Académique Documents

Professionnel Documents

Culture Documents

Im116e Frame 9e

Transféré par

Ali Eng100%(1)100% ont trouvé ce document utile (1 vote)

97 vues31 pagesThis document provides instructions for installing and tensioning studs and nuts for a gas turbine connection using equipment supplied by Riverhawk Company. It details safety warnings and procedures for hardware preparation, tensioning studs using hydraulic tensioners, and removing studs. Installation is to be done per Riverhawk manuals and involves hand tightening studs, tensioning to specified pressures in a pattern, measuring stud stretch, and locking nuts.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides instructions for installing and tensioning studs and nuts for a gas turbine connection using equipment supplied by Riverhawk Company. It details safety warnings and procedures for hardware preparation, tensioning studs using hydraulic tensioners, and removing studs. Installation is to be done per Riverhawk manuals and involves hand tightening studs, tensioning to specified pressures in a pattern, measuring stud stretch, and locking nuts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

97 vues31 pagesIm116e Frame 9e

Transféré par

Ali EngThis document provides instructions for installing and tensioning studs and nuts for a gas turbine connection using equipment supplied by Riverhawk Company. It details safety warnings and procedures for hardware preparation, tensioning studs using hydraulic tensioners, and removing studs. Installation is to be done per Riverhawk manuals and involves hand tightening studs, tensioning to specified pressures in a pattern, measuring stud stretch, and locking nuts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 31

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

INSTRUCTION MANUAL IM-116

For Gas Turbine Tensioned Studs and Nuts

Fr.9E Turbine to 9A3 ELIN Generator GE358A7202P022

The Riverhawk Company reserves the right to make changes updating

this document without dissemination or notice. The latest

revision level may be obtained by contacting Riverhawk Company

directly or visit our website at www.riverhawk.com

VENDOR SUPPLIED DRAWING

GE NOT TO REVISE. GE REVISION LEVEL IS AS SHOWN ON THIS APPLI QUE.

THIS DOCUMENT IS FILED UNDER THE GE DR AWING NUMBER

THIS DOCUMENT SHALL BE REVISED IN ITS ENTI RETY. ALL SHEETS OF THIS DOCUMENT

ARE THE SAME REVISION LEVEL AS INDI CATED IN THI S VENDOR SUPPLI ED DRAWING APPLIQUE

FIRST MADE FOR:

___ OF ___

GE Power Generation

ISSUED

CHECKED

GE SI GNATURES DATE

E

GE DRAWING NUMBER REV

GENERAL ELECTRIC COMPANY

Schenectady, NY

373A4028

GE ALTERATI ON

NOTICE NUMBER

REVISION

LETTER

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

2

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Table of Contents

Section Description

Page

Number

1.0 Cautions and Safety Warnings 3

2.0 Scope 4

3.0 Quick Check-List 5

4.0 General Preparations 8

5.0 Hardware Set Preparations 9

6.0 Stud and Nut Assembly 11

7.0 Assembly of Hydraulic Tensioner Equipment 12

8.0 Assembly of Tensioner on Stud 13

9.0 Stud Pulling and Tensioning 15

10.0 Thread Locking 16

11.0 Stud/Nut Removal 17

12.0 Storage 18

13.0 Frequent Asked Questions 19

14.0 Revision History 22

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

3

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

1.0 Cautions and Safety Warnings

CAUTION

Personal injury and equipment damage can occur if the puller

screw is not securely engaged with the tapered thread of the

stud. Proper engagement is achieved when the puller screw is

tight in the stud and the Tensioner Assembly is free to rotate.

WARNING

The safety cage MUST be in place and hands kept out of designated

areas at all times when the tensioner is pressurized otherwise

personal injury can occur.

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER

BODY. Excessive pressure can damage the stud and the puller

screw.

WARNING

Fire Hazard! DO NOT heat when the puller assembly is in place.

Personal injury or equipment damage may occur. Use of an Oxy-

Acetylene torch is not recommended.

NOTICE

Do not use more thread locking compound than specified or the nut

may be VERY difficult to remove at disassembly.

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER

BODY. Excessive pressure can damage the stud and puller screw

Note: Before threading the puller screw into the stud, carefully

check the cleanliness of both the stud's and the puller screw's

conical threads. Apply a light coat of clean turbine oil or a

spray lubricant to the puller screw. Do not use Never Seize on

the conical threads. This procedure will ease assembly and assure

positive mating of the threads before tightening.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

4

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

2.0 Scope

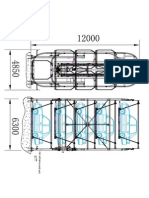

This document describes the procedure to be used to install studs

and nuts supplied by Riverhawk Company in the flanges at the

turbine/coupling and coupling/generator connections. This

hardware is depicted on the following drawings These drawings as

well as the tooling drawings form a part of this manual.

