Académique Documents

Professionnel Documents

Culture Documents

DESIGN OF MACHINE ELEMENTS & MACHINING OF MATERIALS

Transféré par

Deepu Chandran0 évaluation0% ont trouvé ce document utile (0 vote)

41 vues2 pagesThis document outlines the objectives and modules for two engineering courses:

1. PE 04 502: Design of Machine Elements. The objective is to acquaint students with analytical and mathematical tools for designing machine components. The four modules cover principles of mechanical design, welded joints, mechanical springs and shafts, and couplings and bearings.

2. PE 04 503: Machining of Materials. The objective is to provide students with basic concepts, processes and analysis of machining processes and tool selection. The four modules cover tool materials and geometry, mechanics of metal cutting, temperature in machining, tool life and wear, economics of machining, and advanced machining processes.

Description originale:

Titre original

5th

Copyright

© © All Rights Reserved

Formats disponibles

RTF, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document outlines the objectives and modules for two engineering courses:

1. PE 04 502: Design of Machine Elements. The objective is to acquaint students with analytical and mathematical tools for designing machine components. The four modules cover principles of mechanical design, welded joints, mechanical springs and shafts, and couplings and bearings.

2. PE 04 503: Machining of Materials. The objective is to provide students with basic concepts, processes and analysis of machining processes and tool selection. The four modules cover tool materials and geometry, mechanics of metal cutting, temperature in machining, tool life and wear, economics of machining, and advanced machining processes.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme RTF, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

41 vues2 pagesDESIGN OF MACHINE ELEMENTS & MACHINING OF MATERIALS

Transféré par

Deepu ChandranThis document outlines the objectives and modules for two engineering courses:

1. PE 04 502: Design of Machine Elements. The objective is to acquaint students with analytical and mathematical tools for designing machine components. The four modules cover principles of mechanical design, welded joints, mechanical springs and shafts, and couplings and bearings.

2. PE 04 503: Machining of Materials. The objective is to provide students with basic concepts, processes and analysis of machining processes and tool selection. The four modules cover tool materials and geometry, mechanics of metal cutting, temperature in machining, tool life and wear, economics of machining, and advanced machining processes.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme RTF, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

PE 04 502 : DESIGN OF MACHINE ELEMENTS

(3 hours lecture and 1 hour tutorial per week)

Objectives:

The objective of this subject is to acquaint the students with the analytical and mathematical tools

together with practical consideration used for the design and selection of the machine components.

Mod!e I "#$ %o&s'

rinciples of mechanical design ! estimation of design load ! design for steady" fluctuating and dynamic

stresses ! effects of stress concentration ! consideration of creep and thermal stresses in design ! influence

of production processes in design ! tolerances and fits per #.$ specifications ! principles of standardi%ation !

selection of materials ! considerations like wear environment ! human and aesthetic aspects.

Mod!e II "#$ %o&s'

&elded joints ! stresses welded joints ! strength of welded joints ! fatigue loading of welded joints !

design of bolts and screws.

Mod!e III "#$ %o&s'

'echanical springs ! design of helical springs ! helical torsion spring ! critical frequency of helical springs

! energy storage capacity ! common types of leaf springs ! sh afts ! stresses in shafts ! equivalent twisting

and bending moments ! effect of keyways ! transmission shafts ! determination of shaft si%e for strength !

design of shafts for deflection ! critical speeds for shafts ! operating speeds ! shafts subjected to steady and

alternating loads.

Mod!e I( "#$ %o&s'

(ouplings ! rigid and fle)ible coupling ! common types of keys" pins and retainers and their applications *

+esign of journal bearing * ,ntifriction bearing " types and selection.

PE04 50) MACHINING OF MATE*IALS

3 hours lecture and 1 hour tutorial per week

Objective

'achining is one of the important production processes. The paper aims giving the students the basic

concepts" processes and analysis of basic machining processes and selection of processes" tools" etc.

Mod!e I "#$ %o&s'

-istory and development of tool materials ! general requirements of tool materials!tool geometry!systems

of cutting tool nomenclature! single point and multipoint tools! different machining processes and selection

of tools. ! $imple problems.

