Académique Documents

Professionnel Documents

Culture Documents

Materials Selection Assignment. Live

Transféré par

richward5Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Materials Selection Assignment. Live

Transféré par

richward5Droits d'auteur :

Formats disponibles

Material Selection for the Subsea Industry

Assignment

1. AISI 4130 Ferrous, Low Alloy Steel, Cast.

A216 WCC Ferrous, Low Carbon Steel, Cast.

AISI 316 - Ferrous, Stainless Steel, Austenitic, Wrought.

AISI 220 Ferrous, Stainless Steel, Duplex, Wrought. Secon! "eneration Duplex#

I!C"!#$ 62 $on Ferrous, $ic%el Chro&iu& Alloy, Wrought.

'. AISI 4130 (Fe 97-98.2%, Cr 0.8-1.1%, Mn 0.4-0.9%, C 0.28-0.33%, Mo 0.15-0.25%, Si 0.1-

0.35%, P 0-0.04%, S 0-0.04%)

A216 WCC (Fe 96.4%, Mn 0-1.2%, Cr 0-0.5%, Si 0-0.6%, Ni 0-0.5%, Cu 0-0.3%, C 0-0.25%, Mo

0-0.2%, S 0-0.045%, V 0-0.03%)

AISI 316 (Fe, 61.3 72%, Cr 16 18.5%, Ni 10-14%, Mo 2.0-3.0%, Mn 0-2.0%, Si 0-1.0%, C 0-

0.08%, S 0-0.03%, P 0-0.04%)

AISI 2205 (Fe, 63.7 71.4%, Cr 21 23%, Ni 4.5-6.5%, Mo 3-3.5%, Mn 0-2%, Si 0-1.0%, N

0.08-0.2%, C 0-0.03%, S 0-0.02%, P 0-0.03%)

INCONEL 625 (Ni 58-64.9%, Cr 20-23%, Mo 8-10%, N 3.15-4.15%, !" 3.1-4.2%, Co 0.84-1%,

Fe 0-5%, #$ 0-0.4%, C 0-0.1%, Si 0-0.5%, Mn 0-0.5%, !i 0-0.4%, P 0-0.015%, S 0-0.015%)

('.

)he heat treat&ent o* &etals enables the crystal structure o* steels to be &anipulate! to gain speci*ic

&echanical properties. )he heat treat&ent o* steel begins with raising the te&perature o* the steel to

a speci*ic te&perature at a speci*ic rate to gain the !esire! grain structure %ee &r"'( 2.1#. )he

te&perature o* the steel is &aintaine! at the re+uire! te&perature *or a speci*ie! ti&e to allow

internal stresses to be relie,e! %ee &r"'( 2.2# an! *inally the steel is coole! at a speci*ie! rate to

gain the !esire! grain si-e an! structure that will exhibit the re+uire! &echanical properties o* the

steel.

A lot o* the ,ariables in the heat treat&ent process are !eter&ine! by the &etals carbon content (%ee

&r"'( 2.1) an! the !esire! crystal structure. For exa&ple, i* the purpose o* heat treat&ent is to

increase the &etals !uctility an! so*tness then a *errite grain structure woul! be !esirable, howe,er,

the bo!y centre! cubic .CC# structure o* *errite is only achie,able with &etals containing /./''wt

0 carbon. Co¶ti,ely, the *ace centre! cubic FCC# o* ausentite grains witnesse! in steels at

high te&peratures can acco&&o!ate up to '.11wt0 carbon an! can be coole! to *or& a peralite

grain structure.

)here are three !istinct cooling processes e,i!ent in C2S 2!upac%. Firstly, there is the annealing

process. )he annealing processes is a ðo! o* slowly cooling the heate! steel in a heate! *urnace

in or!er to so*ten a steel an! &a%e it &ore wor%able. &r"'( 3.2 shows how cooling a steel o,er a

long perio! o* ti&e at a high te&perature results in the pro!uction o* coarse pearlite. Allowing the

steel to cool o,er a longer perio! o* ti&e allows a &ore uni*or& cooling rate through the &aterial

creating a &ore uni*or& grain structure which can restore lost !uctility within the &aterial. At the

sa&e ti&e a slower cooling rate allows &ore ti&e *or internal stresses to wor% there way out o* the

&aterial as !islocations are re*or&e! in the re-*or&ing crystal structure which increases the

har!ness o* the &aterial. )he higher the heating te&perature the &ore uni*or& the steel will beco&e

!uring cooling.

