal to 1.0 are the parameters considered in this study. On the basis of the study,

interaction curves were developed for normalised axial load and normalised lateral load. The developed interaction curves

for stiffened panels with angle stiffeners and circular opening were found to be non-linear for lower plate slenderness ratio

up to 2.0 and for the range of column slenderness ratio covered in the present study. Interaction equations were also proposed

based on non-linear regression analysis for determining the ultimate strength of stiffened panel under axial, lateral and also

under combined axial and lateral loads.

Keywords: axial load; circular opening; interaction curves; interaction equations; lateral load; stiffened panel; ultimate

strength

Notation

b Width of Plate between stiffeners

d Diameter of opening

E Youngs modulus of elasticity

L Length of plate

P

sq

Squash load

P

u

, P

u0

Axial ultimate load (Q = 0)

P

uQ

Axial ultimate load (for Q = 1/3 q

ut

, Q = 2/3

q

ut

, and Q = q

ut

)

Q Lateral load

Q

n

Normalised lateral load

q

ult

Lateral ultimate load

r Radius of gyration

t Thickness of Plate

w Lateral deection at the centre of plate

Plate slenderness ratio

Poissons ratio

Column slenderness ratio

u

Ultimate Stress of Plate

F

,

y

Yield Stress of plate and stiffener

avg

Average axial stress in the plate

p

Maximum allowable usage factor (usually

taken as 1.0)

Corresponding author. Email: suneel78@rediffmail.com

1. Introduction

Longitudinal stiffened panels in ship decks and offshore

structures are subjected to axial compression due to sag-

ging and hogging moments. Cargo loading and buoyancy

exert lateral pressure over these panels. The failure in pan-

els subjected to axial compression occurs due to instability.

The presence of constant lateral load further reduces the ax-

ial load carrying capacity. Circular openings are provided

in the decks for access, inspection and maintenance. These

openings are provided in the centre of the panel for the

minimal reduction in elasto-plastic buckling stress (Khaled

El-Sawy et al. 2004). The presence of these openings in

plates causes a redistribution of membrane stresses accom-

panied by a signicant change in the buckling and ultimate

strength characteristics. The increase in the size of opening

(d/b) increases the buckling strength up to a certain ex-

tent beyond which it decreases. But increases in the size of

the opening decrease ultimate strength signicantly and are

critical between stiffeners with extending full width in be-

tween them (Gendy and Saleeb 1995; Alagusundaramoor-

thy et al. 1999).

The analysis of a typical stiffened deck in a ship can

be performed at (1) grillage level, (2) stiffened panel

ISSN: 1744-5302 print / 1754-212X online

Copyright C

2009 Taylor & Francis

DOI: 10.1080/17445300902746420

http://www.informaworld.com

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

134 M. Suneel Kumar et al.

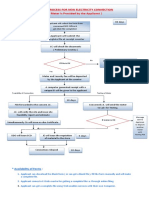

Figure 1. Ship deck (a) with circular opening and (b) typical loads acting.

level between two adjacent transverses and (3) bare plate

element level. Openings in the deck plates are provided for

maintenance, access and piping. Figure 1(a) shows the

location and provision of openings in ship decks. Constant

cargo load acts on the plate surrounding the opening

(Figure 1b) and the same situation is considered in the

present study. The size of opening under any combination

of loads is critical if it is extended over the full width

between stiffeners (Gendy and Saleeb 1995; Alagusun-

daramoorthy et al. 1999). Because of the symmetry in the

stiffened panel, only one panel consisting of a portion of

the plate of width b

p

with a stiffener centred on the plate

strip is considered in the present study (shaded panel in

Figure 1a) as it was found to give a better understanding of

the complex behaviour of a stiffened panel with T stiffeners

under combined load and can be used reasonably for good

prediction of ultimate strength using nite element analysis

(FEA) as stated by Sheikh et al. (2003). The same concept

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Ships and Offshore Structures 135

Figure 2. Modes of failure of stiffened plate without opening

under compression and bending (Sheikh et al., 2003).

of a unit panel is adopted in this paper with the central

circular opening extending for the full width between

the stiffeners for determining the ultimate strength under

axial, lateral and combined axial and lateral loads using

non-linear elasto-plastic FEA.

The normal range of lateral loads acting on ship deck

plates due to cargo varies in the range of 3040 kN/m

2

. As

per clause 3.3.5 of Det Norske Veritas (DnV) Classica-

tion Notes 30.1 (1995), the design pressure (p

d

) for plates

subjected to constant load is given as

p

d

p

4

F

t

b

2

. (1)

The present study considers constant lateral load acting on

deck plates and not variable hydrostatic loading, which acts

on ship-side plates and curved shells. The present study

is only to assess the reduction in ultimate load carrying

capacity and to determine the interactive behaviour due to

openings. On the basis of the reduction in ultimate load,

insert plates can be provided to compensate for the loss of

area which is not in the scope of the present study. The

high stress concentration around the hole observed at the

early stages of loading practically disappears at loads in

excess of the critical load due to the development of large

buckles (Ritchie and Rhodes 1975). Hence, at ultimate load,

stress concentration is not of a concern as redistribution

of the stresses for the surrounding area takes place and

the present study is done up to ultimate load. The present

study focuses on the interactive behaviour between axial

and lateral loads. The interaction equations (IEs) without

much computational effort for the purpose of designers

have also been developed.

