Académique Documents

Professionnel Documents

Culture Documents

Introduction to Steam Power Plant Cycles

Transféré par

Laxman Singh Sankhla100%(1)100% ont trouvé ce document utile (1 vote)

2K vues3 pagesSteam power plants generate electricity through a two stage process. In the first stage, coal is combusted in boilers to produce heat energy which is then converted to high-pressure steam. In the second stage, the steam powers turbines connected to generators to produce electrical energy. Steam travels through a turbine train consisting of a high pressure, intermediate pressure, and low pressure turbine in a closed loop water system. Steam power plant cycles operate below or above the critical pressure of water in sub-critical or supercritical modes respectively. Common boiler types include atmospheric fluidized bed, circulating fluidized bed, pulverized fuel, and stoking boilers. Captive power generation in India has increased to meet growing energy demand and reduce reliance on

Description originale:

Titre original

Steam Power Plant Introduction

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSteam power plants generate electricity through a two stage process. In the first stage, coal is combusted in boilers to produce heat energy which is then converted to high-pressure steam. In the second stage, the steam powers turbines connected to generators to produce electrical energy. Steam travels through a turbine train consisting of a high pressure, intermediate pressure, and low pressure turbine in a closed loop water system. Steam power plant cycles operate below or above the critical pressure of water in sub-critical or supercritical modes respectively. Common boiler types include atmospheric fluidized bed, circulating fluidized bed, pulverized fuel, and stoking boilers. Captive power generation in India has increased to meet growing energy demand and reduce reliance on

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

2K vues3 pagesIntroduction to Steam Power Plant Cycles

Transféré par

Laxman Singh SankhlaSteam power plants generate electricity through a two stage process. In the first stage, coal is combusted in boilers to produce heat energy which is then converted to high-pressure steam. In the second stage, the steam powers turbines connected to generators to produce electrical energy. Steam travels through a turbine train consisting of a high pressure, intermediate pressure, and low pressure turbine in a closed loop water system. Steam power plant cycles operate below or above the critical pressure of water in sub-critical or supercritical modes respectively. Common boiler types include atmospheric fluidized bed, circulating fluidized bed, pulverized fuel, and stoking boilers. Captive power generation in India has increased to meet growing energy demand and reduce reliance on

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

MECHANICAL

Introduction of Steam Power Plants

By

Er.Laxman Singh Sankhla

B.E.Mech., Chartered Engineer

Jodhpur, India

Mail ID: laxman9992001@yahoo.co.in

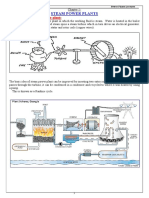

Steam Power Plants

The process of generation of power from steam power plants, utilizing coal or lignite fuel,essentially

entails two stages. In the first stage, the chemical energy stored in the coal isconverted into heat

energy in coal-fired boilers. In the second stage, high-pressure steam,which is generated in the

boilers, is passed through turbines (through conversion of heatenergy into mechanical energy),

which in turn is coupled to generators (through conversion of mechanical energy into electrical

energy), thereby generating electricity. The water steam cycleessentially contains a coal-fired steam

generator, a steam turbine with condenser, a feedwatertank, low-pressure (LP) heaters and high-

pressure (HP) heaters and connecting pipelines.The superheated steam produced in the steam

generator is supplied to the steam turbine,which drives the three-phase AC generator. After leaving

the HP turbine, the steam is reheatedin the steam generator and fed to the intermediate pressure

(IP) turbine. In the LP turbine,the steam coming directly from the IP turbine expands to condenser

pressure and is condensedin the condenser. Closed cycle water system is used for cooling the

condenser. Thecondensation collected in the condenser hot well is discharged by the condensate

pumps andsupplied via the LP condensate heaters into the feedwater tank. The feedwater is

furtherheated by bled steam from turbine and dissolved gases from the feedwater are liberated.

Theboiler feed pumps discharge feed water from the feedwater tank via the HP heaters to

theeconomizer. Steaming starts from this point onwards. The high temperature steam water mix

isfurther converted into steam in water walls and finally passed through the super heaterssections

for converting the saturated steam into superheated steam.

Steam power plant cycles are characterized by the pressure level at which they operate. Sub-critical

cycles use pressures below the critical pressure of water. Typical popular unit sizes of large plants

are in multiples of 125 /135 MW, 250/300 MW, 500 MW or 600 MW. On the otherhand,

supercritical cycles operate above the critical pressure providing higher efficiency. Thesecycles have

varying unit sizes and varying parameters.

