Académique Documents

Professionnel Documents

Culture Documents

V58303B

Transféré par

macanipharoldf62200 évaluation0% ont trouvé ce document utile (0 vote)

30 vues2 pagesiom

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentiom

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues2 pagesV58303B

Transféré par

macanipharoldf6220iom

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Expansion Tanks for Potable Water Systems

ASME And Non-Code

WARNING: Label Part No. 9015-463

must be installed in this location.

If missing, it must be replaced.

WARNING: Label Part No. 9017-078

must be installed in this location.

If missing, it must be replaced.

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNERS USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to

draw attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR SAFETY

IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN A SAFETY HAZARD.

WARNING: Explosion Hazard.

A relief valve must be installed to prevent pressure in

excess of local code requirements or maximum working

pressure in manual, whichever is less. This product must be

installed by a qualified professional. Failure to follow the instructions

in the accompanying product manual may cause a rupture or explo-

sion. Failure to follow this instruction may result in serious personal

injury or death and property damage and void product warranty.

DESCRIPTION

Series PT and PTA expansion tanks are precharged diaphragm-

type vessels. The PTA Series meet the requirements of the ASME

boiler and pressure vessels code. The Series PT and PTA tanks

are designed to absorb the force of expanding water and protect the

potable water system from pressure build up. Refer to table 1 on

page 2 for pressure and temperature information.

WARNING: Carefully read the Instruction Manual to avoid

serious personal injury and property hazards and to

ensure safe use and proper care of this product.

WARNING: Use only potable water. Installer must comply

with all plumbing codes. Do not operate in a setting where

the temperature or pressure can exceed the maximum

limitation specified. Refer to Table 1 on page 2 for the maximum lim-

itations specified. Failure to follow this instruction may result in seri-

ous personal injury or death and property damage.

WARNING: Do not locate this product where leaking or

flood could cause damage to the surrounding area. A drip

pan connected to an adequate drain must be installed if

leaking or flooding could cause property damage. Failure to follow

this instruction may result in property damage.

INSTALLATION INSTRUCTIONS

A. Pre-Installation

1. Visually inspect expansion tank and check for damage

prior to installation.

WARNING: If the expansion tank is damaged, it must be

replaced. Failure to follow this instruction may result in

serious personal injury or death and property damage.

2. Adjust pre-charge to equal incoming pressure.

3. Replace and tighten plastic cap on air fitting.

INSTRUCTION MANUAL

V58303B

MAXIMUM LIMITATIONS FACTORY

MODEL NUMBER PRESSURE TEMPERATURE PRE-CHARGE

PT-5, PT-12, PT-25V, PT-30V, PT-42V, PT-60V, PT-80V, PT-180V, PT-210V 150 PSIG (1035 kPa) 200F (93C) 40 PSIG (379 kPa)

PT-447 through PT-457 150 PSIG (1035 kPa) 240F (115C) 55 PSIG (379 kPa)

PTA-5, PTA-12, PTA-20V, PTA-30V, PTA-42V, PTA-60V,PTA-80V, PTA-180V, PTA-210V 150 PSIG (1035 kPa) 200F (115C) 55 PSIG (379 kPa)

PTA-447 through PTA-457 125 PSIG (862 kPa) 240F (115C) 55 PSIG (379 kPa)

TABLE 1

*Water temperature not to fall below 35F (1.6C).

WARNING: State of California Residents.

This product contains a chemical known by the State of

California to cause cancer. This product contains a

chemical known by the State of California to cause birth defects or

other reproductive harm.

WARNING: System fluid under pressure and/or at high

temperatures can be very hazardous. Before servicing,

reduce system pressure to zero or isolate the vessel from

the system. Allow system to cool below 100F and above 35F.

Failure to follow this Instruction may result in serious personal injury

and/or property damage.

WARNING: Do not adjust the pressure or re-pressurize

this product except for any adjustments at the time of the

initial installation when the product is new. Only qualified

professionals should check, adjust or re-charge the pre-charge

of tanks. failure to follow this instruction may result in serious per-

sonal injury or death and property damage.

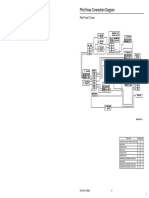

B. Installation

1. Install the expansion tanks on the cold water supply

(CWS) line at a point between the water heater and back-

flow preventer, check valve or pressure reducing valve

(see Figure 1).

2. Once tank is installed fill system and check for any leak-

age. Make repairs if necessary.

WARNING: Rupture or Explosion Hazard.

Like most pressurized tanks, this tank can over time cor-

rode, weaken, and burst or explode. Failure to follow this

instruction may result in serious personal injury or death and prop-

erty damage.

