Académique Documents

Professionnel Documents

Culture Documents

Controlador para Calderetea de Motores Lmo44.255 - 38ld0015

Transféré par

Pablo AllosiaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Controlador para Calderetea de Motores Lmo44.255 - 38ld0015

Transféré par

Pablo AllosiaDroits d'auteur :

Formats disponibles

CC1N7145en

20.07.2004

Si emens Bui l di ng Technol ogi es

HVAC Products

7

145

Oil Burner Control LMO44.255C2

Microcontroller-based oil burner control for the startup, supervision and control

of forced draft oil burners in intermittent operation.

Oil throughput above 30 kg / h.

The LMO44.255C2 and this Data Sheet are intended for use by OEMs which inte-

grate the burner controls in their products.

Use, features

The LMO44.255C2 is designed for the startup and supervision of 1- or 2-stage forced

draft oil burners in intermittent operation. Yellow-burning flames are supervised with

photoresistive detectors QRB..., blue-burning flames with blue-flame detectors QRC...

In terms of housing dimensions, electrical connections and flame detectors, the

LMO44.255C2 is identical with the LOA... oil burner controls.

- Oil burners with fans to EN 267

- Burner controls for use with atomization oil burners of monoblock design to EN 230

- LMO44.255C2 for use with stationary direct-fired air heaters

- Undervoltage detection

- Electrical remote reset

- Bridging contact for oil preheater

- Monitoring of time for oil preheater

- Accurate and reproducible control sequence thanks to digital signal handling

- Controlled intermittent operation after 24 hours of continuous operation

- Limitation of the number of repetitions

- Multicolor indication of fault status and operational status messages

Use

General features

2/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes should be observed!

Do not open, interfere with or modify the unit!

All activities (mounting, installation and service work, etc.) must be performed by

qualified staff

Before performing any wiring changes in the connection area of the LMO..., com-

pletely isolate the burner control from the mains supply (all-polar disconnection)

Ensure protection against electric shock hazard by providing adequate protection

for the burner controls connection terminals

Check to ensure that wiring is in an orderly state

Press the lockout reset button / operation button only manually (applying a force of

no more than 10 N), without using any tools or pointed objects

Fall or shock can adversely affect the safety functions. Such units must not be put

into operation, even if they do not exhibit any damage

Mounting notes

Ensure that the relevant national safety regulations are complied with

Installation notes

Always run the high-voltage ignition cables separately while observing the greatest

possible distances to the unit and to other cables

Install switches, fuses, earthing, etc., in compliance with local regulations

Ensure that the maximum permissible amperages will not be exceeded (refer to

Technical data)

Do not feed external mains voltage to the control outputs of the unit. When testing

the components controlled by the burner control (fuel valves, etc.), the

LMO44.255C2 may never be plugged in

Do not mix up live and neutral conductors

Electrical connection of the flame detectors

It is important to achieve practically disturbance- and loss-free signal transmission:

Never run the detector cable together with other cables

Line capacitance reduces the magnitude of the flame signal

Use a separate cable

Observe the maximum permissible lengths of the detector cables (refer to Techni-

cal data)

Commissioning notes

Prior to commissioning the plant, check to ensure that wiring is in an orderly state

When commissioning the plant or when doing maintenance work, make the follow-

ing safety checks:

Safety check Anticipated response

a) Burner startup with flame detector dark-

ened

Lockout at the end of TSA

b) Burner startup with flame detector ex-

posed to extraneous light

Lockout after no more than 40

seconds

c) Burner operation with simulated loss of

flame; for that purpose, darken the flame

detector during operation and maintain

that state

Repetition followed by lockout at

the end of TSA

3/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Standards and certificates

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity)

- Low-voltage directive

89 / 336 EEC

73 / 23 EEC

ISO 9001: 2000

Cert. 00739

ISO 14001: 1996

Cert. 38233

Service notes

Each time a unit has been replaced, check to ensure that wiring is in an orderly

state and make the safety checks as described in Commissioning notes

Use the service adapters KF8885 / KF8833 / KF8840 for short periods of time only

Disposal notes

The unit contains electrical and electronic components and may not be disposed of

together with household waste.

Local and currently valid legislation must be observed.

Mechanical design

The housing is made of impact-proof, heat-resistant and flame-retarding plastic.

It is of plug-in design and engages audibly in the base.

