Académique Documents

Professionnel Documents

Culture Documents

Guidelines For Milk Quality Tests

Transféré par

Osman Aita100%(1)100% ont trouvé ce document utile (1 vote)

304 vues12 pagesGuidelines for Milk Quality Tests

Titre original

Guidelines for Milk Quality Tests

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentGuidelines for Milk Quality Tests

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

304 vues12 pagesGuidelines For Milk Quality Tests

Transféré par

Osman AitaGuidelines for Milk Quality Tests

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 12

21

THE DAIRY PRACTICES COUNCIL

GUIDELINES FOR

RAW MILK QUALITY TESTS

Publication: DPC 21

Single Copy: $ 4.00

April 2003

First Printing August 1976

First Revision July 1984

Second Revision September 1991

Third Revision April 2003

Prepared by

Laboratory & Quality Control Procedures, Patrick Boyle, Director

Rebecca Piston, Lead Author

Contributors

Robert Kiser Dan Scruton

Fran Matusiak Sally Stephenson

Steven Murphy Kelly Wedding

Ruth Riner

Sponsored by

THE DAIRY PRACTICES COUNCIL

Lynn S. Hinckley, President

Jeffrey M. Bloom, Vice President

Terry B. Musson, Executive Vice President

APPROVED COPY

EXCEPTIONS FOR INDIVIDUAL STATE, IF ANY, WILL BE FOUND IN FOODTNOTES

Order From: DPC, 51 East Front Street, Suite 2, Keyport, NJ 07735, Tel. (732) 264-2643

ht t p: / / www. dai r ypc . or g

ABSTRACT

This guideline provides information on the common tests used for evaluating the quality of raw milk. It is

written to provide basic background information to dairy producers and others interested in raw milk test

procedures and how the parameters measured influence dairy product quality. It includes discussion of

such tests as odor, flavor, temperature, various bacteria counts, freezing point, acidity, drug residues and

sediment. This guideline does not stand as a laboratory procedure document but provides references to

such and to other guidelines and resources.

PREFACE

This Guideline was initiated by the Quality Assurance Task Force, Dr. Charles W. Livak, Penn Dairies,

Chairman. The first revision was written under the leadership of Prof. Sidney E. Barnard, The

Pennsylvania State University, assisted by Dr. Henry V. Atherton, University of Vermont, Charles W.

Livak, and Albert F. Zimmermann, Consultant, QC, Inc. The second revision of this document was

prepared through the leadership of Rebecca Piston, Cabot Farmers' Coop. Creamery, and assisted by Prof.

Sidney E. Barnard, The Pennsylvania State University, Dr. J. Russell Bishop, Virginia Tech., M. Jeffrey

Bloom, Environmental Systems Service, Patrick J. Cleary, St. Albans Coop. Creamery, Prof. Susan

Duncan, Virginia Tech., Laurie Justis, Vermont Dept. of Agric., Food & Markets, Susan Sausville, Agri-

Mark, and Dan L. Scruton, Vermont Dept. of Agric., Food & Markets.

This third revision was prepared by the team of Ms. Rebecca Piston, Garelick Farms; Mr. Robert Kiser,

University of Kentucky; Ms. Fran Matusiak, Meadowbrook Dairy; Mr. Steven Murphy, Cornell

University; Ms. Ruth Riner, Upstate Farms; Mr. Dan Scruton, Vermont Department of Agriculture; Ms.

Sally Stephenson, Michigan Milk Producers Association and Ms. Kelly Wedding, USDA MMA.

GUIDELINE PREPARATIONAND REVIEW PROCESS

Guideline development within Dairy Practices Council (DPC) is unique and requires several levels of peer

review. The first step in the process of guideline development starts with a Task Force subcommittee made

up of individuals from industry, regulatory and education interested in and knowledgeable about the

subject to be addressed. Drafts, called white copies, are circulated until all members are satisfied with the

text. The final white copy may then be distributed to the entire task force, DPC Executive Board, state and federal

regulators, education members, industry members and anyone else the DPC Executive Vice President and the Task

Force Director feels would add to the strength of the review. Following final white copy review and correction

the next step in the process requires a yellow cover draft that is circulated to the member Regulatory

Agency representatives that are referred to as Key Sanitarians. The Key Sanitarians may suggest changes

and insert footnotes if their state standards and regulations differ from the text. After final review and

editing the Guideline is distributed in the distinctive DPC green cover to people worldwide. These

guidelines represent the state of the knowledge at the time they are written.

DPC is a Registered Trademark of The Dairy Practices Council

.

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

2

TABLE OF CONTENTS

ABSTRACT..................................................................................................................................... 1

PREFACE........................................................................................................................................ 1

GUIDELINE PREPARATION AND REVIEW PROCESS............................................................... 1

TABLE OF CONTENTS.................................................................................................................. 2

INTRODUCTION............................................................................................................................. 3

ON-FARM AND PLANT RECEIVING EVALUATION.................................................................... 3

Appearance, Odor and Flavor .................................................................................................................... 3

Temperature ................................................................................................................................................. 4

Collecting and Handling Samples ............................................................................................................... 5

LABORATORY TESTING PROCEDURES.................................................................................... 6

Microbiological Tests ................................................................................................................................... 6

Standard Plate Count (SPC)................................................................................................................... 6

Preliminary Incubation Counts (PIC) ................................................................................................... 7

Thermoduric Bacteria or Laboratory Pasteurization Count (LPC)................................................... 7

Coliform Bacteria Count ........................................................................................................................ 7

Blood Agar & Culturing Procedures..................................................................................................... 8

Titratable Acidity (TA) as an Indication of Bacterial Growth.......................................................... 8

Direct Microscopic Methods........................................................................................................................ 8

Direct Microscopic Clump Count (DMCC) ........................................................................................ 8

Direct Microscopic Somatic Cell Count (DMSCC) and Abnormal Milk........................................ 9

Other Measures Of Adulteration Or Contamination ............................................................................... 9

Drug Residues, Antibiotics and Growth Inhibitors ............................................................................ 9

Added Water and Milk Freezing Point............................................................................................... 10

Sediment ................................................................................................................................................. 10

Pesticides and Chemical Contaminants.............................................................................................. 10

SUMMARY.................................................................................................................................... 11

REFERENCES.............................................................................................................................. 11

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

3

INTRODUCTION

Good quality raw milk is essential for the production of high quality dairy products with consumer acceptance.

There are many factors that can influence the quality of raw milk, many of which are tested for by raw milk

handlers. While odor, flavor, texture and appearance are considered the most important tests for food quality, these

are directly or indirectly influenced by other factors that can also be evaluated or measured, such as holding

temperature, adulteration, or microbial contamination and growth. Currently, raw milk tests required by state and

federal regulatory agencies are limited to a few routine procedures with acceptable standards that may not be

considered to be in the realm of high quality. However, the dairy industry has recently taken the lead in

demanding and paying for (i.e., premiums) higher quality raw milk with increased testing and standards that better

reflect the overall quality of the raw milk and the production efforts of farmers/ producers.

