Académique Documents

Professionnel Documents

Culture Documents

PP Black

Transféré par

Anonymous 8pCXXs0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues5 pagesPP Black

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPP Black

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues5 pagesPP Black

Transféré par

Anonymous 8pCXXsPP Black

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

PP Black

Polypropylene (PP) - This polyolefn is readily formed by polymerizing propylene with

suitable catalysts, generally aluminum alkyl and titanium tetrachloride.

Polypropylene properties ary according to molecular weight, method of production,

and the copolymers inoled. !enerally polypropylene has demonstrated certain

adantages in improed strength, sti"ness and higher temperature capability oer

polyethylene. Polypropylene has been ery successfully applied to the forming of

fbers due to its good specifc strength which is why it is the single largest use of

polypropylene. Polypropylene also happens to be one of the lightest plastics

aailable with a density of #.$#% g&cm'.

Polypropylene (PP) was discoered in ($%) and grew a strong popularity ery

*uickly. +ecause of e,tensie research, fe main ariations of Polypropylene hae

emerged as- homopolymers, impact (block) copolymers, random copolymers,

rubber modifed blends, and specialty copolymers.

Features

.omopolymers , /ood 0ontact 1cceptable , !ood Process ability , 0opolymer , !ood

2mpact 3esistance , .igh /low , !ood 4ti"ness , .igh 2mpact 3esistance , .igh

4ti"ness, 0hemically 0oupled ,

1utomotie 1pplications, .ousehold !oods, 0ontainers, 4oft plastic 1ppliances, /ilm

0arpet sheet, Packaging, 5lectrical&5lectronic 1pplications, 1utomotie 2nterior

Parts, 2ndustrial 1pplications, and !eneral Purpose

Disadvantages

- 6egraded by 78

- /lammable, but retarded grades aailable

- 1ttacked by chlorinated solents and aromatics

- 6i9cult to bond

- 4eeral metals accelerate o,idatie degrading

- :ow temperature impact strength is poor

Applications

Product Description

This data represents typical values that have been calculated from all products classifed as:

Generic PP Alloy

This information is provided for comparative purposes only.

General

Material Status Commercial: Active

Availability

Physical Nominal Value Unit Test Method

Specifc Gravity 0,892 to 1,06 ASTM D792

Mechanical Nominal Value Unit Test Method

Flexural Modulus (73F) 25500 to 327000 psi ASTM D790

Coefcient of Friction 0,25 to 0,40 ASTM D1894

Films Nominal Value Unit Test Method

Film Thickness - Tested 60 to 200 mil

Secant Modulus ASTM D882

MD 362000 to 435000 psi

TD 304000 to 522000 psi

Tensile Strength ASTM D882

MD : Yield 24700 to 34700 psi

TD : Yield 27400 to 30500 psi

Tensile Elongation ASTM D882

MD : Break 89 to 120 %

TD : Break 80 to 130 %

Seal Strength 0,94 lbf/in ASTM F88

Seal Initiation Temperature 223 to 269 F

Oxygen Permeability (73F) 0,39 to 100 cmmil/100in/atm/24 hr ASTM D3985

Water Vapor Transmission Rate 0,050 to 0,65 g/100 in/24 hr ASTM F1249

Blocking Load 6,0 g ASTM D3354

Optical Nominal Value Unit Test Method

Gloss 95 to 140 ASTM D2457

Haze 1,3 to 2,6 % ASTM D1003

Product Description

This data represents typical values that have been calculated from all products classifed as:

Generic PP Copolymer - Mineral

This information is provided for comparative purposes only.

General

Material Status Commercial: Active

Filler / Reinforcement Mineral

Physical Nominal Value Unit Test Method

Specifc Gravity

-- 0.962 to 2.11 ASTM D792

73F 0.975 to 1.17 g/cm ISO 1183

Melt Mass-Flow Rate (MFR)

230C/2.16 kg 4.7 to 35 g/10 min ASTM D1238

230C/2.16 kg 0.70 to 28 g/10 min ISO 1133

Melt Volume-Flow Rate (MVR) (230C/2.16

kg)

0.284 to 1.12 in/10min ISO 1133

Molding Shrinkage

Flow : 73F 0.0010 to 0.012 in/in ASTM D955

73F 0.81 to 1.2 % ISO 294-4

Water Absorption (73F, 24 hr) 0.020 to 0.050 % ISO 62

Mechanical Nominal Value Unit Test Method

Notes

1

Typical properties: these are not to be construed as specifcations.

