Académique Documents

Professionnel Documents

Culture Documents

Handlng & Lifting Manual

Transféré par

GustiKetut0 évaluation0% ont trouvé ce document utile (0 vote)

36 vues18 pagesprocedure

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentprocedure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

36 vues18 pagesHandlng & Lifting Manual

Transféré par

GustiKetutprocedure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 18

HANDLING & INSTALLATION

OPERATION & MAINTENANCE

INSTRUCTIONS

200 N. GOODING STREET - P.O. BOX 160 BELDING, MI 48809-0160

TELEPHONE: (616) 794-1130 TOLL FREE: (800) 253-4252 FAX: (616) 794-3666

E-MAIL: bttsales@beldingtank.com WEBSITE: www.beldingtank.com

Page 1

TABLE OF CONTENTS

HANDLING AND INSTALLATION INSTRUCTIONS

ABOVE GROUND STORAGE TANKS Page 2

INSPECTION Page 2

HANDLING Page 3

Flat Bottom Page 4

Dished or Cone Bottom Page 5

Horizontal Page 5

INSTALLATION Page 6

Tank Bottom Support Pad Page 6

Bottom Buffer Pad Page 6

Pipe Connections Page 6

Water Fill Test Page 6

Side Bottom Flange Pad Cut Out Page 7

Hold Down Lugs

Standard Lugs Page 8

Anchor Dogs / Load Ledge Page 9

Dished or Cone Bottom Tank Page 10

Horizontal Tank Page 11

OPERATION AND MAINTENANCE INSTRUCTIONS

GENERAL Page 12

TANK CLEANING Page 12

AIR LOADING Page 13

MANWAY AND FLANGE BOLTING Page 14

FLANGE LOADS Page 15

TANK USAGE Page 16

WARRANTY STATEMENT

Page 2

HANDLING AND INSTALLATION INSTRUCTIONS

ABOVE GROUND STORAGE TANKS

The following handling and installation instructions are intended to help customers install

tanks properly and efficiently.

Handling and installation instructions are only recommendations. They do not relieve the

purchaser from full responsibility for proper inspection, handling and installation. Improper

handling or installation, which results in damage or tank failure, is the sole responsibility of

the purchaser. Failure by the customer to comply with the handling or installation

instructions will void the tank warranty. Unknown situations or conditions are also the

burden of the purchaser.

The presence of BELDING TANK TECHNOLOGIES personnel or an authorized

representative at the installation site does not relieve the purchaser of their responsibilities.

INSPECTION

At the time of delivery the customer shall be responsible for inspecting the tank for damage

during transit. Both the inside and the outside of the tank must be inspected. If damage has

occurred it should be noted on the delivery receipt prior to signing acceptance, whether it be

a BELDING TANK TECHNOLOGIES truck or common carrier. In the case of a common

carrier, claim should be immediately filed by the customer with the delivering carrier. If

delivery is made by a BELDING TANK TECHNOLOGIES truck, the factory should be

immediately contacted prior to unloading or acceptance. The customer accepts all future

responsibility for a damaged tank if the procedures set forth are not followed.

Minor damage can be repaired at the delivery site.

Page 3

HANDLING AND INSTALLATION INSTRUCTIONS

BELDING TANK TECHNOLOGIES tanks are designed to withstand normal handling. Note

the following handling precautions.

1. NEVER roll or slide a tank. Lift the tank using a crane or other approved method.

2. Operators of hoist equipment should follow proper rigging procedures at all times.

NEVER allow tank to swing out of control.

3. Do not drop or allow hard impact from tools, spreader bars, etc.

4. Avoid the use of equipment inside the tank that could scratch or damage the inner

corrosion barrier

5. NEVER use cables or chains around tank.

6. NEVER lift tank by using fittings. Use designated lifting lugs.

7. If tanks are being stored prior to installation, be sure to lay on padded surface and tie

down securely.

HANDLING TANKS SHIPPED

HORIZONTALLY

Small tanks shipped by common carrier are

palletized to facilitate handling by forklift. To

remove tank, pull on the bottom of the skid. DO

NOT PULL ON THE TANK.

LIFTING / HANDLING LUGS

The lugs are designed for equal load on both ear

tabs of the lug. BELDING TANK

TECHNOLOGIES recommends using a pipe

spacer between the ear tabs to achieve equal load.

