Académique Documents

Professionnel Documents

Culture Documents

70 - 75 - 80 - 90 - 100 - 115 HP

Transféré par

LorenzoGabrielSilvaDonoso0 évaluation0% ont trouvé ce document utile (0 vote)

188 vues3 pagesThis document is a service manual for Mercury outboard motors from 1987-1993 with 3 and 4 cylinder engines. It provides serial number ranges for United States, Belgium, and Canadian models and lists the models covered, which include 70, 75, 80, 90, 100, and 115 HP engines. The manual is intended to aid mechanics and service personnel in servicing these outboard motors and contains notices about safety alerts and procedures.

Description originale:

Titre original

70_75_80_90_100_115 hp

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document is a service manual for Mercury outboard motors from 1987-1993 with 3 and 4 cylinder engines. It provides serial number ranges for United States, Belgium, and Canadian models and lists the models covered, which include 70, 75, 80, 90, 100, and 115 HP engines. The manual is intended to aid mechanics and service personnel in servicing these outboard motors and contains notices about safety alerts and procedures.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

188 vues3 pages70 - 75 - 80 - 90 - 100 - 115 HP

Transféré par

LorenzoGabrielSilvaDonosoThis document is a service manual for Mercury outboard motors from 1987-1993 with 3 and 4 cylinder engines. It provides serial number ranges for United States, Belgium, and Canadian models and lists the models covered, which include 70, 75, 80, 90, 100, and 115 HP engines. The manual is intended to aid mechanics and service personnel in servicing these outboard motors and contains notices about safety alerts and procedures.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

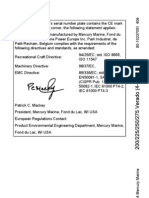

(3 Cylinder)

UNITED STATES S/N 0A996142 thru 0D283221

BELGIUM S/N 09502135 thru 09793576

CANADA S/N 0A722297 and Above

BELGIUM

CANADA

S/N 0B209468 thru 0D283221

S/N 09523034 thru 09793576

S/N 0A731673 and Above

MODELS

70 75 80 90 100 115

SERVICE

MANUAL

19871993 70 75 75 Marathon

75XD 75 Seapro 80 90

19881993 100 115 (4 Cylinder)

with Serial Numbers

with Serial Numbers

UNITED STATES

Printed in U.S.A.

1995, Brunswick Corporation

90-13645--2 1095

Notice

Throughout this publication, Dangers, Warnings

and Cautions (outlined in a border and accompa-

nied by the International HAZARD Symbol ) are

used to alert the mechanic to special instructions con-

cerning a particular service or operation that may be

hazardous if performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY!

These Safety Alerts alone cannot eliminate the

hazards that they signal. Strict compliance to these

special instructions when performing the service, plus

common sense operation, are major accident

prevention measures.

DANGER

DANGER Immediate hazards which WILL result

in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION Hazards or unsafe practices which

could result in minor personal injury or product or

property damage.

CAUTION

Notice to Users of This Manual

This service manual has been written and published

by the service department of Mercury Marine to aid

our dealers mechanics and company service person-

nel when servicing the products described herein.

It is assumed that these personnel are familiar with

the servicing procedures of these products, or like or

similar products manufactured and marketed by Mer-

cury Marine, that they have been trained in the recom-

mended servicing procedures of these products

which includes the use of mechanics common hand

tools and the special Mercury Marine or recom-

mended tools from other suppliers.

We could not possibly know of and advise the service

trade of all conceivable procedures by which a ser-

vice might be performed and of the possible hazards

and/or results of each method. We have not under-

taken any such wide evaluation. Therefore, anyone

who uses a service procedure and/or tool, which is

not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the

products safety will be endangered by the service

procedure selected.

All information, illustrations and specifications con-

tained in this manual are based on the latest product

information available at the time of publication. As re-

quired, revisions to this manual will be sent to all deal-

ers contracted by us to sell and/or service these prod-

ucts.

