Académique Documents

Professionnel Documents

Culture Documents

QSL9 G5

Transféré par

Edgardo J. MamaniDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

QSL9 G5

Transféré par

Edgardo J. MamaniDroits d'auteur :

Formats disponibles

Basic Engine Model:

Curve Number:

QSL9-G5

FR-91545

Engine Critical Parts List:

Date:

CPL: 8693

15Aug05

Cummins Inc.

Columbus, Indiana 47201

Engine Data Sheet

Displacement : 8.8 litre (543 in3 )

Bore : 114 mm (4.49 in.) Stroke : 145 mm (5.69 in.)

No. of Cylinders : 6

Aspiration : Turbocharged and Charge Air Cooled

Engine Speed

Standby Power

Prime Power

G-DRIVE

QSL

1

Continuous Power

RPM

kWm

BHP

kWm

BHP

kWm

BHP

1500

310

415

268

359

228

305

1800

355

476

307

412

261

350

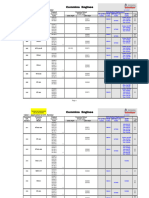

Engine Performance Data @ 1500 RPM

OUTPUT POWER

FUEL CONSUMPTION

Litre/hour

80.0

kWm

kg/

kWmh

BHP

lb/

BHPh

litre/

hour

U.S. Gal/

hour

60.0

STANDBY POWER

100

310

70.0

415

0.206

0.338

75

19.8

50.0

40.0

PRIME POWER

100

268

359

0.199

0.328

63

16.6

30.0

75

201

269

0.194

0.319

46

12.1

20.0

50

134

180

0.196

0.323

31

8.2

10.0

25

67

90

0.213

0.351

17

4.4

0.0

0

CONTINUOUS POWER

100

228

305

50

100

150

200

250

300

Gross Engine Output - kWm

0.196

0.323

53

13.9

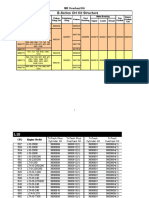

Engine Performance Data @ 1800 RPM

OUTPUT POWER

%

kWm

BHP

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

litre/

hour

U.S. Gallons / hour

U.S. Gal/

hour

20.0

STANDBY POWER

100

355

25.0

476

0.214

0.352

89

23.6

15.0

PRIME POWER

100

307

412

0.208

0.342

75

19.9

75

231

309

0.201

0.331

55

14.4

50

154

206

0.202

0.332

36

9.6

25

77

103

0.221

0.363

20

5.3

0.204

0.335

63

16.5

10.0

5.0

0.0

0

50

CONTINUOUS POWER

100

261

350

CONVERSIONS:(litres = U.S. Gal x 3.785) (U.S.Gal = litres x 0.2642)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations. STANDBY POWER RATING: Applicable for supplying emergency power for the duration of the utility power

outage. No overload capability is available for this rating. Under no condition is an engine allowed to operate in parallel

with the public utility at the Standby Power rating. This rating should be applied where reliable utility power is available. A

Standby rated engine should be sized for a maximum of an 80% average load factor and 200 hours of operation per year.

This includes less than 25 hours per year at the Standby Power rating. Standby ratings should never be applied except in

true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency. PRIME POWER RATING: Applicable for supplying electric power in lieu of commercially purchased power. Prime

Power applications must be in the form of one of the following two categories:UNLIMITED TIME RUNNING PRIME POWER: Prime Power is available for an unlimited number of hours per year in a variable load application. Variable load should

not exceed a 70% average of the Prime Power rating during any operating period of 250 hours. The total operating time

at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a period of 1 hour

within a 12-hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER: Limited Time Prime Power is available for a limited number of hours in a nonvariable load application. It is intended for use in situations where power outages are contracted, such as in utility power

curtailment. Engines may be operated in parallel to the public utility up to 750 hours per year at power levels never to exceed the Prime Power rating. The customer should be aware, however, that the life of any engine will be reduced by this

constant high load operation. Any operation exceeding 750 hours per year at the Prime Power rating should use the Continuous Power rating.CONTINUOUS POWER RATING : Applicable for supplying utility power at a constant 100% load for

an unlimited number of hours per year. No overload capability is available for this rating.