This guideline will give an overview of the tests and procedures used by regulatory agencies and the dairy industry

to evaluate raw milk quality including sensory evaluation (i.e., odor, flavor, appearance, etc.), various

microbiological methods (i.e., bacteria count procedures), herd health parameters (i.e., somatic cell counts),

adulteration and contamination (i.e., drug residues, water, sediment, etc.). Although this guideline is not designed

to be a procedure manual, the importance of proper sample collection and handling and acceptable laboratory

techniques and methodology will be addressed. For those looking for more specific information on laboratory

procedures, most of the tests covered in this guideline can be found in the most recent addition of Standard Methods

for the Examination of Dairy Products (SMEDP- American Public Health Association). Where appropriate, the

reader will be referred to other Dairy Practices Council (DPC) Guidelines, specific regulations cited in the most

recent version of the Grade A Pasteurized Milk Ordinance (PMO Public Health Service/Food and Drug

Administration (FDA), Publication 229) or to other sources of information.

While this guideline was prepared primarily for producers of raw milk, the principles covered also apply to

handlers, haulers, dairy product manufacturers and to all others interested in raw milk testing and quality. A

discussion of each quality test will include the purpose of the test and general procedures for performing the

analyses, how product quality is influenced by the results, regulatory and recommended quality standards, and

practical steps used to achieve compliance with these standards.

ON-FARMAND PLANT RECEIVINGEVALUATION

Appearance, Odor and Flavor

The ability to detect off odors and flavors does not require special laboratory equipment, but does require a keen

sense of smell and taste. Although the ability to detect odors and flavors varies, most people can develop the

capacity to distinguish between good and poor quality milk. Producers should routinely check their own milk. Bulk

milk haulers, and receivers at the plant, should check all milk by lifting the tank covers, using caution to prevent

contamination, to visually inspect and to smell the air over the milk. Any significant visual abnormality (i.e.,

floating debris or off color) would suggest contaminated or adulterated milk that should not be collected or further

processed. Off odors can be detected by placing your nose directly over the porthole or manhole. Volatile odors

such as feedy, unclean, rancid, sour and malty can generally be detected by smell, unless the surrounding air

contains strong odors.

Several off-flavors and odors can be present in raw milk due to practices on the farm. Some are minor and

unavoidable, while others are due to poor practices and are reason for rejection. Most flavor/odor defects will be

carried over into the finished product, although some of the volatile defects can be partially removed. Defects in

milk can be classified as Absorbed animals breathing in odors in the air can transmit these to the milk through

their blood stream, or odors may be absorbed by the milk itself; Bacterial growth of spoilage microorganisms; or

Chemical related to enzymes, feed and health of the animal as well as milk handling procedures. More details on

sensory defects in milk, including their causes and prevention, are contained in DPC Guideline 38, Preventing Off

Flavors in Milk. More details on sensory defects in dairy goat milk are contained in DPC Guideline 59, Production

and Regulation of Quality Dairy Goat Milk.

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

4

The most common off odors or flavors detected at the farm or at the receiving location are:

Barny/Cowy: Associated with strong barn odors (i.e., poor ventilation) that are inhaled by the animal and

transmitted to the milk or directly absorbed by milk during storage. Some animals will produce cowy milk that

is related to poor health (i.e., ketosis).

Feedy: Associated with strong feed odors that are absorbed or inhaled by the animal and transmitted to the milk

or directly absorbed into the milk during storage. Feed odors or flavors are most often related to the nature of the

feed and/or feeding immediately before milking. Removal of the offending feeds and/or preventing feeding of

legumes/corn silage and other strong feeds within two hours of milking should prevent or minimize the problem.

Malty/Acid/Sour: Defect caused by the growth of bacteria that produce acid, some of which can produce a malty

defect. This defect is relatively rare as it is most often associated with poor cooling of the milk, though it may

still occur as a result of equipment failure (i.e., broken compressor). Increases in the titratable acidity (TA) of the

milk are often apparent as a result of this type of microbial spoilage. (See Titratable Acidity)

Oxidized: Cardboardy or old-oil odor and flavor resulting from the oxidation of milk fats. This defect is often

catalyzed by the presence of certain metals (i.e., copper contamination). Feeding excessive high fat feeds (i.e.,

soy beans) and or low levels of vitamin E may also increase the susceptibility to oxidation. Some animals are

more susceptible to the production of oxidized milk.

Rancid: Sour-like defect that occurs in milk due to excessive agitation (i.e., risers, starved pumps, air leaks, etc.)

and other factors responsible for disrupting the fat globule membrane and/or increasing the susceptibility of the

milk fat to the hydrolytic enzyme lipase. Lipase breaks down butter fat triglycerides (the major component of

milk fat) to free fatty acids (FFA) that result in rancid off-flavors (i.e., soapy, baby-vomit, blue cheese, etc.).

Generally, the short chain FFA's (i.e., butyric, caproic) are most often responsible for rancid off flavors. The

Acid Degree Value (ADV) test may be used as an indication of milk fat hydrolysis or high levels of free fatty

acids in milk, although caution should be used if results are compared in reference to taste judgments. Few

laboratories are set up to run ADVs. Although individual sensitivity varies and the results of the ADV are based

on measuring longer FFAs, most people will start to detect off-flavors when ADVs are 1.0 to 1.4. High ADVs

and rancid farm milk have become less common with improved milking system designs.

If the odor is questionable, warming the milk will help make defects become more apparent. A sample vial of milk,

collected with sufficient headspace, can be heated in warm water to temperatures greater than 15.5C (60F) to help

intensify the odor. After warming the sample, place your nose directly at the cap when opening to detect off odors.

Rancid defects can often be detected by rubbing a few drops on the back of the hand and smelling for the volatile

components as the milk warms.

Some defects cannot be detected by smell but may become evident when the milk is tasted. Tasting raw milk is not

recommended because of concerns with the potential presence of milk borne pathogens. As a safety precaution, if

raw milk needs to be tasted, it should be lab pasteurized at 63C (145F) for 30 minutes. Defects in the early stages

of development may be difficult to detect. Rancid, oxidized, and bacterial odors/flavors are the result of enzymatic

and/or chemical action that may develop further over time, which is why it is also recommended that processing or

laboratory personnel smell a sample from each raw storage tank prior to processing.

When milk in a farm bulk tank is found to have a strong, objectionable odor, the milk hauler should leave the milk

at the farm and take a sample to the receiving plant for evaluation. Plant management must make a decision about

collecting the milk later. This would apply to similar situations at raw milk receiving in a processing plant.

Temperature

Proper refrigeration of raw milk is required to prevent the growth of microorganisms that may cause defects (i.e.,

spoilage) or be of public health concern (i.e., toxins, pathogens). The PMO prohibits the acceptance of Grade A

raw milk that is above 7C (45F). According to the PMO, milk at the farm must be Cooled to 10q C (50qF) or less

within four (4) hours or less, of the commencement of the first milking, and to 7C (45F) or less within two (2)

hours after the completion of milking. Provided, that the blend temperature after the first milking and subsequent

milkings does not exceed 10C (50F). From a milk quality standpoint, it is highly recommended that milk be

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

5

cooled to 4.4C (40 F) or below within 30 minutes of milking, with blend temperatures not to exceed 7C (45F).

