Académique Documents

Professionnel Documents

Culture Documents

Bleaching Sodium Hypochlorite

Transféré par

Sivakumar K0 évaluation0% ont trouvé ce document utile (0 vote)

28 vues3 pagesQUESTION AND ANSWER

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentQUESTION AND ANSWER

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

28 vues3 pagesBleaching Sodium Hypochlorite

Transféré par

Sivakumar KQUESTION AND ANSWER

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

FT2255 - Dyeing, Printing and Pollution Control

QUESTION WITH NSWE!

"ran#$% "&Te#$ 'ear ( Se)% II ( III

Unit * I "+ECHIN,

-& E./lain t$e )e#$ani0) and /ro#e00 o1 0odiu) $y/o#$lorite 2lea#$ing 3it$ 0uita2le

re#i/e&

Sodiu) $y/o#$lorite

Sodium hypochlorite is a sodium salt of hypochlorous acid (HOCI).

Sodium hypochlorite is called as the strongest oxidative bleaching agent used in textile

processing because of it is released the nascent oxygen (bleaching agents) at room

temperature in alkali condition (pH!".# to !!)

$he strength of hypochlorites is generally expressed as the a4aila2le #$lorine #ontent. $he

amount of chlorine present in one liter of sodium hypochlorite solution

5e#$ani0) o1 2lea#$ing

$he mechanism of sodium hypochlorite (%aOCl) bleaching is four step processes.

!. Hydrolysis

&. 'elease of bleaching agent

(. )aximum development of bleaching active agent (HOCl)

*. +vailable chlorine

-& Hydroly0i0

Sodium hypochlorite is dissolved in ,ater and it-s release the Hypochlorous acid (HOCl)

Hypochlorous acid (HOCl) is the active bleaching agent.

NaOCl 6 H

2

O NaOH 6 HOCl

2& !elea0e o1 2lea#$ing agent

Hypochlorous acid (HOCl) is a ,eakest acid in alkali condition. So that it is selfly

decomposed in this condition and disassociates in strongest hydrochloric acid (HCl) and

nascent oxygen (O).

$he nascent oxygen is a bleaching agent. It is oxdising the natural colouring matters and

converts to simple colourless compound.

HOCl 7 HCl 6 8O9

:& 5a.i)u) de4elo/)ent o1 2lea#$ing a#ti4e agent 8HOCl9

$o develop the maximum amount of amount bleaching active agent (HOCl) ,ith help of

hydrochloric acid (HCl) present solution.

NaOCl 6 HCl 7 NaCl 6 HOCl

;& For)ation o1 1ree #$lorine

$o release the chlorine for bleaching process

HOCl 6 HCl H

2

O6Cl

2

Pro#e00%

$he process of hypochlorite bleaching is normally batch process.

!. .abric preparation

&. /leaching solution preparation

(. /leaching

*. 0ashing

#. Souring

1. ,ashing

2. +ntichlor treatment

3. 0ashing

-& Fa2ri# /re/aration

.abric must be desi4ed and scoured.

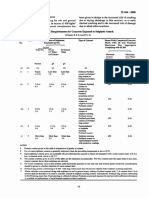

2& "lea#$ing 0olution /re/aration

$he solution is prepared based on the belo, recipe

!e#i/e5

%aOCl 6 !.# to ( gpl of available chlorine

%a

&

CO

(

6 ".# gpl

Fun#tion o1 C$e)i#al

%aOCl 6 /leaching +gent

%a

&

CO

(

6 Its act as a buffer and to control pH of the solution. It-s also called bleaching

active agent

:& "lea#$ing

$he bleaching normally done in batch process. 7igger8 ,inch8 kier8 cistern8 soft flo,

dyeing machine normally used for bleaching process

Condition o1 /ro#e00%

$emperature 5 'oom temperature

pH 5 !".# 6 !!

$ime 5 !& Hours

Cistern machine5

Part0%

;& Wa0$ing

+fter bleaching8 the bleached fabric ,ashing ,ith hot ,ash and clod ,ash

5& Souring

/leached fabric is treated ,ith diluted hydrochloric acid or sulphuric acid ,ith (" mins to

make neutral condition for bleached fabric.