The housing accommodates the

- microcontroller for the control sequence and the control relays for load control

- electronic flame signal amplifier

- lockout reset button with its integrated 3-color signal lamp (LED) for operational

status and fault status messages and the socket for connecting the interface

adapter OCI400

- Multicolor indication of operational status and fault status messages

- Transmission of operational status and fault status messages and detailed service

information via additional interface adapter OCI400 and PC Windows software

ACS400

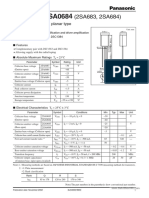

Type summary

) Remote

reset

Times Comparable type of

LOA... )

Type reference Mains

voltage

Fuel

valve

stages

Burner

capacity

tw

max.

t1 / t1

min.

TSA-

max.

t3

min.

t3n

max.

t4

min.

Suited for direct-fired air heaters

LMO44.255B2 AC 230 V 2 >30kg / h 5 s 25 / 26 s 5 s 25 s 5 s 5 s LOA44.252A27

TSAmax. Maximum ignition safety time

tw Waiting time

t1 Prepurge time

t1 Purge time

t3 Preignition time

t3n Postignition time

t4 Interval from flame signal to release of BV2

) Bridging contact for oil preheater

) LMO... can replace LOA..., but the instructions given in the Data Sheet, other tech-

nical documentation and the specification must be followed

Indication and diagnosis

Legend

4/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Ordering

Oil burner control (without plug-in base) refer to Type summary

Electrical connections refer to Data Sheet N7201

- Plug-in base AGK11...

- Cable holders AGK65..., AGK66, AGK67...

- Cable strain relief elements for AGK67...

Electrical connections refer to Data Sheet N7203

- Plug-in base AGK13...

- Plug-in housing AGK56...

- Cover AGK68...

Flame detectors

- Photoresistive detectors QRB1... refer to Data Sheet N7714

- Blue-flame detectors QRC1... refer to Data Sheet N7716

Diagnostic tool refer to Data Sheet N7614

- Interface adapter OCI400

- PC Windows software ACS400

Demo case KF8891

- For demonstrating the functions of burner controls

- Refer to User Manual B7989

Test adapter KF8885

- For checking the functions of burner controls on the burner

- With switch for manual startup of the burner

- With switch for simulating the oil preheaters release contact

- With 2 pairs of jacks for measuring the flame detector current

- Refer to Operating Instructions B7986

Test adapter KF8833

- For checking the functions of burner controls on the burner

- With signal lamps for program indication

- With one pair of jacks for measuring the flame detector current

Test adapter KF8840

- For checking the functions of burner controls on the burner

- With signal lamps for program indication

- With on / off switch for simulating the flame signal

- With holes for checking the control voltages at the tabs of the burner control

- With one pair of jacks for measuring the flame detectors resistance

Extension of lockout reset button

- Extension 19 mm AGK20.19

- Extension 43 mm AGK20.43

- Extension 55 mm AGK20.55

5/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Technical data

Mains voltage AC 230 V +10 % / -15 %

Mains frequency 50...60 Hz 6 %

External primary fuse (Si) 6.3 A (slow)

Power consumption 12 VA

Mounting orientation optional

Weight approx. 200 g

Safety class I

Degree of protection IP 40 (to be ensured through mounting)

Perm. cable lengths max. 3 m at a line capacitance of 100 pF/m

Detector cable laid separately 20 m

Remote reset laid separately 20 m

Max. perm. current at cos 0.6 LMO44.255C2

Terminal 1, 3 and 8 5 A

Terminals 6 2 A

Terminals 4, 5 and 10 1 A

Storage DIN EN 60 721-3-1

Climatic conditions class 1K3

Mechanical conditions class 1M2

Temperature range -20...+60 C

Humidity <95 % r.h.

Transport DIN EN 60 721-3-2

Climatic conditions class 2K2

Mechanical conditions class 2M2

Temperature range -30...+70 C

Humidity <95 % r.h.

Operation DIN EN 60 721-3-3

Climatic conditions class 3K3

Mechanical conditions class 3M2

Temperature range -20...+60 C

Humidity <95 % r.h.

Condensation, formation of ice and ingress of water are not permitted!