HF-0813

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

5

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

3.0 Quick Checklist

The following checklist is intended as a summary of the steps

needed to use the Riverhawk-supplied equipment. New personnel or

those experienced personnel who have not used the Riverhawk

equipment recently are encouraged to read the entire manual.

EQUIPMENT INSPECTION

Check oil level in hydraulic pump.

Check air pressure at 80 psi [5.5 bar] minimum. (For air-

driven pumps)

Check hydraulic hose for damage.

Test pump.

Inspect tensioner for any damage.

NUT AND STUD PREPARATION

Inspect stud and nuts for any damage.

Measure stud length.

Clean the studs and nuts.

Install studs and nuts (off-center) into the flange.

Set stick-out dimension on the coupling side of the flange.

Hand tighten all studs.

Verify stick-out measurement (VERY IMPORTANT)

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

6

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Tensioning (Bolt installation)

Match the tensioner setup to the flange joint.

Apply a light coat of clean turbine oil or spray lubricant

to the puller screw. DO NOT USE NEVER SEIZE ON THE CONICAL

THREADS.

Slide spanner ring over the puller screw.

Mount the tensioner on the stud in flange.

Install spanner ring onto nut.

Insert 1/2 hex Allen wrench into the back side of the stud.

Tighten the puller screw.

Back off puller screw 1/2 turn.

Retighten the puller screw and leave tight. DO NOT BACK OFF

PULLER SCREW.

Bleed the tensioner. Do NOT bleed tensioner off of a stud!

Damage to the tool will result!

Tension to 50%. Consult manual for correct pressure.

Use the pin wrench in spanner ring to tighten nut.

Release pressure, move to next stud in pattern.

Repeat above steps at final pressure.

Measure final stud length and record on stretch datasheets.

Calculate stretch.

Torque nuts' set screws.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

7

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Detensioning (Stud removal)

Loosen nuts' set screws

Inspect and clean studs' conical threads. Do not continue

until ALL debris is removed from the threads! Do not try to

use the tensioner to remove a damaged stud!

Apply a light coat of clean turbine oil or spray lubricant

to the puller screw. DO NOT USE NEVER SEIZE ON THE CONICAL

THREADS.

Slide spanner ring over the puller screw.

Mount the tensioner on the stud.

Install spanner ring into nut.

Tighten the puller screw.

Back off puller screw 1/2 a turn.

Retighten the puller screw and leave tight. DO NOT BACK OFF

PULLER SCREW.

Bleed the tensioner. Do NOT bleed tensioner off of a stud!

Damage to the tool will result!

Apply final pressure.

Loosen nut with the spanner ring and pin wrench.

Move to next stud in pattern

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

8

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

4.0 General Preparations

Read and understand all instructions before installing studs.

This equipment produces very high hydraulic pressures and very

high forces. Operators must exercise caution, wear safety glasses

and hard hats when using this equipment.

High pressure fluid from the Hydraulic Pressure Kit system

pressurizes the tensioner which generates a stretching force that

actually stretches the stud. As the stud is stretched the nut

lifts off the flange. The nut is then reseated into position on

the flange by turning a nut driver by hand. When the nut is tight

against the flange, the pressure in the tensioner is released

leaving the stud loaded to its predetermined value.

4.1 Machine Preparation

The flange to be tensioned must be fully closed prior to

positioning of studs in the flanges. There must be provision to

turn the shafts of the turbine and the generator. Also, it will

be advantageous to remove as many obstructions as possible from

the flange area, such as speed probes and conduit.

4.2 Hardware Balance

Hardware is supplied as weight balanced sets

Studs and Nuts are interchangeable within sets

Do not mix with other sets

Save weight certification for the purchase of spares

4.3 Tensioner Care and Handling

When not in use, the tensioner shall be maintained in a clean

environment and all caps and plugs for hydraulic openings and

fittings must be in place.

When in use, the tensioner shall be protected from sand and

grit

Long term storage coat tensioner with oil, return to

original container, seal container and protect from moisture

Shipment coat tensioner with oil and ship in original

container

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

9

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

4.4 Hand Tools

Several hand wrenches and micrometers will be required to perform

installation and measurement of the studs:

5/8 wrench

1" wrench

1 socket and impact wrench

A set of Allen Wrenches

3 4 Breaker Bar

9 to 10 micrometer or caliper

10 to 11 micrometer or caliper

4.5 Special Tools

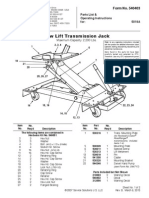

Hydraulic Tensioner Kit: HT-0814 Hydraulic Tensioner

Hydraulic Pump Kit: AP-0532 Air-Operated Hydraulic Pump

(recommended)

(reference GE 359B2502)

MP-0130 Manual Hand-Operated

Hydraulic Pump

(reference GE 359B2506)

5.0 Hardware Set Preparations

5.1 Nut Preparation

For new installations, the nuts should come sealed from the

factory and will need no cleaning.

Previously installed nuts require cleaning as follows: Wire

brush using a petroleum based solvent to remove any foreign

material on the external surfaces and threads.

