Académique Documents

Professionnel Documents

Culture Documents

Typical QAP

Transféré par

hemantmech09Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Typical QAP

Transféré par

hemantmech09Droits d'auteur :

Formats disponibles

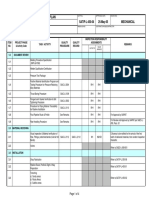

QUALITY ASSURANCE PLAN

CUSTOMER M/S.JSW STEEL LIMITED ITEM 3.5 KL GAN QAP NO. SES/QAP/11

PROJECT: QTY. : 1 NO. REV. 0

DRAWING NO.: P.O. NO. :

EQUIPMENT NO.: DATE : 03.07.2013 PAGE : 1 OF 3

Sr. Stages Charecterostoc Type of Check Format of Remarks

No. Record SES TPI CLIENT

1.0 WPS/PQR/WPQ Welding Parameter & other

Supp. Rev.

WPS/PQR P R --

2.0 Boughtout items viz. Verification of Review of MTCs Manf.T.Cs P W --

Pipes, Fittings,forgings Sub Orders Visual & Dimnl. Insp.Report

3.0 Identification of Material

a) Pressure Parts, i.e. Phy.Chem,UT Visual,Dimn. And MTCs & Matl. P W I

Plate, Pipe, Flange Sur.defects & Dimn. Verification of TCs identif.Reports

Impact test

b) Non Pressure Parts Surface defects Visual & Dimn. Insp.Report P R --

Dimensions Verification of TCs Matl.TestCert.

4.0 Fabrication Stages in a). Long-seam setups Insp.Report P W/R

--

Shop Floor

b) Long-seam Back chip Weld Defects Insp.Report P R --

L.P. Test

c) Radiography Test of Weld Defects Insp.Report P R --

Long Seam

d) Shell to Shell C.S. Setup Joint allignment, root gap,

C.F. at joint edge L.P. Test,

Allignment, Edge preparation

RT Report P W/R -- Film Review

e) Curcuim seam, Back Weld Defects Insp.Report P R --

chip, L.P. Test

f) Radiography Test of Weld Defects Insp. Report P R --

Cirseam

g) Dish end forming I.D height, C.F. min thk, Idn.

Mark, Profile

Insp. Report P R --

Joint allignment, root

gap,Ovality, C.F. , Joint

Design, edge, L.P. Test

100%

100%

100%

App. Drg./Code

App. Drg./Code

Code

100%

100%

(PD 5500 CAT-1 &

SMPV(U) RULES 1999)

App. Drg./Code

App. Drg./Code

100%

100%

App. Drg./Code

Code

Ext.of

Check

100%

100%

100%

100%

Insp.by Accept.

Norms

App. Drg./Code

App. Drg./Code

App. Drg./Code

Code

Page 1 of 4

QUALITY ASSURANCE PLAN

CUSTOMER M/S.JSW STEEL LIMITED ITEM 3.5 KL GAN QAP NO. SES/QAP/11

PROJECT: QTY. : 1 NO. REV. 0

DRAWING NO.: P.O. NO. :

EQUIPMENT NO.: DATE : 03.07.2013 PAGE : 2 OF 3

Sr. Stages Charecterostoc Type of Check Format of Remarks

No. Record SES TPI CLIENT

h) Nozzle Opening Projection from vessel centre

line, identification mark,

Orientation, Elevation

Inspection Report P P ---

i) Pipe to Flange Setup Dimension, Joint Detail Inspection Report P R ---

j) Nozzle to Shell D end Projection from vessel Inspection Report P W ---

Fit up centre line, Elevation

identification mark, root gap

orientation

k) Nozzle to Shell/ D end Weld Defects Inspection Report P R ---

B/ Chip D.P Test

l) D end to Shell C.S. setup Joint allegnment, ID OD

match taper edge, L.P. test

C.F. at joint

Inspection Report P W ---

m) Cir seam Back Chip L.P. Weld Defects Inspection Report P R ---

Test

n) Radiography Test Weld Soundness Inspection Report P R ---

o) R.F. Pad Pneumatics Test Weld Defects Inspection Report P W ---

p) External fit up & welding of Inspection Report P R ---

Lifting Lug, Nameplate

bracket

q) Skirt support fit-up Height, devation, hole dia

joint design, dimension etc.

