Académique Documents

Professionnel Documents

Culture Documents

Current Meter Propeller Type

Transféré par

Sasank0 évaluation0% ont trouvé ce document utile (0 vote)

43 vues6 pagesCurrent Meter Propeller Type

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCurrent Meter Propeller Type

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

43 vues6 pagesCurrent Meter Propeller Type

Transféré par

SasankCurrent Meter Propeller Type

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

10.

009 CURRENT METER, PROPELLER-TYPE

Approval Date: 23 October 2007 Version: 2

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-1/6

Purpose

The current meter will be used for flowing water velocity and thus discharge measurements

in rivers and canals. It may be used in wading or suspended mode.

Conditions & Requirements

The current meter shall be of such a design that it operates reliably and accurately under

the prevailing flow and environmental conditions.

The current meter shall be easy to operate and maintain.

The current meter shall be supplied with the accessories as needed for effective

deployment.

All materials of the current meter shall be non-corrosive.

An operators manual, related to the type and model of the current meter, shall be part

of the delivery.

The current meter shall come with the calibration data, i.e. actual calibration velocity

versus actual revolutions per second as collected during the calibration process.

Calibration data shall uniquely identify the instrument body, the propeller, observer, rating

tank, way of suspension, methodology and similar information.

The current meter shall come with a rating table and a rating chart in m/s versus

revolutions per second, uniquely related to the propeller by propeller serial number. Each

impeller (propeller) of the current meter is calibrated individually and calibration chart for

individual impeller is supplied (multiple calibration)

The propeller calibration shall be independent of the current meter body, propellers shall be

interchangeable from one body to another body of the same model with change in

calibration.

The current meter shall have a provision to adjust its trimming.

The design shall be sediment resistant and have an oil-filled bearing chamber.

The bearings shall be field exchangeable.

The current meter shall come without a protection ring/yoke in front of the propeller; such a

yoke would make the current meter sensitive to its alignment into the flow, which should be

avoided.

The current meter shall be as slim as possible to avoid excessive drag.

The electrical connections shall be small, of a reliable and sturdy construction.

The current meter and accessories shall be supplied in a sturdy carrying case.

An appropriate tool-set shall be included in the delivery.

The current meter shall generally comply with IS 3910-1992

For operation, adequate fish weight shall be attached below the current meter or integrated

with current meter body and tail.

The fish weight shall have a streamlined form and shall be suspended from a bar of

adequate strength.

Horizontal and vertical tail fins at the rear end shall align the fish weight in the direction of

flow.

Except for the suspension bar, no elements shall protrude from the body.

The fish weight shall generally comply with IS 4073-1967 and ISO 3454-1983.

Specifications

The purchaser may execute his judicious discretion in the choice of configuration and

options.

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-2/6

1. Current meter

current meter range 0.025 to 5 m/s (starting to maximum operational velocity)

propeller 2 to 4 blades

propeller diameter 0.1 to 0.2 m

propeller length about 0.1 m

The current meter may be provided with one propeller or with a set of propellers that

differ in their pitch and/or in their diameter.

The propellers shall be made interchangeable.

The propellers shall be made of cast material, e.g. bronze, polycarbonate or similar

tough, high impact resistant and corrosion proof material.

The response shall be instantly and consistent to all changes in velocity.

The rate of change of the angular velocity of the propeller shall be synchronous with the

rate of change of the flow velocity.

Propellers of the same model shall be interchangeable without affecting calibration.

