Académique Documents

Professionnel Documents

Culture Documents

Nitrogen Asphyxiation Bulletin Training Presentation

Transféré par

nestorsoftDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nitrogen Asphyxiation Bulletin Training Presentation

Transféré par

nestorsoftDroits d'auteur :

Formats disponibles

US Chemical Safety and Hazard

Investigation Board

The Hazards of Nitrogen

Asphyxiation

Introduction

Nitrogen makes up 78% of the air we

breath; because of this it is often assumed

that nitrogen is not hazardous.

However, nitrogen is safe to breath only if it is

mixed with an appropriate amount of oxygen.

Additional nitrogen (lower oxygen) cannot

be detected by the sense of smell.

Introduction

Nitrogen is used commercially as an inerting

agent to keep material free of contaminants

(including oxygen) that may corrode

equipment, present a fire hazard, or be toxic.

A lower oxygen concentration (e.g., caused by

an increased amount of nitrogen) can have a

range of effects on the human body and can be

fatal if if falls below 10%

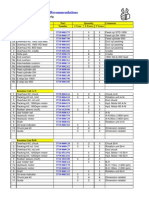

Effects of Oxygen Deficiency on

the Human Body

Atmospheric Oxygen

Concentration (%)

Possible Results

20.9 Normal

19.0 Some unnoticeable adverse physiological effects

16.0 Increased pulse and breathing rate, impaired thinking and

attention, reduced coordination

14.0 Abnormal fatigue upon exertion, emotional upset, faulty

coordination, poor judgment

12.5 Very poor judgment and coordination, impaired

respiration that may cause permanent heart damage,

nausea, and vomiting

<10 Inability to move, loss of consciousness, convulsions,

death

Source: Compressed Gas Association, 2001

Statistics on Incidents

CSB reviewed cases of nitrogen asphyxiation that

occurred in the US between 1992 and 2002 and

determined the following:

85 incidents of nitrogen asphyxiation resulted

in 80 deaths and 50 injuries.

The majority of incidents occurred in

manufacturing and industrial settings, but

several incidents occurred in other settings

including laboratories and medical facilities.

Facilities and Areas Where

Incidents Occurred

14%

13%

5%

6%

62%

Manufacturing/industry

Trenches, manhole covers (not

identified)

Maintenance activities (not

necessarily at manufacturing sites)

Laboratories

Miscellaneous (including medical

facilities and transportation)

Statistics on Incidents

(contd)

The majority of incidents

occurred in and around

confined spaces, though

several incidents occurred in

open areas, including inside

buildings and outdoors near

equipment.

Almost half the incidents

involved contractors, including

construction workers.

Contractors account for over

60% of the fatalities.

Statistics on Incidents

(contd)

Causes of the incidents included:

Failure to detect an oxygen-

deficient atmosphere in and

around confined spaces.

Mistakenly using nitrogen instead

of breathing air.

Inadequately preparing for rescue.

Data Sources for Statistics

Data sources for the CSB review included

regulatory agencies, media reports, technical

publications, and contacts with safety

personnel; however, only those incidents

that were reported and accessible are

evaluated. Statistical analysis is based on

the available, limited information.

Although the summary data reported above

are not all-inclusive, the numbers clearly

indicate that nitrogen asphyxiation presents

a serious hazard in the workplace.

Case Study: Failure to Recognize

Asphyxiation Hazards Near

Confined Spaces

Three workers were cleaning filters in a

hydrogen purifying tank.

Tank was purged with nitrogen during

cleaning.

One worker leaned over a manway

opening in the upper portion of the

tank.

He was found unconscious and later

died.

Case Study: Failure to Recognize

Asphyxiation Hazards Near

Confined Spaces

An operator was conducting a flammable gas

test on a line connected to a flare in order to

issue a hot work permit.

The operator issued a permit that required

an air-supplied respirator.

Two contractors wore respirators to remove

a valve, but the operator did not.