Figure 3. Unit panel.

2. Literature review

Azizian and Roberts (1983) have presented a FEA for the

elastic buckling and geometrically non-linear elasto-plastic

collapse of perforated plates subjected to inclined loading.

Triangular elements with three bending and two membrane

degrees of freedom at each corner node are used to model

the plates. Sabir and Chow (1983) employed the method

of FEA to determine the elastic critical buckling loads

of at square panels containing circular and square holes.

In-plane loads such as uniaxial, biaxial or shear distributed

uniformly along the straight edges of the panels were con-

sidered. Narayanan and der Avanessian (1984) dealt with

elastic shear buckling of simply supported and clamped

plates with circular and rectangular openings. Roberts and

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

136 M. Suneel Kumar et al.

Table 1. Details of parametric study.

Plate Slenderness ratio

Sl. no. b (mm) t (mm) b/t Section

Column

Slenderness

ratio () Specimen P

u

(kN) q (kN/m

2

)

1 170 6 28 1 ISA 5030 6 0.92 B1C1 374.86 0.00

267.95 61.88

167.60 123.77

0.00 185.65

ISA 7045 6 0.60 B1C2 427.43 0.00

322.90 114.04

216.95 228.08

0.00 342.12

ISA 10065 6 0.40 B1C3 502.50 0.00

384.45 189.54

247.80 379.08

0.00 568.62

ISA 12595 6 0.31 B1C4 584.98 0.00

457.95 254.82

308.90 509.65

0.00 764.47

2 340 6 57 2 ISA 5030 6 1.00 B2C1 628.39 0.00

402.80 31.30

204.80 62.61

0.00 93.91

ISA 7045 6 0.64 B2C2 681.34 0.00

522.00 57.22

334.80 114.45

0.00 171.67

ISA 10065 6 0.42 B2C3 755.66 0.00

590.50 95.36

369.00 190.72

0.00 286.08

ISA 12595 6 0.32 B2C4 838.00 0.00

672.70 127.24

438.70 254.49

0.00 381.73

3 510 6 85 3 ISA 5030 6 1.03 B3C1 564.67 0.00

397.50 22.43

170.80 44.86

0.00 67.29

ISA 7045 6 0.66 B3C2 621.47 0.00

492.70 38.39

304.90 76.79

0.00 115.18

ISA 10065 6 0.43 B3C3 692.76 0.00

540.00 67.35

271.80 134.70

0.00 202.05

ISA 12595 6 0.32 B3C4 791.89 0.00

584.70 93.01

300.40 186.01

0.00 279.02

4 765 6 128 4.5 ISA 5030 6 1.05 B4C1 618.51 0.00

362.30 15.72

129.70 31.43

0.00 47.15

ISA 7045 6 0.67 B4C2 695.40 0.00

480.00 28.03

222.40 56.07

0.00 84.10

ISA 10065 6 0.43 B4C3 747.85 0.00

519.70 48.54

248.30 97.09

0.00 145.63

ISA 12595 6 0.32 B4C4 846.08 0.00

593.50 65.68

306.30 131.36

0.00 197.04

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Ships and Offshore Structures 137

Figure 4. Load/deection curves for stiffened plate under axial

load.

Azizian (1984) generated interaction curves for the ulti-

mate strength of square plates with central square and cir-

cular holes for the range of d/b of 0 to 0.5 subjected to

uniaxial compression, biaxial compression and pure shear.

For uniaxial compression, the buckling load was almost

independent of the size of the hole for d/b ranging from

0 to 0.5. The ultimate load of all the plates studied de-

creased with increase in size of the hole. The reduction in

the ultimate load was most signicant for lowplate slender-

ness values. Narayanan and Chow (1984) developed design

charts based on ultimate capacity of uniaxially compressed

perforated plates with square and circular openings for the

range of d/b of 0 to 0.5. Narayanan and Chan (1985) pre-

sented design charts based on ultimate strength of plates

containing circular holes for the range of d/b of 0 to 0.5

under linearly varying edge displacements. A Marginal de-

crease in ultimate load was observed for many practical

plates (b/t < 50) with unloaded edges free to wave in or

kept straight. Also, ultimate load is not much affected for

plates with holes located away fromthe centre. Shanmugam

et al. (1986) presented an approximate method for the anal-

ysis of stiffened ange plates containing circular or square

openings loaded axially. The failure is considered to oc-

cur in the plate rst. The loss in the stiffness of plates was

taken into account by means of effective width. Reports

of the experiments carried out on small-scale steel models

of perforated stiffened plates were presented. A compar-

ison of ultimate loads with the proposed method was in

good comparison with experimental results. Brown et al.