100

150 200 250 300 350

Gross Engine Output - BHP

400

450

500

Data Subject to Change Without Notice

Reference AEB 10.47 for determining Electrical Output.

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO3046 conditions of 100 kPa (29.53 in Hg) barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

Derates shown are based on 15 in H2 0 air intake restriction and 2 in Hg exhaust back pressure.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/litre (7.1 lbs/U.S. gal). Power output curves are

based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging

alternator, fan, optional equipment and driven components.

Data Status: --Limited Production-Data Tolerance: 5%

Chief Engineer:

G-DRIVE

QSL

2

1800 RPM Derate Curves

1500 RPM Derate Curves

Standby

Standby

40

40

35

35

Ambient Temp. C / F

% Derate of Rated Power

% Derate of Rated Power

Ambient Temp. C / F

30

50 / 122

25

20

40 / 104

15

10

30

50 / 122

25

40 / 104

20

15

25 / 77

10

25 / 77

500

1000

1500

2000

2500

3000

1000

2000

3000

Altitude (meters)

4000

Prime

6000

7000

8000

9000

10000

Prime

40

40

35

35

% Derate of Rated Power

% Derate of Rated Power

Ambient Temp. C / F

30

25

50 / 122

20

15

40 / 104

10

Ambient Temp. C / F

30

50 / 122

25

20

40 / 104

15

10

25 / 77

25 / 77

0

0

500

1000

1500

2000

2500

3000

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

9000

10000

Altitude (feet)

Altitude (meters)

Continuous

Continuous

40

40

35

35

% Derate of Rated Power

Ambient Temp. C / F

% Derate of Rated Power

5000

Altitude (feet)

Ambient Temp. C / F

50 / 122

30

30

25

25

50 / 122

20

20

40 / 104

15

15

40 / 104

10

10

25 / 77

25 / 77

0

0

500

1000

1500

2000

2500

Altitude (meters)

Operation At Elevated Temperature And Altitude:

For Standby operation above these conditions, derate by an additional 4%

o

per 300 m (1000 ft), and 4% per 10 C (18 F).

For Prime operation above these conditions, derate by an additional 5% per

300 m (1000 ft), and 8% per 10o C (18o F).

3000

1000

2000

3000

4000

5000

6000

7000

8000

Altitude (feet)

Operation At Elevated Temperature And Altitude:

For Standby operation above these conditions, derate by an additional 3.0%

o

o

per 300 m (1000 ft), and 5% per 10 C (18 F).

For Prime operation above these conditions, derate by an additional 5.0% per

300 m (1000 ft), and 10% per 10o C (18o F).

G-DRIVE

QSL

3

Cummins Inc.

Engine Data Sheet

ENGINE MODEL : QSL9-G5

CONFIGURATION NUMBER : D563007GX03

INSTALLATION DIAGRAM

Fan to Flywheel

: xxxxxxx

DATA SHEET : DS91545

DATE :15Aug05

PERFORMANCE CURVE : FR-91545

CPL NUMBER

Engine Critical Parts List

8693

GENERAL ENGINE DATA

Type ...............................................................................................................................................................

Aspiration .......................................................................................................................................................

Bore x Stroke.............................................................................................................. in x in (mm x mm)

Displacement .............................................................................................................................. in3 (litre)

Compression Ratio........................................................................................................................................