Min. detector current

required

(with flame)

Max. perm. detector

current

(without flame)

Max. possible detector

current with flame

(typically)

QRB... 45 A 5.5 A 100 A

QRC... 70 A 5.5 A 100 A

The values given in the table above only apply under the following conditions:

- Mains voltage AC 230 V

- Ambient temperature 23 C

Detector current in operation:

- Flame signal instable

- Green LED flashing

Detector current in operation:

- Flame signal stable

- Green LED steady on

QRB... <45 A >45 A

QRC... <45 A >45 A

The values given in the table above only apply under the following conditions:

- Mains voltage AC 230 V

- Ambient temperature 23 C

General unit data

Environmental

conditions

Flame supervision with

QRB... or QRC...

Green LED for opera-

tional status indication

6/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

QRB... QRC...

12

11 LMO...

bl

A DC

+

QRB...

7145v01/0504

sw

12 11 LMO... 1

sw bl br

A DC

+

QRC1...

Legend

A DC DC microammeter

with an internal

resistance of

Ri =max. 5 k

bl Blue

sw Black

br Brown

As an alternative to detector current measurement, the diagnostic tool OCI400 /

ACS400 can be used. In that case, the DC microammeter is not required.

Function

Burner control is reset

All contacts in the line are closed and there is demand for heat

No undervoltage

Flame detector is darkened and there is no extraneous light

Safety shutdown from the operating position takes place should mains voltage drop

below about AC 165 V (UN =AC 230 V)

Restart is initiated when mains voltage exceeds about AC 175 V (UN =AC 230 V)

If the oil preheaters release contact does not close within 10 minutes, the burner control

will initiate lockout.

After no more than 24 hours of continuous operation, the burner control will initiate

automatic controlled shutdown followed by a restart.

If lockout occurs, the outputs for the fuel valves, the burner motor and the ignition

equipment will immediately be deactivated (<1 second).

Cause Response

Mains failure Restart

Voltage has fallen below the undervoltage

threshold

Restart

Extraneous light during t1 Lockout at the end of t1

Extraneous light during tw Prevention of startup, lockout after 40 sec-

onds at the latest

No flame at the end of TSA Lockout at the end of TSA

Loss of flame during operation Max. 3 repetitions, followed by lockout

Oil preheaters release contact does not

close within 10 minutes

Lockout

In the event of lockout, the LMO44.255C2 remains locked and the red signal lamp (LED)

will light up. The burner control can immediately be reset.

This state is also maintained in the case of mains failure.

When lockout occurs, the burner control can immediately be reset. To do this, press the

lockout reset button for about 1 second (<3 seconds).

The LMO44.255C2 can only be reset when all contacts in the line are closed and when

there is no undervoltage.

If the flame is lost during operation, a maximum of 3 repetitions can be made.

If the flame is lost for the fourth time during operation, the burner will initiate lockout.

The repetition count is restarted each time controlled switching on by R takes place.

Measuring circuit

for detector current

Preconditions for

startup

Undervoltage

Time supervision

oil preheater

Controlled intermittent

operation

Control sequence in

the event of fault

Resetting the

burner control

Limitation of repetitions

7/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Operation, display, diagnosis

EK

7

1

4

5

z

0

1

/

0

5

0

4

Lockout reset button EK... is the key operating element for resetting

the burner control and for activating / deactivating the diagnostic func-

tions.

LED

7

1

4

5

z

0

2

e

/

0

7

0

4

Red

Yellow

Green

The multicolor signal lamp (LED) in the lockout reset button is the key

indicating element for both visual diagnostics and interface diagnostics.

Both EK... and LED are located under the transparent cover of the lockout reset

button.

There are 2 diagnostic choices:

1. Visual diagnostics: Operational status indication or diagnostics of the cause of fault.

2. Interface diagnostics: With the help of the interface adapter OCI400 and PC soft-

ware ACS400 or flue gas analyzers of different makes (refer to Data Sheet N7614).

Visual diagnostics:

In normal operation, the different operational statuses are indicated in the form of color

codes according to the color code table given below. Interface diagnostics is activated

by pressing the lockout reset button for at least 3 seconds (refer to Data Sheet N7614).

If, by accident, interface diagnostics has been activated, in which case the slightly red

light of the signal lamp flickers, it can be deactivated by pressing again the lockout

reset button for at least 3 seconds. The instant of switching over is indicated by a yel-

low light pulse.