(1987) determined the buckling coefcients for plates with

rectangular opening.

Shanmugam and Arockiasamy (1996) conducted ulti-

mate strength tests on stiffened plates simply supported on

Figure 5. Finite element mesh.

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

138 M. Suneel Kumar et al.

all four edges subjected to combined action of axial and lat-

eral loads. The test specimens were analysed by using the

elasto-plastic FE package ABAQUS to determine the be-

haviour and ultimate load capacity of stiffened panels. The

comparison of FE results with those obtained experimen-

tally established the accuracy of the FE modelling. Motok

(1997) carried out stress concentration studies on the con-

tour of a plate opening of an arbitrary corner radius of cur-

vature. Shanmugam(1997) reviewed the effects of openings

for the range of d/b of 0 to 0.5 in plate elements subjected to

uniaxial compression, biaxial compression and pure shear

in stiffened plates, shear webs and cold formed steel sec-

tions. Grondin et al. (1998) investigated experimentally and

numerically the effect of unloaded edges boundary restraint,

combination of axial and lateral loads, and imposed plate

damage on the buckling capacity of stiffened steel plates.

Shanmugam et al. (1999) presented the design formula for

axially compressed perforated plates with circular openings

under axial compression for simply supported and clamped

boundary conditions. The ultimate load carrying capacity of

perforated plates decreased signicantly with the increase

in hole size and slenderness ratio. The strength of perforated

plates with simply supported edges was lower as compared

to that of plates with clamped edges. The plates with cir-

cular holes generally had higher ultimate loads compared

to the square perforated plates. Paik et al. (2001) presented

ultimate strength formulations for ship plating with plate

slenderness ratio in the range of 1.0 to 5.0 under combined

biaxial compression/tension, edge shear and lateral load.

The study was focused at bare plate level and the validity

of the proposed interaction formulae was veried. Sheikh

et al. (2003) studied the behaviour of steel plates stiffened

with T stiffeners subjected to axial load with and without

bending moments by considering unit panel. The various

modes of failure (Figure 2) observed were categorised as (1)

plate-induced overall buckling, (2) stiffener-induced over-

all buckling, (3) plate buckling and (4) stiffener tripping.

It is observed that both the behaviour and strength are pre-

dominantly affected by plate and column slenderness ratio.

A comparison of ultimate strength with DnV (1995) and

American Petroleum Institute (API) codes is made. It was

found that the predicted ultimate strengths using DnV and

API for stiffener tripping mode were unreliable. Suneel

Kumar et al. (2007) studied the ultimate strength of ship

deck plating with a centrally located increasing rectangular

opening along the width of the plate. Adesign equation was

proposed for a square plate with rectangular opening under

axial compression.

A comprehensive procedure for the computation of

buckling strength of stiffened panels under axial and lat-

eral loads exists in API and DnV codes. The interactive

buckling phenomenon is not mentioned in either of these

two codes. Design guidelines for a stiffened panel with cir-

cular opening extending full width between stiffeners under

axial and lateral loads are not available in the DnV and API

Figure 6. Axial load/axial deformation curves for (a) case

(i), (b) case (ii), and (c) case (iii).

codes. A critical review of literature indicates that studies

are conducted on the effect of circular opening in the range

of d/b of 0 to 0.9 on the buckling and ultimate strength of

unstiffened plates only. Till now researchers have focused

on the effect of circular openings on the ultimate strength at

the bare element level only. This methodology is only valid

if the stiffener is stocky and the failure is by plate buckling.

In case of low stiffener rigidity, the interaction between

plate and stiffener has to be considered. Hence, it is desir-

able to analyse at panel level to account for the rigidity of

the stiffener in the analysis. It may be observed that there

is not much information available on the ultimate strength

of a stiffened panel with a circular opening extending full

width between stiffeners under axial and lateral loads in the

literature. An attempt is made in this paper to determine the

interaction behaviour between axial and lateral loads for a

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Ships and Offshore Structures 139

Figure 7. Deformation pattern plate buckling overall (Vector mode).

stiffened panel with a circular opening subjected to axial

and lateral loads.

3. Numerical study

A unit panel consisting of a portion of the plate of width

b with a stiffener centred on the plate strip provided with

circular opening in the centre of the panel is as shown in

Figure 3. As it is symmetrical with respect to the unit panel,

only a half portion of the circular opening is considered in

the analysis (shaded portion of panel shown in Figure 1).

