Académique Documents

Professionnel Documents

Culture Documents

AGV 50 Gas Turbine Fuel Valve

Transféré par

hzq1eDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AGV 50 Gas Turbine Fuel Valve

Transféré par

hzq1eDroits d'auteur :

Formats disponibles

F O R H E A V Y I N D U S T R I A L G A S T U R B I N E S

APPLICATION

The AGV50 Valve is used to meter gas fuel to gas turbine engines in the

horsepower range of 5000HP to 60,000HP, with only minor differences within

the valves to accommodate the range in flow. The valve has been designed to

provide an optimum interface between a PLC control system and a gas turbine

engine. The valve is linear, that is, the metered fuel flow is proportional to the

4-20 ma fuel demand signal from the PLC.

The valve is a two-stage servo valve with two control loops. The fuel flow is

measured in the valve and compared to the fuel requested by the 4-20 ma signal

from the customers controller. The error signal generated is used to correct the

fuel flow. The valve has exceptionally fast response, and can provide outstanding

transient performance when used in a generator application. It will also provide

superior engine performance in any mechanical drive application.

The high accuracy of the valve in the start fuel range assures the engine will have

excellent light-off and consistent starting characteristics.

Gas Fuel Metering

Valve AGV50

Metering Gas Fuel to Gas Turbines ISO 9001 Certified

RELIABLE STARTING

ROBUST & DURABLE

DIRT TOLERANT

IMPROVED ENGINE

PERFORMANCE

BUILT-IN FLOW METER

ALL ELECTRIC

LOW POWER

24 VDC, 1 AMP

IDEAL FOR USE WITH

PLC SYSTEMS

COMPUTER-BASED

Model AGV50

D E S I G N F E A T U R E S

EXCELLENT START RELIABILITY

Eliminates fuel system-related starting problems,

even under the most adverse conditions because

the valve precisely controls the fuel flow with flow

meter accuracy.

SPEED STABILITY

There are no through-the-wall seals or other

internal points of friction that cause speed

instability. Engine operation is smooth and steady.

HIGH FORCE

The spring that closes the poppet valve has a spring

rate of 350 pounds per inch and is pre-loaded

closed with 60 pounds of force. This produces a

pressure of over 1000 PSI on the resilient valve seat

to assure a positive shut-off.

LOW POWER

The valve is powered from a 24VDC battery

source. The current required is less than 1 amp.

HIGH DIRT TOLERANCE

The flow-through design minimizes the effects of

particulate contamination. Dirt normally found in

pipeline applications passes through and does not collect

in the valve. An internal 11-micron filter is included to

prevent particles from entering the pilot stage. In extreme

cases where the gas is wet and/or dirty and the internal

filter would need to be changed frequently, provisions

have been made for the use of a larger external filter.

FAIL-SAFE

The main poppet valve is spring-loaded closed.

It closes on loss of power, loss of gas pressure, or

other internal failure.

BUILT-IN FLOW METER

The fuel valve includes a unique annular venturi

flow meter for measuring fuel flow. The fuel flow

measurement is available to the user for display and

logging purposes. 2% of reading or 0.5% of full

scale, whichever is greatest.

COMPUTER CONTROL

The control of fuel flow is performed by an

electronic computer assembly. The computer

receives the 4-20 ma fuel demand signal and

compares it to the fuel flow signal from the built-

in flow meter. It then adjusts the throttling orifice

to change the fuel flow as necessary to make the

measured fuel flow equal to the fuel demand.

SERIAL PORT

An RS-485 serial port is provided for interfacing

the valve with other computer systems. The data

available includes:

Fuel supply pressure

Fuel temperature

Flow meter orifice differential pressure

Engine fuel manifold pressure

Measured fuel flow

Valve control pressure (for diagnostic use)

CONTROL CONCEPT

The inner control loop includes a pressure

feedback signal to improve the response of the

pilot stage and the metered fuel flow.

The valve assembly contains an in-line actuator

assembly that strokes an in-line poppet valve. The

valve provides the throttling function and controls

the main gas stream. It is located just inside the

inlet flange.

The gas exits from the poppet valve radially, and

flows outward through the annulus around the

internal actuator. The flow path is streamlined to

eliminate turbulence and provide a smooth flow

into the annular-shaped venturi near the discharge

end of the valve.

The differential pressure between the flow area

upstream of the venturi and the throat of the

venturi is used in the flow calculation.

Model AGV50 Cutaway

G A S V A L V E C O N S T R U C T I O N

The throttling valve is pressure-balanced and

spring-loaded closed with a high pre-load. Control

gas pressure applied to a diaphragm provides the

force to open the valve. The stroke of the poppet

valve is proportional to the control pressure after

overcoming the pre-load offset.

FUEL GAS SUPPLY PRESSURE

Pressure variation in the fuel supply does not

affect the gas flow through the valve, providing

the pressure does not drop below the minimum

required for that fuel flow.