If previous installations employed a thread locking compound,

which will be visible as a grayish-green residue, remove as much

of this compound as possible.

Do not apply thread lubricants to the threads.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

10

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Finish the cleaning process by rinsing in a volatile solvent such

as acetone and allow to dry.

5.2 Stud Preparation

For new installations, the studs should come sealed from the

factory and will need no cleaning.

5.2.1 Stud Cleaning - Old Installations

Previously installed studs may require cleaning. Clean conical

threads should have a bright and shiny appearance.

If cleaning is required, follow these steps:

1. Blow out the threads with compressed air to remove loose

debris and dry conical threads. Do not apply a solvent or

other cleaning solution to the threads as this may

chemically attack the stud.

2. Use Stud Cleaning Kit, GT-4253 or a similar 1" diameter

Brass power brush.

Picture of Brass Power Brush

3. Insert the brush into an electric drill and set drill to run

in a counterclockwise direction at high speed.

4. Work the drill in a circular motion while moving the brush

in and out to clean all of the threads. Try not to hold the

brush in one place too long, so as not to remove the stud's

protective coating.

5. Blow out the threads with compressed air to remove loosened

debris.

6. Visually inspect threads for cleanliness. Threads should be

bright and shiny.

7. Repeat if any dirt can be seen in the threads.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

11

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

8. Inspect threads for any damage that may have been caused by

previous installation.

Do not apply thread lubricants to the threads.

Finish the cleaning process by rinsing in a volatile solvent such

as acetone and allow to dry.

5.3 Stud Length Measurement

Measure and record the initial lengths of the studs. The

following recommendations will improve your results.

Plan to start and finish any flange in the same day.

Studs and flange must be at the same temperature.

Number each stud with a marker.

Mark the location of measurement on stud end with a permanent

marker.

Measure each stud to nearest 0.001 inch.

Record each measurement on the supplied charts.

Do not allow the measuring instruments to set in the sun.

6.0 Stud and Nut Assembly

Refer to hardware assembly drawing (HF-0813) listed in Section

2.0 of this manual. Assemble cylindrical nut to the tapered

thread end (Pull End) of the stud. Slide the stud and cylindrical

nut assembly into the flange as shown in Figures 1 & 2 and

install the other nut on the backside. Adjust the nut/stud

assembly so that the stud protrudes from the face of the

cylindrical nut the amount as depicted on the hardware drawing

(HF-0813). SETTING THIS PROTRUSION OF STUD TO NUT IS CRITICAL FOR

PROPER TENSIONER OPERATION. Hand tighten the assembly to a snug

fit. See photos 1 & 2 for view of studs in flange prior to

tensioning.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

12

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

7.0 Assembly of Hydraulic Tensioner Equipment

7.1 Kit Assembly

Assemble the hydraulic pump with its hose to the puller tool and

bleed the system of air per following instructions. Photo 4

shows hose connected to manifold of tensioner.

Clean puller screw and check for any debris and dents.

Puller screw should be free to rotate and move back and forth.

Seam between cylinders closed tightly.

Inspect tensioner guard for any signs of damage. Bent guards

should be replaced. Also, be sure the rubber pad is in place on

the end of the guard, if missing, replace.

7.1.1 Fittings

Make sure both male and female parts are clean and free of

debris, see Figure 3 for fitting configuration. Hold female part

securely when tightening so as to prevent damage to adjacent

tubing. If fitting leaks first try retightening as needed. If

leaking continues then disassemble and check for scratches or

debris on the seating conical surfaces. Clean as required.

Replace plastic caps when finished with tooling.

7.2 Pump

The pump kit is shipped full of hydraulic oil. The pump reservoir

cap is sealed for shipment. To use turn cap to the vent position.

To prevent oil spillage close cap when not in use, during storage

and shipment. Lost oil should be replaced with Enerpac Hydraulic

Oil. ISO 32. Mineral Oil may be substituted, if necessary.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

13

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

7.3 Bleeding Hydraulic System

Follow the tensioner assembly instructions of Section 8.0.

TO AVOID FAILURE, ENSURE SAFETY AND PROPER OPERATION THE

TENSIONER ASSEMBLY MUST BE MOUNTED ON THE STUD BEFORE BLEEDING

THE SYSTEM AND TENSIONING BEGINS.

The tensioner has four ports see Fig. 5, one for pressurizing,

two for bleeding the system and a fourth pressure relief port.

To facilitate bleeding, start by first mounting the tensioner at

either the 3 0clock or 9 oclock stud position depending on

which will critically place the bleed ports in their uppermost

position. In addition, make sure that the pump is always situated

below the tensioner assembly.

The puller tool is equipped with 5/8 in. [16 mm] Hex coned stem

bleeder fittings installed in the bleeder ports. With theses two

fittings loosened simultaneously, stroke the pump repeatedly

until the streams of oil exiting the tool from each port are free

of air, then retighten the fittings.