The length of panel and thickness of the plate are taken

as 1500 mm and 6 mm, respectively. The widths of plate

considered in the present study are 170 mm, 340 mm, 510

mm and 765 mm. Unequal Indian Standard Angles (ISA)

such as ISA 5030 6, ISA 7045 6, ISA 10065 6 and ISA

12595 6 are used as stiffeners. Typical ISA 5030 6 denotes

an unequal Indian standard angle of ange width 30 mm,

with overall web depth of 50 mm and uniform thickness of

section 6 mm. The practical range of plate slenderness ratio

( =

b

t

y

E

) and column slenderness ratio =

L

r

y

E

of

the stiffener associated with plating used in ship construc-

tion of 1.04.5 and 0.150.90, respectively (Smith 1975)

are adopted in the study. The selected plate and column

slenderness ratios for the present study considered are 1,

2, 3, and 4.5, and 0.9, 0.6, 0.4 and 0.3, respectively. The

corresponding plate aspect ratios (A/B) adopted are found

to be 8.82, 4.41, 2.94 and 1.96 covering the entire range of

slender plates used in frigates and tankers (Guedes Soares

1988). The depth to width of circular opening (d/b) is kept

constant at 1.0 throughout the study. A combination of ev-

ery plate slenderness ratio with all four column slenderness

ratios is accounted. The study comprises a total of sixteen

specimens with four plate and four column slenderness

ratios. Each specimen is subjected to four load cases as

detailed in the subsequent section. Thus the entire study

results in FEA of sixty-four load cases. The details of the

parametric study are given in Table 1. The yield strength of

plate (

y

) is assumed as 250 N/mm

2

with Youngs modulus

of elasticity (E) as 2 10

5

N/mm

2

and Poissons ratio ()

of 0.3.

4. Non-linear FEA

A general purpose FE software ANSYS is used for mod-

elling, analysis and post processing of stiffened plate with

circular opening under axial and lateral loads. Discrete

stiffened plate approach is adopted for modelling of the

stiffened panels. This approach enables the prediction of

overall buckling and local buckling of the stiffened plates,

and interaction between the plate and stiffener and lo-

cal yielding. A four noded quadrilateral isoparametric lin-

ear shell element (SHELL181) available in the ANSYS

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

140 M. Suneel Kumar et al.

Figure 8. Effect of plate and column slenderness ratios on (a)

normalised axial load (Q = 0) and (b) normalised lateral load

(P = 0).

element library is used for modelling the plate and stiff-

ener. The deformation shapes of the element are linear in

both in-plane directions. This element is well suitable for

analysing the linear, large rotation, and/large strain non-

linear applications. The element has six degrees of free-

dom at each node viz. three translations in U

X

, U

Y

and

U

Z

, and three rotations

X

,

Y

and

Z

. Square shaped el-

ements are used for meshing regular area while triangular

mesh is adopted around the circular opening (Khaled El-

Sawy and Aly Nazmy 2001). Both geometric and material

non-linearities are considered in the analysis. Geometric

non-linearity involves large displacement static analysis

with stress stiffening. The model invokes large displace-

ment using an updated Lagrangian formulation. Bilinear

isotropic rate independent hardening with von Mises yield

criteria is used in material non-linearity. Simply supported

boundary conditions along the loading and reactive edge

are considered. The rotation about the longitudinal edge

is arrested at all the nodes along the unloaded edges. The

displacement along the same nodes is allowed to freely

wave in. This condition is to generate the actual situation

of continuity between individual stiffened panels. A Con-

straint equation is applied along the loading edge on axial

deformation degree of freedom to attain uniform compres-

sion of the loading edge. Incremental load is applied up to

and beyond collapse. NewtonRaphson iterative procedure

in the initial stage of loading and then arc length method

is used to trace the post peak axial load/axial deformation

behaviour.

A stiffened plate of size 500 mm 500 mm 5 mm

simply supported on all four sides, subjected to axial load

is considered for validation (Ueda and Yao 1983). The size

of at stiffener is 50 mm5 mm. The yield stress, Youngs

modulus and Poissons ratio of plate and stiffener are 250

N/mm

2

, 2 10

5

N/mm

2

and 0.3, respectively. Based on

the convergence study, it is found that the mesh size of 25

mm 25 mm is found to be satisfactory for ultimate load

and is used for the analysis of all specimens in this study.

The load/deection curve shown in Figure 4 obtained using

FEA is in good comparison with analytical and numerical

studies conducted by Ueda and Yao (1983). For triangu-

lar mesh around circular opening, the size of the element

adopted is least of b/50 or d/40 (Khaled El-Sawy and

Aly Nazmy 2001). The FE model of typical unit panel with

circular opening is shown in Figure 5. Each specimen is

subjected to and analysed for four different load cases as;

(1) axial load (till failure, P

u0

) with no lateral load (Q =

0), (2) no axial load (P = 0) but lateral load (till fail-

ure, q

u

), (3) axial load (till failure, P

uQ

) corresponding to

constant lateral load (Q = 1/3 q

u

), and (4) axial load (till

failure, P

uQ

) corresponding to constant lateral load (Q =

2/3 q

u

). Ultimate load of the specimens is determined from

the peak of axial load/axial deformation plots (Figure 6).