Ideally, milk should be kept between 1.1C and 4.4C (34qF 38F) during all phases of storage. An interval timer,

required by some states, to agitate the milk for five minutes every hour is strongly recommended to help ensure

uniform cooling.

For all bulk tanks manufactured after January 1, 2000, a recording thermometer is required to show the temperature

history of the milk. In some states a recording thermometer is required to monitor temperature if automatic

refrigeration controls are not present or if the storage tank is not refrigerated.

Before raw milk is loaded on a milk truck, the temperature of the milk must be checked using a pocket thermometer

that is calibrated against a standard thermometer at least every six months (i.e., in an ice and water mixture). A

properly calibrated digital thermometer may also be used. Do not rely on the milk tank thermometer unless it is

certified as accurate. The PMO requires that tanker loads of milk with temperatures above 7C (45F) must not be

accepted at plants. To ensure proper delivery temperature, it is recommended that milk at the farm not be collected

if the temperature is above 4.4C (40F).

Collecting and Handling Samples

Milk haulers are required to collect a representative universal sample at each farm when milk is picked up. Raw

milk quality standards assume that test results are representative of the entire raw supply collected. A valid testing

program must ensure that samples are taken and cared for properly from initial collection until analyzed in the

laboratory. Proper sample collection, identification and handling will ensure that the sample taken represents the

load of milk collected, properly reflecting its quality and the conditions of milk production on the farm.

Samples must be taken under aseptic conditions and held between 0.0qC 4.4C (32qF - 40F), without freezing,

until used. Samples are required to be collected in clean, dry, sterile containers, using a sterile or sanitized sampling

device (i.e., sterile straw or sanitized dipper). Single-service plastic sample vials containing less than 1 organism per

ml of capacity are acceptable and most commonly used. Care must be taken not to contaminate the inside of the

sample container, the collection device or the sample itself. Each sample container must be clearly identified with a

waterproof label or mark.

Dippers carried in a sanitizer solution are typically used for collecting samples. The sanitizer solution must be of

the proper strength, and the container must be taken into the milkhouse. When taking a sample, the dipper must be

drained completely of sanitizer, then dipped in the milk and drained at least two times before taking the sample for

testing. This will avoid water contamination of the sample. Sample vials generally have fill lines, but should not be

filled to greater than 3/4 capacity. When sampling is complete, the dipper must be rinsed thoroughly before being

returned to the sanitizer solution. Similar procedures are used when milk is received at the processing plant.

Once the sample is collected at the farm, it must be immediately placed in an ice and water mixture in an insulated

case for transportation (i.e., stored in the trucks back compartment). During collection and transportation, samples

must be suspended with the ice water level only slightly higher than the level of milk in the sample containers to

prevent contamination of the sample. Racks or floaters should be used to hold sample vials in the ice water.

Refrigeration packs in water may also be used provided they maintain the samples at 0.0qC 4.4C (32qF 40F).

An extra sample must be collected at the first stop of each load, identified, and used as a temperature control. Each

rack of samples must be identified, and the date and time of collection recorded. Temperature at the time of

shipment and receipt (i.e., check temperature control) must be shown. On arrival to the lab, all samples must be

stored under refrigeration, maintained at 0.0qC 4.4C (32qF 40F). Tank truck samples collected at receiving are

generally tested immediately (i.e., drug residues) or placed in a laboratory refrigerator.

For more detailed information on proper milk collection and sampling procedures and requirements, see DPC

Guideline 50, Farm Bulk Milk Collection Procedures, DPC Guideline 7, Guidelines for Sampling Fluid Milk or

Appendix B of the PMO.

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

6

LABORATORYTESTINGPROCEDURES

Following are overviews of a number of laboratory tests that are used to evaluate the quality of raw milk. These

procedures require access to a well-equipped laboratory and trained, competent laboratory technicians. While it is

required that some of the listed testing procedures (Standard Plate Counts (SPC), Direct Microscopic Somatic Cell

Counts (DMSCC), and drug residue testing) be performed on a regular basis (i.e., PMO and State regulations), it is

recommended that more extensive and more frequent quality monitoring be done. If testing is reduced or eliminated,

there is the potential for quality to decline. The general quality tests available include the microbiological tests,

somatic cell counts, and tests for adulteration or contamination.

Microbiological Tests

Bacteria and other microorganisms in milk are of primary concern as they are most often responsible for the

deterioration of milk and dairy product quality. Also of concern is the potential presence of pathogens in the raw

milk supply. When the numbers of microorganism in raw milk are found to be high, they are generally an

indication of poor production practices and/or milk handling procedures. Because raw milk can be stored for

several days before processing, it is critical that levels of contamination be kept at a minimum, as spoilage bacteria

have the potential to grow during storage prior to pasteurization. Heat resistant enzymes, produced by certain

microorganisms during growth in raw milk, may continue to be active even after the milk is heat processed and the

organisms are destroyed.

Microbial contamination of raw milk can occur by a variety of microorganisms; from a variety of sources, including

inadequate cleaning, sanitizing and maintenance of milk handling equipment; poor pre-milking hygiene procedures;

insufficient refrigeration; and in some cases mastitis. Because of this, determining the cause of bacterial defects is

not always clear and straightforward. While high bacteria counts can result from one source, they often are the

result of a combination of factors (i.e., dirty equipment and marginal cooling).

The standard procedure for enumerating bacteria in milk is called the Standard Plate Count (SPC), which along with

modifications of the procedure, is the only PMO required bacteria test for raw milk. In addition to the SPC, a

number of other testing procedures may be used to evaluate the microbiological quality of raw milk, providing

additional insight to farm practices. Alternative tests commonly used include the Preliminary Incubation Count

(PIC), the Laboratory Pasteurization Count (LPC), the Coliform Bacteria Count and specific culturing methods.

These tests generally select for bacteria that occur as contaminants that are not considered to be the natural flora in

the animals milk. Generally, elevated counts using any of these procedures would suggest that production practices

and hygiene procedures on the farm are in need of improvement. A rapid method using the microscope (Direct

Microscopic Count) is also routinely used, especially for screening incoming milk loads. An overview of these

procedures follows:

Standard Plate Count (SPC)

The Standard Plate Count (SPC) is a determination of the number of colony forming units (cfu) in one milliliter

(ml) of milk, which will form visible colonies when incubated for 48 hours at 32C (90F). Raw milk is generally

diluted 1:100 and 1:1000 before mixing the sample in a plate (i.e., petri dish) with a nutrient agar that promotes

bacterial growth, where individual bacteria or bacterial clumps suspended in the agar multiply to form visible

colony forming units (cfus). The cfus are then visually counted on the plate. Diluting the sample allows for

easier, more accurate counting. The Petrifilm Aerobic Count (PAC), a dehydrated plating system, is equivalent to

the SPC procedure, again incubating for 48 hours at 32C (90F). While the SPC procedure requires two dilutions,

the Plate Loop Count (PLC) as used with SPC or PAC is an acceptable alternative method, delivering a calibrated

0.001 ml or a 1:1000 dilution to be mixed with the SPC agar or deposited on a PAC plate using the same time and

temperature of incubation.