Page 4

HANDLING AND INSTALLATION INSTRUCTIONS

FLAT BOTTOM TANKS

Larger tanks shipped by BELDING TANK TECHNOLOGIES truck and special built

trailers, require a spreader bar and slings attached to the appropriate lifting lugs to unload

tanks. Use a guide line to keep the load under control.

Large tanks should be stood up by hoisting with spreader bar and lines to lifting lugs,

adequate padding is necessary to protect the pivot point. Control the tank with guide lines to

insure tank is gently set on its base.

Use a spreader bar and lines attached to appropriate lifting lugs to move tank when in upright

position.

Page 5

HANDLING AND INSTALLATION INSTRUCTIONS

DISHED OR CONE BOTTOM TANKS

NOTE: When standing a tank with legs, DO NOT pivot tank on legs. Lift the entire tank.

Rotate to a vertical position. Set straight down on all legs.

Proper

Improper

HORIZONTAL TANKS

Proper See Installation Page 10

Page 6

HANDLING AND INSTALLATION INSTRUCTIONS

TANK BOTTOM SUPPORT PAD

BELDING TANK flat bottom and slope bottom tanks require continuous bottom support.

The most common support pad is a concrete slab. However, any other support structure with

sufficient strength to support the combined weight of the tank and its contents, with a

reasonable factor of safety, is acceptable. Design for bearing strength of support pad is the

responsibility of the purchaser. The support pad must exceed tank diameter by 6" minimum,

and be flat within +/- 1/16".

INSTALLATION NOTE: Support pad must be clean and free of all foreign objects prior to

settling tank in place.

TANK BOTTOM BUFFER PAD

Liquid grout such as concrete, epoxy, etc., MUST NOT be used under standard flat bottoms.

BELDING TANK recommends using two layers of 30 pound roofing felt as a buffer between

tank support and tank bottom. When applying the roofing felt, be sure there are no overlaps

or wrinkles causing ridges under the bottom. It is the responsibility of the purchaser to see

that tanks are properly installed. Any deviation from the above outlined procedure must be

approved by BELDING TANK TECHNOLOGIES or it will void your warranty.

PIPE CONNECTIONS

Flexible pipe connections should be used wherever possible. If rigid piping must be used, be

certain it is self-supporting. If rigid piping is used and is not self-supporting, and results in

damage to a tank fitting, your warranty will be void. CAUTION: METALLIC FITTINGS

MUST NOT BE USED ON FRP NIPPLES OR COUPLINGS.

WATER FILL TESTING

BELDING TANK recommends that each tank be water filled (hydro tested) for a 24 hour period after the

tank is installed, and prior to use.

Page 7

HANDLING AND INSTALLATION INSTRUCTIONS

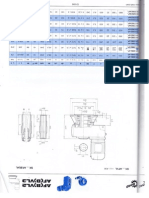

SIDE BOTTOM FLANGE PAD CUT OUT:

CAUTION: When installing any BELDING TANK TECHNOLOGIES tank with a side

bottom flange, your pad cut-out dimensions must conform to the specifications as detailed

below. Any deviation without the written consent of BELDING TANK TECHNOLOGIES

may cause serious damage and will void warranty.

Consult the factory if you have any questions. 1-800-253-4252.

Drain Size A B C

2" 9 8 3-1/4

3" 10 8 3-3/4

4" 11 8 4-3/4

6" 13 8 5-3/4

8" 15 8 6-3/4

10" 18 8 8-1/2

12" 21 8 10

Page 8

HANDLING AND INSTALLATION INSTRUCTIONS

HOLD DOWN LUGS - Standard

The required hold down lugs are supplied as standard equipment on all BELDING TANK

TECHNOLOGIES tanks. Anchor bolts and hold down hardware are supplied by the

customer.

Preferred Method of Anchor Installation:

Customer Supplied

Anchoring System

Customer Supplied

Pipe Sleeve

Expansion anchor or resin capsule anchor.

Belding Tank recommends the use of two nuts on the top of the lug. When the tank is

EMPTY, hand tighten the first nut onto the top of the lug. Hand tighten the second

(jam nut) nut onto the top of the bottom nut. Then, using two wrenches, HOLD the

bottom nut and tighten the jam nut onto the bottom nut.

Do not over tighten hold down lugs.

INSTALLATION NOTE: Do not locate or pre-set anchor holes/bolts in the tank pad before

receipt of tank. BELDING TANK will not be responsible for pre-set anchor holes/bolts.