Boiler types can be alternatives of various capacity parameters, namely:

Atmospheric Fluidized Bed Combustion type (AFBC);

Circulating Fluidized Bed Combustion type (CFBC);

Pulverized Fuel type (PF); and

Stoking Boilers.

Captive Power Generation in India

Captive power refers to power generation from a project set up for captive industrialconsumption.

Due to the continuing shortage of power and Indias economic growth, there hasbeen an increase in

the requirement for captive power projects in India. As most captive unitsare based on diesel

generator sets, the cost of generation has increased sharply with risingcrude oil and diesel prices.

Vous aimerez peut-être aussi

- Thermal Power Plant ChapterDocument37 pagesThermal Power Plant Chapterfiraol tekaPas encore d'évaluation

- Super Critical Power PlantDocument27 pagesSuper Critical Power PlantPrabir Kumar PatiPas encore d'évaluation

- Final Mini Project ReportDocument30 pagesFinal Mini Project ReportRatheesh SPas encore d'évaluation

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshPas encore d'évaluation

- Mechanical Engg.: Report On Industrial TrainingDocument44 pagesMechanical Engg.: Report On Industrial TrainingSakshi SanghiPas encore d'évaluation

- Draft SystemDocument28 pagesDraft SystemLofi RadioPas encore d'évaluation

- 2 ERG 401 2015 Energy Performance Analysis of BOILERDocument57 pages2 ERG 401 2015 Energy Performance Analysis of BOILERnaveenPas encore d'évaluation

- BOILER PERFORMANCE TESTSDocument3 pagesBOILER PERFORMANCE TESTSSubbarayan SaravanakumarPas encore d'évaluation

- Powr PlantDocument10 pagesPowr PlantSajjad Ibraheem100% (1)

- IEEE BoilerDocument9 pagesIEEE Boiler4nagPas encore d'évaluation

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpPas encore d'évaluation

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul KediaPas encore d'évaluation

- Vapor Power CyclesDocument51 pagesVapor Power Cyclesفضائح لا تصدق100% (1)

- TPP Overview: Thermal Power Plant BasicsDocument35 pagesTPP Overview: Thermal Power Plant BasicsMansoor Chowdhury100% (1)

- Rankine Regenerative CycleDocument4 pagesRankine Regenerative CyclePhúc BạchPas encore d'évaluation

- Fluid Mechanics AMIEDocument17 pagesFluid Mechanics AMIEsayhigaurav07Pas encore d'évaluation

- Vapour Power CycleDocument65 pagesVapour Power CycleRajan GoyalPas encore d'évaluation

- Calculating PHR and Boiler LossesDocument13 pagesCalculating PHR and Boiler LossesSiddhant SatpathyPas encore d'évaluation

- Steam Power Plant Thermal EfficiencyDocument47 pagesSteam Power Plant Thermal EfficiencyMahtab IlyasPas encore d'évaluation

- Introduction to 500 MW Once Through Boiler DesignDocument18 pagesIntroduction to 500 MW Once Through Boiler DesignAlok Ranjan TripathiPas encore d'évaluation

- 100 TOP POWER PLANT Engineering Questions and Answers PDFDocument3 pages100 TOP POWER PLANT Engineering Questions and Answers PDFEarl Jenn AbellaPas encore d'évaluation

- Boiler and Its AuxilliariesDocument22 pagesBoiler and Its Auxilliariesabhijit.adgube3376Pas encore d'évaluation

- Refrigerant Leakage and Its DetectionDocument8 pagesRefrigerant Leakage and Its DetectionDeepak0% (1)

- Report On Jamshoro Thermal Power PlantDocument24 pagesReport On Jamshoro Thermal Power PlantSuresh Kumar100% (2)

- Thermal Power StatonDocument15 pagesThermal Power StatonShiv ashish sharmaPas encore d'évaluation

- Calculation of Coal Requirement in Steam PlantDocument3 pagesCalculation of Coal Requirement in Steam PlantRavindra K BelapurkarPas encore d'évaluation

- Thermal power plant economiser guideDocument7 pagesThermal power plant economiser guideSteve M D'souzaPas encore d'évaluation

- Boilers of Thermal Power PlantsDocument150 pagesBoilers of Thermal Power PlantsanasawaisPas encore d'évaluation