The axial ultimate load, P

u0

(the specimen is under ax-

ial load and lateral load Q = 0) and axial ultimate load,

P

uQ

(the specimen is under the combined action of axial

load and lateral load Q = 1/3 q

ut

, Q = 2/3 q

ut

, and Q =

q

ut

, respectively) are determined for varied plate and col-

umn slenderness ratios. The values of ultimate strength for

all the specimens with varied plate and column slender-

ness ratios are given in Table 1. A typical lateral deforma-

tion pattern for overall plate buckling mode is shown in

Figure 7.

5. Results and discussion

The axial and lateral ultimate load obtained fromthe present

study (Table 1) are as (1) normalised axial ultimate load

as P

u0

/P

sq

(for Q = 0), P

sq

being the squash load; (2) nor-

malised axial ultimate load under combined load as P

uQ

/P

u0

and (3) normalised lateral load (Q

n

) as

QE

(

y

)

2

(Guedes Soares

and Gordo 1996) in which Q = 1/3q

ut

, Q = 2/3q

ut

, and

Q = q

ut

. Squash load (P

sq

) is dened as the summation of

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Ships and Offshore Structures 141

Figure 9. Interaction curves for stiffened panel with circular opening under axial and lateral load.

product of cross-sectional area of plate with yield stress of

plate and cross-sectional area of stiffener with yield stress

of stiffener (Alagusundaramoorthy et al. 1999). Using the

geometrical parameters ( and ), interaction curves are

developed for varied column slenderness ratios as (1) nor-

malised axial load (P

u0

/P

sq

) vs. plate slenderness ratio (),

(2) normalised lateral load (Q

n

) vs. plate slenderness ratio

() and (3) normalised axial load (P

uQ

/P

u0

) vs. normalised

lateral load (Q

n

). The effect of plate and column slender-

ness ratios on the normalised ultimate strength for all the

specimens subjected to axial load (with Q = 0) and lateral

load (with P = 0) are shown in Figure 8a and 8b, respec-

tively. It is observed from Figure 8a that the entire range of

(0.321.00), the normalised axial ultimate load decreases

linearly with increase in for the range 1.04.5. From Fig-

ure 8b it can be ascertained that normalised lateral load

carrying capacity decreases drastically for in the range of

1.02.0 beyond which the decrease is gradual and remains

linear for the entire range of (0.321.00). The interaction

curves for panels with circular opening for varied plate and

column slenderness ratios are shown in Figure 9. The in-

teraction behaviour is non-linear for plate slenderness ratio

only up to 2.0 beyond which it is linear for the entire range

of column slenderness ratio (0.31.0) for all the specimens

under axial and lateral load.

Shanmugam et al. (1999) used best t regression analy-

sis in developing the design formula to predict the ultimate

load of square plates with centrally placed square or circu-

lar openings subjected to uniaxial and biaxial compression.

Based on the present study, design equations are developed

using regression analysis to determine the ultimate load

carrying capacity of stiffened panels with circular opening

(d/b =1.0). The below mentioned interaction in Equations

(2) and (3) correspond to stiffened panels under axial load

(with Q = 0) and lateral load (P = 0), respectively.

P

u0

P

sq

= 0.092 +0.027 +0.657

0.025

0.202

(2)

Q

n

= 0.031 0.091 +0.643

0.828

1.149

. (3)

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

142 M. Suneel Kumar et al.

Figure 10. Comparison of normalised ultimate load for panels

under (a) axial load (Q = 0), (b) axial and lateral load, and (c)

lateral load (P = 0).

From the interaction curves (Figure 9), it may be observed

that relationship between plate slenderness ratio (), col-

umn slenderness ratio (), and normalised lateral load (Q

n

)

on the normalised axial load (P

uQ

/P

u0

) varies non-linearly.

The interaction of these parameters is important and there

is a need for simple formulae for the design. Hence non-

linear regression analysis is adopted to predict the rela-

tionship among these variables. A non-linear regression

can estimate models with an arbitrary relationship between

the dependent variable (P

uQ

/P

u0

) and a set of independent

variables (, and Q

n

). The proposed IE for the design

of stiffened panels with circular opening under axial and

lateral loads is given below:

P

u0

P

sq

= 0.001

2.831

+1.067

0.061

+0.595Q

n

0.041

1.606Q

n

0.095Q

n

0.765Q

n

. (4)

It is found that for the above mentioned proposed inter-

action in Equations (2), (3) and (4), the R-squared value is

found to be 0.992, 0. 999 and 0.985, respectively and hence

ts well in the data obtained using non-linear FEA. Thus the

developed formula is simple, reliable and can be used for

the estimation of ultimate strength by practical engineers.