Tensile Modulus

73F 145000 to 447000 psi ASTM D638

73F 179000 to 379000 psi ISO 527-2

Tensile Strength

Yield, 73F 1450 to 4450 psi ASTM D638

Yield, 73F 2470 to 3990 psi ISO 527-2

Break, 73F 2470 to 6530 psi ASTM D638

Break, 73F 2100 to 3630 psi ISO 527-2

73F 2450 to 3530 psi ASTM D638

73F 2880 to 4350 psi ISO 527-2

Tensile Elongation

Yield, 73F 3.0 to 5.0 % ASTM D638

Yield, 73F 2.8 to 8.1 % ISO 527-2

Break, 73F 2.3 to 200 % ASTM D638

Break, 73F 2.5 to 100 % ISO 527-2

Flexural Modulus

73F 116000 to 509000 psi ASTM D790

73F 183000 to 365000 psi ISO 178

Flexural Strength

73F 2900 to 7600 psi ASTM D790

73F 2890 to 7320 psi ISO 178

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength (73F) 1.1 to 12 ftlb/in ISO 179

Charpy Unnotched Impact Strength (73F) 18 to 46 ftlb/in ISO 179

Notched Izod Impact

73F 0.56 to 4.7 ftlb/in ASTM D256

73F 1.8 to 22 ftlb/in ISO 180

Unnotched Izod Impact Strength (73F) 8.6 to 38 ftlb/in ISO 180

Hardness Nominal Value Unit Test Method

Rockwell Hardness

73F 40 to 90 ASTM D785

73F 70 to 76 ISO 2039-2

Shore Hardness (73F) 59 to 71 ISO 868

Ball Indentation Hardness 7250 to 10400 psi ISO 2039-1

Thermal Nominal Value Unit Test Method

Defection Temperature Under Load

66 psi, Unannealed 219 to 308 F ASTM D648

66 psi, Unannealed 162 to 259 F ISO 75-2/B

264 psi, Unannealed 131 to 159 F ASTM D648

264 psi, Unannealed 119 to 150 F ISO 75-2/A

Vicat Softening Temperature

-- 122 to 287 F ASTM D1525

-- 118 to 306 F ISO 306

Melting Temperature (DSC) 329 F ISO 3146

CLTE - Flow

-- 0.000028 to

0.000040

in/in/F ASTM D696

-- 0.000026 to

0.000044

in/in/F ISO 11359-2

Electrical Nominal Value Unit Test Method

Surface Resistivity 7.5E+13 to 1.0E+15 ohm IEC 60093

Volume Resistivity (73F) 1.0E+13 to 1.0E+15 ohmcm IEC 60093

Comparative Tracking Index 595 to 600 V IEC 60112

Flammability Nominal Value Unit Test Method

Glow Wire Flammability Index 1560 to 1760 F IEC 60695-2-

12

Glow Wire Ignition Temperature 1020 to 1390 F IEC 60695-2-

13

Injection Nominal Value Unit

Drying Temperature 176 to 190 F

Drying Time 3.0 hr

Rear Temperature 401 to 410 F

Middle Temperature 408 to 438 F

Front Temperature 408 to 457 F

Processing (Melt) Temp 409 to 473 F

Mold Temperature 104 to 141 F

Injection Pressure 12700 to 14500 psi

Holding Pressure 7610 to 7670 psi

Back Pressure 43.5 to 76.1 psi

Screw Speed 50 to 75 rpm

Clamp Tonnage 3.3 tons/in

Injection Notes

This data represents typical values that have been calculated from all products classifed as:

Generic PP Copolymer - Mineral

This information is provided for comparative purposes only.