"raph '.3 highlights the positi,e bene*its o* the annealing process to the toughness an! !uctility o*

the &etal.

An alternati,e cooling process to annealing is to use a process calle! nor&alising. $or&alising

cools the steel at a *aster rate than annealing as it allows the steel to cool in air at roo& te&perature.

)he increase! rate o* cooling pro!uces a stronger an! har!er &etal than the annealing process as

seen in &r"'( 2.4.

)he reason *or the increase in strength is that with &ore rapi! cooling there is less o* the so*ter

*errite grain structure *or&e! as the carbon &olecules ha,e less ti&e to !i**use *ro& the lattice

structure resulting in the *or&ation o* high carbon content pearlite an! ce&entite *or&ing.

$or&alising pro!uces a &uch *iner grain pattern o* pearlite an! ce&entite as there is a ,ery

localise! buil! up o* iron carbi!es ce&entite# as the carbon !i**uses +uic%ly *ro& the FCC

structure present at austenitic te&peratures.

)he *inal cooling process a,ailable *or steels is to increase the cooling rate *urther by +uenching the

hot steel in a cool li+ui! in a process %nown as +uenching or har!ening. 4n this process the cooling

rate is so rapi! that the carbon cannot !i**use *ro& the FCC structure present in austenite an!

beco&es trappe!, pro!ucing a &artensitic steel. (uenching pro!uces the har!est, strongest an! &ost

brittle steels out o* the three cooling options as can be seen in &r"'( 2.4.

)he +uenching process o*ten pro!uces steels that are so har! an! brittle they are un-wor%able. )o

restore so&e !uctility to the steel, the &etal is heate! up post-+uenching to relie,e so&e o* the

internal stresses in a process calle! te&pering. )he process in,ol,es heating the brittle &artensitic

structure allowing the trappe! carbon to !i**use into the surroun!ing structure pro!ucing layers o*

ce&entite. Why low alloy steels per*or& the best56

%3&

A &aterial reco&&en!ation *or a short length Su%e" F$o) *ine using .S 2$ 1/'/7-' L888 as a

co¶ble &aterial.

1&'eneral (lo)line *esign S+ecifications

1.1 Subsea *lowlines transport the pro!uction *lui! *ro& the well hea!, a long the seabe! to the

base o* a riser that extracts the pro!uction *lui! to a processing *acility at sur*ace le,el. Flowlines

are typically entrenche! into the seabe! to a,oi! exposure to strong currents.

1.1.1 )he pro!uction *lui! enters the *lowline *ro& the well at high te&perature an! high

pressure. As the pro!uction *lui! tra,els a long the *low line heat !issipates into the surroun!ing

en,iron&ent creating a ther&al ,ariance along the pipe which can result in ther&al buc%ling. For

this reason *lowlines &ust be &a!e o* non-brittle &aterials that allow so&e elastic !e*or&ation. 4n

a!!ition, as the pro!uction *lui! cools there is an increase! chance o* a buil! up o* hy!rates on the

internal sur*ace o* the pipe. 9,erall, the ther&al per*or&ance o* the *lowline is a %ey consi!eration

when !esigning *lowlines.

i

1.1.' Flowlines are costly an! !i**icult to replace. Any !a&age !uring installation an! !uring its

operation &ust be %ept to a &ini&u&. )he &aterials resistance to crac% *or&ation an! crac%

propagation are both i&portant *actors when consi!ering &aterials. Choosing a &aterial with a high

toughness &ini&ises the *lowlines li%elihoo! to *racture an! *or that *racture to propagate the length

o* the *lowline.

1.1.3 )he irregularity o* the sea *loor o*ten re+uires *low line routes to na,igate nu&erous pea%s

an! troughs an! the *low line &ust be able to cope with the &echanical stresses an! a!!e! internal

corrosion proble&s this brings. )his re+uire&ent will test the yiel! strength an! corrosi,e resistance

o* the &aterial. A &aterial &ust ha,e a high yiel! strength an! an a!e+uate *atigue strength to

ensure its per*or&ance is &aintaine! throughout its !esign li*e

1.' :aterial 2n,iron&ent - Subsea *lowlines are typically !eploye! in low te&perature

en,iron&ents Sea be! te&perature ; 1<C# where they are expose! to strong currents an! high

hy!rostatic pressures. )he &aterial &ust ha,e goo! resistance to salt water corrosion externally an!

goo! resistance to the corrosion an! erosion experience! *ro& the pro!uction *lui!s insi!e the pipe.