Inspection Report P R ---

r) Final dimension check-up Dimension Dimension Report P H ---

(Internal & External, Nozzle)

s) Visual Inspection Appearance, Touch aps etc. Inspection Report P H ---

5.0 NDT Clearance for PWHT Review of NDT Reports NDT Report P H ---

6.0 Dimensional & Visual Compliances Dimensional, Visual Insp.Report P H/W ---

7.0 Hydro Test Leaks Visual Hydro Test P H W

Report

App. Drg./Code

100% App. Drg.

App. Drg./Code 100%

100% Code

Code

100% Code

100% App. Drg./Code

100%

Drg

Drg./Code 100%

100%

100%

Ext.of

Check

100%

100%

Straightrenss, Perpendicularity

joint design, dimension etc.

Accept.

Norms

App. Drg./Code

Insp.by

App. Drg./Code

100% Code

100% App. Drg.

100% App. Drg.

100% Code

Page 2 of 4

QUALITY ASSURANCE PLAN

CUSTOMER M/S.JSW STEEL LIMITED ITEM 3.5 KL GAN QAP NO. SES/QAP/11

PROJECT: QTY. : 1 NO. REV. 0

DRAWING NO.: P.O. NO. :

EQUIPMENT NO.: DATE : 03.07.2013 PAGE : 3 OF 3

Sr. Stages Charecterostoc Type of Check Format of Remarks

No. Record SES TPI CLIENT

8.0 Final Stamping Identification Review of all documents Inspection Report P H

---

9.0 Documentation COC, Hard Stamp rub-off,

Hydrotest Report, Pnuematic

Test Report, Final Dimension,

Report, PWHT Chart, Material

Chart with T.C., Radiography

Report with sketch, Painting

Report, WPS/PQR and As built

drawing.

Inspection Report P H I

FOR SPACETECH EQUIPMENTS & STRUCTURALS PVT.LTD. FOR CUSTOMER

DATE & SEAL DATE & SEAL

LEGENDS

H : INSPECTION COMPULSORY SES: Spacetech Equipments & Structurals Pvt.Ltd. I : Information MOC: Material of Construction

W : Witness (Offer for Inspection but don't TPI : Third party inspection MT : Magnetic Partical Test SS : Stainless Steel

hold beyond 24 hours) UT : Ultrasonic Test PWHT : Post Weld Heat Treatment CS : Carbon Steel

R : Review RT : Radiographic Test PR : Purchase Requisition

A : Approval PT : Penetrant Test PO : Purchase Order

P : Performer

100% App. Drg./Code

App. Drg./Code 100%

Accept. Insp.by

Check Norms

Ext.of

Page 3 of 4

Page 4 of 4

Vous aimerez peut-être aussi

- Heroes Unlimited Character Sheet PDFDocument1 pageHeroes Unlimited Character Sheet PDFBumpybot123Pas encore d'évaluation

- Bond 11 Plus: 11 Plus English Practice TestDocument9 pagesBond 11 Plus: 11 Plus English Practice Testthayanthiny100% (1)

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHPas encore d'évaluation

- PD5500 2012 UpdatebrochureDocument4 pagesPD5500 2012 UpdatebrochureLisa Carlson33% (3)

- J910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)Document15 pagesJ910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)rudi sarifudinPas encore d'évaluation

- Asme Viii QC ManualDocument70 pagesAsme Viii QC Manualneurolepsia3790Pas encore d'évaluation

- Steel Test ResultsDocument2 pagesSteel Test ResultsDevendra SinghPas encore d'évaluation

- Best Practices in Quality Assurance & Inspection IN NTPCDocument39 pagesBest Practices in Quality Assurance & Inspection IN NTPCPrincy SinghPas encore d'évaluation

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALPas encore d'évaluation

- QAP For Pipes For Hydrant and Sprinkler SystemDocument3 pagesQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaPas encore d'évaluation

- GSB Test FormatsDocument4 pagesGSB Test FormatsGaurav TripathiPas encore d'évaluation