- Starting Up The Power Station SimulatorDocument7 pagesStarting Up The Power Station SimulatoraajilPas encore d'évaluation

- Summer Training Report On NTPC Tanda Ambedkar NagarDocument9 pagesSummer Training Report On NTPC Tanda Ambedkar NagarNaman ShahPas encore d'évaluation

- TPP Steel PlantDocument25 pagesTPP Steel PlantPRASANTHPas encore d'évaluation

- Test On Vapor Compression Refrigeration FINALDocument8 pagesTest On Vapor Compression Refrigeration FINALUdara ManawaduPas encore d'évaluation

- Experiment No.6 Stefan Boltzmann'S Apparatus: Heat Transfer Laboratory (MECH3123)Document6 pagesExperiment No.6 Stefan Boltzmann'S Apparatus: Heat Transfer Laboratory (MECH3123)Raj PratyushPas encore d'évaluation

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument17 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamHumayun Rashid KhanPas encore d'évaluation

- Complete NTPC ReportDocument111 pagesComplete NTPC ReportSunil Kumar SinghPas encore d'évaluation

- Design and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaDocument4 pagesDesign and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaKvvPrasadPas encore d'évaluation

- Pumps in Steam Power PlantsDocument51 pagesPumps in Steam Power Plantssen_subhasis_58Pas encore d'évaluation

- Gas Power Cycles Sivakumar.E VITDocument47 pagesGas Power Cycles Sivakumar.E VITmohan govindasamyPas encore d'évaluation

- Power Plant and Calculations - Steam TurbineDocument16 pagesPower Plant and Calculations - Steam TurbineSIPL CPPPas encore d'évaluation

- Regenerative Rankine CycleDocument2 pagesRegenerative Rankine CycleRowin Mark SabornidoPas encore d'évaluation

- 04-Binary Vapour Cycle and Co-GenerationDocument9 pages04-Binary Vapour Cycle and Co-GenerationMohtasin SheikhPas encore d'évaluation

- Boost Boiler Efficiency With An Air PreheaterDocument26 pagesBoost Boiler Efficiency With An Air Preheaterkowsar0221Pas encore d'évaluation

- Condenser PPT 2Document51 pagesCondenser PPT 2Neil John CatapangPas encore d'évaluation

- Tata Chemicals Limited Mithapur 1 x 200 TPH CFBC Boiler Logic SystemDocument26 pagesTata Chemicals Limited Mithapur 1 x 200 TPH CFBC Boiler Logic Systemraveekas6148Pas encore d'évaluation

- Vapor and Combined Power Cycles: TopicsDocument52 pagesVapor and Combined Power Cycles: TopicsAshlin Augusty100% (1)

- Industrial Training Report-IPGCL& PPCLDocument92 pagesIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Shell and Tube Heat ExchangerDocument12 pagesShell and Tube Heat ExchangerZi ChingPas encore d'évaluation

- Ch1 - Steam Power PlantsDocument43 pagesCh1 - Steam Power PlantsShiau Fen100% (1)

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungPas encore d'évaluation

- Unit 1: Introduction To PPE: A) Power GenerationDocument55 pagesUnit 1: Introduction To PPE: A) Power GenerationArun PatilPas encore d'évaluation

- Mechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inDocument24 pagesMechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inbtdoss72100% (1)

- Chapter 2 - Analysis of Steam Power Plant CycleDocument61 pagesChapter 2 - Analysis of Steam Power Plant Cyclerrhoshack100% (1)

- Boiler & Auxiliaries Maintenance Manuall Qn1 Sec G 04 TP 009Document276 pagesBoiler & Auxiliaries Maintenance Manuall Qn1 Sec G 04 TP 009Bui Vanluong100% (1)

- Power PlantDocument4 pagesPower PlantNumair AshrafPas encore d'évaluation

- Power Plant Layout and Essential Feature of RankineDocument7 pagesPower Plant Layout and Essential Feature of RankineMonglafru MogPas encore d'évaluation

- Brief Description of Tanda Thermal Project: 1.1 Geographical LocationDocument22 pagesBrief Description of Tanda Thermal Project: 1.1 Geographical Locationcoolvipin1988Pas encore d'évaluation

- Thermal Power PlantsDocument24 pagesThermal Power Plantslakshmigsr6610100% (1)

- Gajendra KumarDocument23 pagesGajendra KumarGAJENDRA KUMARPas encore d'évaluation