Nitrogen inadvertently entered the flare and

the operator lost consciousness.

Case Study: Inadequate

Monitoring of Atmosphere

A tank car at a refinery contained white

mineral oil, and an employee started

cleaning it.

The mineral oil was offloaded by

injecting nitrogen gas into the car.

The nitrogen was still present when the

employee started to clean the car and he

was asphyxiated.

Case Study: Corrupt Breathing

Air Supply

Two contractors were abrasive blasting tubes

inside a boiler.

They wore supplied-air respirators

connected to compressed air cylinders.

After the workers failed to respond to an air

horn, they were found unconscious.

Follow-up testing of the air supply which

had been manufactured by mixing oxygen

and nitrogen - found that it contained less

than 5% oxygen.

Case Study: Mix-Up Nitrogen

and Air, and Improper Rescue

The atmosphere inside a coated tank was

tested and ventilated the day before

work was to be performed inside.

A contractor entered the tank to clean it the

next day and collapsed.

Two plant employees attempted rescue and

were overcome. All three workers died.

The tank had mistakenly been ventilated

with nitrogen instead of compressed air.

Case Study: Mix-up Nitrogen

and Air

A contract employee planned to use a

hammer powered by air to chip residue

from a furnace in an aluminum foundry.

He wore an airline respirator.

Two compressed gas lines were available,

one was labeled natural gas and one was

labeled air.

Once the respirator was in place, the

employee was asphyxiated. The air line

actually contained pure nitrogen.

Case Study: Mix-up Breathing

Air Supply in a Medical

Facility

A supplier mistakenly delivered a

cylinder of nitrogen during a

delivery of oxygen cylinders.

The nursing home employee

mistakenly accepted the nitrogen tank.

The cylinder was labeled with a

nitrogen label partially covering an

oxygen label.

Case Study: Mix-Up Breathing

Air Supply in a Medical

Facility (contd)

The tank had nitrogen-compatible

fittings.

A maintenance employee removed

the fittings from an empty oxygen

cylinder and used it as an adapter

to connect the nitrogen tank to the

oxygen system.

Four patients died and six were

injured.

Good Practices for Safe

Handling of Nitrogen

Implement warning systems and

continuous atmospheric monitoring of

enclosures

Continuously monitor for oxygen-deficient,

toxic, or explosive atmospheres.

Employ warning systems including flashing

lights, alarms, and auto-locking entryways.

Use personnel monitors to indicate low

oxygen concentrations.

Remember that the atmosphere can change

over time.

Good Practices for Safe

Handling of Nitrogen

Ensure ventilation with fresh-air in

confined and enclosed areas.

Maintain continuous forced draft

ventilation with fresh air before job

begins and through completion.

Ensure that ventilation systems are

properly designed, evaluated, and

maintained.

Use warning systems to alert personnel

if the system fails.

Good Practices for Safe

Handling of Nitrogen

Implement a system for the safe retrieval

and rescue of workers

Employees in confined spaces should wear

equipment to facilitate retrieval, such as a

body harness, anklets, or wristlets, and a

lifeline.

Standby personnel must be present at all

times and have constant communication with

personnel inside.

Personnel should not attempt rescue unless

they are properly trained and equipped.

Good Practices for Safe

Handling of Nitrogen

Ensure the uninterrupted flow and

integrity of breathing air

Take steps to ensure that supplied air is not

interrupted. Steps include having alternate sources

of power for air compressors, inspecting and

replacing air hoses, and restricting traffic in areas

with supply hoses.

Carry escape packs.

Ensure the composition of supplied breathing air is

correct. Continuously monitor the air supply.

Good Practices for Safe

Handling of Nitrogen

Prevent inadvertent mix-up of

nitrogen and breathing air

Ensure that personnel understand the

reason for specific unique fittings on

cylinders of different compressed

gases. Do not fabricate adapters to

defeat their purpose.

Ensure that cylinders are clearly

labeled.