Page 9

HANDLING AND INSTALLATION INSTRUCTIONS

HOLD DOWN LUGS Anchor DOG / Load Ledge

1. Position & set Anchors -- See Tank Drawing for position.

2. Minimum height of anchors above tank base =height of DOG +top plate +height of

(2) nuts + minimum.

3. Position anchor DOGS over anchor bolts; locate dog ledge away from sidewall

and on top of load ledge & level DOGS; -- shim if needed.

4. When tank is empty fill anchor DOG box with non-shrink grout.

5. Put cover plate over anchor DOG box and hand- tighten bottom nut.

6. Hand tighten second J AM top nut onto bottom nut.

7. Lock bottom nut onto top nut. Do not adjust after tank is filled.

TO SUIT LG.

1/2 CLEARANCE

SHIM PER INSTRUCTIONS ABOVE.

CUSTOMER SUPPLIED

ANCHOR BOLTS

HAND TIGHTEN, LOCK WITH

J AM NUT PER INSTRUCTIONS

ABOVE.

ISO VIEW

TANK LOAD LEDGE

DOG LEDGE

1/4 CLEARANCE

Page 10

HANDLING AND INSTALLATION INSTRUCTIONS

DISHED BOTTOM TANKS

The pad surface must be smooth and level. Consideration must be given to the concentrated

nature (4-10 points) of the loading, the magnitude of which could require footings beneath

each leg to spread the load over a larger area. The design of footings is the responsibility of

the purchaser.

The tank is designed to rely upon firm even support at each of its legs. In order to allow for

uneven pads, floors, and legs, the floor pads on each leg may require shims to insure uniform

support.

Consult factory if you have any questions. (1-800-253-4252)

Page 11

HANDLING AND INSTALLATION INSTRUCTIONS

HORIZONTAL TANK INSTALLATION

Installation of horizontal tanks is much the same as the dished bottom. Tanks are supplied

with the required number of steel support saddles. These saddles are to be placed under the

designated support rings. The saddles must be centered on the support ring and through the

centerline of the tank. Caution must be taken to insure that the tank support ring is in contact

with each saddle.

Caution: Modification of saddles in any way voids your warranty.

SUPPORT RI NG

SADDLE

150

SADDLE

CONTACT

AREA

Page 12

OPERATION AND MAINTENANCE INSTRUCTIONS

Because of FIBERGLASS REINFORCED PLASTIC tanks unique, physical and structural characteristics;

they are flexible, lightweight, corrosion resistant, and stronger than tanks made of other plastic materials.

Care, however, should be taken to follow the Handling and Installation instructions. Once the tank has been

properly installed and placed in service, BTT recommends regular routine inspections as a part of your

preventative maintenance program.

The care and operation of FRP vessels rely mostly on common sense. To maximize trouble free service,

Belding Tank recommends:

1. Inspect your vessel thoroughly upon receipt.

2. Follow the Handling and Installation instruction.

3. Wash your vessel thoroughly w/detergent and rinse before putting in service (see FDA Requirements)

AFTER THE TANK IS PUT IN SERVICE:

1. Keep the vessel clean.

a. It will remain more aesthetically pleasing.

b. If the tank is ever damaged, it will be evident.

2. Make a visual tank inspection inside and outside the tank every 6-12 months.

TANKS FOR FOOD APPLICATION:

BELDING TANK TECHNOLOGIES tanks will comply with U.S. Food, Drug and Cosmetic Act, as

amended, and applicable FDA regulations (21 cfr 177.2420). These tanks may be used as components

intended for repeated use in contact with food, subject to certain limitations described in that regulation.

BELDING TANK TECHNOLOGIES tanks are chemically acceptable in processing or storage areas for

contact with meat or poultry food products prepared under federal inspection and used at temperatures below

250 F. This acceptance has been given by the United States Department of Agriculture.

Prior to shipping your tank, B.T.T. applies a (4) hour heat cure followed by a hot water wash to the tank

interior.

After installation and before your tank is put into service, attention to the following procedures is important

to achieve FDA compliance:

1. After tank installation, steam-treat or steep tank with hot water for 8-16 hours at 160 180 F. This

should remove all residual styrene from the laminate surface.