Providing that the hose is not disconnected or loosened in the

process of tensioning all the studs, bleeding the assembly once

at the first position should suffice to fill the assembly and

preclude the need to repeat the bleeding process.

Note: The hose is stiff, use of this tooling can be simplified by

temporarily mounting the puller tool on one stud prior to final

tightening of fittings. This will reduce the tendency for the

fittings to loosen.

8.0 Assembly of Tensioner on Stud

All tensioning will be performed from the tapered thread end of

the stud with orientation of the stud to the flange as shown in

Figures 1 & 2. Refer to Tensioner assembly drawing and Figure 5

for tensioner to flange mounting.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

14

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

This assembly has the following features which should make stud

tensioning safe and easy.

The safety cage is integral (bolted) to the puller tool

The hydraulic piston is spring loaded to retract.

The puller screw is a 2-piece design which requires that the

operator tighten the puller screw into the stud.

Assembly sequence is as follows:

1. Open the hydraulic return valve on the hand pump to allow

hydraulic fluid to be pushed back from the puller tool into

the pump reservoir. (This is automatic with the air-operated

hydraulic pump)

2. Place the spanner ring on the puller side cylindrical nut

3. Apply a light coat of clean turbine oil or a spray lubricant

to the puller screw. Do not use Never Seize on the conical

threads.

4. Place and hold the tensioner assembly over the end of the stud

to be tightened. See photos 3,4 &5.

5. Slide the puller screw in to the tapered thread of the stud

and hand tighten. Be sure not to cross thread assembly.

6. Tighten the puller screw using Allen wrenches on the puller

screw and the stud. DO NOT wrench on the nut opposite the

puller tool.

7. At this point the Tensioner Assembly MUST BE FREE TO ROTATE,

the puller screw must be tight in the stud and the puller nut

has been backed-off 2 flats.

If the puller tool is not free to rotate when the puller screw is

tight, then either. (1) The tensioner is damaged, or. (2) The

stud is not properly positioned in the flange and the nuts must

repositioned. This can be done as follows.

1. Slightly loosen the puller screw

2. Back the nut opposite the puller tool off about 1/2 turn

3. Tighten the puller screw side nut to take up the slack.

4. Retighten the puller screw per above and check for looseness

of tool

CAUTION

Personal injury and equipment damage can occur if the puller

screw is not securely engaged with the tapered thread of the

stud. Proper engagement is achieved when the puller screw is

tight in the stud and the Tensioner Assembly is free to rotate.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

15

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

9.0 Stud Pulling and Tensioning

The studs will be tensioned in two steps, at approximately 50%

pressure and at final pressure. Follow the tensioning sequence

for each flange joint as defined on the data sheets found at the

end of this manual

Note: Before threading the puller screw into the stud, carefully

check the cleanliness of both the stud's and the puller screw's

conical threads. Apply a light coat of clean turbine oil or a

spray lubricant to the puller screw. Do not use Never Seize on

the conical threads. This procedure will ease assembly and assure

positive mating of the threads before tightening.

WARNING

The safety cage MUST be in place and hands kept out of designated

areas at all times when the puller tool is pressurized otherwise

personal injury can occur.

9.1 Tensioning at 50% pressure

After the tensioner is properly installed apply hydraulic

pressure to the tool. Bring the pressure to the 50% level in

accordance with the following table.

Flange Position Stud Size 50% Pressure 50% Stretch

Turbine to

Coupling

2.784"

[71 mm]

9000 psi

[620 bar]

Do not measure

Do not use

Coupling to

Generator

2.283"

[58 mm]

10000 psi

[690 bar]

Do not measure

Do not use

9.1.1 Tightening the Turbine/Coupling and Coupling/Generator Nuts

Turn the cylindrical nut using the spanner ring and pin wrench as

depicted in Figure 5 until it bottoms on the flange.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

16

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

9.2 Removing the Tensioner from an Installed Stud

Puller tool removal is to accomplished as follows:

1. Release the puller tool pressure by opening the valve on the

pump. Leave the valve open. This is automatic on the air-

operated hydraulic pump.

2. Unscrew the puller screw using a wrench

3. Tapping the wrench with a hammer may be necessary to loosen

the puller screw.

4. Move the tool to the next stud/nut assembly to be tensioned,

following the sequence/pattern as defined on the supplied

data sheets.

9.3 Tensioning at Final Pressure

Repeat the pulling and tightening procedure stated above at full

pressure. Measures the length of the studs after all have been

tensioned. The final pressure and required stretch values are

listed in the following table

Flange Position Stud Size Final Pressure Final Stretch

Turbine to

Coupling

2.784"

[71 mm]

18000 psi

[1170 bar]

0.011" - 0.014"

[0.28 mm - 0.36 mm]

Coupling to

Generator

2.283"

[58 mm]

20500 psi

[1240 bar]

0.019" - 0.023"

[0.48 mm - 0.58 mm]

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER

BODY. Excessive pressure can damage the stud and the puller screw

10.0 Retensioning

For the procedures of Section 9.3 excessive stretch variation or

low stretch values can be corrected by retensioning all or

selected studs to the pressure values stated in the above table.