)here is also a possibility that the &il!ly aci!ic pro!uction *lui! &ay contain hy!rogen sulphi!e

creating a sour gas en,iron&ent= this &ust be ta%en into account !uring &aterial selection.

1.3 Fiel! Application 4nstalling *lowlines in,ol,es lowering the pipe sections *ro& the sur*ace

to the seabe!. )he &echanical stresses en!ure! by lowering cables an! pipe sections !uring this

process can be &ini&i-e! i* the pipe weight is %ept to a &ini&u&. For this reason, the speci*ic

strength the strength to weight ratio# &ust be consi!ere! when reco&&en!ing a &aterial.

1.3.1 Flowlines are installe! at great !epths an! the installation can be ,ery !i**icult. 4n or!er to

assist in both the *abrication an! installation o* the *lowlines it is ,ital that the &aterial selecte! is

wel!able.

1.3.' Finally, the o,erri!ing *actor to consi!er when selecting a &aterial is the &aterial>s cost. All

!esigns &ust wor% within a pro?ect bu!get an! any &aterial reco&&en!ation &ust a!here to this

*act.

2& S+ecific (lo)line A++lication

'.1 )he .S 2$ 1/'/7 L888 &aterial has the che&ical co&position e+ual to that in !"$e 3.1 an!

the &ini&al &echanical properties as liste! in !"$e 3.2.

!"$e 3.1 +S ,N10208 *555 -(e.i-"$ -o.'o%i/ion.

(C,V."0 C"ron ,1ui2"$en-e3 /o e "4ree5 (/".))

!"$e 3.2 +S ,N10208 *555 .e-("ni-"$ 'ro'er/ie% re1uire.en/

(6. !en%i$e S/ren4/(, 6/0.5 7ie$5 S/ren4/( 8or 0.5% ,$on4"/ion)

4n a!!ition to these &echanical properties there are also se,eral re+uire&ents speci*ic to the

!i&ensions o* the *lowline !esign. )hese re+uire&ents will be ta%en into consi!eration !uring the

&aterial selection test an! analysis section.

)he .S 2$1/'/7 also co&&ents on the re+uire&ent highlighte! in 1.3= 9/(e re1uire.en/% 8or /(e

-(e.i-"$ -o.'o%i/ion o8 /(e %/ee$% "n5 in '"r/i-u$"r /(e $i.i/in4 2"$ue% 8or /(e -"ron e1ui2"$en/

C,V ("2e een %e$e-/e5 /o in%ure /("/ /(e %/ee$% 5e$i2ere5 in "--or5"n-e )i/( /(i% 5o-u.en/ "re

)e$5"$e.:

ii

)he C2@

&ax

*or $ is greater than /.13 an! there*ore the .S 2$1/'/7 reco&&en!s

a C2@

&ax

be agree! be*ore &anu*acture. Aro,i!ing the C2@

&ax

re&ains below /.18, then the

&aterial can be classi*ie! as ha,ing goo! wel!ability as re+uire! by .S 2$1/'/7.(See #''en5i0

!"$e 1).

4n a!!ition to being co¶ble to 2$ 1/'/7 L888, the reco&&en!e! &aterial &ust also be *it *or

purpose in all the re+uire! *iel!s highlighte! in the 1.;e%i4n S'e-i8i-"/ion abo,e. )o ensure the

&aterial is *it *or purpose it &ust hol! co¶ble &echanical properties to the &aterials alrea!y in

use in the subsea en,iron&ent liste! in (1. !"$e 3.3 shows the &axi&u& an! &ini&u&

&echanical properties that the reco&&en!e! &aterial &ust be withinB

Table 3.3 S(o)in4 /(e r"n4e o8 .e-("ni-"$ 'ro'er/ie% o8 ."/eri"$% in Q1, " re-o..en5e5 ."/eri"$ .u%/ ("2e

-o.'"r"$e 'ro'er/ie%.

(Fr"-/ure /ou4(ne%% %ee #''en5i0 &r"'( 13F"/i4ue S/ren4/( "/ 10<7 -=-$e% See #''en5i0 &r"'( 23 7oun4>%

Mo5u$u% %ee #''en5i0 &r"'( 3 )

L555

555 675

625

0.9

ELONGATION (% at Fracture) 18%

YIELD T!ENGT" (#$a)

TENILE T!ENGT" (#$a)

!