Specific requirements are set forth in Sections 6 and 7 of the PMO regarding sampling and testing of raw milk for

regulatory compliance. Most states require at least one such sample and analysis each month. Some cooperative,

dealer and state quality control programs provide for twice a month or more frequent testing. The regulatory limit

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

7

for SPC for producer raw milk is 100,000 cfu/ml while for commingled raw milk (i.e., tank-trucks) it is 300,000

cfu/ml. Recommended industry standards are generally 50,000/ml or lower.

The SPC gives an overall indication of the total bacteria present in a milk sample. When sanitation is good and

cooling is adequate, bacteria counts of fresh producer samples are often less than 5,000/ml, and generally represent

the natural flora of the animals milk and minor levels of contamination. Under ideal conditions, counts can be less

than 1,000/ml. Many dairy companies offer quality premiums for SPCs of less than 10,000/ml, which should be

easily achievable for most farms. Counts in excess of 10,000 cfu/ml indicate that improvements in production

and/or milk-handling practices are warranted.

In some cases, low SPC values do not correlate well with the actual sanitation conditions on farms. Prompt cooling

of milk and other procedures may yield low counts, disguising unclean milking equipment or poor production

practices. Several additional tests that give insight to production conditions have been recommended and are

routinely used in the dairy industry. These include the Preliminary Incubation Count (PIC), the Laboratory

Pasteurization Count (LPC), and the Coliform Bacteria Count. More selective culturing procedures have also been

found to be a useful tool, especially when mastitis is suspected as a source of high bacteria counts.

Preliminary Incubation Counts (PIC)

The Preliminary Incubation count (PIC) is performed by incubating a milk sample at 12.8C (55F) for 18 hours,

followed by the SPC procedure. This incubation temperature selects for bacterial contaminants in a sample that are

capable of growth at cool temperatures, and is based on the theory that the natural flora of the animals milk and

most mastitis bacteria generally will not grow significantly at the PI temperature in 18 hours. The PIC should

always be compared to a fresh SPC, and PIC results should be less than 3-4x the SPC. Desirable results are

25,000/ml or less. There is no legal limit, although values of 25,000 to 50,000/ml are often used as targets when the

test is used in premium programs. When the PIC is high compared to the fresh SPC, poor production practices, such

as inadequate cleaning; omitted sanitization; poor udder washing procedures; or marginal cooling are indicated.

The bacteria that are most often associated with high PICs are generally psychrotrophic in nature, that is, they are

capable of growing at refrigeration temperatures (7.2C/45F or less). Psychrotrophic Bacteria Counts can be

determined directly by plating samples by the same methodology as for the SPC but with incubation of the plates at

7C for 10 days. A rapid, modified psychrotrophic count may also be made by following the same plating

technique, but with the incubation at 21 C (70F) for 25 hours (48 hours with Petrifilm). The most common

psychrotrophic bacteria are capable of growing and increasing in numbers during prolonged refrigerated storage of

raw milk, especially if temperatures are marginal. Generally, these bacteria do not survive pasteurization, but they

may produce heat stabile enzymes that may degrade dairy product quality.

Thermoduric Bacteria or Laboratory Pasteurization Count (LPC)

The Laboratory Pasteurization Count (LPC) is performed by heating the milk sample to 62.8C (145F) for 30

minutes (simulates batch pasteurization) followed by the SPC procedure. Samples are usually diluted 1:10 or 1:100

prior to plating. This procedure counts those bacteria that survive pasteurization. Although the SPC limit for

pasteurized milk is 20,000/ml, there are no legal standards for thermoduric bacteria in raw milk. Levels in raw milk

following laboratory pasteurization, and in pasteurized milk should be less than 250-300/ml. The natural flora of

the animals milk and most mastitis bacteria generally do not survive pasteurization. Excessive LPC values have

been associated with dirty equipment (especially areas that are persistently neglected in cleaning or often left

insufficiently cleaned), old rubber parts, and poor pre-milking hygiene procedures. Generally, thermoduric bacteria

do not grow or grow very slowly at proper refrigeration temperatures of 4.4 C (40F) or less, although they may

limit the extension of pasteurized milk shelf-life, especially if the milk is held at marginal refrigeration (i.e., 7.2C

or 45F).

Coliform Bacteria Count

The Coliform Bacteria Count is performed by plating the sample on Violet Red Bile Agar (VRBA), which is a

microbial growth medium that selects for coliform bacteria (i.e., it contains inhibitors that prevent most other

bacteria from growing). Incubation is at 32 C (90F) for 24 hours. Coliforms are associated with fecal and/or

environmental contamination. Counts in raw milk produced under good production methods should be less than 50-

100/ml, while counts of less than 25 should be easily obtainable. There are no legal limits for coliform bacteria

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

8

counts for raw milk as defined under the PMO, although some states may have standards, especially if the milk is

allowed to be sold for raw consumption (i.e., < 10/ml). Coliform organisms may comprise the dominant flora on the

SPC, causing it to exceed 100,000/ml. This test may be used as an indication of production methods, since

excessive levels have been associated with poor pre-milking hygiene, dropped milking units, dirty equipment, and,

in some cases, with coliform mastitis.

Coliform counts are commonly used to check for contamination following thermal processing of pasteurized milk

and dairy products. This group of bacteria does not survive pasteurization. While the legal limit in pasteurized milk

is <10/ml, their presence at any level indicates post-pasteurization contamination. In pasteurized milk samples,

coliform counts should be made using 1 ml of undiluted sample, plated with VRBA. After the plate solidifies, it

should be overlaid with a second layer of VRBA to inhibit surface colony formation. The Petrifilm coliform count is

an accepted alternative method.

Blood Agar & Culturing Procedures

Blood agar (5% bovine blood, 0.1g/100 ml. of esculin, added to a soy-based agar) and other differential and/or

selective media have long been used in identifying disease-causing organisms in milk. Blood agar and other medias

have also been shown to be useful in identifying the causes of high bacteria counts. Unlike the SPC procedure,

blood agar not only gives a relative count of how many organisms are present, but can be used to characterize

certain organisms based on blood hemolytic reactions, esculin hydrolysis and colony morphology. Knowing the

type of organisms present is useful in identifying the source of problems on the farm (e.g., the source of

Streptococcus agalactia, an organism associated with contagious mastitis that gives characteristic growth on blood

agar, would most likely be an infected animal).