<& Wa0$ing

+fter bleaching8 the bleached fabric ,ashing ,ith hot ,ash and clod ,ash

=& nti #$lorine treat)ent

+nti chlorine treatment is to remove the chlorine content present in the hypochlorite

bleached fabric to avoid the yello,ise problem due to formation of chloramines by using

sodium bisulphate or sodium thiosulphate or sodium hydrosulphite.

>& Wa0$ing

+fter bleaching8 the bleached fabric ,ashing ,ith hot ,ash and clod ,ash

Vous aimerez peut-être aussi

- Knitting Elememts Sinker and CamDocument19 pagesKnitting Elememts Sinker and CamSivakumar KPas encore d'évaluation

- Evaulation of False Twist YarnDocument25 pagesEvaulation of False Twist YarnSivakumar K100% (1)

- Knit Deknit ProcessDocument9 pagesKnit Deknit ProcessSivakumar KPas encore d'évaluation

- Knit Deknit ProcessDocument9 pagesKnit Deknit ProcessSivakumar KPas encore d'évaluation

- Flat Bed KnitingDocument21 pagesFlat Bed Knitingvasiney100% (1)

- 40 TT 404 - Knitting Technology QUESTION BANKDocument6 pages40 TT 404 - Knitting Technology QUESTION BANKSivakumar KPas encore d'évaluation

- Unit I Study Material CsDocument19 pagesUnit I Study Material CsSivakumar KPas encore d'évaluation

- Eco FriendlyDocument50 pagesEco FriendlySivakumar K100% (1)

- Warp KnittingDocument93 pagesWarp KnittingSivakumar K100% (1)

- Unit III - Clothing Science Question Bank WITH ANSWERDocument5 pagesUnit III - Clothing Science Question Bank WITH ANSWERSivakumar KPas encore d'évaluation

- Unit III MerchandisingDocument103 pagesUnit III MerchandisingSivakumar K100% (2)

- Kfs Study Material Unit IIDocument13 pagesKfs Study Material Unit IISivakumar K100% (1)

- Eco FriendlyDocument50 pagesEco FriendlySivakumar K100% (1)

- Unit I Clothing Science Two Marks With Answer and Question BankDocument3 pagesUnit I Clothing Science Two Marks With Answer and Question BankSivakumar KPas encore d'évaluation

- Unit - 1Document4 pagesUnit - 1Sivakumar KPas encore d'évaluation

- Ssi IDocument13 pagesSsi ISivakumar KPas encore d'évaluation

- Angel: College of Engineering and Technology TIRUPUR 641 665Document21 pagesAngel: College of Engineering and Technology TIRUPUR 641 665Sivakumar KPas encore d'évaluation

- Patteren Mechanism in Knitting - JacquardDocument27 pagesPatteren Mechanism in Knitting - JacquardSivakumar K100% (3)

- Warp Knitting StructureDocument29 pagesWarp Knitting StructureSivakumar K100% (1)

- Warp Knitting BasicsDocument64 pagesWarp Knitting BasicsSivakumar K100% (1)

- Kfs Unit II Two Marks With AnswerDocument2 pagesKfs Unit II Two Marks With AnswerSivakumar KPas encore d'évaluation

- LykraDocument27 pagesLykraSivakumar KPas encore d'évaluation

- Interlock StructuresDocument15 pagesInterlock StructuresSivakumar KPas encore d'évaluation

- Unit - II Kfs Two Marks With AnswerDocument4 pagesUnit - II Kfs Two Marks With AnswerSivakumar KPas encore d'évaluation

- Warp Knitting StructureDocument29 pagesWarp Knitting StructureSivakumar K100% (1)

- CC Unit I and Unit II Two Marks Question With AnswerDocument7 pagesCC Unit I and Unit II Two Marks Question With AnswerSivakumar KPas encore d'évaluation

- Unit I TCP Study MaterialDocument4 pagesUnit I TCP Study MaterialSivakumar KPas encore d'évaluation

- Unit VDocument2 pagesUnit VSivakumar KPas encore d'évaluation

- SpectrophotometerDocument46 pagesSpectrophotometerSivakumar KPas encore d'évaluation

- Colour FastnessDocument37 pagesColour FastnessSivakumar K100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Aquifers of Dera Ghazi KhanDocument12 pagesAquifers of Dera Ghazi KhanArslan geoscientistPas encore d'évaluation