The propellers shall be uniquely identifiable by engraved serial number.

materials all materials of the current meter and combinations thereof shall

be corrosion proof

bearing low friction, field replaceable without affecting the calibration

rotation sensor reed switch closure, one closure per revolution

accuracy for velocities up to 0.3 m/s 1 % Full Scale

for velocities >0.3 m/s 0.5 % Full Scale

2. Suspension

Wading

wading rod total length 3 m, graduation in cm

electrical cable running from current meter to counter, 10 m

From a cable

suspension cable suspension cable with single integrated electrical wire for

rotation sensor and bottom detector

length 30 m

diameter 2.5 to 3.5 mm

electrical cable from winch to counter, 7 m

cable torque torque free suspension cable

The suspension cable should not exert any torque that may adversely affect the alignment of

the flow sensor into the direction of flow. In particular in case a heavy suspension weight is

used, there is a risk of cable induced torque.

suspension-rod for cable suspended measurements with light weight sinkers

The suspension rod shall have sufficient freedom of movement to allow it to accommodate to

inclination of the suspension cable under high current velocities.

inclination range -45 (forward) to 10 (backward) from vertical.

tail fin length >0.6 m beyond the attach point of the suspension

The tail fin shall be capable of aligning the current meter in the direction of flow and keep it

stable in that position throughout the full velocity range.

3. Fish weight

model USGS Columbus or similar

material cast iron or lead

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-3/6

finish smooth, painted surface

mass of fish weights 25, 50 and 100 kg, as required for depth and current velocity.

The fish weight may be integrated in the instrument or an addition below the instrument.

bottom detector the bottom detector shall be small and sturdy

bottom detection bottom detection will be signalled by permanently closing a reed

switch. That switch will override the rotation sensor switch. The

bottom detection signal will be sent on the same integrated wire

as the rotation signals.

suspension bar, fitting current meter and cable terminal

Option

propeller for velocities up to 10 m/s

if the instrument is used from a cable way then an integrated bottom detector is required

Accessories

standard instrument tools

spare bearings

carrying case for current meter with counter

carrying case for fish weight(s)

Consumables

bearing oil

10.009 CURRENT METER, PROPELLER-TYPE

As per HP-I

Approval Date: 30 November 2000 Version: 2

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-4/6

Purpose

The current meter will be used for flowing water velocity and thus discharge measurements

in rivers and canals. It may be used in wading or suspended mode.

Conditions & Requirements

The current meter shall be of such a design that it operates reliably and accurately under

the prevailing flow and environmental conditions.

The current meter shall be easy to operate and maintain.

The current meter shall be supplied with the accessories as needed for effective

deployment.

All materials of the current meter shall be non-corrosive.

An operators manual, related to the type and model of the current meter, shall be part

of the delivery.

The current meter shall come with the calibration data, i.e. actual calibration velocity

versus actual revolutions per second as collected during the calibration process.

Calibration data shall uniquely identify the instrument body, the propeller, observer, rating

tank, way of suspension, methodology and similar information.

The current meter shall come with a rating table and a rating chart in m/s versus

revolutions per second, uniquely related to the propeller by propeller serial number. Each

impeller (propeller) of the current meter is calibrated individually and calibration chart for

individual impeller is supplied (multiple calibration)

The propeller calibration shall be independent of the current meter body, propellers shall be

interchangeable from one body to another body of the same model with change in

calibration.

The current meter shall have a provision to adjust its trimming.

The design shall be sediment resistant and have an oil-filled bearing chamber.

The bearings shall be field exchangeable.

The current meter shall come without a protection ring/yoke in front of the propeller; such a

yoke would make the current meter sensitive to its alignment into the flow, which should be

avoided.

The current meter shall be as slim as possible to avoid excessive drag.

The electrical connections shall be small, of a reliable and sturdy construction.

The current meter and accessories shall be supplied in a sturdy carrying case.

An appropriate tool-set shall be included in the delivery.

The current meter shall generally comply with IS 3910-1992

For operation, adequate fish weight shall be attached below the current meter or integrated

with current meter body and tail.

The fish weight shall have a streamlined form and shall be suspended from a bar of

adequate strength.

Horizontal and vertical tail fins at the rear end shall align the fish weight in the direction of

flow.

Except for the suspension bar, no elements shall protrude from the body.

The fish weight shall generally comply with IS 4073-1967 and ISO 3454-1975.

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-5/6

Specifications

The purchaser may execute his judicious discretion in the choice of configuration and

options.