Use color coding to identify systems.

Good Practices for Safe

Handling of Nitrogen

Develop and implement training programs for

employees and contract personnel, including

information on:

Proper use of ventilation, retrieval, air monitoring, and

air supply systems.

Safe practices for confined space entry and rescue.

Precautions to take when working around confined

areas.

Dangers of nitrogen enriched atmosphere and

preventing mix-ups between breathing air and

nitrogen.

Implementing good hazard communication.

More Information

A safety bulletin and 1-page brochure on

the hazards of nitrogen asphyxiation, as

well as this presentation, are available

from the US Chemical Safety and Hazard

Investigation Board.

www.csb.gov

(202)261-7600

Vous aimerez peut-être aussi

- Nitrogen Asphyxiation Bulletin Training PresentationDocument24 pagesNitrogen Asphyxiation Bulletin Training Presentationav78670% (1)

- CSB Nitrogen Asphyxiation BulletinDocument24 pagesCSB Nitrogen Asphyxiation BulletinNguyễn Ngọc SơnPas encore d'évaluation

- Case Studies Involving Incidents in A Manufacturing PlantDocument28 pagesCase Studies Involving Incidents in A Manufacturing PlantKian TecsonPas encore d'évaluation

- Industrial Hygiene 2 PresentationDocument19 pagesIndustrial Hygiene 2 PresentationYashini DussoyePas encore d'évaluation

- Medical Gases. Piped and Cylinder Training. Aim Understand The Reasons For Medical Gas TrainingDocument36 pagesMedical Gases. Piped and Cylinder Training. Aim Understand The Reasons For Medical Gas TrainingAhmed shawkyPas encore d'évaluation

- Post Contract Corporate Health, Safety Policy On Respiratory Infections Group One 1.5410 . 2.54 .. 3.54 . 4.54 5.54 .Document24 pagesPost Contract Corporate Health, Safety Policy On Respiratory Infections Group One 1.5410 . 2.54 .. 3.54 . 4.54 5.54 .E-Lie NarteyPas encore d'évaluation

- Safety Bulletin CSB Dangers Purging Gas Piping BuildingsDocument5 pagesSafety Bulletin CSB Dangers Purging Gas Piping BuildingspiolinwallsPas encore d'évaluation

- SL0205Document3 pagesSL0205Moisés Camarillo HaroPas encore d'évaluation

- 03 Industrial HygieneDocument50 pages03 Industrial HygieneSaniha Aysha AjithPas encore d'évaluation

- Control MeasuresDocument52 pagesControl MeasuresAaron Jhan PerezPas encore d'évaluation

- Respirator Safety Program Pablo Larrea HerediaDocument20 pagesRespirator Safety Program Pablo Larrea HerediaMohamed KargboPas encore d'évaluation

- Confined Space RescueDocument27 pagesConfined Space RescuePRITAM KUMARPas encore d'évaluation

- Confined Space Accident Case StudiesDocument29 pagesConfined Space Accident Case StudiesJoseLuisMatiasLuciani80% (5)

- Pine Confined SpaceDocument31 pagesPine Confined Spacemigas_7Pas encore d'évaluation

- Ome754 Industrial Safety - Unit III NotesDocument87 pagesOme754 Industrial Safety - Unit III Notesraghul balaPas encore d'évaluation

- Tank and Petroleum Use MishapsDocument9 pagesTank and Petroleum Use MishapsNorthPas encore d'évaluation

- Confined Space Safety Presentation OSDocument25 pagesConfined Space Safety Presentation OSSajjad AfzalPas encore d'évaluation

- Oxygen Therapy - DevicesDocument28 pagesOxygen Therapy - Deviceskuruba mahendraPas encore d'évaluation

- Schlenk and Vacuum Line SafetyDocument15 pagesSchlenk and Vacuum Line SafetystrawberryblackberryPas encore d'évaluation