S U G G E S T E D I N S T A L L A T I O N

PREFERRED INSTALLATION

In the diagram above, the engine is shut down

with the two shut-off valves closed and the vent

valve open (when a vent line is available). During

the start sequence, the upstream valve (A) is

opened first. Start fuel flow is established through

the vent, then the downstream valve (B) opens and

the vent valve (C) closes.

APPLICATION

The valves can be customized for specific engine

applications and purchased by OEM suppliers,

or they may be used for retrofitting existing

equipment.

FLANGES

The valves are supplied with 2" SAE 4-bolt flanges.

INTELLIGENT VALVE

An embedded computer and internal sensors make

it possible for the valve to control the acceleration

of the engine as well as the governing function.

CCC also manufactures electronic control systems,

valves and other components for both gas and

liquid fuels. Please contact us for your special

requirements.

A D V A N C E D F E A T U R E S

P R O D U C T C E R T I F I C A T I O N S

8845 Rehco Rd., San Diego, CA 92121 USA

Tel: 858-453-9880 Fax: 858-453-5078

www.continentalcontrols.com

rfisher@continentalcontrols.com

CSA: Class I, Division 1 & 2, Group D

NOTIFIED BODY: CSA International

CERTIFICATE NUMBER: 1166409 (LR 109715)

ATEX: Directive 94/9/EC (ATEX)

NOTIFIED BODY: KEMA Quality BV

CERTIFICATE NUMBERS: KEMA 03ATEX2551

KEMA 03ATEXQ3142

PED: Pressure Equipment Directive 97/23/EC (PED)

NOTIFIED BODY: TV Industrie Service GmbH

CERTIFICATE NUMBER: USA 04/06/69/001

Vous aimerez peut-être aussi

- Overfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsDocument4 pagesOverfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsAntonio FullerPas encore d'évaluation

- Axiomatic Electronic Assitant GuideDocument9 pagesAxiomatic Electronic Assitant GuidelunikmirPas encore d'évaluation

- 4TTS Installer's GuideDocument28 pages4TTS Installer's GuideAlejandro OrdoñezPas encore d'évaluation

- Williams W Series Pump IomDocument25 pagesWilliams W Series Pump Iomjuan ramirez garcia100% (2)

- ER-105-3 Digital No-Flow Timer (DNFT)Document8 pagesER-105-3 Digital No-Flow Timer (DNFT)EzequielPas encore d'évaluation

- DelugeDocument4 pagesDelugeBogdan Axinte100% (1)

- TDXMDocument20 pagesTDXMJavier PalaciosPas encore d'évaluation

- Combustion Smart Analyzer SMA-90 2Document226 pagesCombustion Smart Analyzer SMA-90 2Sura LayaPas encore d'évaluation

- Rabo Rotary Gas Meter: Instruction ManualDocument12 pagesRabo Rotary Gas Meter: Instruction Manualmfg_serviciosPas encore d'évaluation

- Atuador ADB225 PIB2000 - C - 225 SeriesDocument1 pageAtuador ADB225 PIB2000 - C - 225 SeriesnandomataPas encore d'évaluation

- Catalogue Brushless DC Drives GB 02 2007Document56 pagesCatalogue Brushless DC Drives GB 02 2007Bianca CerveiraPas encore d'évaluation

- Series 47K Gas Detector: Operation ManualDocument32 pagesSeries 47K Gas Detector: Operation ManualGunawan MSPas encore d'évaluation

- 'R QRW Zhog RQ Ru Durxqg HQJLQH Xqohvv WKH, JQL WLRQ 0rgxoh KDV Ehhq Xqsoxjjhg) Dloxuh WR GR VR PD/ GDPDJH WKH, JQLWLRQ 0rgxohDocument11 pages'R QRW Zhog RQ Ru Durxqg HQJLQH Xqohvv WKH, JQL WLRQ 0rgxoh KDV Ehhq Xqsoxjjhg) Dloxuh WR GR VR PD/ GDPDJH WKH, JQLWLRQ 0rgxohLuis PumaPas encore d'évaluation

- 1s6bdien 6-6-2018 Bdi50 enDocument186 pages1s6bdien 6-6-2018 Bdi50 enCristi AsmarandeiPas encore d'évaluation

- DCR Web PDFDocument4 pagesDCR Web PDFMahmoud AyadPas encore d'évaluation

- P0134Document2 pagesP0134johnny_nfs_2Pas encore d'évaluation

- Emerson Lc320em8Document66 pagesEmerson Lc320em8Edilberto Avila100% (1)

- Manual PFCL - 01i PDFDocument32 pagesManual PFCL - 01i PDFAnonymous uw1GPbmen5100% (1)

- Electroducto Square DDocument44 pagesElectroducto Square DEulalio HortaPas encore d'évaluation

- Owners Manual - Maytag Atlantis III WasherDocument24 pagesOwners Manual - Maytag Atlantis III WasherBaltoPas encore d'évaluation

- JMS 312 GS-B.L: Technical SpecificationDocument4 pagesJMS 312 GS-B.L: Technical SpecificationMartin KratkyPas encore d'évaluation

