Académique Documents

Professionnel Documents

Culture Documents

Ford F15a Assembly Instructions

Transféré par

sharkmouth0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues8 pagesMirror Models F15A model kit instructions

Titre original

Ford f15a Assembly Instructions

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMirror Models F15A model kit instructions

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues8 pagesFord F15a Assembly Instructions

Transféré par

sharkmouthMirror Models F15A model kit instructions

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 8

Go through assembly guide before you start your work.

Some gates are larger, because we dont want

any ejector marks on parts, and also very thin true-to scale parts require larger gates to avoid filling

issues, you need to use a little razor blade and sharp scalpel to remove these parts carefully.

Images in rows one by one show usually one small assembly step

Heat up PE parts with lighter before use, brass will soften and become easy to bend and work with.

Gunze Mr. Cement or Tamiya Super Thin Glue recommended for plastic parts, let the glue work for a few

seconds, then push parts together, melted plastic will fill the gaps between parts. You can also melt

sprue frame and use it as an amazing filler for small works, or use this glue to wash out tiny seam lines

on little parts or make texture on some parts etc.

The Canadian Military Pattern truck was a class of military trucks made in large numbers in Canada during World War II

to British Army specifications for use in the armies of the British Commonwealth allies. Standard designs were drawn up just

before the beginning of the war. CMP trucks were also sent to the Soviet Union following the Nazi invasion of Russia, as part

of Canada's lend-lease program to the Allies. During the War CMP trucks saw service around the world in the North African

Campaign, the Allied invasion of Sicily, the Italian Campaign, the Russian Front, the Burma Campaign, the Battle of the

Philippines (1941-42), the liberation of Northwest Europe, and the Western Allied invasion of Germany. CMP trucks also saw

service in post-war conflicts in Indonesia, French Indochina, and the Portuguese colonies in Africa. Most CMP trucks were

manufactured by the Chevrolet division of General Motors of Canada Ltd and by the Ford Motor Company of Canada. Just over

400,000 CMP trucks were manufactured in Canada, accounting for roughly half of the 815,729 military vehicles made in Canada

during World War II. The Ford-built CMP trucks had a 239 cu in (3.9 L), 95 bhp (70.8 kW) V8 engine. Cab design changed twice,

first designed at Ford, second and third cab designs - called No. 11, 12 and 13. First two type were similar, the main difference

being a two-part radiator grille in No.12 cab, its upper part was opened with a bonnet, which was known as the "Alligator cab".

The production of CMP truck bodies in Canada was subcontracted out to smaller companies in Ontario and Manitoba, organized

into the wartime Steel Body Manufacturers Association by the Department of Munitions and Supply. The wide variety of truck

body designs included general service, water tanker, fuel tanker, vehicle recovery, dental clinic, mobile laundry, wireless house,

machinery, folding boat transport, and anti-tank gun portee. F15 Ford was often seen in desert service with top of the cab removed

Ford F15A assembly instructions

Prepare subassemblies:

Rear wheel assembly Front wheel assembly

AA

BB

CC

DD

S2 S1

S4

S2

(S5 for spare wheel)

S1

S3

E9

E8

E10

E11

E12

E21

E24

E22 E23

E3

E15

E14

E16

W35

W35

W37 (W36)

W38

W30

PE1

1

PE1

Make two, left and right ones

EE

FF

GG

engine

Z25

E17

E18

A16

F2

F1

E19

E20

F11

F18_2

F18

W33

W33

W33

F11

A11

A12

A9

A10

A2

A7

A8 (A7)

A15

A3

A4

A13 (A14)

Z3

Z2

A1

A5

A6

0,6mm

wire

strip of tape

used for belt

0,3mm wire lengths

use lengths of 0,3mm wire to connect hinges and create true

looking appearance of folding down body walls

0,3 wire

for handles

Body

GG

G1

G4

G5

G2

G3

G6

G7

G8

W3

W1

W2

HH

A17

2

Cab 11

E33

E31

E30

E32

H1

H9

H11

H10

H20

H23

E27

PE5

PE6

push all rivets

from back

PE7

PE8

PE9

H4

H3

H22

H21

C1

PE10

PE11

H5

H6

H7

(PE12)