%

& !

t0.5

' ( #) $ * N+ T(

L555 0.16% 0.,5% 1.80% 0.0-% 0.02% 0.10% 0.06% 0.06%

'E*

%a.

t+a.

#() #a.

Fracture T/u01)e22 (#$a) 29 -58

Fat(0ue tre)0t1 (#$a) 207 6-9

Y/u)032 #/4u5u2 (G$a) 189 201

4* we apply the li&its in !"$e 3.3 to the !atabase o* &aterials in 2!upac% '/13 we gain the

*ollowing resultsB

C' out o* 3D/8 &aterials ha,e &echanical properties that are e+ui,alent to 2$ .S1/'/7 L888 an!

ha,e co¶ble &echanical properties to existing in!ustry &aterials. &r"'( 3.1 highlights the

acceptable &aterials in blue. )he &aterials are ran%e! by their speci*ic strength an! categori-e! into

those with suitable !urability in a salt water en,iron&ent. At this stage, the i!eal &aterial will ha,e

a high speci*ic strength an! excellent !urability in salt water con!itions.

So&e acceptable &aterials are only categori-e! as >li&ite! use> but a corrosion resistant alloy

CEA# can be applie! to the sur*ace o* the &etal to !ecrease the rate o* corrosion &a%ing the&

&ore suitable *or the subsea en,iron&ent. Fowe,er, as this speci*ic *lowline is only >%(or/> in length

the cost o* the CEA lining will be expensi,e per unit length o* piping, there*ore all poorly

per*or&ing &etals will be !isregar!e! at this stage.

)he next stage in the &aterial reco&&en!ation is to ran% the acceptable &aterials with respect to

the !esign re+uire&ents highlighte! in 1.1 ;e%i4n re1uire.en/%. Consi!eration 1.1.1 i!enti*ies the

ther&al per*or&ance o* the &aterial as a %ey *actor when !esigning *lowlines. )he ability o* the

&aterials to cope with stress cause! by ther&al expansion when co&pare! to the *racture toughness

is illustrate! in &r"'( 3.2.

At this stage in the selection we are loo%ing *or &aterials that ha,e a high *racture toughness to

pre,ent crac% propagation along the *low line an! exhibit a low ther&al stress to pre,ent buc%ling

an! internal stresses at high te&perature !i**erentials. Currently the $ic%el-base! &etals an! the

Duplex Stainless steel &etals are best suite! to this re+uire&ent, with certain :artensitic stainless

steels also pro!ucing attracti,e results.

W a t e r ( s a l t )

6 ) a c c e 7 t a + 5 e L ( % ( t e 4 u 2 e A c c e 7 t a + 5 e E . c e 5 5 e ) t

S

p

e

c

i

f

i

c

S

t

r

e

n

g

t

h

[

Y

i

e

l

d

s

t

r

e

n

g

t

h

(

e

l

a

s

t

i

c

l

i

m

i

t

)

/

D

e

n

s

i

t

y

]

1 e 8 5

1 e 8 ,

0 . 0 0 1

0 . 0 1

0 . 1

1

)he ther&al stress in &r"'( 3.2 will be !rastically re!uce! in the *iel! by insulating the *lowline,

howe,er the &ini&isation o* ther&al stress begins with initial &aterial selection *or the *lowline.

With this in &in!, austenitic stainless steels &ay be !isregar!e! because o* the potential *or high

ther&al stresses an! low *racture resistance to *racture propagation.

)he next stage in the process is to !eter&ine which &aterials possess the yiel! strength an! the

corrosi,e resistance to the pro!uction *lui!s that are highlighte! in 1.1.3. &r"'( 3.3 co&pares the

speci*ic strength against the price per %g o* &aterial o* the &etals categorise! as ha,ing >2xcellent>

!urability in a wea% aci! Sour "as# 2n,iron&ent. )he cost o* the &aterial has been consi!ere! as

there can be a case &a!e *or selecting &ore expensi,e &aterial i* less &aterial can be use! to gain

the !esire! !esign strength. )he graph shows that the $ic%el-base! &etals, *or exa&ple 4$C9$2L,

o**er co¶ble Speci*ic Strengths but at a &uch higher cost.