Operating position

EK

>3 s

Interface diagnostics

PC / analyzer

7

1

4

5

z

0

3

e

/

0

7

0

4

Visual diagnostics

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

Color code table

Operating position

During startup, status indication takes place according to the following table:

Color code table for multicolor signal lamp (LED)

Status Color code Color

Waiting time tw, other waiting states ....................................... Off

Oil preheater on ....................................... Yellow

Ignition phase, ignition controlled Flashing yellow

Operation, flame o.k. ....................................... Green

Operation, flame not o.k. Flashing green

Extraneous light on burner startup Green-red

Undervoltage Yellow-red

Fault, alarm ....................................... Red

Error code output (refer to Error code

table)

Flashing red

Interface diagnostics Red flicker light

...... Steady on Red

Off Yellow

Green

Operation

Operational status

indication

Legend

8/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

After lockout, the red fault signal lamp remains steady on. In that condition, the visual

diagnostics of the cause of fault according to the error code table can be activated by

pressing the lockout reset button for more than 3 seconds. Pressing the reset button

again for at least 3 seconds, the interface diagnostics will be activated (for more de-

tailed information, refer to Data Sheet N7614).

The following sequence activates the diagnostics of the cause of fault:

EK

>3 s

Flashing

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

Error code table

EK

>3 s

Interface diagnostics

PC / analyzer

O

C

I

4

0

0

EK

<3 s

7

1

4

5

z

0

4

e

/

0

7

0

4

Reset

On

Visual diagnostics

Lockout position

Lockout position Lockout position

Error code table

Red blink code of

signal lamp (LED)

AL at

term. 10

Possible cause

2 blinks

hh

On No establishment of flame at the end of TSA

- Faulty or soiled fuel valves

- Faulty or soiled flame detector

- Poor adjustment of burner, no fuel

- Faulty ignition equipment

3 blinks

hhh

On Free

4 blinks

hhhh

On Extraneous light on burner startup

5 blinks

hhhhh

On Free

6 blinks

hhhhhh

On Free

7 blinks

hhhhhhh

On Too many losses of flame during operation (limi-

tation of the number of repetitions)

- Faulty or soiled fuel valves

- Faulty or soiled flame detector

- Poor adjustment of burner

8 blinks

hhhhhhhh

On Time supervision oil preheater

- Oil preheater failed 5 times during prepurging

9 blinks

hhhhhhhhh

On Free

10 blinks

hhhhhhhhhh

Off Wiring fault or internal fault, output contacts

During the time the cause of fault is diagnosed, the control outputs are deactivated:

- Burner remains shut down

- Fault status signal AL at terminal 10, according to the error code table

The diagnostics of the cause of fault is quit and the burner switched on again by reset-

ting the burner control. Press the lockout reset button for about 1 second (<3 seconds).

Diagnostics of the

cause of fault

9/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Connection diagram and internal diagram Control sequence

1 2 6 7 4 5 10 11 12

W

SB

R

L

N

M Z BV1

AL

Si

8 3

OW

OH

N

8 3

QRB

QRC

br

bl sw

1

7145a01e/0704

9

EK2

EK1

C control

K1

K2

K4

BV2

LED

kbr

FSV

C2 C1

K3

R

W

SB

OH

OW

M

Z

BV2

FS

A A B C D

1

8

3

3

6

5

11

12

t1

t3 t3n

TSA

tw

BV1 4

t4

t1

7145d01/0504

AL Alarm device

BV... Fuel valve

EK1 Lockout reset button

EK2 Remote lockout reset button

FS Flame signal

FSV Flame signal amplifier

K... Contacts of control relay

kbr... Cable link (required only when no oil preheater is used)

LED 3-color signal lamp

M Burner motor

OW Release contact of oil preheater

OH Oil preheater

QRB Photoresistive flame detector

QRC Blue-flame detector

bl =blue, br =brown, sw =black

R Control thermostat or pressurestat

SB Safety limit thermostat

Si External primary fuse

W Limit thermostat or pressure switch

Z Ignition transformer

TSA Ignition safety time

tw Waiting time

t1 Prepurge time

t1 Purge time

t3 Preignition time

t3n Postignition time

t4 Interval from flame signal to release of BV2

A Start of startup sequence with burners using an OH

A Start of startup sequence with burners using no OH

B Time of flame establishment

C Operating position

D Controlled shutdown by R

Control signals

Required input signals

Perm. input signals

C1 Microcontroller 1

C2 Microcontroller 2

Legend

10/10

Siemens Building Technologies CC1N7145en

HVAC Products 20.07.2004

Dimensions

Dimensions in mm

5

,

2

5

3

,

9

88

91

41,6

4

7

,

2

6

2

,

5

7

1

4

5

m

0

1

/

0

7

0

4

22

7

1

4

5

m

0

2

/

0

7

0

4

7

,

4

4

L

Type reference Length L in mm

AGK20.20 19

AGK20.43 43

AGK20.55 55

LMO44.255C2

LMO44.255C2 with

extension of lockout

reset button AGK20...