Dry Weight

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Wet Weight

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Moment of Inertia of Rotating Components

with FW 9520 Flywheel ......................................................................................... lbm ft2 (kg m 2)

with FW 9525 Flywheel .......................................................................................... lbm ft2 (kg m 2)

Center of Gravity from Rear Face of Block ............................................................................... in (mm)

Center of Gravity Above Crankshaft Centerline ....................................................................... in (mm)

Maximum Static Loading at Rear Main Bearing .......................................................................... lb (kg)

4-Cycle; In-line; 6-Cylinder Diesel

Turbocharged and Charge Air Cooled

4.49 x 5.69 (114 x 145)

543 (8.8)

16.8 : 1

1575

(714)

1627

(738)

TBD

TBD

16.89

8.35

N.A.

(TBD)

(TBD)

(429 )

(212 )

N.A.

1000

( 1356)

(76)

25

15

(635)

(381)

2.9

60

180 - 199

15

230 / 219

5

4

(11)

(18.3)

(82 - 93)

(103)

(110 / 104)

(35)

(28)

45

4

2.5

(25)

(102)

(63.5)

15

40 - 60

250

(103)

(276 - 414)

(121)

( 22.7 )

( 26.5 )

45

45

45

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block......................................................... lb ft (N m)

EXHAUST SYSTEM

Maximum Back Pressure................................................................................................ in Hg (mm Hg)

AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

with Dirty Filter Element ......................................................................................... in H2O (mm H2O)

with Clean Filter Element....................................................................................... in H2O (mm H2O)

COOLING SYSTEM

Jacket Water Circuit Requirements

Coolant Capacity Engine Only ...................................................................................... US gal (litre)

Maximum Static Head of Coolant Above Engine Crank Centerline

ft (m)

Standard Thermostat (Modulating) Range

F (C)

Minimum Pressure Cap ........................................................................................................... psi (kPa)

Maximum Top Tank Temperature for Standby / Prime Power

F (C)

Maximum Coolant Friction Head External to Engine ........ 1800 rpm

psi (kPa)

1500 rpm................................. psi (kPa)

Air-to-Air Core Requirements

Maximum Temp. Rise Between Engine Air Intake and Intake Manifold............................................. F (C)

Maximum Air Pressure Crop from Turbo Air outlet to Intake Manifold 1800 rpm ............. in Hg (mm Hg)

1500 rpm............. in Hg (mm Hg)

LUBRICATION SYSTEM

Oil Pressure @ Idle Speed.................................................................................................... psi (kPa)

@ Governed Speed ......................................................................................... psi (kPa)

Maximum Oil Temperature .......................................................................................................... F (C)

Oil Capacity with OP 9451 Oil Pan : High - Low ............................................................. US gal (litre)

Total System Capacity (Including Combo Filter) .............................................................. US gal (litre)

Angularity of OP 9451 Oil Pan

Front Down .....................................................................................

Front Up..........................................................................................

Side to Side.....................................................................................

6

7

G-DRIVE

FUEL SYSTEM

Type Injection System..................................................................................................................................................................

Maximum Restriction at Lift Pump................................................................................................................ in Hg (mm Hg)

Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head)......... in Hg (mm Hg)

Maximum Fuel Flow to Injection Pump..................................................................................................... US gph (litre / hr)

Maximum Fuel Return Flow ...................................................................................................................... US gph (litre / hr)

Maximum Fuel Inlet Temperature ............................................................................................................................... F (C)

Bosch HPCR

6

(152)

10

(254)

43

(165)

8

(30)

160

(70)

ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement).................................................................................................. volt

Battery Charging System, Negative Ground........................................................................................................ ampere

Maximum Allowable Resistance of Cranking Circuit............................................................................................... ohm

Minimum Recommended Battery Capacity

Cold Soak @ 50-F (10-C) and Above.......................................................................................................... 0F CCA

Cold Soak @ 32 to 50-F (0 to10-C) ............................................................................................................ 0F CCA

Cold Soak @ 0 to 32-F (-18 to 0-C) ............................................................................................................. 0F CCA

12

100

0.001

24

70

0.002

TBD

TBD

1500

(TBD)

(TBD)

(750)

TBD.