WARNING: Chlorine & Aggressive Water Warning.

The water quality can significantly influence the life of

your product. You should test for corrosive elements,

acidity, total solids, and other relevant contaminants, including chlo-

rine and treat your water appropriately to insure satisfactory per-

formance and prevent premature failure. Failure to follow this

instruction may result in serious personal injury or death and prop-

erty damage.

WARNING: Install or store where tank will not be

exposed to temperatures below freezing or above rated

working temperature. Do not expose to any type of

weather.

3. Before the initial firing of the water heater, open a hot

water fixture and draw water until all air is removed from

the system. Turn the water heater temperature control to

desired ending temperature level (see water heater

instructions).

4. To relieve initial thermal expansion, slightly open a hot

water faucet. Continue until water heater aquastat tem-

perature is satisfied. Once heater is at its operating range,

no further bleeding of expanded water is required.

5. The system water heater and expansion tank will now be

operational. The expansion tank will absorb pressure

increases caused by thermal expansion to a level well

below the water heater relief valve setting.

OPERATING INSTRUCTIONS

1. The expansion tank is installed in the supply line between

the backflow preventer and the water heater. Its sealed-in

air pre-charge prevents water from entering the tank until

the system pressure exceeds the pre-charge pressure.

2. As the water temperature rises, expanded water enters

the expansion tanks non-corrosive water reservoir. The

pre-charge air chamber absorbs the pressure increase,

keeping system pressures below the relief valve setting.

3. As hot water is used, the pressure in the air chamber

forces water back into the system until the expansion

tank is empty. At this point, the pressure in the air cham-

ber once again equals the supply pressure.

NOTE: Models PT-5, PT-12 and PT-25V are IAPMO listed.

Models PT-5 thru PT-210V are listed under ANSI/NSF Std

61 and City of Los Angeles.

Models PTA-5 thru PTA-210V are listed under ANSI/NSF

Std. 61 and City of Los Angeles.

SERIES PT OR PTA

IN-LINE MOUNT

MODELS

SERIES PT OR PTA

FLOOR MOUNT

MODELS

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

2012 Xylem Inc. V58303B May 2012

Vous aimerez peut-être aussi

- Bell & Gossett Domestic Series SA High Temperature Condensate UnitsDocument8 pagesBell & Gossett Domestic Series SA High Temperature Condensate Unitsmacanipharoldf6220Pas encore d'évaluation

- Bell & Gossett: Submittal A-606.6Document1 pageBell & Gossett: Submittal A-606.6macanipharoldf6220Pas encore d'évaluation

- 220CDocument6 pages220Cmacanipharoldf6220Pas encore d'évaluation

- Series 90: In-Line Mounted Centrifugal PumpsDocument12 pagesSeries 90: In-Line Mounted Centrifugal Pumpsmacanipharoldf6220Pas encore d'évaluation

- Model IAS In-Line Air SeparatorDocument2 pagesModel IAS In-Line Air Separatormacanipharoldf6220Pas encore d'évaluation

- Bell & Gossett: Submittal A-606.3Document1 pageBell & Gossett: Submittal A-606.3macanipharoldf6220Pas encore d'évaluation

- Series 60: Sleeve Bearing In-Line Mounted Centrifugal PumpsDocument16 pagesSeries 60: Sleeve Bearing In-Line Mounted Centrifugal Pumpsmacanipharoldf6220Pas encore d'évaluation

- FHD 18Document1 pageFHD 18macanipharoldf6220Pas encore d'évaluation

- Domestic Pump - Adapter Flange Kit Parts ListDocument1 pageDomestic Pump - Adapter Flange Kit Parts Listmacanipharoldf6220Pas encore d'évaluation

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220Pas encore d'évaluation

- Board of Master Plumber-SBDocument7 pagesBoard of Master Plumber-SBdereckaPas encore d'évaluation

- RBG2346MVK R1Document4 pagesRBG2346MVK R1macanipharoldf6220Pas encore d'évaluation

- Proklima Hygienic KU H enDocument8 pagesProklima Hygienic KU H enmacanipharoldf6220Pas encore d'évaluation

- Waste Water Home BasedDocument4 pagesWaste Water Home Basedmacanipharoldf6220Pas encore d'évaluation

- Jfcfsu) 1$4: %Ftjhofegpsuif&G Djfou$Ppmjohpg4Nbmm%Bub$FoufstDocument6 pagesJfcfsu) 1$4: %Ftjhofegpsuif&G Djfou$Ppmjohpg4Nbmm%Bub$Foufstmacanipharoldf6220Pas encore d'évaluation