Notes

1

Typical properties: these are not to be construed as specifcations.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

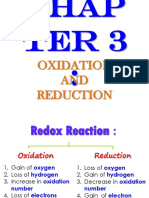

- Oxidation and Reduction SPM Form 5Document63 pagesOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- Snap Fit DesignDocument4 pagesSnap Fit DesignAlex DobrescuPas encore d'évaluation

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroPas encore d'évaluation

- Advanced Control Theory 2nd Nagoor KaniDocument3 pagesAdvanced Control Theory 2nd Nagoor Kaniunnvishnu20% (25)

- Boq Iimu Modular Kitchen and WardrobeDocument4 pagesBoq Iimu Modular Kitchen and WardrobePrajeet HegadePas encore d'évaluation

- Lab Manual Foundation EngineeringDocument39 pagesLab Manual Foundation Engineeringartiraha100% (1)

- Chapter 20 PetrucciDocument67 pagesChapter 20 PetrucciLoeyPas encore d'évaluation

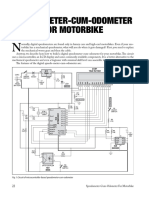

- Speedometer-Cum-odometer For MotorbikeDocument6 pagesSpeedometer-Cum-odometer For MotorbikeAnonymous 8pCXXs100% (2)

- GATE Instrumentation Engineering - SampleDocument31 pagesGATE Instrumentation Engineering - SampleAnonymous 8pCXXsPas encore d'évaluation

- B 549 - 13 PDFDocument8 pagesB 549 - 13 PDFTuanbk Nguyen0% (1)

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocument10 pagesUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamPas encore d'évaluation

- Special Issue (ICIIECS 16) Year 2016Document5 pagesSpecial Issue (ICIIECS 16) Year 2016Anonymous 8pCXXsPas encore d'évaluation

- Chapter 6.2Document21 pagesChapter 6.2Anonymous 8pCXXsPas encore d'évaluation

- 10 1016@j Jprocont 2016 11 001Document13 pages10 1016@j Jprocont 2016 11 001Anonymous 8pCXXsPas encore d'évaluation

- Laplace TableDocument2 pagesLaplace Tablecabeza2750% (2)

- Top 30 Chemical Engineering TextbooksDocument28 pagesTop 30 Chemical Engineering TextbooksAnonymous 8pCXXsPas encore d'évaluation

- Effect of Noise Variance on Percentage Error for BPSK and QPSK ModulationDocument2 pagesEffect of Noise Variance on Percentage Error for BPSK and QPSK ModulationAnonymous 8pCXXsPas encore d'évaluation

- Lenovo-T440 Thinkpad DetailsDocument2 pagesLenovo-T440 Thinkpad DetailsAnonymous 8pCXXsPas encore d'évaluation

- Engineering GenralDocument1 pageEngineering GenralAnonymous 8pCXXsPas encore d'évaluation

- Control Tutorials for MATLAB and Simulink - Motor Position: Digital Controller DesignDocument1 pageControl Tutorials for MATLAB and Simulink - Motor Position: Digital Controller DesignAnonymous 8pCXXsPas encore d'évaluation

- Process Control Laboratory-Student's ManualDocument105 pagesProcess Control Laboratory-Student's ManualAnonymous 8pCXXsPas encore d'évaluation

- PDF 73Document3 pagesPDF 73Anonymous 8pCXXs0% (1)

- Eee Ug 2010 OnwardsDocument14 pagesEee Ug 2010 OnwardsAnonymous 8pCXXsPas encore d'évaluation

- FFF Gavitations Type 1Document3 pagesFFF Gavitations Type 1Anonymous 8pCXXsPas encore d'évaluation

- Part IDocument9 pagesPart IAnonymous 8pCXXsPas encore d'évaluation

- Mechanical 2011Document11 pagesMechanical 2011Lalit Choudhary0% (1)

- Study Package: Subject: PHYSICS TopicDocument7 pagesStudy Package: Subject: PHYSICS Topicvishal110085Pas encore d'évaluation

- BOOKS To StudyDocument2 pagesBOOKS To Studymanpreetsingh3458417Pas encore d'évaluation

- Part IDocument9 pagesPart IAnonymous 8pCXXsPas encore d'évaluation

- Internet and Web Technology Exercises With AnswersDocument87 pagesInternet and Web Technology Exercises With AnswersAnonymous 8pCXXs100% (1)