The test is performed by smearing or spreading a measured amount of milk sample over the surface of a blood agar

plate, leaving a thin film, followed by incubation at 37C (98.6F) for 48 hours before being read. Using this agar as

a characterization tool requires experience and a trained eye. For information on organism identification, see the

Laboratory and Field Handbook on Bovine Mastitis produced by the National Mastitis Council (NMC). Also see,

DPC Guideline 24, Guidelines for Troubleshooting On-Farm Bacteria Counts in Raw Milk.

Titratable Acidity (TA) as an Indication of Bacterial Growth

The titratable acidity (TA) test has been used as an indirect method of indicating bacterial growth or possibly acid

contamination. Lactic acid and other acid levels generally are increased in milk as the result of excessive growth of

acid producing bacteria, especially when milk is improperly cooled. The TA of milk is determined using 0.1 N

sodium hydroxide and is expressed as the amount of lactic acid in milk. Normal titratable acidities range from

0.13% to 0.17%. This acidity comes from the normal constituents of the milk and is directly related to the solids

content of the milk. Milk that is high in solids will have a high titratable acidity, and may exceed the normal range.

Before rejecting milk based on the TA test, it is important that laboratories establish the normal acidity for each of

their milk supplies. If the acidity is above what is considered normal, a direct microscopic count should be

performed along with flavor and odor checks to determine the status of the milk. Generally, milk with a titratable

acidity of 0.20% or less is acceptable, unless other test results indicate otherwise. Also, it should be noted that it is

possible for milk to have odor, flavor and bacterial problems yet have the TA within the normal range.

Direct Microscopic Methods

The Direct Microscopic Clump Count (DMCC) and the Direct Microscopic Somatic Cell Count (DMSCC) are

determined by counting bacterial or somatic cells (following procedures set forth in Standard Methods for the

Examination of Dairy Products) in a representative portion of 0.01 ml of milk smeared over 1 square centimeter,

using a microscope of 1000x magnification. The milk smears are stained with a special milk stain, Levowitz-Weber

mod. Newman-Lampert (LW/NL Tetrachlorethane or LW/NL Xylene) Stain or the Canadian modification

(LW/NL F) to facilitate counting of bacteria and somatic cells. Estimated counts are determined by using a

microscopic factor based on the field of view of the microscope.

Direct Microscopic Clump Count (DMCC)

Although the sensitivity of the DMCC test is limited, it can be performed in less than 15 minutes. This test is

routinely used to screen incoming milk supplies at dairy plants and can easily mark loads that are approaching the

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

9

legal commingled limit of 300,000/ml. The test has also been used to rapidly identify individual producers with

high counts and can sometimes lend insight into potential causes of bacterial problems based on bacterial shapes

and configurations (i.e., pairs or chains of cocci may indicate cooling or sanitation problems). A DMCC should be

performed regularly on samples from all loads of raw milk when received. For more information on bacteria in raw

milk, see DPC Guideline 24, Troubleshooting On-Farm Bacteria Counts in Raw Milk.

Direct Microscopic Somatic Cell Count (DMSCC) and Abnormal Milk

Milk normally contains leucocytes (white blood cells) and other body tissue cells, collectively known as somatic

cells. Somatic cells counts (SCC) may increase naturally during late lactation or due to aging, but most significant

increases are the result of some form of udder infection (mastitis) or injury where somatic cells infiltrate the milk in

the udder as part of the animals immune response. Milk is considered abnormal when the number of somatic

cells is excessive. While the legal limit under the PMO is 750,000 SCC/ml, counts in excess of 200,000 -

300,000/ml are considered to be above the level expected in a healthy herd. High numbers of somatic cells in bulk

milk suggest mastitis problems in a herd and may result in products of lower quality and yield. Premiums are often

paid for milk with counts less than 200,000/ml.

Official determinations of SCC and abnormal milk are based on the DMSCC procedure or on results from one of

several approved automated procedures. The National Mastitis Council (NMC) recognizes several rapid "screening"

tests as valid procedures to estimate SCC in raw milk, though these are not considered official regulatory tests.

Because goats have a different physiology than cows, a special stain (Pyronin Y-Methyl Green) and DMSCC

procedure is required to be used to determine the number of cells in milk from dairy goats when automated

screening tests exceed the 1,000,000 SCC /ml limit. For sheep, the same methods and limits as used for cows

currently apply, although the validity of these requirements is in the process of being studied.

For help in correcting abnormal milk situations, see DPC Guideline 18, Fieldpersons Guide to High Somatic Cell

Counts, DPC Guideline 72, Farmers Guide to Somatic Cell Counts in Goats, and DPC Guideline 71, Farmers

Guide to Somatic Cell Counts in Sheep.

Other Measures Of Adulteration Or Contamination

Drug Residues, Antibiotics and Growth Inhibitors

Dairy animals are occasionally treated with antibiotics and other drugs to help cure or prevent certain diseases,

including mastitis. If drugs are not administered properly or if the milk from treated animals is not withheld from

the bulk tank for sufficient time, the potential for contaminating the milk supply exists. Drug residues, antibiotics

and other microbial growth inhibitors found in milk samples have been defined as adulterants and thus are subject to

penalty under existing law. Violators may be required to pay for milk loss, and may be subject to potential loss of

market for stated periods, fines, or both. Milk found to be contaminated with drug residues cannot be marketed or

purchased and must be disposed of in a manner acceptable to the regulatory agency. Detection of antibiotics or other

growth inhibitors in raw milk and other dairy products is made possible by validated growth inhibitor assays or by

several rapid receptor based screening kits or procedures. Acceptable methods have been validated and approved

by FDA and are listed in the most recent update of an FDA memorandum (M-a-85). Several available methods

have been used successfully on the farm to prescreen treated animals or suspected contaminated tanks and are

recommended. Under Appendix N of the PMO, it is required that all tank trucks be tested for Beta lactam drug

residues before unloading/processing at receiving stations/plants and that if a load is confirmed positive, producer

trace back testing must be performed. Individual producer samples are also routinely tested under Section 6

guidelines of the PMO.

Abnormal milk and residues of antibiotics and pesticides are illegal in milk from either goats or cows. Of

immediate concern is the fact that few of the antibiotics approved for use in milking cows have been tested and

approved for treating goats. There are now rapid antibiotic tests available that have been tested using goat milk.

Contact your local regulatory agency or milk handler for a current list of the approved tests.

DPC Guideline 22, Control of Antibiotics and Growth Inhibitors in Milk and Milk Products, has been prepared to

outline procedures for the detection of antibiotics and growth inhibitors in milk and other dairy products. Other

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

10

useful references include Appendix N of the PMO and pertinent memorandums and updates issued by the FDA

(available at http://www.cfsan.fda.gov/~ear/prime.html).

Added Water and Milk Freezing Point

Water added to milk, either at the farm, in transit or at the plant is considered adulteration. Added water dilutes the

solids and the value of the milk, and in some cases may contribute to microbial contamination. This might occur due

to poorly drained milk handling equipment (i.e., pipes, tanks, trucks etc.) or in some cases by intentional addition.