It should be kept in mind, while working on the

product, that the electrical system and ignition system

is capable of violent and damaging short circuits or

severe electrical shocks. When performing any work

where electrical terminals could possibly be

grounded or touched by the mechanic, the battery

cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed

during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive inter-

nal damage when the engine is started.

It is important to note that, during any maintenance

procedure, replacement fasteners must have the

same measurements and strength as those re-

moved, whether metric or customary. Numbers on the

heads of the metric bolts and on surfaces of metric

nuts indicate their strength. Customary bolts use ra-

dial lines for this purpose, while most customary nuts

do not have strength markings. Mismatched or incor-

rect fasteners can result in damage or malfunction, or

possible personal injury. Therefore, fasteners re-

moved should be saved for re-use in the same loca-

tions whenever possible. Where the fasteners are not

satisfactory for re-use care should be taken to select

a replacement that matches the original.

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many ma-

chined, honed, polished and lapped surfaces with tol-

erances that are measured in the ten thousands of an

inch. When any product component is serviced, care

and cleanliness are important. Throughout this

manual, it should be understood that proper cleaning,

and protection of machined surfaces and friction

areas is a part of the repair procedure. This is consid-

ered standard shop practice even if not specifically

stated.

Whenever components are removed for service, they

should be retained in order. At the time of installation,

they should be installed in the same locations and

with the same mating surfaces as when removed.

Before raising or removing an outboard engine from a

boat, the following precautions should be adhered to:

1. Check that flywheel is secured to end of

crankshaft with a locknut and lifting eye is

threaded into flywheel a minimum of 5 turns.

2. Connect a hoist of suitable strength to the lifting

eye.

In addition, personnel should not work on or under an

engine which is suspended. Engines should be at-

tached to work stands, or lowered to ground as soon

as possible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent in-

formation concerning the products described in this

manual.

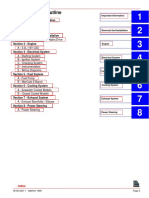

Service Manual Outline

1 - General Information and Specifications

2 - Electrical and Ignition

A - Ignition System

B - Battery, Charging System and

Starting System

C - Timing/Synchronizing and Adjusting

D - Wiring Diagrams

3 A - Fuel System and Carburetion

B - Oil Injection System

4 A - Powerhead (3-Cylinder Engines)

B - Powerhead (4-Cylinder Engines)

5 - Lower Unit

A - Gear Housing

B - Mid Section

C - Shock Absorber

6 - Power Trim

A - Design I (Side Fill Reservoir)

B - Design II (Aft Fill Reservoir)

C - Single Ram

7 - Outboard Motor Installation/Attachments

A - Engine Attachments/Engine Installation

B - Tiller Handle and Co-Pilot

Vous aimerez peut-être aussi

- 2018catalogue PDFDocument44 pages2018catalogue PDFRahman RahmmanPas encore d'évaluation

- Manual YDS Versión 1.32Document232 pagesManual YDS Versión 1.32Isaac Rodríguez BetancourtPas encore d'évaluation

- Includes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmDocument139 pagesIncludes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmbugmeyoucan100% (1)

- CoverDocument3 pagesCoverBaxter LoachPas encore d'évaluation

- L510013 07Document61 pagesL510013 072791957Pas encore d'évaluation

- Mercury 20 - 25 HP - 25 Marathon - 25 SeaproDocument371 pagesMercury 20 - 25 HP - 25 Marathon - 25 SeaproIanLandererPas encore d'évaluation

- 31 GM SBC 2001Document1 096 pages31 GM SBC 2001The Boat DocturPas encore d'évaluation

- Manual (YDIS Ver1.30)Document220 pagesManual (YDIS Ver1.30)jflatt3100% (1)

- Merc Thunderbolt IV and V Ignition FlowchartDocument3 pagesMerc Thunderbolt IV and V Ignition Flowchartpat obrienPas encore d'évaluation