Co&paring &r"'( 3.2 an! 3.3 there is a clear tra!e o** between *racture toughness an! the cost o*

the &aterial. 4* exceptional toughness is re+uire! it co&es at cost. For the purpose o* a >short>

*lowline, the bene*it o* ha,ing exceptional toughness is not worth the expense an! there*ore at this

stage it is ?usti*iable to !isregar! the $ic%el-base! &etals.

.elow is a table o* the best per*or&ing &aterials that ha,e &a!e it through the li&itations

co&paring their corrosion resisti,ity an! there Carbon 2+ui,alence C2@.# 4n a!!ition their

per*or&ance on the &r"'(% 3.1 an! &r"'( 3.2 is also ran%e!.

)he &artensitic stainless steels outper*or& the Duplex steels on their ther&al per*or&ance an!

PRE

ta()5e22 2tee59 %arte)2(t(c9 1585$" 6.5 9.5 15.5 17.5 1 -

ta()5e22 2tee59 %arte)2(t(c9 'u2t/% ,50 ,.9 6.07 15.5 19.- 2 2

ta()5e22 2tee59 %arte)2(t(c9 $" 1-88#/ 5.7 8 8.6 1, 15.5 - ,

ta()5e22 2tee59 4u75e.9 LD:2101 5.29 26 6 1

ta()5e22 2tee59 4u75e.9 6N -2550 7.28 9.7 -5.2 ,-.9 , 5

ta()5e22 2tee59 4u75e.9 6N -2760 6.-- 7.9- -7.1 ,, 5 6

!E" (%)

#ract$re

%&$ghness

(!a);)

Specific Strength

/ Price (!a);)

per*or& ,ery well on the speci*ic strength to cost ration, howe,er there is a signi*icant !i**erence in

their corrosi,e per*or&ance. )he Duplex stainless steels ha,e a &uch greater Chro&iu& content

an! conse+uently a &uch greater pitting resistance nu&ber.

)he carbon content *or all the top per*or&ing &aterials is below /.110 an! there*ore none o* the

&aterials are susceptible to Fy!rogen Assiste! Crac%ing FAC# !uring wel!ing. Fowe,er, the

&artensitic Steels are not consi!ere! wel!able ,ia the sub&erge! arc wel!ing SAW# process an! it

is the SAW process &ost *a,oure! by the .S 2$1/'/7 stan!ar! an! by the in!ustry. Conse+uently,

the :artensitic steels &ust be !isregar!e! at this stage.

)hree Duplex Stainless steels re&ain as a possible &aterial reco&&en!ations. Although the

cheapest o* the three choices, Duplex LDG'1/ !oes not o**er goo! enough *racture toughness or

pitting resistance to be a *inal reco&&en!ation. 4n co&parison Stainless Steel Duplex H$ SS3'88/

o**ers a greater *racture toughness with a si&ilar expecte! ther&al stress at high te&peratures. 4n

a!!ition H$ S3'88/ has a higher strength to weight ration than H$ S3'CID an! at a lower cost. 4t

is *or the reasons abo,e that 4 woul! reco&&en! a Stainless Steel *u+le,- .! S320.

i Su%e" Pi'e$ine% "n5 6i%er% (,$%e2ier ?-e"n ,n4ineerin4)

AublisherB 2lse,ier Science Lt!= 'n! Ee,ise! e!ition e!ition '1 $o, '//8#

LanguageB 2nglish

4S.$-1/B //7/118IIC

4S.$-13B DC7-//7/118II3

ii .S 2$ 1/'/7-' - - Wel!ability 7.1.1

Vous aimerez peut-être aussi

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesD'EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesPas encore d'évaluation

- Lesson Pipe Materials & Special Pipes: Sub-ObjectiveDocument14 pagesLesson Pipe Materials & Special Pipes: Sub-Objectivemister pogiPas encore d'évaluation

- Anchor Weld LboatDocument15 pagesAnchor Weld LboatPolaris BridgemanPas encore d'évaluation

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicD'EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicPas encore d'évaluation

- Heat Treatment of SteelDocument26 pagesHeat Treatment of SteelVishal KumarPas encore d'évaluation

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithD'EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithPas encore d'évaluation

- About SteelDocument80 pagesAbout SteelpkjenaleoPas encore d'évaluation

- Classification of SteelsDocument29 pagesClassification of SteelsjanakPas encore d'évaluation

- Hi Structures Class:: Steel. (Steel Is A Iron Alloy With Very Low Carbon Content, Often With Some OtherDocument12 pagesHi Structures Class:: Steel. (Steel Is A Iron Alloy With Very Low Carbon Content, Often With Some Otheramirthraj74Pas encore d'évaluation