Have final stretch values approved by the supervisor responsible

for the installation.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

17

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

11.0 Thread Locking

Once pulling and tensioning is complete all studs and nuts must

be locked in position. The lock nuts used in the turbine/coupling

and coupling/generator connections employ a mechanical locking

feature. These mechanical lock nuts have two set screws located

on the top face, see Figure 4.

Before threading the nut onto the stud check to be certain that

the set screws are free to turn. Once the nut is seated torque

the set screws to the values specified in the following table.

When seated and torqued to the values specified the load created

by the set screw displaces the thread of the nut in the area of

the web creating the desired locking action.

Stud Size Set Screw Size Torque

2.784"

[71 mm]

3/8"-24 UN

200 inlbs - 250 inlbs

[22.6Nm 28.2 Nm]

2.283"

[58 mm]

1/4"-28 UN

80 inlbs - 90 inlbs

[9.0 Nm 10.2 Nm]

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

18

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

12.0 Stud/Nut removal

Removal is accomplished as follows:

1. Using a wire brush and shop air clean the internal tapered

thread of the stud to remove any debris/deposits which may

have accumulated during service. (see section 5.2.1)

2. With an Allen-wrench loosen the two locking set screws but

do not remove from the nut see Figure 4.

3. Install the appropriate puller tool to the stud as described

in Section 8.0.

4. Apply the appropriate hydraulic pressure per the following

Table and using the spanner ring and spanner/pin wrenches

shown in Figure 5 loosen the nut, then release the pressure

and remove the puller tool.

Flange Position Stud Size Removal Pressure

Turbine to Coupling

2.784"

[71 mm]

18000 psi

[1170 bar]

Coupling to Generator

2.283"

[58 mm]

20500 psi

[1240 bar]

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

19

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

13.0 frequently Asked Questions

This section contains some frequently asked questions and

problems. If the steps listed here do not solve your problem,

contact the Riverhawk Company thru our website, email, or phone

call.

Q: A tensioner has pulled itself out of the stud's conical

threads. Can I continue using a tensioner on this stud?

A: No. Both the tensioner and the stud may have been damaged.

If the stud is tensioned, a Nut Buster repair kit, from

Riverhawk, must be used to remove the damaged stud by

drilling out the nut. Riverhawk can supply a replacement

stud and nut based on the initial weight certification

supplied with the hardware set (see section 4.2). The

damaged tensioner should also be returned to Riverhawk for

inspection and repair.

Q: The hydraulic tensioner has been taken up to its final

pressure. The final stretch length is short of the final

stretch target. What is the next step?

A: Do not increase the hydraulic pressure. Check if the

hydraulic pump is set to the right pressure. Install the

tensioner and re-pressurize the tensioner to the final

pressure then recheck the stretch measurement. If the

stretch value is still short, remove the stud from the hole

and re-measure the stud's initial length then try to install

the stud again.

Q: The hydraulic tensioner has been taken up to its final

pressure. The final stretch length is larger than the final

stretch target. What is the next step?

A: Remove the stud from the bolt hole. Check if the hydraulic

pump is set to the right pressure. Re-measure the stud's

initial length then try to install the stud again.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

20

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Q: Is there an easier way to support or move the tensioner

around the coupling shaft?

A: Use two straps. One around the coupling shaft and the other

attach to any overhead support. Straps must be slack during

mounting tensioner to stud and during tensioning.

Q: The tensioner is at its final pressure, but the nut cannot

be loosen.

A: If the nuts cannot be loosened at the final pressure,

continually increasing the pressure will not help and can be

dangerous and in some cases make it harder to remove the

nut. Check the nut to see if its set screws have been

loosened. Check for and remove any corrosion around the

nut's threads.

Q: How do I clean the conical threads on a stud?

A: The conical threads are best cleaned using a spiral wound

brass brush in a drill as described in section 5.2.1

Q: During the initial steps of removing a tensioned stud, the

stick-out length is found to be wrong.

A: Do not proceed. Contact Riverhawk for assistance. With the

wrong stick-out length, the hydraulic tensioner has a

limited stroke and may not work properly and can be damaged.

Q: The hydraulic pump appears to be leaking.

A: Check the hose connection to the hydraulic pump. If the 1/4"

high pressure fitting is not assembled correctly, it may

look like the pump is leaking. If the problem continues, it

may be necessary to open the pump kit. Contact Riverhawk for

guidance.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

21

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Q: The hydraulic hose has a collar on it that can't be moved by

hand

A: The collar is sometimes held in place with a thread locking

compound. This prevents the collar from moving too easily.