- Concrete Cube Durability Test Report SubmittalDocument13 pagesConcrete Cube Durability Test Report SubmittalNawar ZainoPas encore d'évaluation

- Four Laning of Munger to Mirzachauki (NH-80)-Start From Kharia Village Junction to the Exisiting Bhagalpur Bypass (PKG-2-CH: KM 95+580 to KM 125+000) on Hybrid Annuity Mode in the State of BiharDocument1 pageFour Laning of Munger to Mirzachauki (NH-80)-Start From Kharia Village Junction to the Exisiting Bhagalpur Bypass (PKG-2-CH: KM 95+580 to KM 125+000) on Hybrid Annuity Mode in the State of BiharAmit MaityPas encore d'évaluation

- Compressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Document1 pageCompressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Shoyeeb AhmedPas encore d'évaluation

- Field Quality Plan For LgfsDocument7 pagesField Quality Plan For LgfsUday PratapPas encore d'évaluation

- Foundation DesignDocument2 pagesFoundation Designhemantmech09Pas encore d'évaluation

- Foundation DesignDocument2 pagesFoundation Designhemantmech09Pas encore d'évaluation

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraPas encore d'évaluation

- Oisd 116 Fire Protection Facilities Petroleum RefineriesDocument52 pagesOisd 116 Fire Protection Facilities Petroleum Refineriesdeua200483% (12)

- QAP CivilDocument249 pagesQAP CivilGoanengineerPas encore d'évaluation

- Insectopia CompendiumDocument53 pagesInsectopia Compendiumnaruto hyuga67% (3)

- Saudi Aramco Fence Inspection ChecklistDocument3 pagesSaudi Aramco Fence Inspection ChecklistAbuAhmedQuaziPas encore d'évaluation

- Scaffold ChecklistDocument5 pagesScaffold ChecklistMohamed GhariebPas encore d'évaluation

- Concrete Trial Mix Checklist - 01.09.2022Document5 pagesConcrete Trial Mix Checklist - 01.09.2022Pandiaraj VPas encore d'évaluation

- NR Letter Submission of ITP For HSFG BoltsDocument2 pagesNR Letter Submission of ITP For HSFG BoltsLakhwant Singh KhalsaPas encore d'évaluation

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaPas encore d'évaluation

- Halloween Vocabulary Esl Unscramble The Words Worksheets For Kids PDFDocument4 pagesHalloween Vocabulary Esl Unscramble The Words Worksheets For Kids PDFEdurne De Vicente Pereira0% (2)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputPas encore d'évaluation

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pages04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraPas encore d'évaluation

- Evaluating LNG Operations Risk with Passive MitigationDocument53 pagesEvaluating LNG Operations Risk with Passive Mitigationtaufik mahlanPas encore d'évaluation

- QC - Pred QC-CC Road Part - 1Document23 pagesQC - Pred QC-CC Road Part - 1D. BalanarasimhaiahPas encore d'évaluation

- ACP-EU Energy Facility LVIA Shashamene Final AuditDocument3 pagesACP-EU Energy Facility LVIA Shashamene Final AuditTesfuPas encore d'évaluation

- Quality Assurance & Quality Control Checklist ForDocument37 pagesQuality Assurance & Quality Control Checklist Forrajesh1707Pas encore d'évaluation

- Authorisation For Layig GSB and WMM-Rev-R2Document1 pageAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranPas encore d'évaluation

- Gammon Bulletin Oct - Dec 2013Document20 pagesGammon Bulletin Oct - Dec 2013balagaikwadPas encore d'évaluation

- Method Statement of Lateral Load Test (BHEL ANPARA)Document11 pagesMethod Statement of Lateral Load Test (BHEL ANPARA)sugurpraveenPas encore d'évaluation

- Client Consultant: 49/2012-Construction and Execution of Ras Al Khaimah Ring RoadDocument8 pagesClient Consultant: 49/2012-Construction and Execution of Ras Al Khaimah Ring RoadMansoor AliPas encore d'évaluation

- NABL 103 Doc Chemical Testing LaboratoryDocument30 pagesNABL 103 Doc Chemical Testing LaboratoryKaushik SenguptaPas encore d'évaluation