Mod!e II "#$ %o&s'

'echanics of metal cutting! mechanism of chip formation * forces on cutting tool! merchant.s circle * tool

dynamometers! tool force measurements! friction in metal cutting. ! $imple problems.

Mod!e III "#$ %o&s'

Temperature in machining * temperature distribution ! effect of machining variables on temperature *

measurement of temperature.

Tool life and tool wear * effect of machining parameters on tool wear! selection" properties and application

of cutting fluids. $imple problems.

Mod!e I( "#$ %o&s'

/conomics of machining * choice of parameters * metal removal rates.

advanced machining processes * introduction * operating principles * process parameters and application

of 0$'",1'"&1'"/('"/(2"/+'"/3'"43'",' and chemical milling.

Vous aimerez peut-être aussi

- Design Machine ElementsDocument7 pagesDesign Machine ElementsNinad PawarPas encore d'évaluation

- Machine Design - Introduction PDFDocument13 pagesMachine Design - Introduction PDFDida KhalingPas encore d'évaluation

- Solapur University Tool Engineering Course OverviewDocument3 pagesSolapur University Tool Engineering Course OverviewAmirDeshmukhPas encore d'évaluation

- Mechanical System Design by R B Patil PreviewDocument7 pagesMechanical System Design by R B Patil Previewmo juned0% (2)

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDocument16 pagesMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarPas encore d'évaluation

- Introduction To MechanicalDocument12 pagesIntroduction To MechanicalabasPas encore d'évaluation

- FDC AssignmentDocument4 pagesFDC AssignmentsumikannuPas encore d'évaluation

- Mee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFDocument2 pagesMee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFAK PRODUCTIONSPas encore d'évaluation

- Wear Analysis of Multi Point Milling Cutter using FEADocument8 pagesWear Analysis of Multi Point Milling Cutter using FEAAravindkumarPas encore d'évaluation

- SyllabusDocument2 pagesSyllabusAyush BhadauriaPas encore d'évaluation

- Manufacturing Processes GuideDocument22 pagesManufacturing Processes GuideMeer UmarPas encore d'évaluation

- Theory of Metal Cutting KTU SyllabusDocument3 pagesTheory of Metal Cutting KTU SyllabusAron PanickerPas encore d'évaluation

- Study Material 10ME52 DME1Document242 pagesStudy Material 10ME52 DME1Sagar GowdaPas encore d'évaluation

- ME 314 Design of Machine Elements (3-0-0-6) : TextsDocument9 pagesME 314 Design of Machine Elements (3-0-0-6) : TextsKrishna MurthyPas encore d'évaluation

- QITT06 - Bolted Joints PDFDocument192 pagesQITT06 - Bolted Joints PDFRonald GeorgePas encore d'évaluation

- Syllabus For Odd Semester 2014-15Document7 pagesSyllabus For Odd Semester 2014-15Sanjay GomastaPas encore d'évaluation

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecPas encore d'évaluation

- Manufacturing Technology-IIDocument70 pagesManufacturing Technology-IISaideep GhimirePas encore d'évaluation

- Chapter 1 IntroDocument40 pagesChapter 1 IntroMoustafa SabeaPas encore d'évaluation

- Finite Element Analysis of Cutting Tools Prior To Fracture in Hard Turning Operations 2005 Materials DesignDocument8 pagesFinite Element Analysis of Cutting Tools Prior To Fracture in Hard Turning Operations 2005 Materials DesignEdo DestradaPas encore d'évaluation

- Me 703Document2 pagesMe 703Yash Kr RockingPas encore d'évaluation

- 073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusDocument2 pages073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusM A JomahPas encore d'évaluation

- Prediction of Tool Life - An Empirical Approach Tool Wear MonitoringDocument63 pagesPrediction of Tool Life - An Empirical Approach Tool Wear MonitoringRamya MandavaPas encore d'évaluation

- Lesson Plan DRMTMR 2014 AiDocument6 pagesLesson Plan DRMTMR 2014 AiMatthew SmithPas encore d'évaluation