It may be necessary to adjust this collar with a set of

vise-grip pliers. Be careful to not strip the threads off

the tube or hose end.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

22

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

14.0 Revision History

Revision

Letter

Effective

Date

Description

E Jun 10, 2009 Added turbine oil and removed Never

Seize from sections 1.0, 3.0, 8.0, and

9.0

D Mar 25, 2009 Added sections 3 and 13, Added GE Title

block to all pages

C Jun 23, 2000 Page 2 para 2.0, Page 4 para 4.0, Page

5 para 5.3, page 7 para 7.3

B Jan 11, 2000 Page 1

A Jul 20, 1999

- Mar 19, 1999 Released

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

23

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

24

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

25

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

26

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Photo 1

Section of 9FA turbine flange with

studs in place prior to tensioning.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

27

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Photo 2

Back side of 9FA turbine flange

showing studs and nuts in place.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

28

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Photo 3

Side view of tensioner mounted

on 9FA turbine flange.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

29

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Photo 4

Tensioner in operation while

mounted on 9FA turbine flange.

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

30

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Photo 5

View of operator tightening nuts

on Fr. 9FA turbine flange

Instruction Manual IM-116

For Gas Turbine Tensioned Studs & Nuts

31

215 Clinton Road.

New Hartford, NY 13413

Tel: 315-768-4855

Fax: 315-768-4941

Email: info@riverhawk.com

373A4028 E

REV.

SH. FIRST MADE FOR:

GE DRAWING NUMBER

Vous aimerez peut-être aussi

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Im101s Frame 6faDocument41 pagesIm101s Frame 6faDefinal ChaniagoPas encore d'évaluation

- IM 377 9FA HSIG TensionerDocument35 pagesIM 377 9FA HSIG TensionerAdil MajeedPas encore d'évaluation

- 15 Series Tube Fittings and TubesDocument8 pages15 Series Tube Fittings and TubesNilesh MistryPas encore d'évaluation

- Oil Filter Installation & ServiceDocument16 pagesOil Filter Installation & ServicemdhelicoptersPas encore d'évaluation

- Power Team PQ120 ManualDocument10 pagesPower Team PQ120 ManualTitanplyPas encore d'évaluation

- 390 InstructionsDocument48 pages390 InstructionsemaanazeemPas encore d'évaluation

- Tuthill - Manual de Mantenimiento Linea Equalizer (4000-6000)Document44 pagesTuthill - Manual de Mantenimiento Linea Equalizer (4000-6000)Pedro FernandezPas encore d'évaluation

- Viking 4324A Oandm TSM6303 PDFDocument11 pagesViking 4324A Oandm TSM6303 PDFQOBITPas encore d'évaluation

- Section B 23 Series PDFDocument4 pagesSection B 23 Series PDFPartsGopher.comPas encore d'évaluation

- Power Team PQ60 ManualDocument10 pagesPower Team PQ60 ManualTitanply100% (1)

- Greenlee Dobladora de TubosDocument16 pagesGreenlee Dobladora de TuboswilfredoPas encore d'évaluation

- Rudder Repeatback Rudder Angle Transmitter.Document469 pagesRudder Repeatback Rudder Angle Transmitter.Nutriologa Adriana LazaroPas encore d'évaluation

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezPas encore d'évaluation

- 50 GPM Users Guide 101102Document14 pages50 GPM Users Guide 101102Aprizal AzisPas encore d'évaluation

- Manual OTC Jack TransmisionDocument3 pagesManual OTC Jack Transmisionlucass1Pas encore d'évaluation

- 2 Installation Maintenance - FantechDocument12 pages2 Installation Maintenance - FantechLoi Chan TuPas encore d'évaluation

- Typical Module Maintenance Schedule - Turbine MeteredDocument1 pageTypical Module Maintenance Schedule - Turbine MeteredRindu Putra AmbaritaPas encore d'évaluation

- FRH FRG ManualDocument23 pagesFRH FRG ManualdlanorxPas encore d'évaluation

- Til 1214-3R3Document7 pagesTil 1214-3R3Hernan Giraut100% (2)

- Greenlee Pipe and Tube Bender 782 IM823REV08Document18 pagesGreenlee Pipe and Tube Bender 782 IM823REV08Leonard100% (1)

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010Pas encore d'évaluation

- 940-0502 Onan NHE Service ManualDocument104 pages940-0502 Onan NHE Service ManualmichaelpendergastPas encore d'évaluation

- A 084 BDocument12 pagesA 084 BDenis JimenezPas encore d'évaluation

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengPas encore d'évaluation

- DPT 100Document72 pagesDPT 100Gregory StewartPas encore d'évaluation

- LPG Pump IOM LGL2 LGL3 PDFDocument12 pagesLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- In-Line Hydraulic TesterDocument5 pagesIn-Line Hydraulic TesterMasterrPas encore d'évaluation

- Hydraulic Pump Start-Up ProcedureDocument3 pagesHydraulic Pump Start-Up ProcedureCésar A. ChacónPas encore d'évaluation