- Thermal Power PlantDocument36 pagesThermal Power PlantAshvani Shukla100% (1)

- Thermal Power StationDocument12 pagesThermal Power StationSalehAfadlehPas encore d'évaluation

- Textile Yarns: Process of Yarn Manufacturing Classification of Yarns Yarn Numbering Sewing ThreadsDocument4 pagesTextile Yarns: Process of Yarn Manufacturing Classification of Yarns Yarn Numbering Sewing ThreadsLaxman Singh SankhlaPas encore d'évaluation

- Changing Over Centrifugal PumpDocument2 pagesChanging Over Centrifugal PumpLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump Operation in ParallelDocument1 pageCentrifugal Pump Operation in ParallelLaxman Singh SankhlaPas encore d'évaluation

- Pump Packing and Mechanical SealsDocument3 pagesPump Packing and Mechanical SealsLaxman Singh SankhlaPas encore d'évaluation

- PUMP ImpellerDocument3 pagesPUMP ImpellerLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump Operation in SeriesDocument2 pagesCentrifugal Pump Operation in SeriesLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump Checks: Discharge, Suction, Bearings, Noise & MoreDocument1 pageCentrifugal Pump Checks: Discharge, Suction, Bearings, Noise & MoreLaxman Singh SankhlaPas encore d'évaluation

- Pump BearingsDocument3 pagesPump BearingsLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump Normal OperationDocument3 pagesCentrifugal Pump Normal OperationLaxman Singh SankhlaPas encore d'évaluation

- Radial and Axial Flow Pump TypesDocument2 pagesRadial and Axial Flow Pump TypesLaxman Singh SankhlaPas encore d'évaluation

- Pump ClassificationDocument3 pagesPump ClassificationLaxman Singh SankhlaPas encore d'évaluation

- Pump VoluteDocument2 pagesPump VoluteLaxman Singh SankhlaPas encore d'évaluation

- Drawing of Centrifugal PumpDocument1 pageDrawing of Centrifugal PumpLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump CasingDocument2 pagesCentrifugal Pump CasingLaxman Singh SankhlaPas encore d'évaluation

- Pump Wear RingsDocument1 pagePump Wear RingsLaxman Singh Sankhla100% (1)

- Safety ValvesDocument1 pageSafety ValvesLaxman Singh SankhlaPas encore d'évaluation

- PUMP Bearing Housing and CouplingDocument2 pagesPUMP Bearing Housing and CouplingLaxman Singh SankhlaPas encore d'évaluation

- Air Required For Combustion Per Pound of CoalDocument1 pageAir Required For Combustion Per Pound of CoalLaxman Singh SankhlaPas encore d'évaluation

- SEALING OF Valves. By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument2 pagesSEALING OF Valves. By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump Drawing and PartsDocument2 pagesCentrifugal Pump Drawing and PartsLaxman Singh SankhlaPas encore d'évaluation

- Level Control Valve Automatic OperationDocument2 pagesLevel Control Valve Automatic OperationLaxman Singh SankhlaPas encore d'évaluation

- Centrifugal Pump OperationDocument2 pagesCentrifugal Pump OperationLaxman Singh SankhlaPas encore d'évaluation

- Emergency Shut Down Valves - ESDDocument2 pagesEmergency Shut Down Valves - ESDLaxman Singh SankhlaPas encore d'évaluation

- Pressure Relief ValvesDocument1 pagePressure Relief ValvesLaxman Singh SankhlaPas encore d'évaluation

- Motor Operated Valve MOVDocument1 pageMotor Operated Valve MOVLaxman Singh Sankhla100% (1)

- Diaphragm Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument1 pageDiaphragm Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh Sankhla100% (1)

- Air Operated Valves AOVDocument2 pagesAir Operated Valves AOVLaxman Singh SankhlaPas encore d'évaluation

- Butterfly ValvesDocument1 pageButterfly ValvesLaxman Singh SankhlaPas encore d'évaluation

- Types of Check & Non-Return ValvesDocument3 pagesTypes of Check & Non-Return ValvesLaxman Singh SankhlaPas encore d'évaluation

- Globe Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument1 pageGlobe Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh SankhlaPas encore d'évaluation

- Other Models Are Available, Please E-Mail Us.: Automatic Water Refill !Document1 pageOther Models Are Available, Please E-Mail Us.: Automatic Water Refill !marcello_oliveiraPas encore d'évaluation