The mean (x), standard deviation () and coefcient of vari-

ation (cov) are found to be 1.001, 0.032 and 0.032 for the

results obtained in Equation (2), 1.002, 0.040 and 0.040 for

Equation (3), and 0.970, 0.073 and 0.076 for Equation (4),

respectively. It can be observed that the ultimate strength of

panels obtained using the proposed Equations (2) and (3)

are slightly higher while Equation (4) underestimates and

hence conservative for the purpose of design. A plot (Fig-

ure 10) is drawn for the normalised ultimate load based on

FEA vs. normalised ultimate load obtained using proposed

IE for the specimens considered in the present study. The

ultimate load can be predicted using the proposed Equa-

tions (2), (3) and (4) with an error of 4 %, +5% to 10%

and 2 % correspondingly for the practical range of plate

and column slenderness ratios used in ship construction of

1.04.5 and 0.150.90, respectively.

6. Summary and conclusions

The interaction behaviour of a unit stiffened panel with

circular central opening on the ultimate strength under ax-

ial, lateral and combined load was studied. The effect of

plate and column slenderness ratios on ultimate strength

was also evaluated. Equations for the developed interac-

tion curves for stiffened panels with circular opening under

axial, lateral and combined load were developed based on

non-linear regression analysis. The error analysis for the

developed equations indicates to yield satisfactory results.

The proposed equations were found to predict accurately

the ultimate strength of panels under axial load (Q = 0)

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Ships and Offshore Structures 143

and lateral load (P = 0), but slightly underestimating un-

der combined axial and lateral loads.

References

Alagusundaramoorthy P, Sundaravadivelu R, Ganapathy C. 1999.

Experimental study on collapse load of stiffened panels with

cutouts. J Const Steel Res. 52(2):235251.

American Petroleum Institute. 1987. Bulletin on design of at

plate structures, API Bulletin 2V. 1st ed. Washington, DC.

Brown CJ, Yettram AL, Burnett M. 1987. Stability of plates

with rectangular holes. ASCE J. Struct. Eng. 113(5):1111

1116.

Det Norske Veritas. Classication notes no. 30.1, buckling

strength analysis. Hovik, Norway: Det Norske Veritas, 1995.

Gendy AS, Saleeb AF. 1995. Consistent mixed model for stability

of stiffened panels with cut-outs. Comp Struct. 54(1):119

130.

Guedes Soares C. 1988. A code requirement for the compressive

strength of plate elements. Mar Struc. 1(1):7180.

Guedes Soares C, Gordo JM. 1996. Compressive strength of rect-

angular plates under biaxial load and lateral pressure. Thin-

Walled Struc. 24(3):231259.

Grondin GY, Chen Q, Elwi AE, Cheng JJR. 1998. Stiffened steel

plates under compression and bending. J Const Steel Res.

45(2):125148.

Khaled M El-Sawy, Aly S Nazmy. 2001. Effect of aspect ratio on

the elastic buckling of uniaxially loaded plates with eccentric

holes. Thin-Walled Struc. 39(12):983998.

Khaled M El-Sawy, Aly S Nazmy, Mohammad Ikbal Martini.

2004. Elasto-plastic buckling of perforated plates under uni-

axial compression. Thin-Walled Struc. 42(8):10831101.

Motok MD. 1997. Stress concentration on the contour of a plate

opening of an arbitrary corner radius of curvature. Mar Struct.

10(1):112.

Narayanan R, Chow FY. 1984. Ultimate capacity of uniaxially

compressed perforated plates. Thin-Walled Struc. 2(3):241

264.

Narayanan R, der Avanessian, NGV (1984) Elastic buckling of

perforated plates under shear. Thin-Walled Struc. 2(1):5173.

Narayanan R, Chan SL. 1985. Ultimate capacity of plates contain-

ing holes under linearly varying edge displacements. Comp

Struct. 21(4):841849.

Paik JK, Thayamballi AK, Kim BJ. 2001. Advanced ultimate

strength formulations for ship plating under combined biaxial

compression/tension, edge shear, and lateral pressure loads.

Mar Tech. 38(1):925.

Ritchie D, Rhodes J. 1975. Buckling and post-buckling behaviour

of plates with holes. Aeronaut Q. 26:281296

Azizian ZG, Roberts TM. 1983. Instability and strength of perfo-

rated plates. Proc Inst Civil Engrs. 75(2):761.

Roberts TM, Azizian ZG. 1984. Strength of perforated plates

subjected to in-plane loading. Thin-Walled Struc. 2(2):153

164.