4. Current meter

current meter range 0.025 to 5 m/s (starting to maximum operational velocity)

propeller 2 to 4 blades

propeller diameter 0.1 to 0.2 m

propeller length about 0.1 m

The current meter may be provided with one propeller or with a set of propellers that

differ in their pitch and/or in their diameter.

The propellers shall be made interchangeable.

The propellers shall be made of cast material, e.g. bronze, polycarbonate or similar

tough, high impact resistant and corrosion proof material.

The response shall be instantly and consistent to all changes in velocity.

The rate of change of the angular velocity of the propeller shall be synchronous with the

rate of change of the flow velocity.

Propellers of the same model shall be interchangeable without affecting calibration.

The propellers shall be uniquely identifiable by engraved serial number.

materials all materials of the current meter and combinations thereof shall

be corrosion proof

bearing low friction, field replaceable without affecting the calibration

rotation sensor reed switch closure, one closure per revolution

accuracy for velocities up to 0.3 m/s 1 % Full Scale

for velocities >0.3 m/s 0.5 % Full Scale

5. Suspension

Wading

wading rod total length 3 m, graduation in cm

electrical cable running from current meter to counter, 10 m

From a cable

suspension cable suspension cable with single integrated electrical wire for

rotation sensor and bottom detector

length 30 m

diameter 2.5 to 3.5 mm

electrical cable from winch to counter, 7 m

cable torque torque free suspension cable

The suspension cable should not exert any torque that may adversely affect the alignment of

the flow sensor into the direction of flow. In particular in case a heavy suspension weight is

used, there is a risk of cable induced torque.

suspension-rod for cable suspended measurements with light weight sinkers

The suspension rod shall have sufficient freedom of movement to allow it to accommodate to

inclination of the suspension cable under high current velocities.

inclination range -45 (forward) to 10 (backward) from vertical.

tail fin length >0.6 m beyond the attach point of the suspension

The tail fin shall be capable of aligning the current meter in the direction of flow and keep it

stable in that position throughout the full velocity range.

Equipment Specification: CURRENT METER, PROPELLER-TYPE Version 2 10.009-6/6

6. Fish weight

model USGS Columbus or similar

material cast iron or lead

finish smooth, painted surface

mass of fish weights 25, 50 and 100 kg, as required for depth and current velocity.

The fish weight may be integrated in the instrument or an addition below the instrument.

bottom detector the bottom detector shall be small and sturdy

bottom detection bottom detection will be signalled by permanently closing a reed

switch. That switch will override the rotation sensor switch. The

bottom detection signal will be sent on the same integrated wire

as the rotation signals.

suspension bar, fitting current meter and cable terminal

Option

propeller for velocities up to 10 m/s

if the instrument is used from a cable way then an integrated bottom detector is required

Accessories

standard instrument tools

spare bearings

carrying case for current meter with counter

carrying case for fish weight(s)

Consumables

bearing oil

Vous aimerez peut-être aussi

- Dismantling Joint DN350 To DN2400 PN16 VJ DSDocument1 pageDismantling Joint DN350 To DN2400 PN16 VJ DSVignesh NadimuthuPas encore d'évaluation

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloPas encore d'évaluation

- Advanced Composite Bearings for Hydro Power PlantsDocument12 pagesAdvanced Composite Bearings for Hydro Power PlantsSasankPas encore d'évaluation

- C-2208-CARB Toroidal Roller BearingsDocument1 pageC-2208-CARB Toroidal Roller BearingsSasankPas encore d'évaluation

- Thrust Ball Bearings, Double DirectionDocument1 pageThrust Ball Bearings, Double DirectionSasankPas encore d'évaluation

- Energies 10 00103Document19 pagesEnergies 10 00103SasankPas encore d'évaluation

- Dismantling Joints GuideDocument2 pagesDismantling Joints GuideSasankPas encore d'évaluation