- 25 EfiDocument540 pages25 EfiFERNANDO MINUTOPas encore d'évaluation

- Serial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Document654 pagesSerial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Ingo BorchersPas encore d'évaluation

- Gti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeDocument22 pagesGti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeAlexandru DiaconuPas encore d'évaluation

- Mercruiser QSD 28 42Document182 pagesMercruiser QSD 28 42Per Østbø100% (1)

- Merc Gas EnginesDocument181 pagesMerc Gas EnginesyamyrulesPas encore d'évaluation

- Shibaura Diesel Engine S773L - Tier4 XXDocument28 pagesShibaura Diesel Engine S773L - Tier4 XXMihai PopaPas encore d'évaluation

- Number 6: Sterndrive Units R MR Alpha One Alpha One SSDocument7 pagesNumber 6: Sterndrive Units R MR Alpha One Alpha One SSmarujopePas encore d'évaluation

- 2003 200 Bow RiderDocument36 pages2003 200 Bow Riderbbenz62Pas encore d'évaluation

- GM 4 CilindroDocument422 pagesGM 4 CilindroGerardo Espinola Cardozo100% (1)

- Tech Spec For Plate Heat ExchangersDocument37 pagesTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- Notice To Users of This Manual: DangerDocument126 pagesNotice To Users of This Manual: DangerDeni NuryantoPas encore d'évaluation

- SM - 3.0L - 4cycl PDFDocument420 pagesSM - 3.0L - 4cycl PDFtablePas encore d'évaluation

- 00X31ZW26300 PDFDocument139 pages00X31ZW26300 PDFMisho MishoPas encore d'évaluation

- 2002 Deep Snow Service ManualDocument392 pages2002 Deep Snow Service Manualwireless303Pas encore d'évaluation

- Cover PDFDocument3 pagesCover PDFJim LassPas encore d'évaluation

- Analog Gauge Connections For Digital Optimax ModelsDocument6 pagesAnalog Gauge Connections For Digital Optimax ModelsGet SmartCraft100% (1)

- Evinrude E-TEC 115-200 HP PDFDocument443 pagesEvinrude E-TEC 115-200 HP PDFWilliam SebestikPas encore d'évaluation

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerPas encore d'évaluation

- SUZUKI DF200 225 250 Service Man 5Document78 pagesSUZUKI DF200 225 250 Service Man 5Candido IsazaPas encore d'évaluation

- Mercury VeradoDocument107 pagesMercury VeradoStefanos Grammenos67% (3)

- Electronic Remote Control: Operation ManualDocument30 pagesElectronic Remote Control: Operation ManualSurendran PattineyapanPas encore d'évaluation

- DF 200Document152 pagesDF 200ruge13484246Pas encore d'évaluation

- DF150T/Z DF150TG/ZG DF175T/Z DF175TG/ZG: Parts CatalogueDocument867 pagesDF150T/Z DF150TG/ZG DF175T/Z DF175TG/ZG: Parts CatalogueJeniffer ramirezPas encore d'évaluation

- Alpha Transom Assembly & ServiceDocument73 pagesAlpha Transom Assembly & ServiceDave Lamers100% (1)

- DTS Wiring DiagramDocument2 pagesDTS Wiring DiagramTrevor Richardson PeraconPas encore d'évaluation

- © 2019 Yamaha Motor Corporation, U.S.A.: F200 LF200 F225 F250 LF250Document112 pages© 2019 Yamaha Motor Corporation, U.S.A.: F200 LF200 F225 F250 LF250Tormod LarsenPas encore d'évaluation

- Mercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsDocument8 pagesMercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsGerardo Espinola Cardozo100% (1)

- Lit 18626 06 75 - 1369Document90 pagesLit 18626 06 75 - 1369andysuomi100% (1)

- P & I DiagramsDocument26 pagesP & I Diagramsengrfarhansiddiqui100% (3)

- Mfs6bz - Mfs8b - Mfs9.8b - 2016Document92 pagesMfs6bz - Mfs8b - Mfs9.8b - 2016Alessandro MenichiniPas encore d'évaluation