Sabir AB, Chow FY. 1983. Elastic buckling of at panels contain-

ing circular and square holes. In Morris LJ (Ed.), Instability

and plastic collapse of steel structures. Granda, London. p.

311321.

Shanmugam NE, Paramasivam P, and Lee Seng-Lip. 1986.

Stiffened anges containing openings. ASCE J Struct Eng.

112(10):22342246.

Shanmugam NE, Arockiasamy M. 1996. Local buckling of stiff-

ened plates in offshore structures. J Const Steel Res. 38(1):41

59.

Shanmugam NE. 1997. Openings in thin-walled steel structures.

Thin-Walled Struc. 28(34):355372.

Shanmugam NE, Thevendran V, Tan YH. 1999. Design formula

for axially compressed perforated plates. Thin-Walled Struc.

34(1):120.

Sheikh IA, Elwi AE, Grondin GY. 2003. Stiffened steel plates un-

der compression and bending. J Const Steel Res. 59(7):911

930.

Smith CS. 1975. Compressive strength of welded steel ship gril-

lages. Trans RINA. 117:325359.

Suneel Kumar M, Alagusundaramoorthy P, Sundaravadivelu R.

2007. Ultimate strength of square plate with rectangular open-

ing under axial compression. J. Nav Archit Mar Eng. 4(1):15

26.

Ueda Y, Yao T. 1983. Ultimate strength of compressed stiffened

plates and minimum stiffness ratio of their stiffeners. Eng

Struc. 5(2): 97106.

D

o

w

n

l

o

a

d

e

d

B

y

:

[

A

B

M

U

t

v

i

k

l

i

n

g

S

T

M

/

S

S

H

p

a

c

k

a

g

e

s

]

A

t

:

1

0

:

0

2

2

1

J

u

l

y

2

0

0

9

Vous aimerez peut-être aussi

- Institute Meritlist For The Year 2010 and SemnoDocument50 pagesInstitute Meritlist For The Year 2010 and SemnoMarco MorrisPas encore d'évaluation

- Advanced SACS Training - 1st & 3rd To 5th April 2013, MumbaiDocument2 pagesAdvanced SACS Training - 1st & 3rd To 5th April 2013, MumbaiMarco MorrisPas encore d'évaluation

- The RMS CCRA Training Program CertifiedDocument12 pagesThe RMS CCRA Training Program CertifiedMarco MorrisPas encore d'évaluation

- The RMS CCRA Training Program CertifiedDocument12 pagesThe RMS CCRA Training Program CertifiedMarco MorrisPas encore d'évaluation

- Additional Information To Accompany The Marriage Notice Application Form MioDocument1 pageAdditional Information To Accompany The Marriage Notice Application Form MioMarco MorrisPas encore d'évaluation

- AmmunitionDocument6 pagesAmmunitionMarco MorrisPas encore d'évaluation

- New Elect ConnDocument1 pageNew Elect ConnMarco MorrisPas encore d'évaluation

- Sesam Software Versions Download with CrackDocument2 pagesSesam Software Versions Download with CrackMarco MorrisPas encore d'évaluation

- Part 2 Navy e July10Document226 pagesPart 2 Navy e July10Marco MorrisPas encore d'évaluation

- DotschDocument2 pagesDotschMarco MorrisPas encore d'évaluation

- An Automatized In-Place Analysis of A Heavy Lift Jack-Up Vessel Under Survival ConditionsDocument15 pagesAn Automatized In-Place Analysis of A Heavy Lift Jack-Up Vessel Under Survival ConditionsMarco MorrisPas encore d'évaluation

- Rules For Classification and Construction V Analysis TechniquesDocument60 pagesRules For Classification and Construction V Analysis TechniquesMarco MorrisPas encore d'évaluation

- RR 019Document68 pagesRR 019jpsingh823632Pas encore d'évaluation

- GRPDocument138 pagesGRPMarco MorrisPas encore d'évaluation

- GRPDocument138 pagesGRPMarco MorrisPas encore d'évaluation

- Crosby ShacklesDocument12 pagesCrosby ShacklesK Lennox ChungPas encore d'évaluation

- Fatigue Cracking (Offshore Engineering)Document14 pagesFatigue Cracking (Offshore Engineering)Marco MorrisPas encore d'évaluation

- Blast Loads Analyis For OffshoreDocument14 pagesBlast Loads Analyis For OffshoreWaseem HakeemPas encore d'évaluation

- Sample2 APVDocument21 pagesSample2 APVngoduynam123Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Independent Study Guidance - Further Maths.86642862Document2 pagesIndependent Study Guidance - Further Maths.86642862Emmaculate OngumPas encore d'évaluation

- DI CFS FSI Outlook-BankingDocument70 pagesDI CFS FSI Outlook-Bankinghuizhi guoPas encore d'évaluation