2004 Siemens Building Technologies Production GmbH

Subject to change!

Vous aimerez peut-être aussi

- 51 Best BandsawsDocument54 pages51 Best BandsawsKeone SemanaPas encore d'évaluation

- E-23 Shore Connection BoxDocument27 pagesE-23 Shore Connection Boxcengiz kutukcuPas encore d'évaluation

- Travel Systems - 7Document59 pagesTravel Systems - 7اياد القباطيPas encore d'évaluation

- Kitchen Appliances: Profile No.: 123 NIC Code: 27504Document13 pagesKitchen Appliances: Profile No.: 123 NIC Code: 27504Subrahmanya Prasad NelabhotlaPas encore d'évaluation

- FDASDocument22 pagesFDASAly Bueser67% (3)

- RMO-RMG Burner ControllerDocument21 pagesRMO-RMG Burner ControllerTiyyagura RoofusreddyPas encore d'évaluation

- VD4 36kV Manual EngDocument32 pagesVD4 36kV Manual EngleryzPas encore d'évaluation

- Utilization Factor PDFDocument4 pagesUtilization Factor PDFMuraryspotty33% (3)

- TLE Project ProposalDocument10 pagesTLE Project ProposalGine FrencilloPas encore d'évaluation

- For 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971Document6 pagesFor 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971marioalf674150Pas encore d'évaluation

- EquivalenciasDocument17 pagesEquivalenciasPablo AllosiaPas encore d'évaluation

- Burner Control LGB21Document22 pagesBurner Control LGB21douglasPas encore d'évaluation

- LGB BControlDocument21 pagesLGB BControlaalfaqiPas encore d'évaluation

- Automate Arzatoare Siemens Lme Landis Gyr Carte Tehnica Limba EnglezaDocument23 pagesAutomate Arzatoare Siemens Lme Landis Gyr Carte Tehnica Limba EnglezaXiLvEERPas encore d'évaluation

- Automate Arzatoare Siemens LMG Landis Gyr Carte Tehnica Limba EnglezaDocument17 pagesAutomate Arzatoare Siemens LMG Landis Gyr Carte Tehnica Limba EnglezaexperthvachomePas encore d'évaluation

- Building Technologies: HVAC ProductsDocument22 pagesBuilding Technologies: HVAC ProductsThiago FernandesPas encore d'évaluation

- Oil Burner Controls: Building TechnologiesDocument18 pagesOil Burner Controls: Building TechnologiesSaheer AmbadanPas encore d'évaluation

- Siemens LALDocument20 pagesSiemens LALjimmybb81Pas encore d'évaluation

- LGBDocument22 pagesLGBThiago FernandesPas encore d'évaluation

- Gas Burned Siemens Landis LGA41Document11 pagesGas Burned Siemens Landis LGA41Abelardo PeironePas encore d'évaluation

- Mmi 810-1 811-1Document4 pagesMmi 810-1 811-1SinišaPas encore d'évaluation

- LEC1Document17 pagesLEC1christophermrequintoPas encore d'évaluation

- Siemens LFL1..Document18 pagesSiemens LFL1..lucasjohn1964Pas encore d'évaluation

- Lga 52Document11 pagesLga 52caner8948Pas encore d'évaluation

- Honeywell Mmi 813.1 Mod 23Document5 pagesHoneywell Mmi 813.1 Mod 23nestor_moPas encore d'évaluation

- Controlador Llama Siemens Lga PDFDocument12 pagesControlador Llama Siemens Lga PDFPaolo CruzPas encore d'évaluation

- Oil Burner Controls: Building TechnologiesDocument18 pagesOil Burner Controls: Building TechnologiesThiago FernandesPas encore d'évaluation

- LG An 7418 en 14032006Document11 pagesLG An 7418 en 14032006Thiago FernandesPas encore d'évaluation

- Lfe 50 N 7783 en 09052007Document14 pagesLfe 50 N 7783 en 09052007Thiago FernandesPas encore d'évaluation