Added water can be detected by determining the milk freezing point (FP), which is considered relatively constant.

The FP is generally determined by commercial milk cryoscope instruments that are found in most dairy

laboratories. Because of the soluble components, such as lactose and salts, normal milk freezes slightly below the

freezing point of pure water. Samples from loads, representing a number of herds, should give values between -

0.540H and -0.550H (H= Hortvet a scale modified from Celsius used almost exclusively for milk FP -

conversion factors may be found in Standard Methods for the Examination of Dairy Products.) Small amounts of

added water dilute the soluble solids in milk causing the freezing point to move upward toward that of water.

Determination of freezing points to detect added water should be made on all loads of milk received at a processing

plant or receiving station.

Although most farm milks will have freezing points of less than 0.540H, factors related to specific herds (i.e.,

nutrition) may result in higher than normal FPs. Natural low-solids milk may have higher freezing points, but in

most cases will not cause a sample to be much above the normal range. Generally, FP readings above the average

for a geographical area suggest that the milk contains some added water. Milk samples having a freezing point

above -0.530H to -0.525H may be considered to be adulterated and thus subject to regulatory action. Where added

water is suspected, a milking time inspection and sample retest are recommended. Start with an empty, well-drained

system and test samples at the end of each milking. This is to ensure that the high FP determination was not the

norm for the tested farm.

For more information on freezing point standards for small ruminant milk contact your local regulatory agency.

Further discussion of added water and acceptable freezing points may be found in DPC Guideline 17, Prevention of

& Testing for Added Water in Milk.

Sediment

Sediment levels in milk provide an indication of milk production practices, and the cleanliness of animals and

surroundings and reflect the amount of soil that might be in the milk. Excessive levels result from dirty animals,

poor pre-milking hygiene procedures and/or milking claw slippage. Sediment is determined by filtering a portion of

milk by suction through a fine fiber filter. The sediment collected on the filter is compared to visual standards with

results reported in milligrams (mg) per gallon. This test is required for manufactured milk and by some states for

fluid milk. Levels should be less than 1.0 mg per gallon of milk, although levels less than 1.50 mg may be accepted.

A complete discussion of testing procedures and a list of recommended practices can be found in DPC Guideline

11, Sediment Testing and Producing Clean Milk.

Pesticides and Chemical Contaminants

It is required that raw and pasteurized milk be free (i.e., below detection or established safe levels) of adulterants,

including pesticides and other chemical contaminants. Adulteration of this nature has been rare and testing is done

infrequently with the exception of routine pesticide testing done by state and federal laboratories. Most dairy labs

are not equipped to run these types of tests. Testing for chemical contaminants in milk may be increased if

warranted (i.e., contaminated feed discovered) or if contamination is suspected. In these situations, it is

recommended that producers notify the regulatory authority as soon as possible, as consequences can be wide

spread. Procedures outlined in the latest edition of Official Methods of Analysis of the Association of Official

Analytical Chemists (AOAC International) should be followed.

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

11

SUMMARY

High quality raw milk is required for high quality dairy products. Therefore, it is imperative that raw milk be

produced and handled, from farm to plant, under conditions that do not alter its quality or consequently, the quality

of the finished product. A number of quality tests are available to evaluate raw milk that include microbiological,

chemical and physical testing methods. This document described how to interpret the results of these tests and the

practical implications of these quality parameters. Specific procedures for most of these tests can be found in the

latest edition of Standard Methods for the Examination of Dairy Products and other referenced documents. This

document also lays the groundwork for a number of other DPC Guidelines that give more detailed information on

the specific milk quality areas covered.

REFERENCES

The references below were used to develop this guideline. Some of these are routinely updated and revised and the

reader is referred to the most recent updates:

FDA Prime Connection (FDA Memorandums, etc) at http://www.cfsan.fda.gov/~ear/prime.html

Grade A Pasteurized Milk Ordinance, US Department of Health & Human Services, Public Health Service, Food

& Drug Administration.

Laboratory and Field Handbook on Bovine Mastitis, 1999. National Mastitis Council. Madison WI.

Standard Methods for the Examination of Dairy Products, 16

th

Edition. 1992. American Public Health Association,

Washington D.C.

Trouble-shooting sources and causes of high bacteria counts in raw milk. 2000. S. C. Murphy & K. J. Boor. Dairy

Food & Environmental Sanitation 20:606-611.

Official Methods of Analysis of the Association of Official Analytical Chemists, AOAC, International, Gaithersburg,

MD, www.aoac.org

THE DAIRY PRACTICES COUNCIL

DPC 21, April 2003

Vous aimerez peut-être aussi

- Tecnia Institute of Advanced Studies: Business PlanDocument21 pagesTecnia Institute of Advanced Studies: Business Plantajinder kaurPas encore d'évaluation

- Chemical Composition and Legal Standards of Dairy Products 0.2Document23 pagesChemical Composition and Legal Standards of Dairy Products 0.2shraddha dubeyPas encore d'évaluation

- Waste Water Disposal and Pollution Control in DairyDocument14 pagesWaste Water Disposal and Pollution Control in Dairy19 CH 056 Vaishali Vivek100% (1)

- Smart DustbinDocument24 pagesSmart Dustbinhamed raza100% (1)

- Biruk AsnakeDocument25 pagesBiruk AsnakeBiruk AsnakePas encore d'évaluation

- Project Topics and Materials in Food Science and TechnologyDocument44 pagesProject Topics and Materials in Food Science and TechnologyGrace OparaPas encore d'évaluation

- Laboratory Manual FOT440 Traditional and Value Added Dairy ProductsDocument7 pagesLaboratory Manual FOT440 Traditional and Value Added Dairy ProductsVeeraprasad CGPas encore d'évaluation

- Dairy On Brand PositioningDocument64 pagesDairy On Brand PositioningRK FeaturesPas encore d'évaluation

- Course - CHEESE TECHNOLOGYDocument5 pagesCourse - CHEESE TECHNOLOGYAmit Kr GodaraPas encore d'évaluation

- Packaging For Beverages: Beverage Technology Soegijapranata Catholic UniversityDocument15 pagesPackaging For Beverages: Beverage Technology Soegijapranata Catholic UniversityMaura Yosefina MartanPas encore d'évaluation

- Amul MilkDocument81 pagesAmul MilkRavi SharmaPas encore d'évaluation

- Microbiology of Khoa and Khoa Based ProductsDocument9 pagesMicrobiology of Khoa and Khoa Based Productsshraddha dubeyPas encore d'évaluation

- Milk Fermented Products 2013Document16 pagesMilk Fermented Products 2013Miguel RivasPas encore d'évaluation

- Inplant Training Report-Coke2009Document80 pagesInplant Training Report-Coke2009patkiprashantPas encore d'évaluation

- 2015 Extrusion Extruded Products Changes Quality Attributes Affected Extrusion ProcessDocument110 pages2015 Extrusion Extruded Products Changes Quality Attributes Affected Extrusion Processalcy renePas encore d'évaluation