- Spherical Roller Bearings-22210 EDocument2 pagesSpherical Roller Bearings-22210 EManoj TyagiPas encore d'évaluation

- C-2208-CARB Toroidal Roller Bearings PDFDocument1 pageC-2208-CARB Toroidal Roller Bearings PDFSasankPas encore d'évaluation

- Effects of Load Variation On A Kaplan Turbine Runner: ArticleDocument13 pagesEffects of Load Variation On A Kaplan Turbine Runner: ArticleSasankPas encore d'évaluation

- National Pension System (Enps) - Subscriber Registration FormDocument8 pagesNational Pension System (Enps) - Subscriber Registration FormSasankPas encore d'évaluation

- 10 11648 J Ijepe 20150404 14 PDFDocument11 pages10 11648 J Ijepe 20150404 14 PDFbacuoc.nguyen356Pas encore d'évaluation

- Quantifiable Crack Detection in Newly Installed Pelton TurbineDocument4 pagesQuantifiable Crack Detection in Newly Installed Pelton TurbineSasankPas encore d'évaluation

- RT765E 2 Product Guide ImperialDocument1 pageRT765E 2 Product Guide ImperialAnonymous 6XyAh3DPas encore d'évaluation

- Thrust Ball Bearings, Double DirectionDocument1 pageThrust Ball Bearings, Double DirectionSasankPas encore d'évaluation

- RT765E 2 Product Guide ImperialDocument1 pageRT765E 2 Product Guide ImperialAnonymous 6XyAh3DPas encore d'évaluation

- FSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreDocument4 pagesFSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreSasankPas encore d'évaluation

- Calculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedDocument28 pagesCalculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedSasankPas encore d'évaluation

- Pre-Proposal Conference Cum Webinar - FlyeDocument3 pagesPre-Proposal Conference Cum Webinar - FlyeSasank0% (1)

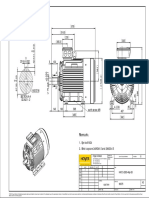

- Remark : HMC3-280S-46p-B3Document1 pageRemark : HMC3-280S-46p-B3SasankPas encore d'évaluation

- QSMicrohydroSEP2005 PDFDocument57 pagesQSMicrohydroSEP2005 PDFSasank0% (1)

- CARB Toroidal Roller Bearings PDFDocument1 pageCARB Toroidal Roller Bearings PDFSasankPas encore d'évaluation

- Piping Elbows - Thrust Block ForcesDocument5 pagesPiping Elbows - Thrust Block ForcesSasankPas encore d'évaluation

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloPas encore d'évaluation

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloPas encore d'évaluation

- DCP NcovDocument5 pagesDCP NcovNicoleta MPas encore d'évaluation

- Bureau of Indian Standards-List For StudentsDocument23 pagesBureau of Indian Standards-List For StudentsSasankPas encore d'évaluation

- Small Hydropower Standards GuideDocument62 pagesSmall Hydropower Standards GuideSasank100% (1)

- Bolted JointsDocument3 pagesBolted JointsGiuseppe GiuseppePas encore d'évaluation

- Article - Bolted Joint DesignDocument15 pagesArticle - Bolted Joint DesignPiyush YardiPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Tirfor OMDocument12 pagesTirfor OMDang Minh HuongPas encore d'évaluation

- Machine Design Exam QuestionsDocument5 pagesMachine Design Exam QuestionsSYBRELLE CRUZPas encore d'évaluation

- SKF Serv 417199 (4th Ed)Document688 pagesSKF Serv 417199 (4th Ed)Jaime castroPas encore d'évaluation

- Add Info B-62163e 04Document10 pagesAdd Info B-62163e 04Kapil SoodPas encore d'évaluation

- Self-Retracting Devices: Labels & MarkingsDocument1 pageSelf-Retracting Devices: Labels & Markingssossoh marcPas encore d'évaluation