- SM 592.2 Caja de Control ElectromagneticaDocument6 pagesSM 592.2 Caja de Control ElectromagneticaHectorI.GoCaPas encore d'évaluation

- Satronic BoxDocument6 pagesSatronic BoxbethmongPas encore d'évaluation

- Honeywell Satronic DKG972Document6 pagesHoneywell Satronic DKG972maccsyPas encore d'évaluation

- LgaDocument10 pagesLgaThiago FernandesPas encore d'évaluation

- VM 42Document4 pagesVM 42Ronan CristhiamPas encore d'évaluation

- Sequence Cont. ManualDocument6 pagesSequence Cont. ManualVijay BhurePas encore d'évaluation

- Instructions and Advices To Use The Electronic Controller Logik 19Document31 pagesInstructions and Advices To Use The Electronic Controller Logik 19Muhammad Zeeshan SaeedPas encore d'évaluation

- Abt Meter SpecificationsDocument11 pagesAbt Meter SpecificationsriteshnaikPas encore d'évaluation

- DKG 972Document6 pagesDKG 972David RamirezPas encore d'évaluation

- Lmof 123Document10 pagesLmof 123Idham JaelaniPas encore d'évaluation

- BRAHMA Control de Llama MPIDocument5 pagesBRAHMA Control de Llama MPIAriel SantambrosioPas encore d'évaluation

- LFL Gas Burner ControlDocument26 pagesLFL Gas Burner ControlRoyalty GouldPas encore d'évaluation

- CDG 6000Document31 pagesCDG 6000Alex AlexPas encore d'évaluation

- ZX2Document56 pagesZX2ecodian100% (1)

- PNTDocument2 pagesPNTnnabyendu.sahaPas encore d'évaluation

- Motan 960Document11 pagesMotan 960DgfdghfghFfdhgfhjgPas encore d'évaluation

- Elec Floor Heating HandbookDocument60 pagesElec Floor Heating HandbookNavanee KrishnanPas encore d'évaluation

- Siemens Lme22 331c2 ManualDocument27 pagesSiemens Lme22 331c2 ManualIkaz UomimatPas encore d'évaluation

- LOA2 LOA3 Oil Burner Controls2 PDFDocument10 pagesLOA2 LOA3 Oil Burner Controls2 PDFAdamPas encore d'évaluation

- tmg740 3Document6 pagestmg740 3tespakPas encore d'évaluation

- ATS22C41Q: Product Data SheetDocument9 pagesATS22C41Q: Product Data SheetDheeraj YadavPas encore d'évaluation

- Sequence Cont. Manual PDFDocument6 pagesSequence Cont. Manual PDFVijay BhurePas encore d'évaluation

- Cu 104Document16 pagesCu 104PonyPantsPas encore d'évaluation

- Univario Tech Data CombinedDocument10 pagesUnivario Tech Data CombineddbrodarPas encore d'évaluation

- Bcu370 Burner Control - Brochure PDFDocument6 pagesBcu370 Burner Control - Brochure PDFFernando QueirozPas encore d'évaluation

- NXT4 Bia e 1Document24 pagesNXT4 Bia e 1Felipe AchurraPas encore d'évaluation

- Ldu 11 Eun 7696 en 25042005Document16 pagesLdu 11 Eun 7696 en 25042005Thiago FernandesPas encore d'évaluation

- Mircom MDHSL2000P Data SheetDocument2 pagesMircom MDHSL2000P Data SheetJMAC SupplyPas encore d'évaluation

- Digicold Digicold Digicold Digicold: SeriesDocument4 pagesDigicold Digicold Digicold Digicold: SeriesdbricchiPas encore d'évaluation

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 pagesTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnPas encore d'évaluation

- Gas Burner Control Box TFI 812Document5 pagesGas Burner Control Box TFI 812Paulo AlexandrePas encore d'évaluation

- Manual 1 PDFDocument31 pagesManual 1 PDFdarrel_julioPas encore d'évaluation

- Ilm 2 3Document8 pagesIlm 2 3joquispePas encore d'évaluation

- Non-Addressable Initiating Peripherals: FeaturesDocument4 pagesNon-Addressable Initiating Peripherals: Featureshassan_said_8Pas encore d'évaluation

- Dvi 980 - 982 (En)Document6 pagesDvi 980 - 982 (En)Jozo ĆurčićPas encore d'évaluation

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicPas encore d'évaluation

- Ignition ControlDocument86 pagesIgnition ControlLucian SinpetruPas encore d'évaluation