- Energy Valorization of Biogas in Santa CatarinaDocument10 pagesEnergy Valorization of Biogas in Santa CatarinagrimdorlfPas encore d'évaluation

- BF 175 - 250 Manual (Eng)Document164 pagesBF 175 - 250 Manual (Eng)HuyPas encore d'évaluation

- Declaration of Conformance - Mercury Mercruiser: Applicable Requirement Standards AppliedDocument96 pagesDeclaration of Conformance - Mercury Mercruiser: Applicable Requirement Standards AppliedNeil TataPas encore d'évaluation

- Service Manual: Models 30 JET 40 (4 CYL)Document532 pagesService Manual: Models 30 JET 40 (4 CYL)Martin VojtěchPas encore d'évaluation

- ATT III - 2. Use Internal Communication SystemsDocument9 pagesATT III - 2. Use Internal Communication Systemsedwin90276Pas encore d'évaluation

- Hpdi Main ScheduleDocument2 pagesHpdi Main Schedulefabbromauricioyahoo.com.arPas encore d'évaluation

- MFS 75 115 Tohatsu ManualDocument89 pagesMFS 75 115 Tohatsu Manualabdulateefnsr100% (1)

- 8.2L Mag/H.O./Seacore Sterndrive Models Non Ect: Operation and Maintenance ManualDocument119 pages8.2L Mag/H.O./Seacore Sterndrive Models Non Ect: Operation and Maintenance ManualcharlesPas encore d'évaluation

- Asme Boiler & Pressure Section ViiiDocument22 pagesAsme Boiler & Pressure Section ViiiHesham ismail SeddikPas encore d'évaluation

- 200-350 VeradoDocument122 pages200-350 Veradolee sampson100% (1)

- Design Check List Viii-1 Rev1Document2 pagesDesign Check List Viii-1 Rev1nirmalPas encore d'évaluation

- Verado V12Document134 pagesVerado V12lee sampson100% (1)

- MCM Service BulletinDocument4 pagesMCM Service BulletinHammerheadhunter SmithPas encore d'évaluation

- Owner's Manual: Outboard MotorDocument85 pagesOwner's Manual: Outboard MotorJasmin PartingtonPas encore d'évaluation

- Raymarine Type 150 & 400 Autopilot System Manual PDFDocument64 pagesRaymarine Type 150 & 400 Autopilot System Manual PDFfbeasby100% (1)

- Thank You: WarningDocument127 pagesThank You: WarningRyan TaylorPas encore d'évaluation

- Mercruiser AnodesDocument41 pagesMercruiser AnodesMarine Parts ChinaPas encore d'évaluation

- Evinrude E-TEC 15-30HP Outboards BuletinDocument2 pagesEvinrude E-TEC 15-30HP Outboards Buletinfranklarabie100% (2)

- Honda Marine Outboard Bf115a Bf130a Owner ManualDocument130 pagesHonda Marine Outboard Bf115a Bf130a Owner ManualЯрослав БарновскийPas encore d'évaluation

- Fuel SystemDocument34 pagesFuel Systemwguenon100% (1)

- Mercury Commander Side Mount ControlDocument18 pagesMercury Commander Side Mount ControlTab Sedgwick100% (1)

- Typical Mercury Ignition SystemsDocument11 pagesTypical Mercury Ignition SystemswguenonPas encore d'évaluation

- DT 55 (1985-1987) DT 65 (1985-1987)Document57 pagesDT 55 (1985-1987) DT 65 (1985-1987)Antonio MatronePas encore d'évaluation

- Rigging Guide 2008Document222 pagesRigging Guide 2008Alex1Pas encore d'évaluation

- Manual Honda Bf25Document138 pagesManual Honda Bf25Printer ProvencalPas encore d'évaluation

- Rigging2002 PDFDocument89 pagesRigging2002 PDFJimmy Aleman0% (1)