- Scroll Confidential: Product Engineering SpecificationDocument5 pagesScroll Confidential: Product Engineering SpecificationMike Fioren100% (1)

- ASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsDocument4 pagesASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsPisut LeelalumlertPas encore d'évaluation

- MIG Gas Mix Developed by EdDocument7 pagesMIG Gas Mix Developed by Edc_e_z_a_rPas encore d'évaluation

- Tailormade Course For Bhel - J&K Trainees (Tech)Document5 pagesTailormade Course For Bhel - J&K Trainees (Tech)Yuvaraj ChinthPas encore d'évaluation

- Tutorial 1 Solution - ME3162 NUSDocument1 pageTutorial 1 Solution - ME3162 NUSSuchithra RamanPas encore d'évaluation

- Carbon Nano TubesDocument15 pagesCarbon Nano TubesdineshvhavalPas encore d'évaluation

- Electroplating CopperDocument6 pagesElectroplating CopperLuis EstevesPas encore d'évaluation

- Inglés Técnico para Profesionales Metalúrgicos Technical English For MetallurgistsDocument5 pagesInglés Técnico para Profesionales Metalúrgicos Technical English For MetallurgistspirometalPas encore d'évaluation

- The Family Tree of Stainless SteelDocument14 pagesThe Family Tree of Stainless Steelnike_y2kPas encore d'évaluation

- The Link Between Operational Practice and Maximising The Life of Stainless Steel Electrodes in Electrowinning and Electrorefining ApplicationsDocument14 pagesThe Link Between Operational Practice and Maximising The Life of Stainless Steel Electrodes in Electrowinning and Electrorefining ApplicationskianPas encore d'évaluation

- 05 SteelsDocument4 pages05 SteelsRama Krishna Reddy DonthireddyPas encore d'évaluation

- Construction DetailingDocument12 pagesConstruction DetailingNurin MansoorPas encore d'évaluation

- Presentation 031512-FinalDocument58 pagesPresentation 031512-FinalwtfisfPas encore d'évaluation

- Low-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementDocument6 pagesLow-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementEdisonCorderoPas encore d'évaluation

- AcarDocument5 pagesAcarrenatoeliegePas encore d'évaluation

- Part Viii List Bis CodeDocument9 pagesPart Viii List Bis Codejoydeep_d3232Pas encore d'évaluation

- Piping QTDocument51 pagesPiping QTSaif Ul Haq Mohammed100% (1)

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranPas encore d'évaluation

- 2 Fire DamperDocument28 pages2 Fire Damperntt_121987Pas encore d'évaluation

- Terada 2014 IOP Conf. Ser.: Mater. Sci. Eng. 63 012088Document6 pagesTerada 2014 IOP Conf. Ser.: Mater. Sci. Eng. 63 012088Badrul AminPas encore d'évaluation

- Sheet Pile Baja (JFESP)Document15 pagesSheet Pile Baja (JFESP)berangketrPas encore d'évaluation

- Effect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsDocument5 pagesEffect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsEngels OchoaPas encore d'évaluation

- 1982AustSS FSWeldJntFalrs WeldJDocument11 pages1982AustSS FSWeldJntFalrs WeldJthisaintwapPas encore d'évaluation

- Materials: Submerged Arc WeldedDocument2 pagesMaterials: Submerged Arc WeldedMat ComiaPas encore d'évaluation

- 1 Wire Ropes, Elements and DefinitionsDocument6 pages1 Wire Ropes, Elements and DefinitionsDiego RodriguezPas encore d'évaluation

- Avoid Chromium Oxide in Welding of SsDocument1 pageAvoid Chromium Oxide in Welding of SsKarthikeyan ShanmugavelPas encore d'évaluation

- I C Engines-KathiresanDocument4 pagesI C Engines-KathiresanBhupender RamchandaniPas encore d'évaluation

- Fusion WeldingDocument4 pagesFusion WeldingSanthosh KumarPas encore d'évaluation

- 02-Hålogalandsbrua IABSE Denmark Mini-Seminar 2013.Ppt (Read-Only) (Compatibility Mode)Document38 pages02-Hålogalandsbrua IABSE Denmark Mini-Seminar 2013.Ppt (Read-Only) (Compatibility Mode)André BiscayaPas encore d'évaluation