E13

Z22

Z23

Z24

H18

H19

H8

C2

F17

F17

F9

E7

E6

H17

H16

3

PE19

PE20

F17

PE36+PE37

5

6

,

3

m

m

For F15A (4x4) truck remove plastic marked grey

on parts B1 and B2 before further assembly

B1

B2

D14

D12

D13

C8

C6

C7

C5

C12

C10

C11

C9

D2

D1

D2

D1

D3

D3

D7

D7

REAR AXLE

FRONT AXLE

D4

D4

D11

D11

MIND DIRECTIONS

OF PARTS!!!

0,5mm wire 0,5mm wire

PE13

PE13

D14

D10

D10

B3

B4

B11

B6

B9 B9

for this truck

variant assemble

B6 in slots located

further to the

front

B7

W39

W39

C2

C1

C3

C4

D6

D6

PE14

PE15

PE14 and PE15 cut the end as long

as needed and bend slightly if necessary

AA

D15

D15

B10

4

Z14

Z15

Z16

(Z17)

Z13

PE2

PE3

PE4

Z19

Z18

0,6mm wire

Z27

BB

E5

E4

HH

Dry-fit HH into crossbeam opening first, glue engine in its place

and then glue HH with engine

Assemble front axle

PE15 (PE14)

F18

F10

F12

F10

FF

F12

F10

Z8+Z9

cut length of Z8 rod if needed

5

PE16 PE16

PE16 PE16

DD right

DD left

CC

EE

Z6

Z5

Z7

Z7

cut Z5, Z6, Z7 to length needed

remove

H26

C3

PE6

F3

F4

F5

F7

fill this hole on B1, B2

!

!

close up look on assembly

repeat on the right side

F15

6

PE17

PE18

W34

W34 to correspond with

frame sides inner

rivets !

E1

E2

Assemble wheels

Interior decals

Painting - olive drab, some trucks were painted in usual 2 or 3 color camo, depending on army and

service used, sand yellow common in desert service

Nice camo examples available at: http://www.german.o5m6.de/

Markings - see dashboard above and examples on next page

Part list: 1x various parts Z

1x body parts G

1x Cab11 parts H

1x clear parts parts C

1x engine parts A

1x frame parts B

1x under chassis parts C

2x under chassis parts D

1x various parts E

2x under chassis parts F

1x wheels parts S

1x under chassis parts W

4x tyre, PE detail set, selection of wire

15

7

Canadian service

German service

British service

8

Vous aimerez peut-être aussi

- Hornet HeadsDocument6 pagesHornet HeadssharkmouthPas encore d'évaluation

- Fe121 1Document1 pageFe121 1sharkmouthPas encore d'évaluation

- Transparency and Shine Enhancer TutorialDocument3 pagesTransparency and Shine Enhancer TutorialMauri MrmPas encore d'évaluation

- P-47D-25 Thunderbolt: ReferencesDocument2 pagesP-47D-25 Thunderbolt: ReferencessharkmouthPas encore d'évaluation

- Kat K01Document1 pageKat K01sharkmouthPas encore d'évaluation

- Usaf Tech Order TO 1-1-4Document176 pagesUsaf Tech Order TO 1-1-4yesitsdave100% (1)

- Fe197 P-47D PlacardsDocument3 pagesFe197 P-47D PlacardssharkmouthPas encore d'évaluation

- P-47M Thunderbolt: 1/48 Scale Detail Set For Tamiya Kit - Sada Detailù Pro Model Tamiya 1/48Document2 pagesP-47M Thunderbolt: 1/48 Scale Detail Set For Tamiya Kit - Sada Detailù Pro Model Tamiya 1/48sharkmouthPas encore d'évaluation