10

(TBD)

(-12)

COLD START CAPABILITY

Minimum Ambient Temperature for Aided (with Coolant Heater) Cold Start within 10 seconds........................ F (C)

Minimum Ambient Temperature for Unaided Cold Start ....................................................................................... F (C)

PERFORMANCE DATA

All data is based on:

Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure : 100 kPa (29.53 in Hg)

Air Temperature

: 25 C (77 F)

Altitude

: 110 m (361 ft)

Relative Humidity : 30%

Steady State Stability Band at Any Constant Load ....................................................................................................... %

Exhaust Noise at 1m Horizontal from Centerline of Exhaust Pipe Outlet Upwards at 45.......................................--- dBA

STANDBY

60 hz

50 hz

Governed Engine Speed ............................................................. rpm

Engine Idle Speed ....................................................................... rpm

Gross Engine Power Output........................................... BHP (kWm )

Brake Mean Effective Pressure ........................................... psi (kPa)

Piston Speed ................................................................ ft / min (m / s)

Friction Horsepower.......................................................... HP (kWm )

Engine Water Flow at Stated Friction Head External to Engine:

2.5 psi Friction Head........................................ US gpm (litre / s)

Maximum Friction Head.................................. US gpm (litre / s)

1800

700 - 900

476

(355

387 (2668)

1707

(8.7)

47

(35)

64

60

(242)

(227)

1500

700 - 900

415

(310)

404 (2785)

1422

(7.2)

35

(26)

52

47

(195)

(178)

+/- 0.25

TBD

PRIME POWER

60 hz

50 hz

1800

700 - 900

412

(307)

335

(2309

1707

(8.7)

47

(35)

64

60

1500

700 - 900

359 (268)

350 (2413)

1422

(7.2)

35

(26)

(242)

(227)

52

47

(195)

(178)

Engine Data with Dry Type Exhaust Manifold

Intake Air Flow................................................................ cfm (litre / s)

Exhaust Gas Temperature ..................................................... F (C)

Exhaust Gas Flow .......................................................... cfm (litre / s)

Air to Fuel Ratio..................................................................... air : fuel

Radiated Heat to Ambient ..................................... BTU / min (kWm )

Heat Rejection to Jacket Coolant.......................... BTU / min (kWm )

Heat Rejection to Exhaust ..................................... BTU / min (kWm )

Heat Rejection to Fuel............................................ BTU / min (kWm )

Heat Rejected to Aftercooler.................................. BTU / min (kWm )

Charge Air Flow...................................................... lb / min (kg / min)

Turbocharger Compressor Outlet Pressure ............. in Hg (mm Hg)

Turbocharger Compressor Outlet Temperature.................... F (C)

870

(410)

1070

(580)

1355

(640)

22.1 : 1

2070

(40)

7705

(140)

17175

(305)

N/A

4535

(80)

60

(27)

75 (2006)

437

(225)

715

(340)

1040

(560)

1100

(520)

21.7:1

1720

(35)

6610

(120)

13385

(240)

N/A

3580

(65)

51

(23)

77 (1950)

426

(219)

820

(390)

945

(500)

1270

(600)

24.8 : 1

1745

(35)

6425

(115)

14120

(250)

N/A

3765

(70)

57

(26)

71 (1815)

401

(205)

660 (310)

930 (500)

1030 (490)

23.8:1

1455

(30)

5550 (100)

11125 (200)

N/A

2865

(55)

46

(21)

63 (1600)

381 (194)

N.A. - Not Available

N/A - Not Applicable to this Engine

TBD - To Be Determined

Cummins Inc.