- B.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsDocument11 pagesB.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsAnkesh KapilPas encore d'évaluation

- Design Syl Lab UsDocument2 pagesDesign Syl Lab UsrohithreddyPas encore d'évaluation

- Machining Science: Jigs & FixturesDocument26 pagesMachining Science: Jigs & FixturesChidu KPas encore d'évaluation

- METAL CUTTING TOOL DESIGN COURSEDocument3 pagesMETAL CUTTING TOOL DESIGN COURSEHemanth YadaPas encore d'évaluation

- Machine Design - IntroductionDocument9 pagesMachine Design - IntroductionvelavansuPas encore d'évaluation

- Puneet Final Semester ProjectDocument50 pagesPuneet Final Semester ProjectPuneet MehraPas encore d'évaluation

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinPas encore d'évaluation

- Syllabus B.tech MAE CBCS 3rd 4th SemDocument23 pagesSyllabus B.tech MAE CBCS 3rd 4th SemM MtPas encore d'évaluation

- Plagiarism - ReportDocument42 pagesPlagiarism - ReportJerick HernandezPas encore d'évaluation

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- Third Year Second Semester: Department of Mechanical Engineering - Course CatalogueDocument8 pagesThird Year Second Semester: Department of Mechanical Engineering - Course CatalogueSudeep GamerPas encore d'évaluation

- Machine Design - IntroductionDocument9 pagesMachine Design - IntroductionSreedhar MadhanaPas encore d'évaluation

- 6th Sem - 7 - Mechanical Engineering - 2 PDFDocument39 pages6th Sem - 7 - Mechanical Engineering - 2 PDFfotickPas encore d'évaluation

- Tool Engineering Jigs and FixturesDocument312 pagesTool Engineering Jigs and FixturesMike100% (5)

- Weld Defects EngineeringDocument29 pagesWeld Defects EngineeringAnatolie6Pas encore d'évaluation

- Construction Personnel Management ElectivesDocument11 pagesConstruction Personnel Management ElectivesLeilani JohnsonPas encore d'évaluation

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayPas encore d'évaluation

- PH.D Programme: Teaching Schedule & Study SchemeDocument3 pagesPH.D Programme: Teaching Schedule & Study SchemeGursharanSinghGandhiPas encore d'évaluation

- Mec223:Design of Machine Elements-I: Course OutcomesDocument2 pagesMec223:Design of Machine Elements-I: Course OutcomesDeepak MehtaPas encore d'évaluation

- 9105 - Automobile Component DesignDocument5 pages9105 - Automobile Component DesignOnkar Sawant100% (1)

- Machining Science: Jigs & FixturesDocument15 pagesMachining Science: Jigs & FixturesChidu KPas encore d'évaluation

- Unit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsDocument30 pagesUnit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsPrasanth YuviPas encore d'évaluation

- Bending Machine Literature ReviewDocument8 pagesBending Machine Literature Reviewzejasyvkg100% (1)

- Course Module (VI Sem)Document7 pagesCourse Module (VI Sem)Vijay KumawatPas encore d'évaluation

- 6th Sem - 7 - Mechanical Engineering PDFDocument37 pages6th Sem - 7 - Mechanical Engineering PDFप्रबुद्ध खिलाड़ीPas encore d'évaluation

- #. VerzijaDocument10 pages#. VerzijaPrco JukicPas encore d'évaluation

- Introduction Only) (Compatibility Mode)Document50 pagesIntroduction Only) (Compatibility Mode)Akshar PatelPas encore d'évaluation

- Introduction To Mechanics of Materials - MSE 305Document5 pagesIntroduction To Mechanics of Materials - MSE 305Martin JaiyeolaPas encore d'évaluation

- T.E. (Mechanical Engineering) Semester VDocument5 pagesT.E. (Mechanical Engineering) Semester Vmanil patilPas encore d'évaluation

- QITT06 - Bolted JointsDocument192 pagesQITT06 - Bolted Jointsxcv100% (3)