- Kat GA03Document1 pageKat GA03sharkmouthPas encore d'évaluation

- Kat GA04Document1 pageKat GA04sharkmouthPas encore d'évaluation

- Kat GA01Document1 pageKat GA01sharkmouthPas encore d'évaluation

- Eduard: P-47D-25 ThunderboltDocument1 pageEduard: P-47D-25 ThunderboltsharkmouthPas encore d'évaluation

- Eduard: Tamiya 1/48 KITDocument1 pageEduard: Tamiya 1/48 KITsharkmouthPas encore d'évaluation

- Kat GL01Document1 pageKat GL01sharkmouthPas encore d'évaluation

- 1/35 Scale Gun Barrels: EA04 PANTHER Ausf. G - LateDocument1 page1/35 Scale Gun Barrels: EA04 PANTHER Ausf. G - LatesharkmouthPas encore d'évaluation

- Ced ListDocument4 pagesCed ListsharkmouthPas encore d'évaluation

- EM CMD Consumer List MayDocument17 pagesEM CMD Consumer List MaysharkmouthPas encore d'évaluation

- Engines & Things CATALOG 2011Document10 pagesEngines & Things CATALOG 2011sharkmouthPas encore d'évaluation

- EM CMD Consumer List JanuaryDocument18 pagesEM CMD Consumer List JanuarysharkmouthPas encore d'évaluation

- Kat EA05Document1 pageKat EA05sharkmouthPas encore d'évaluation

- No Scale: The World's Most Popular Precut Removable Painting Masks For Exciting Modeling Subjects!Document4 pagesNo Scale: The World's Most Popular Precut Removable Painting Masks For Exciting Modeling Subjects!sharkmouthPas encore d'évaluation

- Catalogue 2006Document34 pagesCatalogue 2006sharkmouthPas encore d'évaluation

- 1/35 Accessories: 3 5 A 9 9 35 001X Fenders For 7TP, Vickers, T-26 3 5 A 9 8Document1 page1/35 Accessories: 3 5 A 9 9 35 001X Fenders For 7TP, Vickers, T-26 3 5 A 9 8sharkmouthPas encore d'évaluation

- Blitzscales 19 PDFDocument74 pagesBlitzscales 19 PDFClifford Holm100% (3)

- P-47M Thunderbolt: 1/48 Scale Detail Set For Tamiya Kit - Sada Detailù Pro Model 1/48 TamiyaDocument6 pagesP-47M Thunderbolt: 1/48 Scale Detail Set For Tamiya Kit - Sada Detailù Pro Model 1/48 TamiyasharkmouthPas encore d'évaluation

- Complete Resin Product List: (By Subject, As of August 2002)Document4 pagesComplete Resin Product List: (By Subject, As of August 2002)sharkmouthPas encore d'évaluation

- A5 Naval Const USDocument7 pagesA5 Naval Const USsharkmouthPas encore d'évaluation

- Blitzscales 18Document72 pagesBlitzscales 18sharkmouth100% (2)

- A Simple Guide To Translating ArmoramaDocument5 pagesA Simple Guide To Translating ArmoramasharkmouthPas encore d'évaluation

- P-47D-25 Thunderbolt "Bubbletop": 1/48 Scale Detail Set For Tamiya - Sada Detailù Pro Model 1/ Tamiya 48Document6 pagesP-47D-25 Thunderbolt "Bubbletop": 1/48 Scale Detail Set For Tamiya - Sada Detailù Pro Model 1/ Tamiya 48sharkmouthPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chem AssignmentsDocument3 pagesChem AssignmentsDarshan H. GodhiaPas encore d'évaluation

- Purpose: The Product Which I Have Chosen Is "Toothbrush"Document3 pagesPurpose: The Product Which I Have Chosen Is "Toothbrush"Zainab KashaniPas encore d'évaluation