- Manual PEX 3000Document41 pagesManual PEX 3000LUIS RPas encore d'évaluation

- Bs 302-Part1-1987 (Steel Wire Ropes-Specification For GeneralDocument14 pagesBs 302-Part1-1987 (Steel Wire Ropes-Specification For Generalcelsocarvalh100% (1)

- Crosby Fist Grip Clips - Warnings and Application InstructionsDocument1 pageCrosby Fist Grip Clips - Warnings and Application Instructionsalejandrorhino2 rhinoPas encore d'évaluation

- West Coast Wire Rope IWRC PDFDocument157 pagesWest Coast Wire Rope IWRC PDFjesusgameboyPas encore d'évaluation

- Wire Rope Slings: General InformationDocument16 pagesWire Rope Slings: General Informationegy purePas encore d'évaluation

- 10 Important Guide For SlingsDocument26 pages10 Important Guide For SlingsAhmedPas encore d'évaluation

- Bird Control Product GuideDocument279 pagesBird Control Product GuideMoisa DragosPas encore d'évaluation

- DIEPA AnswersDocument52 pagesDIEPA AnswersMohamed HarbPas encore d'évaluation

- ANSI - NEMA WC 74 ICEA S 93 639 2017 Contents and ScopeDocument11 pagesANSI - NEMA WC 74 ICEA S 93 639 2017 Contents and ScopeNestor PerezPas encore d'évaluation

- BigDutchman Spare Parts June 2019-1-1Document58 pagesBigDutchman Spare Parts June 2019-1-1Daniel IonutPas encore d'évaluation

- Millwright: Rigging Procedures Part ADocument18 pagesMillwright: Rigging Procedures Part ACourseTree LearningPas encore d'évaluation

- Installation Manual: Washer Extractor W575N, W585N, W5105N, W5130N, W5180N, W5250N, W5330NDocument48 pagesInstallation Manual: Washer Extractor W575N, W585N, W5105N, W5130N, W5180N, W5250N, W5330NmayPas encore d'évaluation

- Crosby Wire Rope Clips - Warnings and Safe Installation InstructionsDocument2 pagesCrosby Wire Rope Clips - Warnings and Safe Installation InstructionsToto Toro100% (1)

- Prime Line Industrial Controls CatalogDocument32 pagesPrime Line Industrial Controls CatalogMaria Clara Ybarra CesaroPas encore d'évaluation

- Take Home Exam No. 1Document2 pagesTake Home Exam No. 1Justin Carlo DomingoPas encore d'évaluation

- Idaho Wrecker Sales 2014 CatalogDocument49 pagesIdaho Wrecker Sales 2014 CatalogFred DanPas encore d'évaluation

- 12.0 Fishing For WirelineDocument21 pages12.0 Fishing For WirelineSaritaPas encore d'évaluation

- Lifting Plan HVACDocument10 pagesLifting Plan HVACFMU KSAPas encore d'évaluation

- Opgw 24 AflDocument5 pagesOpgw 24 AflWilliam CallePas encore d'évaluation

- Axially Loaded Members: Changes in Lengths and EffectsDocument59 pagesAxially Loaded Members: Changes in Lengths and EffectsAshok Dargar67% (3)

- Thinktop v50 and v70 Instruction ManualDocument29 pagesThinktop v50 and v70 Instruction ManualpretorianbrPas encore d'évaluation

- Scaffolds PDFDocument30 pagesScaffolds PDFWahyu SundayPas encore d'évaluation

- Install DAB Digital Radio Receiver in 2012 SLK55 (less than 40 charsDocument6 pagesInstall DAB Digital Radio Receiver in 2012 SLK55 (less than 40 charsQuoc LuonglocPas encore d'évaluation

- Operations and Maintenance Manual SCT 35 10-17SDocument22 pagesOperations and Maintenance Manual SCT 35 10-17SIgor Grytsenko100% (1)

- Rig Up Ops Manual - D00625669 - 1Document56 pagesRig Up Ops Manual - D00625669 - 1Prakhar Sarkar100% (3)