- 0005 India Regulation On CoatingDocument33 pages0005 India Regulation On Coatingagustinusset100% (2)

- Chimney NotesDocument3 pagesChimney NotesmonojitdeyPas encore d'évaluation

- Package II Part I.1 Civil BOQ For Transit House BuildingDocument29 pagesPackage II Part I.1 Civil BOQ For Transit House Buildingdox4usePas encore d'évaluation

- Method Statement For Sub Grade: Project Procedure Plan - Fipl#2, Phase 1Document4 pagesMethod Statement For Sub Grade: Project Procedure Plan - Fipl#2, Phase 1HARIOM GUPTAPas encore d'évaluation

- Schedule of pile depth and reinforcement detailsDocument1 pageSchedule of pile depth and reinforcement detailsManas MondalPas encore d'évaluation

- Comprssive Strength of CubesDocument4 pagesComprssive Strength of CubesMansoor AliPas encore d'évaluation

- Blockwork and Plastering - HalulDocument14 pagesBlockwork and Plastering - HalulDindo QuintanPas encore d'évaluation

- Methodstatement For Back Filling in StructuresDocument2 pagesMethodstatement For Back Filling in StructuresLaxminarayana SastryPas encore d'évaluation

- Civil Works Inspection and Test PlanDocument6 pagesCivil Works Inspection and Test PlanWalid AmdouniPas encore d'évaluation

- Italian-Thai Density Test ResultsDocument9 pagesItalian-Thai Density Test ResultsJovanni RodriguezPas encore d'évaluation

- Accessories ListDocument10 pagesAccessories ListShashank HegdePas encore d'évaluation

- Is-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteDocument23 pagesIs-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteSachin PawarPas encore d'évaluation

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharPas encore d'évaluation

- 1888 03Document36 pages1888 03Laura MarquezPas encore d'évaluation

- L&T Quality Quiz-Sample 1Document3 pagesL&T Quality Quiz-Sample 1balaPas encore d'évaluation

- Mix Design M-25 GradeDocument9 pagesMix Design M-25 Gradeenjoy begening lifePas encore d'évaluation

- 8 Material Inspection ReportDocument1 page8 Material Inspection Reportvinson bayPas encore d'évaluation

- 1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Document4 pages1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Bighneswar PatraPas encore d'évaluation

- Is 4464 1985Document21 pagesIs 4464 1985rajenkoleyPas encore d'évaluation

- Checklist-Structural Concrete Post PouringDocument1 pageChecklist-Structural Concrete Post Pouringajit karandikarPas encore d'évaluation

- ការគណនាគ្រឹះជម្រៅ PDFDocument34 pagesការគណនាគ្រឹះជម្រៅ PDFMen Keo RathaPas encore d'évaluation

- S21-CnS Roads and DrainsDocument39 pagesS21-CnS Roads and DrainsLukePas encore d'évaluation

- QAP ReportDocument66 pagesQAP ReportPrabhnoor KaurPas encore d'évaluation

- NHAI Quality Assurance Manual PDFDocument121 pagesNHAI Quality Assurance Manual PDFTejas kalaskarPas encore d'évaluation

- Daily Welding Report PLD LogoDocument1 pageDaily Welding Report PLD Logonike_y2kPas encore d'évaluation

- M45 Grade As Per Is 10262Document4 pagesM45 Grade As Per Is 10262Ashok RajanavarPas encore d'évaluation

- CV Summary - Civil Engineer with 15+ years QA/QC experienceDocument5 pagesCV Summary - Civil Engineer with 15+ years QA/QC experienceFlavioMuhalePas encore d'évaluation

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedPas encore d'évaluation

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikPas encore d'évaluation

- Standard PriceDocument10 pagesStandard PriceNadeesha MihiraniPas encore d'évaluation

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilPas encore d'évaluation

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- Diaphgram Plate Design Rev-0Document1 pageDiaphgram Plate Design Rev-0hemantmech09Pas encore d'évaluation

- Ses 18mt LPG Hmi Mounting PDFDocument1 pageSes 18mt LPG Hmi Mounting PDFhemantmech09Pas encore d'évaluation