- Crystallization Behavior of CaO-SiO2-MgO-Al2O3-Based Slags and Its Potential Application in P-Bearing Steelmaking SlagsDocument6 pagesCrystallization Behavior of CaO-SiO2-MgO-Al2O3-Based Slags and Its Potential Application in P-Bearing Steelmaking SlagsJJPas encore d'évaluation

- A4-80 - A2-80 Material ClassDocument3 pagesA4-80 - A2-80 Material Classcwfh779Pas encore d'évaluation

- Steel Cleanliness PaperDocument34 pagesSteel Cleanliness PaperyanuarPas encore d'évaluation

- D.I. Catalogue) 9th Edition) PDFDocument70 pagesD.I. Catalogue) 9th Edition) PDFArunprasad MurugesanPas encore d'évaluation

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingPas encore d'évaluation

- Report of THERMAL BARRIER COATING OF GAS TURBINE BLADESDocument21 pagesReport of THERMAL BARRIER COATING OF GAS TURBINE BLADESadityanarang1470% (1)

- Study of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDocument43 pagesStudy of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDeepu ChoudharyPas encore d'évaluation

- Shurjoint 2011 CatalogDocument163 pagesShurjoint 2011 CatalogabdulzameerPas encore d'évaluation

- API Standard 650Document10 pagesAPI Standard 650ryan fernandezPas encore d'évaluation

- Di Installation GuideDocument37 pagesDi Installation GuidehaivikramreddyPas encore d'évaluation

- Manufacturing Process For TMTDocument6 pagesManufacturing Process For TMTKratagya SinghalPas encore d'évaluation

- Analysis and Optimization of Parameters For Casting Ductile Iron PipesDocument27 pagesAnalysis and Optimization of Parameters For Casting Ductile Iron PipesSurajit SahaPas encore d'évaluation

- SD Article 46Document8 pagesSD Article 46Mustafa MoussaouiPas encore d'évaluation

- Ibrahim TrainingDocument7 pagesIbrahim Trainingahmedameer20189Pas encore d'évaluation

- Development of Bake-Hardenable Al-Killed Steel Sheet by Box Annealing ProcessDocument10 pagesDevelopment of Bake-Hardenable Al-Killed Steel Sheet by Box Annealing ProcessRamírez WillebaldoPas encore d'évaluation

- 1931 6834 1 SMDocument12 pages1931 6834 1 SMchpinto10% (1)

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeletePas encore d'évaluation

- Welding Requirements: Suggestions For Welding Stainless SteelDocument7 pagesWelding Requirements: Suggestions For Welding Stainless SteelStephanie WebbPas encore d'évaluation

- Reinforcing SteelDocument8 pagesReinforcing SteelPrittam Kumar JenaPas encore d'évaluation

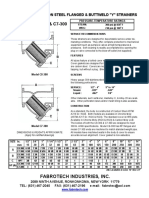

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocument1 pageMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441Pas encore d'évaluation

- Anchoring of Monolithic Refractories - UkDocument9 pagesAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- UL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Document1 pageUL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Nicolás Fernández CanepaPas encore d'évaluation

- Sae Ams 5519N-2014Document5 pagesSae Ams 5519N-2014Mehdi MokhtariPas encore d'évaluation

- Abus 2014 Price ListDocument12 pagesAbus 2014 Price ListSecurity Lock DistributorsPas encore d'évaluation

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuPas encore d'évaluation

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPPas encore d'évaluation

- EN 1090 White Paper17 119019 PDFDocument24 pagesEN 1090 White Paper17 119019 PDFZaza PokumbaPas encore d'évaluation

- 6.2 Aircraft Material - Non Ferrous - Unsurya 2019Document78 pages6.2 Aircraft Material - Non Ferrous - Unsurya 2019Raihan Farhan RamadhanPas encore d'évaluation

- Pin Brazing - DN80 Ph.1Document14 pagesPin Brazing - DN80 Ph.1Nickath BanuPas encore d'évaluation

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerPas encore d'évaluation

- 2-Conduction in SolidDocument46 pages2-Conduction in SolidRichard Adventus HutasoitPas encore d'évaluation

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 pagesCopper and Copper Alloys EN Standards For Copper AlloysLuis ReyesPas encore d'évaluation

- S235JR SteelDocument1 pageS235JR SteelNguyễn Thanh CườngPas encore d'évaluation