- Steel Grades According To Japanese Standards: Mechanical PropertiesDocument2 pagesSteel Grades According To Japanese Standards: Mechanical PropertiesGANESHPas encore d'évaluation

- Domos Volcanicos y Mineralizacion de Oro en El DisDocument21 pagesDomos Volcanicos y Mineralizacion de Oro en El DisfacflPas encore d'évaluation

- Brosure Gridswitch MK 1.1Document1 pageBrosure Gridswitch MK 1.1Anwar regarPas encore d'évaluation

- Analisa Harga SatuanDocument8 pagesAnalisa Harga SatuanMbeda NayPas encore d'évaluation

- Sand Cone Set (T-061) ASTM D1556 - AASHTO T-191Document2 pagesSand Cone Set (T-061) ASTM D1556 - AASHTO T-191Oth'is WatngarninyPas encore d'évaluation

- Sigma Marine Coatings Manual - Part45Document2 pagesSigma Marine Coatings Manual - Part45EngTamerPas encore d'évaluation

- Sculpting With LightDocument15 pagesSculpting With LightMizuho IeiriPas encore d'évaluation

- Rock Cycle QuizDocument2 pagesRock Cycle QuizKizzi Kye Edelweiss BalmoresPas encore d'évaluation

- Pengantar Rekayasa Pertambangan: To MiningDocument30 pagesPengantar Rekayasa Pertambangan: To MiningSasaki HaisePas encore d'évaluation

- V.O. No. 1 - Lemery Pob. Milan FINALDocument50 pagesV.O. No. 1 - Lemery Pob. Milan FINALRamVin AranoPas encore d'évaluation

- Particle BoardDocument51 pagesParticle BoardNUR MAZIAH ATIQAH JAINIPas encore d'évaluation

- Mil L 46010BDocument18 pagesMil L 46010BaguPas encore d'évaluation

- Pipeline Pigging Handbook 9Document1 pagePipeline Pigging Handbook 9Bruno GonçalvesPas encore d'évaluation

- WWW - Ubakus.de: Perete Exterior Spital COVIDDocument4 pagesWWW - Ubakus.de: Perete Exterior Spital COVIDsebi_iasiPas encore d'évaluation

- D4259 ssrf9249Document2 pagesD4259 ssrf9249Raymond TahanPas encore d'évaluation

- BV263 - U Type Butterfly ValveDocument2 pagesBV263 - U Type Butterfly ValveFAIYAZ AHMEDPas encore d'évaluation

- Thin-Walled Pressure VesselsDocument18 pagesThin-Walled Pressure Vesselsjomarie apolinarioPas encore d'évaluation

- Foxboro 871 PHDocument16 pagesFoxboro 871 PHelsalseritoPas encore d'évaluation

- Final Salt AnalysisDocument8 pagesFinal Salt AnalysisAnonymous SomeonePas encore d'évaluation

- Hysys PrintDocument1 pageHysys Printlebiatan89Pas encore d'évaluation

- Equivis ZS: ApplicationsDocument1 pageEquivis ZS: ApplicationsDeka TariganPas encore d'évaluation

- SCCS1624 Eng PH Salinity SodicityDocument39 pagesSCCS1624 Eng PH Salinity SodicityMenzi CekwanePas encore d'évaluation

- Thesis Atomistic Simulation of Shock WavesDocument219 pagesThesis Atomistic Simulation of Shock WavesDavidFurman0% (1)

- Experiment 3: Neutralization Capacity of Commercial Antacid AcidDocument10 pagesExperiment 3: Neutralization Capacity of Commercial Antacid AcidfizaPas encore d'évaluation

- Lecture5 AllDocument43 pagesLecture5 Alladeelyj100% (1)

- Case Study: Materials For Blood Bags: WWW - Blood.co - UkDocument6 pagesCase Study: Materials For Blood Bags: WWW - Blood.co - UkBijuChudraponvelilThomasPas encore d'évaluation

- AltuglasDocument4 pagesAltuglasBhanuPas encore d'évaluation

- IS 456: 2000 8.2.4.2 Maximum Cement Content: Chss TypeDocument1 pageIS 456: 2000 8.2.4.2 Maximum Cement Content: Chss Typesharath1199Pas encore d'évaluation

- CompanyDocument20 pagesCompanyGolden RosesPas encore d'évaluation