- ParleDocument56 pagesParlenamrocks0% (2)

- BAKERYDocument21 pagesBAKERYVishwas SMPas encore d'évaluation

- Milk Production PlantDocument3 pagesMilk Production PlantMie DtsPas encore d'évaluation

- Juice Manufacturing Industry Research ReportDocument26 pagesJuice Manufacturing Industry Research ReportCAKRBPas encore d'évaluation

- Gulkand Flavoured Milk...Document51 pagesGulkand Flavoured Milk...Rahul RathodPas encore d'évaluation

- FAST FOOD Automation Project On C++Document50 pagesFAST FOOD Automation Project On C++Ankit KumarPas encore d'évaluation

- Mohan Meakin ProjectDocument78 pagesMohan Meakin ProjectAmar Goel50% (2)

- Soyaben ProjectDocument66 pagesSoyaben ProjectAmeshe Moges100% (1)

- Cereals and Legume TechnologyDocument23 pagesCereals and Legume TechnologyLê Tất TiếnPas encore d'évaluation

- Thesis NidhiDocument44 pagesThesis NidhiMrityunjay KumarPas encore d'évaluation

- Moreish Presentation 2019Document25 pagesMoreish Presentation 2019Gulfam AnsariPas encore d'évaluation

- Breast Feeding: Meal PlanDocument17 pagesBreast Feeding: Meal PlanBruno Adas FernandesPas encore d'évaluation

- Industrial Visit OxyrichDocument17 pagesIndustrial Visit OxyrichAnu Alreja67% (3)

- "Marketing Survey ND Research": A Summer Traning Project ONDocument86 pages"Marketing Survey ND Research": A Summer Traning Project ONAnonymous V9E1ZJtwoEPas encore d'évaluation

- A Summer Field Training ReportDocument17 pagesA Summer Field Training ReportAshishJaat33% (3)

- Final PPT CADocument90 pagesFinal PPT CAFatma M. BarakatPas encore d'évaluation

- Technologies of Millet Value Added ProductsDocument50 pagesTechnologies of Millet Value Added ProductsblackvenumPas encore d'évaluation

- Tomato Paste and Fruit PulpDocument26 pagesTomato Paste and Fruit Pulppradip_kumarPas encore d'évaluation

- Introduction To Food AdditivesDocument8 pagesIntroduction To Food AdditivesDavid UribePas encore d'évaluation

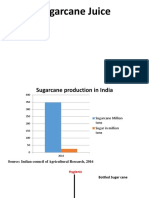

- Sugar Cane ProductionDocument12 pagesSugar Cane ProductionMans SGPas encore d'évaluation

- Dairy DevelopmentDocument30 pagesDairy DevelopmentArun Kumar PalanisamyPas encore d'évaluation

- My Project New EditDocument38 pagesMy Project New Editmuhammad m butuPas encore d'évaluation

- Sensory Perception of Fat in MilkDocument10 pagesSensory Perception of Fat in MilkCostaEdvaldoPas encore d'évaluation

- Baby Diaper English PDFDocument10 pagesBaby Diaper English PDFPriya DarshiniPas encore d'évaluation

- Final ProjetcDocument38 pagesFinal ProjetcMahes100% (2)

- A Summer Training Report On Cramic TileDocument25 pagesA Summer Training Report On Cramic TileVivek Arya0% (1)

- Industrial Applications of Enzymes: CarbohydratesDocument22 pagesIndustrial Applications of Enzymes: CarbohydratesH.J.PrabhuPas encore d'évaluation

- Pakistan Feedstuffs Database 2020 - Final-1Document40 pagesPakistan Feedstuffs Database 2020 - Final-1Jawad JamilPas encore d'évaluation

- Thesis On New Trends in Internet Marketing - 299522304 PDFDocument63 pagesThesis On New Trends in Internet Marketing - 299522304 PDFRUTURAJ DASPas encore d'évaluation

- Food TechnologyDocument41 pagesFood Technologydynav100% (2)

- Role of Sugar, Gur, Liquid SweetnersDocument10 pagesRole of Sugar, Gur, Liquid SweetnersBharath Jaganathan100% (1)

- Good Agricultural Practices For AshwagandhaDocument18 pagesGood Agricultural Practices For AshwagandhaAmol RautPas encore d'évaluation

- International School of Business & Media: Financial Statement AnalysisDocument4 pagesInternational School of Business & Media: Financial Statement AnalysisDeekshaAjeyPas encore d'évaluation

- Micro Organisms in Milk 280Document11 pagesMicro Organisms in Milk 280kirti1111Pas encore d'évaluation

- Smart Washing Brush ReportDocument34 pagesSmart Washing Brush ReportabhiPas encore d'évaluation

- Project Report On Travel and Tourism in Travel AgencyDocument25 pagesProject Report On Travel and Tourism in Travel AgencyMazhar HassanPas encore d'évaluation

- Food ScienceDocument163 pagesFood ScienceAnand SinghPas encore d'évaluation

- Quality Assurance for Animal Feed Analysis LaboratoriesD'EverandQuality Assurance for Animal Feed Analysis LaboratoriesPas encore d'évaluation

- Molecular Microbial Diagnostic Methods: Pathways to Implementation for the Food and Water IndustriesD'EverandMolecular Microbial Diagnostic Methods: Pathways to Implementation for the Food and Water IndustriesPas encore d'évaluation

- Handbook of Microbiological Criteria for FoodsD'EverandHandbook of Microbiological Criteria for FoodsPas encore d'évaluation

- Application of Sampling and Detection Methods in Agricultural Plant BiotechnologyD'EverandApplication of Sampling and Detection Methods in Agricultural Plant BiotechnologyRay ShillitoPas encore d'évaluation

- How to Integrate Quality by Efficient Design (QbED) in Product DevelopmentD'EverandHow to Integrate Quality by Efficient Design (QbED) in Product DevelopmentPas encore d'évaluation

- Food Protection and Security: Preventing and Mitigating Contamination during Food Processing and ProductionD'EverandFood Protection and Security: Preventing and Mitigating Contamination during Food Processing and ProductionShaun KennedyPas encore d'évaluation

- Techniques for Downstream process for Biologic Drugs and VaccinesD'EverandTechniques for Downstream process for Biologic Drugs and VaccinesPas encore d'évaluation

- Quality Solutions: ISO 9001: 2015 Quality Management SystemDocument9 pagesQuality Solutions: ISO 9001: 2015 Quality Management SystemOsman AitaPas encore d'évaluation

- Running 400Document12 pagesRunning 400Osman AitaPas encore d'évaluation

- Food Safe Multi Choice QuestionsDocument2 pagesFood Safe Multi Choice QuestionsOsman Aita88% (17)

- CXS 192eDocument500 pagesCXS 192eOsman AitaPas encore d'évaluation

- CAMEMBERT Cheese ProductionDocument12 pagesCAMEMBERT Cheese ProductionOsman Aita0% (1)