- Analog Electronics Apago PDF AppraiserDocument4 pagesAnalog Electronics Apago PDF AppraiserAnonymous 8pCXXsPas encore d'évaluation

- Physics Vol III Content-IIT-JEE Important Topics For ExamDocument1 pagePhysics Vol III Content-IIT-JEE Important Topics For ExamAnonymous 8pCXXsPas encore d'évaluation

- Reference Books IIT JEE 2014Document1 pageReference Books IIT JEE 2014Anonymous 8pCXXsPas encore d'évaluation

- Physics Vol VI Content-Advanced IIT-JEEDocument1 pagePhysics Vol VI Content-Advanced IIT-JEEAnonymous 8pCXXsPas encore d'évaluation

- Physics Vol III Content-IIT-JEE Important Topics For ExamDocument1 pagePhysics Vol III Content-IIT-JEE Important Topics For ExamAnonymous 8pCXXsPas encore d'évaluation

- Physics Vol VI Content-Advanced IIT-JEEDocument1 pagePhysics Vol VI Content-Advanced IIT-JEEAnonymous 8pCXXsPas encore d'évaluation

- Gandhar - Reliance Industries Limited.Document2 pagesGandhar - Reliance Industries Limited.ash61117Pas encore d'évaluation

- Structural Design Data and SpecificationsDocument6 pagesStructural Design Data and SpecificationsRoland CepedaPas encore d'évaluation

- Aspen Aerogel Pyrogel XT-DSDocument2 pagesAspen Aerogel Pyrogel XT-DSkflimPas encore d'évaluation

- Pow Template Project 2020Document7 pagesPow Template Project 2020EdgarPas encore d'évaluation

- Me 322Document56 pagesMe 322faisalPas encore d'évaluation

- Daily Report - 1Document6 pagesDaily Report - 1Akli Ale ManPas encore d'évaluation

- CV of Dr. Janakarajan RamkumarDocument20 pagesCV of Dr. Janakarajan RamkumarAnonymous fgrTyKxxsLPas encore d'évaluation

- Catalogo de Liquidos Penetrantes PDFDocument77 pagesCatalogo de Liquidos Penetrantes PDFAlan Fredy CcaritaPas encore d'évaluation

- Flexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MembersDocument10 pagesFlexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MemberspicottPas encore d'évaluation

- A 470 - 03 Piezas ForjadasDocument8 pagesA 470 - 03 Piezas ForjadasWILLIAM ROMEROPas encore d'évaluation

- Plastic Surgeon Rob Mouser ProfileDocument3 pagesPlastic Surgeon Rob Mouser ProfileKatie BrownPas encore d'évaluation

- Elevator Buckets CatalogueDocument30 pagesElevator Buckets CatalogueYeffreyn EscalonaPas encore d'évaluation

- FinancialBid2 9487080392Document86 pagesFinancialBid2 9487080392renjith p sPas encore d'évaluation

- Robust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelDocument9 pagesRobust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelFarzad SadrPas encore d'évaluation

- Simulation of torsion in a beamDocument10 pagesSimulation of torsion in a beamToBi MorrisonPas encore d'évaluation

- Low-Bias Transport in Graphene:an IntroductionDocument57 pagesLow-Bias Transport in Graphene:an IntroductionLIAKMANPas encore d'évaluation

- ABB NFLP IE3-Catalogue PDFDocument12 pagesABB NFLP IE3-Catalogue PDFSabir NasimPas encore d'évaluation

- JZ LSR Catalog AllDocument27 pagesJZ LSR Catalog AllJZ HuangPas encore d'évaluation

- Hydrogen Embrittlement Relief Process StandardDocument10 pagesHydrogen Embrittlement Relief Process StandardFelicePas encore d'évaluation

- Jurnal Ekologi Dan LingkunganDocument10 pagesJurnal Ekologi Dan LingkunganArmis NadeakPas encore d'évaluation

- Soap and Detergent: Properties, Preparation, and FunctionsDocument6 pagesSoap and Detergent: Properties, Preparation, and FunctionsJunren KhooPas encore d'évaluation

- Handrail & Baluster DRAFT-1Document2 pagesHandrail & Baluster DRAFT-1jijinjohnPas encore d'évaluation