Columbus Indiana 47202-3005

ENGINE MODEL :

DATA SHEET :

DATE :

CURVE NO. :

QSL9-G5

DS-91545

15Aug05

FR-91545

QSL

4

Vous aimerez peut-être aussi

- Yanmar 6HA2M WDT - DatasheetDocument2 pagesYanmar 6HA2M WDT - DatasheetalbidemolPas encore d'évaluation

- Gobernadores OlympianDocument55 pagesGobernadores OlympianGallego Carlos100% (1)

- Schematic125 170Document4 pagesSchematic125 170agus haryono100% (1)

- Engine-Powered Laden Container Handler 36 000 KG and 40 000 KGDocument4 pagesEngine-Powered Laden Container Handler 36 000 KG and 40 000 KGNuñez JesusPas encore d'évaluation

- Caterpillar C15 P1Z00331Document3 pagesCaterpillar C15 P1Z00331Hendra MechanicPas encore d'évaluation

- Stanadyne 05001Document4 pagesStanadyne 05001José O TelloPas encore d'évaluation

- Engineering and Installation Issues: Rob Johannsen, Product Manager, LPS PlatformsDocument26 pagesEngineering and Installation Issues: Rob Johannsen, Product Manager, LPS PlatformsJose Jimenez SilvaPas encore d'évaluation

- Cummins CPLDocument66 pagesCummins CPLYann LejardPas encore d'évaluation

- Cummins QSB5!9!305 PerfDocument3 pagesCummins QSB5!9!305 PerfVăn Tuấn NguyễnPas encore d'évaluation

- Every Ton.: For Mining ApplicationsDocument4 pagesEvery Ton.: For Mining ApplicationsRichard Sequeiros AlvarezPas encore d'évaluation

- Cummins Fc255Document3 pagesCummins Fc255Milton Milton100% (1)

- FR92154 Busu Isb4.5 PDFDocument4 pagesFR92154 Busu Isb4.5 PDFJuan Diego SarangoPas encore d'évaluation

- Marine CumminsDocument3 pagesMarine CumminsandrelovisiPas encore d'évaluation

- Diesel Engine MitsubishiDocument4 pagesDiesel Engine MitsubishiMarbun Benny100% (1)

- 3SA438 DDC Series 60 Specification - Coach SpecDocument2 pages3SA438 DDC Series 60 Specification - Coach SpecMOHD NAJMAN BIN MUDA100% (1)

- Operating Instruction - Motores DieselDocument254 pagesOperating Instruction - Motores DieselAlbertoPas encore d'évaluation

- Cat00000 PSRPT 2020-05-18 15.01.25 PDFDocument16 pagesCat00000 PSRPT 2020-05-18 15.01.25 PDFArturo A Maldonado OrtizPas encore d'évaluation

- Cummins China 4BTA3.9 G2Document5 pagesCummins China 4BTA3.9 G2joshua surbaktiPas encore d'évaluation

- H O HG: Tata Cummins LimitedDocument3 pagesH O HG: Tata Cummins LimitedDharmesh patelPas encore d'évaluation

- Especificaciones Motor Caterpillar C15Document2 pagesEspecificaciones Motor Caterpillar C15juan carlos rojas cadenaPas encore d'évaluation

- Caterpillar C15 Engine SpecsDocument5 pagesCaterpillar C15 Engine SpecsDesta 77Pas encore d'évaluation

- 8 - Data & Specifications 3Document21 pages8 - Data & Specifications 3agvass100% (1)

- Doosan DP222LC PDFDocument4 pagesDoosan DP222LC PDFLuisDelaHozPas encore d'évaluation

- 1100 Series PerkinsDocument2 pages1100 Series PerkinsGilberto Diaz CastilloPas encore d'évaluation

- Engine Especifications G3520BDocument4 pagesEngine Especifications G3520BYaneth100% (1)

- Specifications KTA38 G DRIVEDocument2 pagesSpecifications KTA38 G DRIVEMehdi ChakrounePas encore d'évaluation

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Document2 pagesMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverPas encore d'évaluation

- DATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesDocument8 pagesDATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesmanuelPas encore d'évaluation

- Perkins Engine ManualsDocument20 pagesPerkins Engine Manuals李文琪100% (1)

- Emissions Data For Cat EngineDocument4 pagesEmissions Data For Cat EngineRajan SharmaPas encore d'évaluation