- Simple File System (SFS) FormatDocument3 pagesSimple File System (SFS) FormatJoe PlainPas encore d'évaluation

- Aleksander Vayntraub, MD Joins New York Cancer & Blood SpecialistsDocument4 pagesAleksander Vayntraub, MD Joins New York Cancer & Blood SpecialistsPR.comPas encore d'évaluation

- Quiz Week 8 Akm 2Document6 pagesQuiz Week 8 Akm 2Tiara Eva TresnaPas encore d'évaluation

- Environment Education Year PlanDocument4 pagesEnvironment Education Year PlanJai GuptaPas encore d'évaluation

- Screenshot 2022-03-14 at 11.11.35 AMDocument1 pageScreenshot 2022-03-14 at 11.11.35 AMnicolergatdulaPas encore d'évaluation

- Financial Reporting, Statements and Analysis-IiDocument3 pagesFinancial Reporting, Statements and Analysis-IiAshi KhatriPas encore d'évaluation

- Schedule Synchronization From Fusion Applications To Oracle IDCSDocument2 pagesSchedule Synchronization From Fusion Applications To Oracle IDCSnitinjain2020Pas encore d'évaluation

- People vs. Romualdez G.R. NO. 166510 - April 29, 2004Document2 pagesPeople vs. Romualdez G.R. NO. 166510 - April 29, 2004MC100% (2)

- Final Project ReportDocument24 pagesFinal Project ReportAbhishek Repswal100% (1)

- Philippine Supreme Court Rules on Bank Loans and Foreclosure CasesDocument158 pagesPhilippine Supreme Court Rules on Bank Loans and Foreclosure CasescrazybedanPas encore d'évaluation

- Sapphire: Roller ChainDocument16 pagesSapphire: Roller ChainARTHURS316Pas encore d'évaluation

- MIBM Placement Brochure 19-20Document32 pagesMIBM Placement Brochure 19-20पै. दिपक सरडेPas encore d'évaluation

- Chapter 3 - Implementing Spanning TreeDocument80 pagesChapter 3 - Implementing Spanning TreeFrancisco Antonio Bolaño CastilloPas encore d'évaluation

- Electrical Safety: NSCI Training ProgrammeDocument5 pagesElectrical Safety: NSCI Training ProgrammeGoutam PatriPas encore d'évaluation

- Term Paper On Leadership TheoriesDocument7 pagesTerm Paper On Leadership Theoriesaflsmyebk100% (1)

- Come Fly With MeDocument6 pagesCome Fly With MeKintyre On Record100% (2)

- Fault Tree Analysis FTA Methode Analisis PohonDocument44 pagesFault Tree Analysis FTA Methode Analisis PohonRahman SonowijoyoPas encore d'évaluation

- Science E-Modul SAL (Year 6) Choose The Correct Answer and Fill in The Yellow BoxDocument9 pagesScience E-Modul SAL (Year 6) Choose The Correct Answer and Fill in The Yellow Boxwongsc70Pas encore d'évaluation

- Access Rights by User Type For Sap® Business Bydesign™Document2 pagesAccess Rights by User Type For Sap® Business Bydesign™giscard_perez2559Pas encore d'évaluation

- Nitte Meenakshi Institute of Technology Nmit Thesis Latex TemplateDocument30 pagesNitte Meenakshi Institute of Technology Nmit Thesis Latex TemplateJAIRO ANDRES CAMACHO GUERREROPas encore d'évaluation

- 10 Constrcution Company-Bm2-Assingment-NocheDocument16 pages10 Constrcution Company-Bm2-Assingment-NocheJerick NochePas encore d'évaluation

- Design-of-2-MW-HYDRO POWER PLANT JETHRO GANELODocument8 pagesDesign-of-2-MW-HYDRO POWER PLANT JETHRO GANELOjethro ganeloPas encore d'évaluation

- Preparation and Evaluation of Microsphere of Antidiabetic Drug by Emulsion Solvent Evaporation MethodDocument21 pagesPreparation and Evaluation of Microsphere of Antidiabetic Drug by Emulsion Solvent Evaporation MethodSujit DasPas encore d'évaluation

- Electronic Lockstitch Button Holer: Service ManualDocument162 pagesElectronic Lockstitch Button Holer: Service ManualgeforceooziePas encore d'évaluation

- G K CatalogueDocument32 pagesG K Cataloguenanda_kavalaPas encore d'évaluation

- Lista Filtros BOBCATDocument18 pagesLista Filtros BOBCATmadscoutPas encore d'évaluation

- HL-30 Operational Manual 1Document132 pagesHL-30 Operational Manual 1MUHAMMAD SAADPas encore d'évaluation

- Fundamentals of Modern Electrical Substations - Part 2 - R2Document22 pagesFundamentals of Modern Electrical Substations - Part 2 - R2Harish De SilvaPas encore d'évaluation