- Chapter 5 - Centralized Gas Supply SystemDocument44 pagesChapter 5 - Centralized Gas Supply Systemmarye agegnPas encore d'évaluation

- Gas Testing BY Commissioning Hse TeamDocument36 pagesGas Testing BY Commissioning Hse Teamsaquib eqbalPas encore d'évaluation

- Scope and Background: Environmental Health and SafetyDocument6 pagesScope and Background: Environmental Health and SafetyJedel ReyesPas encore d'évaluation

- General Design ConsiderationsDocument37 pagesGeneral Design ConsiderationsArif AmancioPas encore d'évaluation

- ISC Safety Lore - Issue No2Document2 pagesISC Safety Lore - Issue No2zsugyenesPas encore d'évaluation

- Confined Space TrainingDocument18 pagesConfined Space TrainingWisnu HarmawanPas encore d'évaluation

- Sick Building Syndrome - Indoor Air QualityDocument15 pagesSick Building Syndrome - Indoor Air QualityRahmi AndariniPas encore d'évaluation

- Fact Sheet Hvac Duct CleaningDocument3 pagesFact Sheet Hvac Duct CleaningKaran GnaniPas encore d'évaluation

- Confined SpaceDocument18 pagesConfined SpaceDrew MayfieldPas encore d'évaluation

- Eopspecialty 180527110942Document96 pagesEopspecialty 180527110942Alex C G CooperPas encore d'évaluation

- Worksafe Bulletin: Carbon Monoxide Exposure During Film ShootsDocument3 pagesWorksafe Bulletin: Carbon Monoxide Exposure During Film ShootsBuddho BuddhaPas encore d'évaluation

- General Awareness: Respiratory ProtectionDocument29 pagesGeneral Awareness: Respiratory ProtectionDaniel MartinsPas encore d'évaluation

- Occupational Safety and HealthDocument36 pagesOccupational Safety and HealthPavithiran100% (1)

- Anesthetic GasDocument3 pagesAnesthetic GasJuan PáezPas encore d'évaluation

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocument81 pagesAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionKritesh RamnathPas encore d'évaluation

- Assignment 3-Case Study PDFDocument7 pagesAssignment 3-Case Study PDFazhani rosliPas encore d'évaluation

- Standard Operating Procedures For Medical Gas Supply in Health Care FacilitiesDocument9 pagesStandard Operating Procedures For Medical Gas Supply in Health Care FacilitiesSandeep ShettyPas encore d'évaluation

- Sterile Product ManufacturingDocument28 pagesSterile Product ManufacturingPredrag RistićPas encore d'évaluation

- Osha Silica 2018Document79 pagesOsha Silica 2018Maria PinedaPas encore d'évaluation

- Anaesthesia Machine Check - 2023Document31 pagesAnaesthesia Machine Check - 2023Melvin CyriacPas encore d'évaluation

- Medical GasesDocument26 pagesMedical Gaseskanika100% (1)

- Summary 1 Analysis of Equipment Failures As Contributors To ChemicalDocument2 pagesSummary 1 Analysis of Equipment Failures As Contributors To ChemicalhafizaltecPas encore d'évaluation

- NIOSH Confined Spaces 1986 PDFDocument22 pagesNIOSH Confined Spaces 1986 PDFBruno ThiemePas encore d'évaluation

- Class Notes Element 7Document9 pagesClass Notes Element 7danish asrarPas encore d'évaluation

- BOSH Case StudyDocument28 pagesBOSH Case StudyTinae, Vincent JayePas encore d'évaluation

- For Testing The Fume Hoods Personnel Must Wear at A Minimum Gloves and Goggles Follow "Appendix A" AlgorithmDocument4 pagesFor Testing The Fume Hoods Personnel Must Wear at A Minimum Gloves and Goggles Follow "Appendix A" AlgorithmsandbadbahriPas encore d'évaluation

- Control of Exposure Through Intervention (Final)Document62 pagesControl of Exposure Through Intervention (Final)Lauro CanceranPas encore d'évaluation