- Walkdown & Punch PointsDocument23 pagesWalkdown & Punch PointsshijomonthomasPas encore d'évaluation

- CHE 406 - Lecture 3 (1) MOMENTUM TRANSFERDocument31 pagesCHE 406 - Lecture 3 (1) MOMENTUM TRANSFERDietrich Jamiro DizonPas encore d'évaluation

- Power Plant Engineering Course Material (As Per OU Syllabus)Document90 pagesPower Plant Engineering Course Material (As Per OU Syllabus)m udaya kumarPas encore d'évaluation

- Fenirol CDM - PDD English v1 - 11 Aug 2009Document56 pagesFenirol CDM - PDD English v1 - 11 Aug 2009Martín BaezaPas encore d'évaluation

- Defining WOG TBDocument2 pagesDefining WOG TBJavier Caamaño VillafañePas encore d'évaluation

- Increase Power Generation with Black Liquor Recovery Boiler MethodsDocument11 pagesIncrease Power Generation with Black Liquor Recovery Boiler MethodsavgpaulPas encore d'évaluation

- Option of HRSG Efficiency ImprovementDocument6 pagesOption of HRSG Efficiency ImprovementmakhdzaniPas encore d'évaluation

- Boosting Efficiency with Large Super Critical TurbinesDocument55 pagesBoosting Efficiency with Large Super Critical TurbinesRaju Sk100% (1)

- Steam Power Board Problems PDFDocument6 pagesSteam Power Board Problems PDFKim Niño FelisminoPas encore d'évaluation

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajPas encore d'évaluation

- Boiler Feedwater ControlDocument14 pagesBoiler Feedwater ControlJonas PeraterPas encore d'évaluation

- Birla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Document2 pagesBirla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Vashistha GargPas encore d'évaluation

- Boiler Soot-Blowing in Power Plants - Compressed Air Best PracticesDocument8 pagesBoiler Soot-Blowing in Power Plants - Compressed Air Best PracticesRoland NicolasPas encore d'évaluation

- Adca Training Part 6: Steam Equipment OverviewDocument27 pagesAdca Training Part 6: Steam Equipment Overviewjoaquin torrano veraPas encore d'évaluation

- KEPL Drive Turbine - R1Document4 pagesKEPL Drive Turbine - R1aminardakaniPas encore d'évaluation

- Marx and LangenheimDocument11 pagesMarx and LangenheimJesus Alberto Lopez SalazarPas encore d'évaluation

- Material Technical Data Sheet: A-SPE Marking TapesDocument2 pagesMaterial Technical Data Sheet: A-SPE Marking TapesAkhmad HarisPas encore d'évaluation

- Amol Jadhav ResumeDocument15 pagesAmol Jadhav ResumeamolPas encore d'évaluation

- Steam sterilizer operator manualDocument42 pagesSteam sterilizer operator manualacurawww100% (1)

- H&I. Condenser Performance MonitoringDocument43 pagesH&I. Condenser Performance MonitoringRajendran SrnPas encore d'évaluation

- SS Power I LTDDocument2 pagesSS Power I LTDmirza ishtiaqPas encore d'évaluation

- Hvac GMP ManualDocument48 pagesHvac GMP ManualMina Maher MikhailPas encore d'évaluation

- Broschuere BlockMoldingMachines A4 2019-ENDocument11 pagesBroschuere BlockMoldingMachines A4 2019-ENAurelian CRANGAPas encore d'évaluation

- Steam Injection Liquid Heating System: Process Heating Solutions WorldwideDocument2 pagesSteam Injection Liquid Heating System: Process Heating Solutions WorldwidenitantharaniPas encore d'évaluation

- Design of Biogas Fired Steam Turbine To Drive Irrigation PumpDocument121 pagesDesign of Biogas Fired Steam Turbine To Drive Irrigation PumpTemesgen Tolcha100% (1)

- Expediting PresentationDocument85 pagesExpediting Presentationnemalipalli007100% (3)

- Latitude Travel Iron: Instructions For UseDocument9 pagesLatitude Travel Iron: Instructions For UseNickPas encore d'évaluation

- Engineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemDocument23 pagesEngineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemInemie-ebi NiweighaPas encore d'évaluation

- Process Control and Instrumentation For BoilerDocument76 pagesProcess Control and Instrumentation For BoilertuyencntnPas encore d'évaluation