2. Wash the tank thoroughly with detergent and rinse it thoroughly.

3. Check state and local regulations for required compliance in addition to the above recommendations.

Page 13

OPERATION AND MAINTENANCE INSTRUCTIONS

AIR LOADING

Tanks are often filled with liquids from tanker trucks by pressurizing the headspace above the liquid within

the tanker with compressed air to force tanker contents into the receiving tank. This is most typically done

when the liquid being transferred is a corrosive chemical, which could damage a pump. Although such a

procedure eliminates the need for a pump, a possibility does exist that the pressurized air within the tanker

will follow the liquid into the receiving tank, and destroy the tank, due to excessive pressure.

Generally speaking, the tanker is connected to the receiving tank by a hose. The compressed air pushing

down on the liquid forces the liquid through the hose and into the receiving tank. The frictional resistance

offered by the hose and the fitting limits the maximum velocity of the liquid moving through the hose to a

reasonable value. The air displaced by the liquid entering the tank escapes through the normal vent provided

on the tank.

However, when the last of the liquid passes through the hose, the compressed air within the tanker rushes

through the hose at an extremely high velocity, because this air does not meet significant frictional resistance

in the hose, as the liquid does. This air enters the headspace in the receiving tank and expands with almost

explosive speed and force. The conventional tank vent cannot relive this excessive pressure within the tank.

When the pressure within the receiving tank exceeds that for which the tank is designed, either the tank head

blows off or some other portion of the tank ruptures.

Preferably, the person operating the tanker will interrupt the liquid flow before the last of the liquid leaves

the tanker, preventing the compressed air from entering the tank. However, through inattention or

carelessness, the operator will occasionally forget to interrupt the liquid at the "appropriate

time"RESULTPOSSIBLE TANK FAILURE.

The quoted description above is the possible occurrence when the tank is air loadedIMPROPERLY;

proper procedure requires that the operator interrupt the liquid at the appropriate time. PROPER

PROCEDURE WILL NOT CAUSE TANK FAILURE.

To guard against tank failure when the tank is air loaded, opening the manhole cover is suggested. This

precaution, if the tank is air loaded improperly, does NOT eliminate the possibility of tank failurebut it

may lessen the possibility.

TO ELIMINATE TANK FAILURE DUE TO IMPROPER AIR LOADING:

A. BUILD A PRESSURE VESSEL, OR

B. ELIMINATE THE POSSIBILITY OF THE AIR PAD PRESSURE IN THE TANKER FROM

REACHING THE TANK EXTERIOR BY:

1. Suspending the fill line above the manway (i.e. line is not to enter tank), OR

2. Monitoring a flow meter to determine when the tanker will be empty, OR

3. Install a "No-Flow" switch in tandem with a control valve.

Note: B.T.T. recommends consulting with a reputable firm in reference to flow meters and no flow switches.

If you have any questions or special circumstances that require discussion, please feel free to contact us at

1-800-253-4252.

Page 14

OPERATION AND MAINTENANCE INSTRUCTIONS

BOLTING SEQUENCE

Maximum Manhole Bolt Torque =60 ft. lbs.

Drawings not to scale

Flanged Nozzle Maximum Bolt Torque

Nozzle Size Bolt Torque

1" - 12" 25 ft. lbs. max

14" - 16" 30 ft. lbs. max.

18" - 20" 35 ft. lbs. max

24" 40 ft. lbs. max.

Page 15

OPERATION AND MAINTENANCE INSTRUCTIONS

Flanged Nozzle Allowable Loads Without Gussets

Size A B C

1 30 LBS. 50 FT./LBS. 30 LBS.

1-1/2 50 LBS. 50 FT./LBS. 50 LBS.

2 50 LBS. 50 FT./LBS. 50 LBS.

3 50 LBS. 50 FT./LBS. 50 LBS.

4 50 LBS. 50 FT./LBS. 50 LBS.

6 50 LBS. 50 FT./LBS. 50 LBS.

8 100 LBS. 50 FT./LBS. 100 LBS.

10 100 LBS. 50 FT./LBS. 100 LBS.

12 100 LBS. 50 FT./LBS. 100 LBS.

Page 16

OPERATION AND MAINTENANCE INSTRUCTIONS

TANK USAGE

This tank has been sold for a specific chemical storage application. Before changing the

chemical environment, consult with BELDING TANK TECHNOLOGIES (your warranty

may be void without written authorization from B.T.T.)