- LNG Quick Facts Data SheetDocument1 pageLNG Quick Facts Data Sheethemantmech09Pas encore d'évaluation

- Reaffirmed 1984Document286 pagesReaffirmed 1984hemantmech09Pas encore d'évaluation

- 01 NitDocument6 pages01 Nithemantmech09Pas encore d'évaluation

- Arrow LNG - Project Description PDFDocument58 pagesArrow LNG - Project Description PDFRoozbeh PPas encore d'évaluation

- Topic14 FoundationDesignDocument38 pagesTopic14 FoundationDesignloserboi101Pas encore d'évaluation

- Mexican Bed BugDocument10 pagesMexican Bed BugPatrick Ross Serquiña DulayPas encore d'évaluation

- PROPHECY: Book Club GuideDocument1 pagePROPHECY: Book Club GuideEpicReadsPas encore d'évaluation

- The First Slam Dunk Online UpdatesDocument7 pagesThe First Slam Dunk Online UpdatesIvan Hernandez BecerraPas encore d'évaluation

- Public Garden Automation ControlDocument3 pagesPublic Garden Automation ControlSebastin Ashok100% (2)

- Dance in the Philippines: A Cultural TraditionDocument13 pagesDance in the Philippines: A Cultural TraditionSTEPHEN C. PASTEDIOPas encore d'évaluation

- Joystick System OperationDocument3 pagesJoystick System OperationHusi NihaPas encore d'évaluation

- Wi-Fi Jamming Using Raspberry Pi: ISSN: 1314-3395 (On-Line Version) Url: Http://acadpubl - Eu/hub Special IssueDocument8 pagesWi-Fi Jamming Using Raspberry Pi: ISSN: 1314-3395 (On-Line Version) Url: Http://acadpubl - Eu/hub Special IssueSarangPas encore d'évaluation

- Types of Mice and Their ComponentsDocument18 pagesTypes of Mice and Their ComponentsMinecraft VillagerPas encore d'évaluation

- Test Paper - Class 6Document7 pagesTest Paper - Class 6Anina Mariana MihaiPas encore d'évaluation

- Who regrets practical jokesDocument2 pagesWho regrets practical jokescidaaalvesPas encore d'évaluation

- Military Diet 4 Day Off PlanDocument4 pagesMilitary Diet 4 Day Off PlanJace100% (1)

- Philippines Festivals GuideDocument44 pagesPhilippines Festivals GuideMichelle GoPas encore d'évaluation

- Training ProgramDocument2 pagesTraining ProgramjenniferPas encore d'évaluation

- The Story of Us Song AnalysisDocument1 pageThe Story of Us Song AnalysisIgnacio II GarzonPas encore d'évaluation

- Online Stocks User Guide IDocument22 pagesOnline Stocks User Guide ITan Teck HweePas encore d'évaluation

- AmouageDocument2 pagesAmouageVidhyesh GawasPas encore d'évaluation

- DND 5th Edition Premade - HexlockDocument4 pagesDND 5th Edition Premade - HexlockVlad DobrePas encore d'évaluation

- FiberHome's XGPON SolutionDocument5 pagesFiberHome's XGPON SolutionoomariniPas encore d'évaluation

- The Island of FeelingsDocument1 pageThe Island of FeelingsKimberley Sicat BautistaPas encore d'évaluation

- Commercialization of Sports MediaDocument2 pagesCommercialization of Sports MediaFaseeh AbidPas encore d'évaluation

- Imran Khan A Hope For NationDocument9 pagesImran Khan A Hope For NationzeePas encore d'évaluation

- Fa#4 Ged0109Document1 pageFa#4 Ged0109sayuwu uwuPas encore d'évaluation

- Mardi GrasDocument23 pagesMardi Grasjayjay1122Pas encore d'évaluation

- The Gold WatchDocument1 pageThe Gold Watchabhijit8sarkar-3Pas encore d'évaluation

- Menu 15 de Septiembre Del 2019Document19 pagesMenu 15 de Septiembre Del 2019gabriel_sulbaránPas encore d'évaluation

- My Tragic Love StoryDocument14 pagesMy Tragic Love Storynrshah123498% (41)