- DF70A DF80A DF90A: Owner'S ManualDocument59 pagesDF70A DF80A DF90A: Owner'S ManualURIEL CABALLEROPas encore d'évaluation

- Workbook Answers: CCEA GCSE PhysicsDocument40 pagesWorkbook Answers: CCEA GCSE PhysicsCanioPas encore d'évaluation

- FILE - 20220113 - 182052 - ĐỀ CƯƠNG ÔN KT CUỐI KỲ 1 - FILE TỔNG - HS - 1640862470293Document11 pagesFILE - 20220113 - 182052 - ĐỀ CƯƠNG ÔN KT CUỐI KỲ 1 - FILE TỔNG - HS - 1640862470293Ichihara YuukoPas encore d'évaluation

- DMM-I Q Bank Answers UNIT-1,2Document14 pagesDMM-I Q Bank Answers UNIT-1,2MrHEMAMAHEHPas encore d'évaluation

- Partial Discharge Theory and Applications To Electrical SystemsDocument15 pagesPartial Discharge Theory and Applications To Electrical SystemsjonathanmartinPas encore d'évaluation

- STK 630Document8 pagesSTK 630Paulo VictorPas encore d'évaluation

- Handbook For Radiological MonitorsDocument44 pagesHandbook For Radiological MonitorsChó MèoPas encore d'évaluation

- Rivulis F3240 English Metric 20191223 WebDocument10 pagesRivulis F3240 English Metric 20191223 WebMehdi BassouPas encore d'évaluation

- How Air Compressor WorksDocument3 pagesHow Air Compressor WorksPinak ParkhiPas encore d'évaluation

- Lanchshire BoilerDocument13 pagesLanchshire Boilerkarthik2468Pas encore d'évaluation

- LIEBHERR R934-StageV-EN-PI-2021-01Document24 pagesLIEBHERR R934-StageV-EN-PI-2021-01ganendra santantikaPas encore d'évaluation

- Model For Mechanical EngineeringDocument121 pagesModel For Mechanical EngineeringAbimael wendimuPas encore d'évaluation

- TR ProtectionDocument23 pagesTR Protectionhafiz_hazreenPas encore d'évaluation

- Test116 3 PlusansDocument5 pagesTest116 3 PlusansAvnish GargPas encore d'évaluation

- Manifold Operating ProcedureDocument7 pagesManifold Operating Proceduresiruslara6491Pas encore d'évaluation

- Residential KitchenBathrooDocument7 pagesResidential KitchenBathrooCarlos Daniel Ayala GonzalezPas encore d'évaluation

- Virus SopDocument34 pagesVirus SopManikPas encore d'évaluation

- Pab 10Document6 pagesPab 10MelvinDapitanonPas encore d'évaluation

- QAS105 Spare PartsDocument90 pagesQAS105 Spare PartsMaycon GiacomimiPas encore d'évaluation

- Temperature Control in The Neonate: Dr. Johanus Edwin, SpaDocument20 pagesTemperature Control in The Neonate: Dr. Johanus Edwin, SpaHeskianoGoeltomPas encore d'évaluation

- D2060-M - Medical Vacuum and Gas SystemsDocument7 pagesD2060-M - Medical Vacuum and Gas Systemspaintbrush793053Pas encore d'évaluation

- Thermal Science and Engineering Progress: Tayebeh Darbandi, Mikael Risberg, Lars WesterlundDocument9 pagesThermal Science and Engineering Progress: Tayebeh Darbandi, Mikael Risberg, Lars WesterlundSaleel ChuriPas encore d'évaluation

- 01-34-11 11-10-2016 Brasil - Feasibility Study For The Waste To Energy Plant Vol.1Document255 pages01-34-11 11-10-2016 Brasil - Feasibility Study For The Waste To Energy Plant Vol.1Sekretariat SPSPPas encore d'évaluation

- The Misadventures of Gale The Birthday ClownDocument7 pagesThe Misadventures of Gale The Birthday ClownChris33% (3)