BELDING TANK standard tanks are NOT designed for pressure or vacuum other than liquid

head. Be sure tanks are properly vented to avoid accidental pressure or vacuum.

STATEMENT OF WARRANTY

Belding Tank Technologies, Inc. warrants its manufactured products against

any defects in the material and workmanship only for a period of (12) months

from shipment.

In the event that the purchaser asserts and Belding Tank Technologies, Inc.

agrees that the product is defective per this warranty, Belding Tank

Technologies, Inc. may, at its election replace, repair or credit the customer,

on the condition that the product is in possession of the original purchaser

and the product has been used for its originally intended purpose and design.

Any component parts that are on products manufactured and designed by

Belding Tank, are warranted only to the extent of the manufacturer of each

component part and to the extent as is enforceable by Belding Tank

Technologies, Inc.

Any alterations, modifications, or changes to any products manufactured or

supplied by Belding Tank Technologies, Inc., automatically voids this

warranty.

No warranty, either expressed or implied, is made by Belding Tank

Technologies, Inc. as to the fitness, merchantability, condition, capacity, or

efficiency of any products or goods sold, and no claims for labor or for

consequential damages will be allowed.

If purchaser attempts to repair product or take any other action, prior to

giving prompt notice and providing a reasonable opportunity for Belding

Tank Technologies, Inc. to inspect and correct said product, as deemed

necessary by the manufacturer, Belding Tank Technologies, Inc. shall not be

held liable for any expenses incurred by the purchaser.

No product may be returned for credit or replacement unless first authorized

by Belding Tank Technologies, Inc.

Belding Tank Technologies, Inc.s liability and the purchasers exclusive

remedies are limited to those set forth in this warranty, to the exclusion of all

others.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- BC 1613Document1 pageBC 1613GustiKetutPas encore d'évaluation

- Pipeline ProcedureDocument26 pagesPipeline ProcedurekeronsPas encore d'évaluation

- Batch Certificate: Test Item Standard ResultDocument1 pageBatch Certificate: Test Item Standard ResultGustiKetutPas encore d'évaluation

- PT Gapura Mandiri: Bolt and Nut Thigtening ProcedureDocument3 pagesPT Gapura Mandiri: Bolt and Nut Thigtening ProcedureGustiKetutPas encore d'évaluation

- BC 1613Document1 pageBC 1613GustiKetutPas encore d'évaluation

- BC 1614Document1 pageBC 1614GustiKetutPas encore d'évaluation

- BC 1612Document1 pageBC 1612GustiKetutPas encore d'évaluation

- BC 1615Document1 pageBC 1615GustiKetutPas encore d'évaluation

- BC 1612Document1 pageBC 1612GustiKetutPas encore d'évaluation

- Running Test ReportDocument2 pagesRunning Test ReportGustiKetutPas encore d'évaluation

- PPG Coatings Indonesia Branch and Product Certificate DetailsDocument1 pagePPG Coatings Indonesia Branch and Product Certificate DetailsGustiKetutPas encore d'évaluation

- Batch Certificate: BC/983/IV/13Document1 pageBatch Certificate: BC/983/IV/13GustiKetutPas encore d'évaluation

- Batch Certificate: Test Item Standard ResultDocument1 pageBatch Certificate: Test Item Standard ResultGustiKetutPas encore d'évaluation

- Symbol HSEDocument1 pageSymbol HSEGustiKetutPas encore d'évaluation

- BC 1838Document1 pageBC 1838GustiKetutPas encore d'évaluation

- BC 1055Document1 pageBC 1055GustiKetutPas encore d'évaluation

- BC 1055Document1 pageBC 1055GustiKetutPas encore d'évaluation

- PT International Paint Indonesia Certificate of AnalysisDocument1 pagePT International Paint Indonesia Certificate of AnalysisgstketutPas encore d'évaluation

- BC 996Document1 pageBC 996GustiKetutPas encore d'évaluation

- BC 996Document1 pageBC 996GustiKetutPas encore d'évaluation

- PPG Coatings Indonesia Branch and Product CertificateDocument1 pagePPG Coatings Indonesia Branch and Product CertificateGustiKetutPas encore d'évaluation

- Structural Tank Instructions 11967-ADocument22 pagesStructural Tank Instructions 11967-Aiftikhar_khalid_1Pas encore d'évaluation