- HDPH436vikingheavypump (German)Document17 pagesHDPH436vikingheavypump (German)Hector_Cornejo_5673Pas encore d'évaluation

- Hydraulic RAM Installation Service Handbook Is-2533Document13 pagesHydraulic RAM Installation Service Handbook Is-2533Arnie SaysonPas encore d'évaluation

- 0.0 TRP-5111 A 660/760 TM SET-UP 1.0 Purpose: SECTION: Hot Tap Services Revision # - 1Document4 pages0.0 TRP-5111 A 660/760 TM SET-UP 1.0 Purpose: SECTION: Hot Tap Services Revision # - 1vuongPas encore d'évaluation

- Bomba Manual Hoja InstruccionesDocument72 pagesBomba Manual Hoja InstruccionesJulio ValderramaPas encore d'évaluation

- HOTSY - 7660 Automatic Parts Washer (Operators Manual)Document54 pagesHOTSY - 7660 Automatic Parts Washer (Operators Manual)SodaProp100% (1)

- GD Qf450sb FeDocument11 pagesGD Qf450sb FeCesar MoraPas encore d'évaluation

- Air CylinderDocument4 pagesAir Cylindersimbua720% (1)

- 'TTA IOM R22 Jan10Document28 pages'TTA IOM R22 Jan10Luong DaoPas encore d'évaluation

- Whitlock DNFTDocument4 pagesWhitlock DNFTJoe TorrenPas encore d'évaluation

- Hydraulic Nut Bottom Collar ManualDocument12 pagesHydraulic Nut Bottom Collar Manualwill_evans8681Pas encore d'évaluation

- Blower TUTHILL ManualDocument48 pagesBlower TUTHILL ManualEd Ortiz100% (1)

- SB388CDocument13 pagesSB388CBenjamin LeedsPas encore d'évaluation

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60Pas encore d'évaluation

- 980a0670 PDFDocument42 pages980a0670 PDFMichael DavenportPas encore d'évaluation

- Manual Taller ARN 125 CC (Idioma Ingles)Document85 pagesManual Taller ARN 125 CC (Idioma Ingles)Cordobessa50% (2)

- 143T-449T TECO Welding House GeneralDocument9 pages143T-449T TECO Welding House GeneralChristian TorresPas encore d'évaluation

- Power Team PE18 ManualDocument8 pagesPower Team PE18 ManualTitanplyPas encore d'évaluation

- Lockheed FlarelessDocument20 pagesLockheed FlarelessGazpachoesiPas encore d'évaluation

- Manual Sc32.PDF Prenza Hidraulica GatesDocument16 pagesManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaPas encore d'évaluation

- Installation Guide 854 Advanced Technology Gauge: July 2008 Part No. 4416.225 Rev. 6Document24 pagesInstallation Guide 854 Advanced Technology Gauge: July 2008 Part No. 4416.225 Rev. 6Brian McKirdyPas encore d'évaluation

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangPas encore d'évaluation

- 70.00.00 Standard Practices - Maintenance ProceduresDocument21 pages70.00.00 Standard Practices - Maintenance ProceduresTimoteo Molina RomeroPas encore d'évaluation

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaPas encore d'évaluation

- REHS1037 - Fuel Priming PumpDocument13 pagesREHS1037 - Fuel Priming Pumpkman548Pas encore d'évaluation

- Gate Valve DSDocument5 pagesGate Valve DSkhaireddin100% (1)

- Acoplamiento Sure-Flex Couplings PDFDocument4 pagesAcoplamiento Sure-Flex Couplings PDFFederico Pérez de LeónPas encore d'évaluation

- Adjustment of The Valve Lash and The Valve Bridge With The 147-5482Document8 pagesAdjustment of The Valve Lash and The Valve Bridge With The 147-5482victor.cipriani50% (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- Wartsila o e W 50df TRDocument16 pagesWartsila o e W 50df TRNoel MejiaPas encore d'évaluation

- Mechanical BooksDocument1 pageMechanical BooksAli EngPas encore d'évaluation

- PM Glossary PDFDocument48 pagesPM Glossary PDFsamirPas encore d'évaluation

- Smart Home Layout1Document1 pageSmart Home Layout1Ali EngPas encore d'évaluation

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- HVAC System Selection Factors in 40 CharactersDocument4 pagesHVAC System Selection Factors in 40 CharactersmokmaphiPas encore d'évaluation

- RadiatorDocument50 pagesRadiatorRajesh Khatri50% (2)

- Laying Cages: High Laying Rates Comfortable Easy To CleanDocument2 pagesLaying Cages: High Laying Rates Comfortable Easy To CleanAli EngPas encore d'évaluation

- Btp-pcs8 Suvs - China OrigenDocument1 pageBtp-pcs8 Suvs - China OrigenAli EngPas encore d'évaluation

- Heavy-Duty Gas Turbine Maintenance ConsiderationsDocument40 pagesHeavy-Duty Gas Turbine Maintenance ConsiderationsAli Eng100% (1)