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdPas encore d'évaluation

- 001a HM02316 - 00 Engine SpecificationsDocument92 pages001a HM02316 - 00 Engine SpecificationsBruno VenturaPas encore d'évaluation

- CAT 3208 Dieselengine Parts Manual Album Modeltrucks25 Completo 182 PaginasDocument178 pagesCAT 3208 Dieselengine Parts Manual Album Modeltrucks25 Completo 182 PaginasLuis Manuel100% (1)

- FPDP TrainingDocument80 pagesFPDP TrainingSpectrumRaijin100% (2)

- C 32Document6 pagesC 32pniyomkaPas encore d'évaluation

- Diesel Engine Product Guide 201608Document28 pagesDiesel Engine Product Guide 201608bethadio rizkyPas encore d'évaluation

- FuelUnitInjector SELD0143-20Document15 pagesFuelUnitInjector SELD0143-20guayanecitroPas encore d'évaluation

- A New HEUI Is Used On C7Document3 pagesA New HEUI Is Used On C7Carlos Indigoyen LimaymantaPas encore d'évaluation

- Dokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Document15 pagesDokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Valeriy Valkovets100% (1)

- Ajuste Serie 400Document64 pagesAjuste Serie 400Javier Robles FontalvoPas encore d'évaluation

- Kta38-G5 Hci634jDocument10 pagesKta38-G5 Hci634jMichael Puma ZeaPas encore d'évaluation

- CPL Cross Reference - Overhaul KitsDocument13 pagesCPL Cross Reference - Overhaul KitsAugusto NuñezPas encore d'évaluation

- John Deere - Especificaciones Marinas - Oct. 2017Document15 pagesJohn Deere - Especificaciones Marinas - Oct. 2017AlbertoPas encore d'évaluation

- Modificacion de ActudorDocument2 pagesModificacion de ActudorPieroPas encore d'évaluation

- Application Engineering BulletinDocument15 pagesApplication Engineering BulletinJose VidalPas encore d'évaluation

- Troubleshooting With Diagnostic Codes 3500B EnginesDocument13 pagesTroubleshooting With Diagnostic Codes 3500B EnginesMohamed Bakheet100% (1)

- Vector 8 Technical and Repair Manual - Industrial ApplicationDocument206 pagesVector 8 Technical and Repair Manual - Industrial ApplicationAlejandro Di Gregorio100% (1)

- Doosan 4v222ti MotorlarıDocument2 pagesDoosan 4v222ti MotorlarıhgulecPas encore d'évaluation

- 16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinDocument9 pages16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinJuan PujolPas encore d'évaluation

- Nef M280Document9 pagesNef M280husan shah100% (1)

- KP-F D XXGV OperationManual EDocument7 pagesKP-F D XXGV OperationManual EabathunPas encore d'évaluation

- QSX15-G8: TA Luft CompliantDocument3 pagesQSX15-G8: TA Luft CompliantNguyen CuongPas encore d'évaluation

- QST30 MineriaDocument4 pagesQST30 MineriaElio Custodio Huachaca100% (1)

- Generador 250kwDocument15 pagesGenerador 250kwmax_velasquezPas encore d'évaluation

- Engine Performance Data at 1500 RPM: QSB 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: QSB 1 Cummins IncMaged Beshara100% (3)

- qsm11 g1nr2Document5 pagesqsm11 g1nr2Eslam MansourPas encore d'évaluation

- 6BTAA5.9G5 - EngineDocument4 pages6BTAA5.9G5 - EngineMuhammad Ali Shamozai100% (1)

- Datasheet QSX15G9Document3 pagesDatasheet QSX15G9walsystem22100% (2)

- FR 5277 QST30 G4 ATADocument6 pagesFR 5277 QST30 G4 ATABernardo GarridoPas encore d'évaluation

- FR 5160Document6 pagesFR 5160Nicholas FryePas encore d'évaluation