- BC 1838Document1 pageBC 1838GustiKetutPas encore d'évaluation

- BC 1838Document1 pageBC 1838GustiKetutPas encore d'évaluation

- Gta733 Pg1908riDocument1 pageGta733 Pg1908riGustiKetutPas encore d'évaluation

- BC 1838Document1 pageBC 1838GustiKetutPas encore d'évaluation

- Gta220 Ph6432riDocument1 pageGta220 Ph6432riGustiKetutPas encore d'évaluation

- G 1000Document1 pageG 1000gstketutPas encore d'évaluation

- Nqs PLP E-Newsletter No68Document5 pagesNqs PLP E-Newsletter No68api-243291083Pas encore d'évaluation

- Presentation On Ich Topics & Guidelines With A Special Reference ToDocument79 pagesPresentation On Ich Topics & Guidelines With A Special Reference ToVidyaPas encore d'évaluation

- HU675FE ManualDocument44 pagesHU675FE ManualMar VeroPas encore d'évaluation

- Rakpoxy 150 HB PrimerDocument1 pageRakpoxy 150 HB Primernate anantathatPas encore d'évaluation

- Mark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'Document5 pagesMark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'bhaskkarPas encore d'évaluation

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihPas encore d'évaluation

- April 3rd - Asynchronous Class - Questions-4Document3 pagesApril 3rd - Asynchronous Class - Questions-4alidrissiPas encore d'évaluation

- Obat LasaDocument3 pagesObat Lasaibnunanda29Pas encore d'évaluation

- Class 9th Chemistry Unit#4 Structure of MoleculesDocument8 pagesClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahPas encore d'évaluation

- PGP TutorialDocument21 pagesPGP TutorialSabri AllaniPas encore d'évaluation

- No.6 Role-Of-Child-Health-NurseDocument8 pagesNo.6 Role-Of-Child-Health-NursePawan BatthPas encore d'évaluation

- 256267a1Document5 083 pages256267a1Елизавета ШепелеваPas encore d'évaluation

- VNC Function Operation InstructionDocument11 pagesVNC Function Operation InstructionArnaldo OliveiraPas encore d'évaluation

- Febrile SeizureDocument3 pagesFebrile SeizureClyxille GiradoPas encore d'évaluation

- Prof. Michael Murray - Some Differential Geometry ExercisesDocument4 pagesProf. Michael Murray - Some Differential Geometry ExercisesAnonymous 9rJe2lOskxPas encore d'évaluation

- Aircraft ChecksDocument10 pagesAircraft ChecksAshirbad RathaPas encore d'évaluation

- Flexible AC Transmission SystemsDocument51 pagesFlexible AC Transmission SystemsPriyanka VedulaPas encore d'évaluation

- Hotel and Restaurant at Blue Nile FallsDocument26 pagesHotel and Restaurant at Blue Nile Fallsbig johnPas encore d'évaluation

- Impact of Recruitment & Selection on Employee RetentionDocument39 pagesImpact of Recruitment & Selection on Employee RetentiongizawPas encore d'évaluation

- Dr. Malik's Farms BrochureDocument18 pagesDr. Malik's Farms BrochureNeil AgshikarPas encore d'évaluation

- Ne 01 20 09 2018Document436 pagesNe 01 20 09 2018VaradrajPas encore d'évaluation

- Introduction To Streering Gear SystemDocument1 pageIntroduction To Streering Gear SystemNorman prattPas encore d'évaluation

- Fundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument35 pagesFundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDrMichelleHutchinsonegniq100% (15)

- Universal Robina Co. & Bdo Unibank Inc.: Research PaperDocument25 pagesUniversal Robina Co. & Bdo Unibank Inc.: Research PaperSariephine Grace ArasPas encore d'évaluation

- Learn Square Roots & Plot on Number LineDocument11 pagesLearn Square Roots & Plot on Number LineADAM CRISOLOGOPas encore d'évaluation

- Hardware Purchase and Sales System Project ProfileDocument43 pagesHardware Purchase and Sales System Project Profilesanjaykumarguptaa100% (2)

- Drypro832 PreInstallGude 0921YH220B 070627 FixDocument23 pagesDrypro832 PreInstallGude 0921YH220B 070627 FixRicardoPas encore d'évaluation

- EMMS SpecificationsDocument18 pagesEMMS SpecificationsAnonymous dJtVwACc100% (2)

- Practical LPM-122Document31 pagesPractical LPM-122anon_251667476Pas encore d'évaluation