- 6th Sem - 7 - Mechanical Engineering PDFDocument39 pages6th Sem - 7 - Mechanical Engineering PDFÃrghýã MåjïPas encore d'évaluation

- (Iv) Chain Drives - Roller Chains, Polygonal Effect, Power Rating, Sprocket Wheel, Silent ChainDocument1 page(Iv) Chain Drives - Roller Chains, Polygonal Effect, Power Rating, Sprocket Wheel, Silent ChainArterixpestcontrolPas encore d'évaluation

- Petal DevelopmentDocument2 pagesPetal DevelopmentDeepu ChandranPas encore d'évaluation

- Time and Work 30 QuestionsDocument5 pagesTime and Work 30 QuestionsDeepu ChandranPas encore d'évaluation

- SyllogismDocument7 pagesSyllogismDeepu ChandranPas encore d'évaluation

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranPas encore d'évaluation

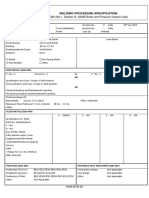

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranPas encore d'évaluation

- Mobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDocument1 pageMobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDeepu ChandranPas encore d'évaluation

- RT OfferDocument12 pagesRT OfferDeepu ChandranPas encore d'évaluation

- 300 Copy Gas Cutting Daily Check ListDocument3 pages300 Copy Gas Cutting Daily Check ListDeepu ChandranPas encore d'évaluation

- Wled LengthDocument1 pageWled LengthDeepu ChandranPas encore d'évaluation

- STA Audit Format-EditableDocument1 pageSTA Audit Format-EditableDeepu ChandranPas encore d'évaluation

- 100 Copy Scaffolding Erection Check ListDocument4 pages100 Copy Scaffolding Erection Check ListDeepu Chandran100% (1)

- Imir 3156Document38 pagesImir 3156Deepu ChandranPas encore d'évaluation

- Sharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDocument3 pagesSharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDeepu ChandranPas encore d'évaluation

- Ladder Inspection Check ListDocument4 pagesLadder Inspection Check ListDeepu ChandranPas encore d'évaluation

- Fabrication Yard LayoutDocument1 pageFabrication Yard LayoutDeepu ChandranPas encore d'évaluation

- RT Summary Report for DWG NO MED-711Document130 pagesRT Summary Report for DWG NO MED-711Deepu ChandranPas encore d'évaluation

- Too1 B LHSDocument347 pagesToo1 B LHSDeepu ChandranPas encore d'évaluation

- Gas Purging Optimises Root WeldsDocument4 pagesGas Purging Optimises Root WeldsDeepu ChandranPas encore d'évaluation

- Sharptank - PF ECR September-16Document11 pagesSharptank - PF ECR September-16Deepu ChandranPas encore d'évaluation

- QC StickerDocument44 pagesQC StickerDeepu ChandranPas encore d'évaluation

- Safety Audit Report SampleDocument24 pagesSafety Audit Report Samplekanakarao187% (15)

- SiteDocument9 pagesSiteDeepu ChandranPas encore d'évaluation

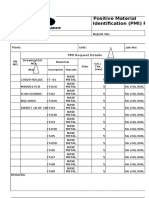

- Reliance: Positive Material Identification (PMI) ReportDocument16 pagesReliance: Positive Material Identification (PMI) ReportDeepu ChandranPas encore d'évaluation

- Paint Type and DFT Requirements for TanksDocument2 pagesPaint Type and DFT Requirements for TanksDeepu ChandranPas encore d'évaluation

- STS Ril 002Document1 127 pagesSTS Ril 002Deepu ChandranPas encore d'évaluation

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- Pneumatic Test ProcedureDocument7 pagesPneumatic Test ProcedureDeepu ChandranPas encore d'évaluation

- Sts-Sez HC Ra 2Document17 pagesSts-Sez HC Ra 2Deepu ChandranPas encore d'évaluation

- Mastering Options StrategiesDocument40 pagesMastering Options Strategiesluong847180% (1)

- 56 Requist Validation MTTDocument3 pages56 Requist Validation MTTDeepu ChandranPas encore d'évaluation