- MJE170GDocument6 pagesMJE170GPablo AllosiaPas encore d'évaluation

- 2SK3565 Datasheet en 20131101 PDFDocument6 pages2SK3565 Datasheet en 20131101 PDFMarcio MoraesPas encore d'évaluation

- ACST67SDocument9 pagesACST67S59yotubePas encore d'évaluation

- Rara Wire Wound ResistorDocument28 pagesRara Wire Wound ResistorPablo AllosiaPas encore d'évaluation

- AD7792Document32 pagesAD7792Pablo AllosiaPas encore d'évaluation

- F N533&..5382 Series: ZENER DIODES (3.3V To 200V) Mechanical DimensionsDocument3 pagesF N533&..5382 Series: ZENER DIODES (3.3V To 200V) Mechanical DimensionsPablo AllosiaPas encore d'évaluation

- Sylvania - Lamps Catalogue 2016 - Full - EnglishDocument236 pagesSylvania - Lamps Catalogue 2016 - Full - EnglishPablo AllosiaPas encore d'évaluation

- Zener Diode: 1N957B 1N982BDocument6 pagesZener Diode: 1N957B 1N982BPablo AllosiaPas encore d'évaluation

- 1N5400Document3 pages1N5400Robert CristobalPas encore d'évaluation

- FQP20N60/FQPF20N60: General Description Product SummaryDocument6 pagesFQP20N60/FQPF20N60: General Description Product SummaryPablo AllosiaPas encore d'évaluation

- 4N25, 4N26, 4N27, 4N28: Vishay SemiconductorsDocument7 pages4N25, 4N26, 4N27, 4N28: Vishay SemiconductorsRichie MartinezPas encore d'évaluation

- 1N746 1n759a, 1N4370 1n4372aDocument3 pages1N746 1n759a, 1N4370 1n4372aPablo AllosiaPas encore d'évaluation

- 1.5KE Series Protection DiodesDocument5 pages1.5KE Series Protection DiodesPablo AllosiaPas encore d'évaluation

- A684 PanasonicDocument4 pagesA684 PanasonicPablo AllosiaPas encore d'évaluation

- Switching Regulator Applications: Absolute Maximum RatingsDocument6 pagesSwitching Regulator Applications: Absolute Maximum RatingsadbeelPas encore d'évaluation

- Smart Lowside Power Switch: Hitfet BTS 149Document11 pagesSmart Lowside Power Switch: Hitfet BTS 149Pablo AllosiaPas encore d'évaluation

- F N533&..5382 Series: ZENER DIODES (3.3V To 200V) Mechanical DimensionsDocument3 pagesF N533&..5382 Series: ZENER DIODES (3.3V To 200V) Mechanical DimensionsPablo AllosiaPas encore d'évaluation

- 1 N 914Document3 pages1 N 914tommy99Pas encore d'évaluation

- 1.5KE Series Protection DiodesDocument5 pages1.5KE Series Protection DiodesPablo AllosiaPas encore d'évaluation

- Cny 117Document9 pagesCny 117Anonymous 0CnvpxSPas encore d'évaluation

- A1321 2 3 DatasheetDocument13 pagesA1321 2 3 DatasheetEwerton BianchiPas encore d'évaluation

- 6 N 137Document16 pages6 N 137Estênio Xavier VarjãoPas encore d'évaluation

- Hs3Ab - Hs3Mb: Taiwan SemiconductorDocument7 pagesHs3Ab - Hs3Mb: Taiwan SemiconductorPablo AllosiaPas encore d'évaluation

- Semiconductor Technical Data: Ultrafast Rectifiers 15 Amperes 200-400-600 VOLTSDocument6 pagesSemiconductor Technical Data: Ultrafast Rectifiers 15 Amperes 200-400-600 VOLTSPablo AllosiaPas encore d'évaluation

- Unisonic Technologies Co., LTD: Audio Power AmplifierDocument4 pagesUnisonic Technologies Co., LTD: Audio Power AmplifierPablo AllosiaPas encore d'évaluation

- 4N25-X, 4N26-X, 4N27-X, 4N28-X Optocoupler, Phototransistor Output, With Base ConnectionDocument7 pages4N25-X, 4N26-X, 4N27-X, 4N28-X Optocoupler, Phototransistor Output, With Base ConnectionTudor SorbanPas encore d'évaluation