- Measuring CBGDocument26 pagesMeasuring CBGChengRosalePas encore d'évaluation

- USAID RISE - SOP On Medical Oxygen Sample Collection Using Tedlar BagDocument8 pagesUSAID RISE - SOP On Medical Oxygen Sample Collection Using Tedlar BagAhmed Abo FornPas encore d'évaluation

- Fire in Operating Room - DR Priyank TapuriaDocument57 pagesFire in Operating Room - DR Priyank TapuriaPriyank TapuriaPas encore d'évaluation

- Aseptic Processing The New GuidanceDocument56 pagesAseptic Processing The New Guidanceipatoff100% (1)

- Labotary Safety Guidence: 1.1 Elements of The Laboratory StandardDocument21 pagesLabotary Safety Guidence: 1.1 Elements of The Laboratory Standardroyroy0093Pas encore d'évaluation

- Oxygen Therapy - Facemask, Nasal ProngDocument47 pagesOxygen Therapy - Facemask, Nasal ProngLimYiPas encore d'évaluation

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTPas encore d'évaluation

- Cpde 3aDocument172 pagesCpde 3aAbdul HaseebPas encore d'évaluation

- FDA Guide To Aseptic ProcessingDocument22 pagesFDA Guide To Aseptic ProcessingĐivềphía Mặt Trời100% (1)

- 4 Chemical Exposure MeasurementDocument58 pages4 Chemical Exposure MeasurementHani Liana100% (1)

- Wa0011.Document3 pagesWa0011.mkwa811Pas encore d'évaluation

- OSHA30 ConfinedSpace V6 SGDocument93 pagesOSHA30 ConfinedSpace V6 SGMatt BelsonPas encore d'évaluation

- Air Quality MonitoringDocument10 pagesAir Quality Monitoringsofia mPas encore d'évaluation

- Basic System Configuration: Wellhead and ManifoldDocument1 pageBasic System Configuration: Wellhead and ManifoldnestorsoftPas encore d'évaluation

- Petroleomics and Structure-Function Relations of Crude Oils and AsphaltenesDocument1 pagePetroleomics and Structure-Function Relations of Crude Oils and AsphaltenesnestorsoftPas encore d'évaluation

- A Brief History of LNG: The 1990'S and The Entry of QatarDocument1 pageA Brief History of LNG: The 1990'S and The Entry of QatarnestorsoftPas encore d'évaluation

- ISA 750101 SPBD PDFDocument8 pagesISA 750101 SPBD PDFnestorsoft0% (1)

- Fire Water System and Fire Fighting Equipment PDFDocument3 pagesFire Water System and Fire Fighting Equipment PDFnestorsoftPas encore d'évaluation

- Membrane Technology and Applications PDFDocument4 pagesMembrane Technology and Applications PDFnestorsoft100% (1)

- 2012 06 Beacon SDocument1 page2012 06 Beacon SnestorsoftPas encore d'évaluation

- AspenTech AspenONE 8.0 InstallDocument6 pagesAspenTech AspenONE 8.0 InstallimoomexPas encore d'évaluation

- Oil Refinery Feasibility Study PDFDocument55 pagesOil Refinery Feasibility Study PDFPatrice Adjei96% (23)

- Feed DefinitionsDocument3 pagesFeed DefinitionsnestorsoftPas encore d'évaluation

- Fundamental of Compressible Fluid MechanicsDocument333 pagesFundamental of Compressible Fluid Mechanicsapi-3710585100% (2)

- 04 - Evaluasi Sifat LanjutDocument25 pages04 - Evaluasi Sifat LanjutNazril FarhanPas encore d'évaluation

- Calculation of Orifice DiameterDocument4 pagesCalculation of Orifice DiameterNaseer HydenPas encore d'évaluation

- Vitodens 200-b2hb SM TDMDocument52 pagesVitodens 200-b2hb SM TDMMartin GarciaPas encore d'évaluation