- Zetor Forterra HSX 3B 4 2014 GBDocument250 pagesZetor Forterra HSX 3B 4 2014 GBSalisbur100% (1)

- CPCDocument46 pagesCPCVignesh KPas encore d'évaluation

- (Oil Refinery in Vadodara) : Internship Project ReportDocument48 pages(Oil Refinery in Vadodara) : Internship Project ReportKARMA 2OpPas encore d'évaluation

- Cummins KTA50-G3Document16 pagesCummins KTA50-G3Teodoro Cornelius AltuvePas encore d'évaluation

- Investigatory ProjectDocument9 pagesInvestigatory ProjectMia AbayonPas encore d'évaluation

- Climax-Catalog LUBRICANTES Y SELLANTES PDFDocument30 pagesClimax-Catalog LUBRICANTES Y SELLANTES PDFNini Jhoana Ardila CamachoPas encore d'évaluation

- 002 Prime-G+ Commercial PerformanceDocument18 pages002 Prime-G+ Commercial Performancesameerjp50% (2)

- Engine C18Document3 pagesEngine C18Putra JawaPas encore d'évaluation

- Fluidized-Bed Catalytic Cracking UnitDocument2 pagesFluidized-Bed Catalytic Cracking UnitSantiago NuñezPas encore d'évaluation

- Terex Elrest SPSDocument20 pagesTerex Elrest SPSLuis jopi50% (2)

- 0d) Introduzione (Ok) - enDocument17 pages0d) Introduzione (Ok) - enLacatusu MirceaPas encore d'évaluation

- Contents, Instructions, Terminology: 00.1 Contents of The ManualDocument236 pagesContents, Instructions, Terminology: 00.1 Contents of The ManualDimitry SilinshPas encore d'évaluation

- BFG Safety How To PreventDocument25 pagesBFG Safety How To PreventPower PowerPas encore d'évaluation

- VG Service Data SheetDocument12 pagesVG Service Data Sheetvnl64t100% (4)

- Backhoe Loader: Cat® 3054C Naturally Aspirated Diesel Engine Standard Optional Backhoe Digging DepthDocument20 pagesBackhoe Loader: Cat® 3054C Naturally Aspirated Diesel Engine Standard Optional Backhoe Digging DepthOutmane Lakhlili100% (1)

- Chuntian QiuDocument173 pagesChuntian QiuKerryPas encore d'évaluation

- Manual de Motor Mack Mp8Document20 pagesManual de Motor Mack Mp8Alex ChampiPas encore d'évaluation

- Trator D6N PDFDocument841 pagesTrator D6N PDFrailson carvalho100% (1)

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuPas encore d'évaluation

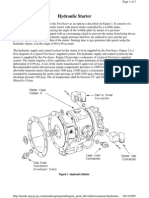

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezPas encore d'évaluation

- V6 EngineDocument11 pagesV6 EngineHarryMalik50% (2)

- CF34-3 Engine Notes Chapter 72 Course NotesDocument30 pagesCF34-3 Engine Notes Chapter 72 Course NotesinternetsurfingPas encore d'évaluation

- 1983 XVZ12TD K Parts CatalogDocument118 pages1983 XVZ12TD K Parts CatalogKevin M. CampbellPas encore d'évaluation

- 02B Regla - Demag EB 60Document120 pages02B Regla - Demag EB 60Rodrigo DíazPas encore d'évaluation

- Elsy PDFDocument3 pagesElsy PDFmohanPas encore d'évaluation

- Lyle Carnegie Biomass CanadaDocument32 pagesLyle Carnegie Biomass CanadaMuhammad NaqviPas encore d'évaluation

- ASVAB Paragraph Comprehension Practice Test 3Document9 pagesASVAB Paragraph Comprehension Practice Test 3ASVABTestBank100% (1)

- Ethanol As An Aviation FuelDocument4 pagesEthanol As An Aviation Fueljeff_wheeler_23Pas encore d'évaluation