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- PaperDocument5 pagesPaperAli EngPas encore d'évaluation

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- LockerDocument1 pageLockerHer Li AntoPas encore d'évaluation

- Torsion Test Determines Key Material PropertiesDocument1 pageTorsion Test Determines Key Material PropertiesAli EngPas encore d'évaluation

- Mercurry ThermometerDocument1 pageMercurry ThermometerAli EngPas encore d'évaluation

- New Text DocumentDocument1 pageNew Text DocumentAli EngPas encore d'évaluation

- Iraq Climate 3Document1 pageIraq Climate 3Ali EngPas encore d'évaluation

- पश्चिम रेलवे के सवारी डिब्बा कारखाने की सितंबर 2021 रिपोर्टDocument50 pagesपश्चिम रेलवे के सवारी डिब्बा कारखाने की सितंबर 2021 रिपोर्टsseab lplPas encore d'évaluation

- Swirl and Tumble PDFDocument2 pagesSwirl and Tumble PDFCarabela AndreeaPas encore d'évaluation

- User Manual Mariner 50Document24 pagesUser Manual Mariner 50Cyrille PVPas encore d'évaluation

- Section 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ADocument19 pagesSection 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ABouazzaPas encore d'évaluation

- Single Split PAC R410A Non-Inverter CatalogDocument12 pagesSingle Split PAC R410A Non-Inverter CataloghuntsecondlifePas encore d'évaluation

- Kings Motorbikes 80cc Bicycle Engine Kit Installation ManualDocument11 pagesKings Motorbikes 80cc Bicycle Engine Kit Installation ManualnwobastardsPas encore d'évaluation

- Toshiba 4550: Service Manual Service HandbookDocument499 pagesToshiba 4550: Service Manual Service Handbookصلاح هزاعPas encore d'évaluation

- Syllabus: Certificate in Subsea EngineeringDocument6 pagesSyllabus: Certificate in Subsea EngineeringJerome LIKIBIPas encore d'évaluation

- Electroanalytical Techniques for Studying Redox ReactionsDocument3 pagesElectroanalytical Techniques for Studying Redox Reactionsjayapandis83Pas encore d'évaluation

- Natural Gas Dryers: Pipeline SeriesDocument2 pagesNatural Gas Dryers: Pipeline SeriesAnonymous 70lCzDJvPas encore d'évaluation

- DHA Anita MHA2 Paper2 Unit 3.1Document34 pagesDHA Anita MHA2 Paper2 Unit 3.1Priyan TripathiPas encore d'évaluation

- Ecro RV: Technical ManualDocument21 pagesEcro RV: Technical ManualHyeong-Ho KimPas encore d'évaluation

- Response of Water Resources Systems To Climate ChangeDocument355 pagesResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- Cassette SPDocument3 pagesCassette SPalex_darPas encore d'évaluation

- Fermentor TypesDocument33 pagesFermentor TypesFahad MukhtarPas encore d'évaluation

- Zone 22 Hazardous Locations Classification and RequirementsDocument3 pagesZone 22 Hazardous Locations Classification and RequirementsVictor TenorioPas encore d'évaluation

- High Voltage Engineering Ref ManualDocument147 pagesHigh Voltage Engineering Ref Manualzeus009100% (1)

- Reiki - More Concerning The SymbolsDocument25 pagesReiki - More Concerning The SymbolsJames Deacon100% (7)

- Parts Catalog for Ingersoll Rand Air CompressorsDocument17 pagesParts Catalog for Ingersoll Rand Air CompressorsHenk Vanhamme100% (4)

- AHU data collection formDocument4 pagesAHU data collection formcajaroPas encore d'évaluation

- Anna University ME2303 Design of Machine Elements Exam QuestionsDocument3 pagesAnna University ME2303 Design of Machine Elements Exam QuestionssathurvedhaPas encore d'évaluation

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Document2 pagesSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaPas encore d'évaluation

- Red Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Document5 pagesRed Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Víctor RojasPas encore d'évaluation

- Dual Ingecon Sun U B Series Family at 1500vdcDocument4 pagesDual Ingecon Sun U B Series Family at 1500vdcRoberto SPas encore d'évaluation

- Diesel Engine Technical SpecificationsDocument3 pagesDiesel Engine Technical SpecificationsFahad MohammedPas encore d'évaluation

- Cylinder Head GasketsDocument2 pagesCylinder Head GasketsAdi_DCE0% (1)

- 64 Meeting January 7-8, 2013Document42 pages64 Meeting January 7-8, 2013ymadhukumarPas encore d'évaluation

- Eec203-Week 1Document62 pagesEec203-Week 1NicoPas encore d'évaluation

- WS XI PH Rotational Motion RollingDocument11 pagesWS XI PH Rotational Motion Rollingkaushik247Pas encore d'évaluation

- NewsStand - 24 of October 2021Document16 pagesNewsStand - 24 of October 2021Ahmed MansourPas encore d'évaluation