- Plasma Ignition Technology For New and RetrofitDocument17 pagesPlasma Ignition Technology For New and Retrofitramesh baluPas encore d'évaluation

- Development of Nozzle Clogging IndexDocument13 pagesDevelopment of Nozzle Clogging Indexsdtd.ranchiPas encore d'évaluation

- H-4140-CBR Test Method for GeoGauge CBR IndexDocument15 pagesH-4140-CBR Test Method for GeoGauge CBR IndexOmar CarlosPas encore d'évaluation

- JENKA System Technical ManualDocument20 pagesJENKA System Technical ManuallutcusPas encore d'évaluation

- SP Tools - MaytoJuly2013Document24 pagesSP Tools - MaytoJuly2013Riverland Welding and Tool SuppliesPas encore d'évaluation

- CJ70Document116 pagesCJ70FlexartPas encore d'évaluation

- 15CV71 Dec18-Jan19 PDFDocument2 pages15CV71 Dec18-Jan19 PDFKavyaPas encore d'évaluation

- Safety and Handling of Organic PeroxidesDocument26 pagesSafety and Handling of Organic PeroxidesМаксим ХилоPas encore d'évaluation

- PAES 317-Metal Sheets - PlatesDocument12 pagesPAES 317-Metal Sheets - Platesandrew cabilesPas encore d'évaluation

- Thermal Insulation Materials and MethodsDocument4 pagesThermal Insulation Materials and Methodsvenkateswara rao PothinaPas encore d'évaluation

- Burn-In, Reliability Testing, and Manufacturing ofDocument19 pagesBurn-In, Reliability Testing, and Manufacturing ofAbhinav SrivastavPas encore d'évaluation

- CNC Bits Buying Guide: C08 C15 SS17 SF17 SB17Document9 pagesCNC Bits Buying Guide: C08 C15 SS17 SF17 SB17Sandro AlcantaraPas encore d'évaluation

- Mel ZG611Document5 pagesMel ZG611jitendraPas encore d'évaluation

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresPas encore d'évaluation

- SCX-8030ND 8040ND SMDocument450 pagesSCX-8030ND 8040ND SMMircea Stefan BogdanPas encore d'évaluation

- Q Max Cumene ProductionDocument4 pagesQ Max Cumene ProductionTey Kaijing100% (1)

- Substance Chemistry Lesson 1Document28 pagesSubstance Chemistry Lesson 1samsonPas encore d'évaluation

- Alfa Laval Orca Series PDFDocument2 pagesAlfa Laval Orca Series PDFNguyễn Thị Kim PhượngPas encore d'évaluation

- Immediate Deflection in Concrete BeamsDocument11 pagesImmediate Deflection in Concrete BeamsSeifeldin Ali MarzoukPas encore d'évaluation

- IntroDocument37 pagesIntrowfd52muni100% (1)

- Souvinir AIMTDR PDFDocument351 pagesSouvinir AIMTDR PDFKushal Singh100% (3)

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepPas encore d'évaluation

- 07 Subsynchronous OscillationsDocument40 pages07 Subsynchronous Oscillationssulemankhalid0% (1)

- Diesel Engineering Handbook Cooling SystemsDocument14 pagesDiesel Engineering Handbook Cooling Systemsmartin.ruben100% (1)

- Kiln Mechanical ProblemsDocument40 pagesKiln Mechanical ProblemsIrshad Hussain83% (6)

- td50 1Document88 pagestd50 1beltranreal6162Pas encore d'évaluation

- Project in TleDocument8 pagesProject in TleFranch Maverick Arellano LorillaPas encore d'évaluation

- Mellitah Plant: Western Libya Gas ProjectDocument662 pagesMellitah Plant: Western Libya Gas ProjectAnas AhmedPas encore d'évaluation

- OferDinamarca16feb - Graduate Talent Programme Novo NordiskDocument6 pagesOferDinamarca16feb - Graduate Talent Programme Novo NordiskClásico MoviePas encore d'évaluation

- Coolant AH 100 protects enginesDocument2 pagesCoolant AH 100 protects enginesshashirajPas encore d'évaluation