- Sequence of Operations For Hvac ControlsDocument4 pagesSequence of Operations For Hvac Controlsmacanipharoldf6220Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Inside BopDocument5 pagesInside BopNigin Parambath100% (1)

- Site Visit Gomti Aqueduct in LucknowDocument17 pagesSite Visit Gomti Aqueduct in LucknowPankajKumar100% (2)

- O&M Manual For Plumbing and Sanitary System Rev 1 (Partial) PDFDocument813 pagesO&M Manual For Plumbing and Sanitary System Rev 1 (Partial) PDFdavidrferrer83% (6)

- Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)Document66 pagesCh8 Steady Incompressible Flow in Pressure Conduits (PartB)avinash_friends21Pas encore d'évaluation

- 2018 ERIKC Common Rail Parts CatalogDocument36 pages2018 ERIKC Common Rail Parts CatalogMichele GuerriniPas encore d'évaluation

- DOLPHIN LX 0030/0055 B: Liquid Ring Vacuum PumpsDocument2 pagesDOLPHIN LX 0030/0055 B: Liquid Ring Vacuum PumpsJohan ConradiePas encore d'évaluation

- WS CalculationDocument29 pagesWS CalculationMac ShaikPas encore d'évaluation

- Válvulas SwagelokDocument17 pagesVálvulas Swagelokkirlaniano@gmail.comPas encore d'évaluation

- A95a ElDocument5 pagesA95a ElBALAKRISHNANPas encore d'évaluation

- How To Calculate The NPSH of Pump in HYSYSDocument3 pagesHow To Calculate The NPSH of Pump in HYSYSAnonymous jqevOeP7100% (3)

- Hydraulic Hand Pumps: Ep 01 T ADocument28 pagesHydraulic Hand Pumps: Ep 01 T AMichel BrassardPas encore d'évaluation

- Pilot Hose Connection Diagram: Pilot P and T LinesDocument8 pagesPilot Hose Connection Diagram: Pilot P and T LinesDhany SiregarPas encore d'évaluation

- Dongguan Suncenter Fluid Control Equipment Co., LTDDocument10 pagesDongguan Suncenter Fluid Control Equipment Co., LTDJeisson DazaPas encore d'évaluation

- Piping Class - DD20Document2 pagesPiping Class - DD20Дмитрий РыбаковPas encore d'évaluation

- O-53b Cargo Pumping SystemDocument453 pagesO-53b Cargo Pumping SystemTimmyJuri100% (2)

- Daily Work Report DP SinghDocument820 pagesDaily Work Report DP SinghShankey JAlanPas encore d'évaluation

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90Pas encore d'évaluation

- D.O. 111, S 2017Document8 pagesD.O. 111, S 2017ZA TarraPas encore d'évaluation

- MultiTank FinalDocument41 pagesMultiTank FinalEdwardhutaurukPas encore d'évaluation

- 13march2020 - Construction Completion Punch List MasterfileDocument143 pages13march2020 - Construction Completion Punch List MasterfileDangolPas encore d'évaluation

- Cylinder Visual Inspection FormDocument2 pagesCylinder Visual Inspection Formzineddine sofienePas encore d'évaluation

- Series LF223, LF223S Specification SheetDocument2 pagesSeries LF223, LF223S Specification SheetWattsPas encore d'évaluation

- WKN WLN: High Pressure Centrifugal PumpsDocument4 pagesWKN WLN: High Pressure Centrifugal PumpsField Marshal Thebe HanyanePas encore d'évaluation

- QSSDocument48 pagesQSSArvind KhaplePas encore d'évaluation

- Roughness Coefficient & Piping Schedule No22Document18 pagesRoughness Coefficient & Piping Schedule No22Joon EeoPas encore d'évaluation

- W07. Open Centre Control ValvesDocument3 pagesW07. Open Centre Control ValvesMohamed BakheetPas encore d'évaluation

- LMI Series AA-B-C-E-J-P Metering Pumps Manual PDFDocument44 pagesLMI Series AA-B-C-E-J-P Metering Pumps Manual PDFRoberto MejiaPas encore d'évaluation

- Eliminador de Ar para Liquidos Pae10 275Document2 pagesEliminador de Ar para Liquidos Pae10 275Keronlline GomesPas encore d'évaluation

- Brosur Pompa KP & KPV PDFDocument8 pagesBrosur Pompa KP & KPV PDFAndiPas encore d'évaluation

- 11d2 Multiplex Plunger Pumps Parts ListDocument68 pages11d2 Multiplex Plunger Pumps Parts ListShivshankar KawalePas encore d'évaluation