- Old Company Name in Catalogs and Other DocumentsDocument8 pagesOld Company Name in Catalogs and Other DocumentsDinh Thang LePas encore d'évaluation

- "ZNR" Transient Surge Absorbers (Type D) PDFDocument24 pages"ZNR" Transient Surge Absorbers (Type D) PDFPablo AllosiaPas encore d'évaluation

- DS Diodo CatalogoDocument4 pagesDS Diodo CatalogoNando Junta PhdPas encore d'évaluation

- 1SFC151003C0201 81Document1 page1SFC151003C0201 81psatyasrinivasPas encore d'évaluation

- LC300 - Online Brochure 202110291Document30 pagesLC300 - Online Brochure 202110291JORGE LUIS TRIANA RODRIGUEZPas encore d'évaluation

- BetaD50 ManualDocument57 pagesBetaD50 Manualmrb88Pas encore d'évaluation

- Kenwood Kdc-208u 248u 4051ug Urm Kdc-Mp148u Mp248u U3049 Kdc-U349a G R S Kdc-U4049 SMDocument33 pagesKenwood Kdc-208u 248u 4051ug Urm Kdc-Mp148u Mp248u U3049 Kdc-U349a G R S Kdc-U4049 SMJimmy Esquen100% (1)

- PB Kandang Ayam A.N Joni Paduraksa B2 33 KvaDocument64 pagesPB Kandang Ayam A.N Joni Paduraksa B2 33 KvaFajar PradanaPas encore d'évaluation

- Chapter 25 Equipment - FurnishingDocument63 pagesChapter 25 Equipment - FurnishingHartomo DK.Pas encore d'évaluation

- Mitsubishi PUHZ RP250YKADocument142 pagesMitsubishi PUHZ RP250YKAAlexandru BocosPas encore d'évaluation

- Borrowers Slip For Hope ResidenceDocument35 pagesBorrowers Slip For Hope ResidenceJohndale RamirezPas encore d'évaluation

- A320 - SRM - 01-Aug-2019 - TASK 55-44-00-300-003 - Partial Replacement of Rudder Tip StructureDocument6 pagesA320 - SRM - 01-Aug-2019 - TASK 55-44-00-300-003 - Partial Replacement of Rudder Tip Structurejr primePas encore d'évaluation

- MS 415 PDFDocument7 pagesMS 415 PDFerode els erodePas encore d'évaluation

- WECON LX3V Product Wiring DiagramDocument2 pagesWECON LX3V Product Wiring DiagramMilind Bhavsar100% (1)

- Act 1&2Document10 pagesAct 1&2John Neil Bibera100% (4)

- Yzem 3001Document14 pagesYzem 3001Juan JJPas encore d'évaluation

- BVP 202277 Datasheet enDocument2 pagesBVP 202277 Datasheet enAlejandro MoralesPas encore d'évaluation

- Power Supplies For Photomultiplier Tube Modules: Type No. C10709 C7169 UnitDocument2 pagesPower Supplies For Photomultiplier Tube Modules: Type No. C10709 C7169 UnitCaver VelasquezPas encore d'évaluation

- TUTORIAL-5 - SHAFT DESIGN With SolutionDocument30 pagesTUTORIAL-5 - SHAFT DESIGN With SolutionAhmad AL-BukharyPas encore d'évaluation

- Planos Electrónicos Monitor Fetal Corometrics Modelo 170 SeriesDocument88 pagesPlanos Electrónicos Monitor Fetal Corometrics Modelo 170 Seriesviviana vargasPas encore d'évaluation

- 7733v3.0 (G52 77331X2) (B75IA E33) 100x150Document204 pages7733v3.0 (G52 77331X2) (B75IA E33) 100x150Antreas DionysiouPas encore d'évaluation

- Pololu G2 High-Power Motor Driver 24v13Document11 pagesPololu G2 High-Power Motor Driver 24v13nikkiPas encore d'évaluation

- 2FB4 PCDocument55 pages2FB4 PClingeshsaikumar030Pas encore d'évaluation

- LCD InterfacingDocument16 pagesLCD InterfacingKarthik DmPas encore d'évaluation

- Electronic Voting MachineDocument70 pagesElectronic Voting MachineSalman Naveed67% (3)

- Technical Data: Mercedes-Benz Econic 1830 NGTDocument2 pagesTechnical Data: Mercedes-Benz Econic 1830 NGTOswaldo Quispe MezaPas encore d'évaluation