- Complete CatalogueDocument67 pagesComplete Cataloguejarrod lyonPas encore d'évaluation

- Process Equipment Design Chapter 5 - Heat Transfer Equipment Design (Part 1)Document86 pagesProcess Equipment Design Chapter 5 - Heat Transfer Equipment Design (Part 1)Naresh GanisonPas encore d'évaluation

- Department of Education: Activity Sheet Qarter 1 Grade IiiDocument8 pagesDepartment of Education: Activity Sheet Qarter 1 Grade IiiMary Rose P. RiveraPas encore d'évaluation

- Boundary LayerDocument12 pagesBoundary Layerhayder alaliPas encore d'évaluation

- Thomas Heitepriem FerrostaalDocument27 pagesThomas Heitepriem FerrostaalNicolae MarinPas encore d'évaluation

- 03 External ConvectionDocument41 pages03 External Convectionalagar krishna kumarPas encore d'évaluation

- MISSION 2500 AG Centrifugal Slurry Pump FlyerDocument2 pagesMISSION 2500 AG Centrifugal Slurry Pump FlyerFaroukPas encore d'évaluation

- Fluid Mechanics Cengel (Solutions Manual) Chap14-001Document87 pagesFluid Mechanics Cengel (Solutions Manual) Chap14-001NURUL SYUHADA BT ISMAIL HAJAR50% (4)

- Midea 10 HP CatalogueDocument10 pagesMidea 10 HP Cataloguethanh longPas encore d'évaluation

- Data Sheet ValveDocument2 pagesData Sheet ValvePraveen Sivasankaran0% (1)

- LPG FuelcellsDocument25 pagesLPG FuelcellsTrupti SahuPas encore d'évaluation

- Properties of Standard AtmosphereDocument6 pagesProperties of Standard AtmosphereErnesto D. AguirrePas encore d'évaluation

- Cavitation On Wet Cylinder Liners of Heavy DutyDocument13 pagesCavitation On Wet Cylinder Liners of Heavy DutyАнтонPas encore d'évaluation

- On-Line Detection of Pressure Relief Device and Block Valve LeaksDocument6 pagesOn-Line Detection of Pressure Relief Device and Block Valve Leaksvaratharajan g rPas encore d'évaluation

- Energy-Saving: Ammonia Refrigeration Applications Using Pump CirculationDocument11 pagesEnergy-Saving: Ammonia Refrigeration Applications Using Pump CirculationbarelihbPas encore d'évaluation

- HenryDocument86 pagesHenryRodrigo GonçalvesPas encore d'évaluation

- Is 15799 RtofDocument10 pagesIs 15799 Rtofdivyadeenu9390Pas encore d'évaluation

- OPW - Cng-Dispensing-Equipment GNVDocument2 pagesOPW - Cng-Dispensing-Equipment GNVGuadalupe Ximena Real MuñozPas encore d'évaluation

- Advancement in Thermal Power PlantDocument31 pagesAdvancement in Thermal Power PlantFake Lover'sPas encore d'évaluation

- Clement's and Desormes' ExperimentDocument3 pagesClement's and Desormes' Experimentkanchankonwar50% (2)

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatPas encore d'évaluation

- Ag 60 PDFDocument2 pagesAg 60 PDFankur_haldarPas encore d'évaluation

- Diamec U6 Spare PartDocument3 pagesDiamec U6 Spare PartJairo Boechat JuniorPas encore d'évaluation

- Pressure Gauges Register - (20221115)Document14 pagesPressure Gauges Register - (20221115)Not GeniusPas encore d'évaluation

- Minevent 2006 PDFDocument12 pagesMinevent 2006 PDFJosé Manuel Berrospi CruzPas encore d'évaluation

- BR5100 Installation and TroubleshootingDocument2 pagesBR5100 Installation and TroubleshootingRégis OngolloPas encore d'évaluation