- Puppiece and Distance WeldmentDocument2 pagesPuppiece and Distance WeldmentwinarnobPas encore d'évaluation

- Pro PDF p27Document1 pagePro PDF p27Андрей НавPas encore d'évaluation

- GMAWDocument53 pagesGMAWJithuJohn100% (1)

- COATING SpecDocument39 pagesCOATING Specjuan MartinezPas encore d'évaluation

- A789 PDFDocument4 pagesA789 PDFmahmoud hanafiPas encore d'évaluation

- Creusabro 4800Document8 pagesCreusabro 4800ravigurajapuPas encore d'évaluation

- PTS DataSheet Slick E Line - Cable Rev A 2020Document1 pagePTS DataSheet Slick E Line - Cable Rev A 2020mahmoud korieshPas encore d'évaluation

- Astm E340 2015 PDFDocument11 pagesAstm E340 2015 PDFnantha kumar100% (1)

- Certificación para Material de Aluminio (ALUMOLD)Document2 pagesCertificación para Material de Aluminio (ALUMOLD)Olvera Sánchez Miguel AngelPas encore d'évaluation

- Steel Equipment CatalogDocument20 pagesSteel Equipment CatalogEdlir PeciPas encore d'évaluation

- 4 - Stainless Steels - Wrought and CastDocument24 pages4 - Stainless Steels - Wrought and CastdennykvgPas encore d'évaluation

- Unit IV OrigionalDocument25 pagesUnit IV OrigionalPrakash SinghPas encore d'évaluation

- Film Applied Galvanising: Zinga Is: Technical SpecificationDocument1 pageFilm Applied Galvanising: Zinga Is: Technical SpecificationAnand SinhaPas encore d'évaluation

- Gibb PresentationDocument16 pagesGibb Presentationmohamed aliPas encore d'évaluation

- Welding Aluminum Alloy 6061 PDFDocument5 pagesWelding Aluminum Alloy 6061 PDFtazzorroPas encore d'évaluation

- ISO 2819-2018 Choque TérmicoDocument27 pagesISO 2819-2018 Choque TérmicoRosario Castaño100% (1)

- BRINELL HARDNESS TEST Panaflex 4Document1 pageBRINELL HARDNESS TEST Panaflex 4Mohsin QaziPas encore d'évaluation

- Aluminum 6351-T6 6351-T651Document2 pagesAluminum 6351-T6 6351-T651Mathi Engineers And Builders Private LimitedPas encore d'évaluation

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontD'EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- Waste: One Woman’s Fight Against America’s Dirty SecretD'EverandWaste: One Woman’s Fight Against America’s Dirty SecretÉvaluation : 5 sur 5 étoiles5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (52)

- Slow Violence and the Environmentalism of the PoorD'EverandSlow Violence and the Environmentalism of the PoorÉvaluation : 4 sur 5 étoiles4/5 (5)

- Principles of direct and superior responsibility in international humanitarian lawD'EverandPrinciples of direct and superior responsibility in international humanitarian lawPas encore d'évaluation

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933D'EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Pas encore d'évaluation

- Introduction to Ecology and Environmental Laws in IndiaD'EverandIntroduction to Ecology and Environmental Laws in IndiaPas encore d'évaluation

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksD'EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksPas encore d'évaluation

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksD'EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksPas encore d'évaluation

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionD'Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionPas encore d'évaluation

- Introduction to Ecology and Environmental Laws in IndiaD'EverandIntroduction to Ecology and Environmental Laws in IndiaPas encore d'évaluation

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaD'EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldD'EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawD'EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawÉvaluation : 4 sur 5 étoiles4/5 (334)

- Environmental Education in Practice: Concepts and ApplicationsD'EverandEnvironmental Education in Practice: Concepts and ApplicationsPas encore d'évaluation

- Down to the Wire: Confronting Climate CollapseD'EverandDown to the Wire: Confronting Climate CollapseÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksD'EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksPas encore d'évaluation

- Obstacles to Environmental Progress: A U.S. perspectiveD'EverandObstacles to Environmental Progress: A U.S. perspectivePas encore d'évaluation

- Busted!: Drug War Survival Skills and True Dope DD'EverandBusted!: Drug War Survival Skills and True Dope DÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Playing with Fire: The Strange Case of Marine Shale ProcessorsD'EverandPlaying with Fire: The Strange Case of Marine Shale ProcessorsÉvaluation : 5 sur 5 étoiles5/5 (1)