- الجبن المطبوخDocument12 pagesالجبن المطبوخOsman Aita100% (1)

- Quality A in NSG 1Document47 pagesQuality A in NSG 1Rakersh PatidarPas encore d'évaluation

- Laboratory Assessment WorksheetDocument28 pagesLaboratory Assessment WorksheetOsman AitaPas encore d'évaluation

- BT Processed CheeseDocument16 pagesBT Processed CheeseOsman AitaPas encore d'évaluation

- Pasteurized Processed American Cheese SpreadDocument1 pagePasteurized Processed American Cheese SpreadOsman AitaPas encore d'évaluation

- Whey - A By-Product of The Dairy IndustryDocument31 pagesWhey - A By-Product of The Dairy IndustryOsman AitaPas encore d'évaluation

- CheeseDocument8 pagesCheeseAurora PuertaPas encore d'évaluation

- Pnadf185 USAIDDocument54 pagesPnadf185 USAIDOsman AitaPas encore d'évaluation

- YogurtDocument9 pagesYogurtOsman AitaPas encore d'évaluation

- Cde Handbook Dairy FoodsDocument5 pagesCde Handbook Dairy FoodsOsman AitaPas encore d'évaluation

- Ecoli Pour PlateDocument17 pagesEcoli Pour PlateOsman AitaPas encore d'évaluation

- Metrological Traceability Eurachem39Document2 pagesMetrological Traceability Eurachem39Osman AitaPas encore d'évaluation

- Strengthening Food Safety LaboratoriesDocument20 pagesStrengthening Food Safety LaboratoriesOsman Aita100% (1)

- Services Cultured ProductsDocument1 pageServices Cultured ProductsOsman AitaPas encore d'évaluation

- Types of Quality ProblemsDocument7 pagesTypes of Quality ProblemsOsman Aita100% (1)

- Cabin Attendant'S Duties: Answer The QuestionsDocument11 pagesCabin Attendant'S Duties: Answer The QuestionsОксана ПаськоPas encore d'évaluation

- Cot 2 - Plating DessertsDocument32 pagesCot 2 - Plating DessertsAngelica CunananPas encore d'évaluation

- Training Report - June 2023Document6 pagesTraining Report - June 2023Hemant RajpootPas encore d'évaluation

- Vladimir Mukhins RecipesDocument5 pagesVladimir Mukhins RecipesPaullo VitorPas encore d'évaluation

- Extension Efforts in Pre and Post Independence EraDocument11 pagesExtension Efforts in Pre and Post Independence EravignanbaratamPas encore d'évaluation

- Delhi Shimla Manali Delhi 5n6d.Document5 pagesDelhi Shimla Manali Delhi 5n6d.Ashree KesarwaniPas encore d'évaluation

- Goto Batangas - Lutong Bahay RecipesDocument4 pagesGoto Batangas - Lutong Bahay RecipesAngel MariePas encore d'évaluation

- Examen Parcial - Semana 4 - ESP - SEGUNDO BLOQUE - VIRTUAL-INGLES GENERAL 2 - (GRUPO B03)Document14 pagesExamen Parcial - Semana 4 - ESP - SEGUNDO BLOQUE - VIRTUAL-INGLES GENERAL 2 - (GRUPO B03)JOHN ESTIVEN SÁNCHEZ PÉREZPas encore d'évaluation

- 1415 - S1 - Food Problem - Unit 2.5&2.6 - AnsDocument7 pages1415 - S1 - Food Problem - Unit 2.5&2.6 - AnsLouisa LauPas encore d'évaluation

- Kantar Worldpanel Dairy Talk: - 8: 3 0 A M - 11:00AM - Sheraton SaigonDocument17 pagesKantar Worldpanel Dairy Talk: - 8: 3 0 A M - 11:00AM - Sheraton SaigonThi TranPas encore d'évaluation

- Brimmer & Heeltap Brunch MenuDocument1 pageBrimmer & Heeltap Brunch MenuMegan HillPas encore d'évaluation

- Week 5 Diet Analysis ProjectDocument2 pagesWeek 5 Diet Analysis Projectapi-253508813100% (1)

- Current State of Nigeria Agriculture and Agribusiness SectorDocument14 pagesCurrent State of Nigeria Agriculture and Agribusiness SectorsenohiPas encore d'évaluation

- 2nd Quarter Performance Task CookeryDocument6 pages2nd Quarter Performance Task CookeryBartclethon L. DelfinPas encore d'évaluation

- Fortified Rice Kernel Manufacturing Industry: (Capacity: 2000kgs Per Hour)Document10 pagesFortified Rice Kernel Manufacturing Industry: (Capacity: 2000kgs Per Hour)kamalPas encore d'évaluation

- Breakfast MenuDocument2 pagesBreakfast MenueatlocalmenusPas encore d'évaluation

- En DellaNonna Menu Ver.1.1 2023Document17 pagesEn DellaNonna Menu Ver.1.1 2023JuanPas encore d'évaluation

- Korean Food Made Easy - Caroline HwangDocument378 pagesKorean Food Made Easy - Caroline HwangNhuQuynhDoPas encore d'évaluation

- Lesson 59 Conversation Between Two Friends Eating Fast FoodDocument4 pagesLesson 59 Conversation Between Two Friends Eating Fast FoodKim Anh100% (1)

- PSMF Diet RecipesDocument34 pagesPSMF Diet Recipesliz100% (2)

- First Periodical Test Tl.e Home EconomicsDocument3 pagesFirst Periodical Test Tl.e Home EconomicsNota Belz95% (93)

- (123doc) - De-Thi-Hoc-Sinh-Gioi-Tieng-Anh-8Document6 pages(123doc) - De-Thi-Hoc-Sinh-Gioi-Tieng-Anh-8Khiêm Trần ThịPas encore d'évaluation

- Home Bawdy: Booty On Phat + Waist On Flat 8 Week Home GuideDocument66 pagesHome Bawdy: Booty On Phat + Waist On Flat 8 Week Home GuideLeena Franklin100% (1)

- Nickel City's Moe's Tavern MenuDocument1 pageNickel City's Moe's Tavern MenuNadia ChaudhuryPas encore d'évaluation

- Top 10 Trends For 2015Document98 pagesTop 10 Trends For 2015PublicaPas encore d'évaluation

- TLE MELCs Grade 7 PDFDocument55 pagesTLE MELCs Grade 7 PDFVincent Emmanuel Salibio40% (5)

- Value Addition of Apple RevisedDocument76 pagesValue Addition of Apple Revisedmunir HussainPas encore d'évaluation

- Unit 5Document38 pagesUnit 5Vy YenPas encore d'évaluation

- Reflection Paper On That Sugar FilmDocument4 pagesReflection Paper On That Sugar FilmMe DiPas encore d'évaluation

- Activity Sheet Quarter 0 MELC 2: Tle-Afa (Food Processing)Document10 pagesActivity Sheet Quarter 0 MELC 2: Tle-Afa (Food Processing)Mari PagxPas encore d'évaluation