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatPas encore d'évaluation

- Tutorials On MachinesDocument2 pagesTutorials On Machinesjenniferi_7Pas encore d'évaluation

- P3 NRJCAT17764EN v16 072019 PDFDocument122 pagesP3 NRJCAT17764EN v16 072019 PDFHoang Bao ThaiPas encore d'évaluation

- Atos E-BM-AC-05FDocument4 pagesAtos E-BM-AC-05FislamooovPas encore d'évaluation

- Manual Bombas Pozo e ImpulsionDocument112 pagesManual Bombas Pozo e ImpulsionFernando PuentesPas encore d'évaluation

- Enerpac PATG1102NDocument72 pagesEnerpac PATG1102NAnonymous G6ceYCzwtPas encore d'évaluation

- RH XDGVDocument120 pagesRH XDGVRAJ NAYAAKPas encore d'évaluation

- Cyl Tel CutsheetDocument2 pagesCyl Tel CutsheetaLeXiNPas encore d'évaluation

- Manual FW230 PDFDocument16 pagesManual FW230 PDFaze20100% (1)

- Ags 200Document2 pagesAgs 200dsimovicPas encore d'évaluation

- Manual Lavadora Extractora Milnor Pellerin 3Document8 pagesManual Lavadora Extractora Milnor Pellerin 3Diego B.E.Pas encore d'évaluation

- Bomba de LiquidoDocument25 pagesBomba de LiquidovicoPas encore d'évaluation

- Series 200Document4 pagesSeries 200Rommyo AlexPas encore d'évaluation

- Varec: Vapor Control Inc. 221 Series Emergency Pressure Relief Manway CoverDocument15 pagesVarec: Vapor Control Inc. 221 Series Emergency Pressure Relief Manway CoverjasmickPas encore d'évaluation

- Gas Booster 5 0.75 Series Models AG AGD AGT S PDFDocument16 pagesGas Booster 5 0.75 Series Models AG AGD AGT S PDFu2006262918100% (1)

- Genie Manual Genie em InglesDocument69 pagesGenie Manual Genie em Inglescesar892000Pas encore d'évaluation

- ICARE Group Presentation - Generic-CompressedDocument53 pagesICARE Group Presentation - Generic-CompressedAnonymous ygQUvDKPas encore d'évaluation

- Limpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Document173 pagesLimpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Piero SánchezPas encore d'évaluation

- Arrancadores General ElectricDocument1 pageArrancadores General ElectricFernando AguíñagaPas encore d'évaluation

- Cheetah Xi50 PDFDocument116 pagesCheetah Xi50 PDFCristian DominguezPas encore d'évaluation

- Panel de Control Compresor ArielDocument40 pagesPanel de Control Compresor ArielTatiana GomezPas encore d'évaluation

- Valvula Diluvio F470Document16 pagesValvula Diluvio F470eduardoPas encore d'évaluation

- ZIS - 49400415A0 - MI.30628 - Gas StopDocument128 pagesZIS - 49400415A0 - MI.30628 - Gas StopFederico Maggi100% (1)

- TachometerDocument2 pagesTachometerKreshia CuasayPas encore d'évaluation

- SRH 444 MillerDocument40 pagesSRH 444 MillerJJMMER100% (1)

- Er-105-1-1 - Proflo No-Flow SwitchDocument10 pagesEr-105-1-1 - Proflo No-Flow SwitchJeff LPas encore d'évaluation

- Daniel Gas Turbine Meter: 4", 6" 8" and 12" SIZES ANSI Class 125 Through 900Document40 pagesDaniel Gas Turbine Meter: 4", 6" 8" and 12" SIZES ANSI Class 125 Through 900Sofyan HadiPas encore d'évaluation

- Bombas 3344 Manual Mantenimiento y ReparaciónDocument14 pagesBombas 3344 Manual Mantenimiento y ReparaciónHECTORPas encore d'évaluation

- FUP1010 Inst PDFDocument286 pagesFUP1010 Inst PDFKristen CollierPas encore d'évaluation

- MAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFDocument56 pagesMAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFGabiBaciuPas encore d'évaluation

- Instructions 95-8581: Inspector Monitor Software For Use With Det-Tronics X-Series Flame DetectorsDocument19 pagesInstructions 95-8581: Inspector Monitor Software For Use With Det-Tronics X-Series Flame DetectorsRoberto HernandezPas encore d'évaluation

- Manual 250-Hp 300-Hp 350-Hp Cleaver-Brooks EquipmentDocument194 pagesManual 250-Hp 300-Hp 350-Hp Cleaver-Brooks EquipmentAlexis CruzPas encore d'évaluation

- Modulo de Accesso A Internet PDFDocument2 pagesModulo de Accesso A Internet PDFWilliam Segundo Matheus TorresPas encore d'évaluation

- AR VAR - Air Eliminators - Sales Bulletin SF03001Document2 pagesAR VAR - Air Eliminators - Sales Bulletin SF03001Victor RojasPas encore d'évaluation

- AGV 10 - Gas Turbine Fuel ValveDocument4 pagesAGV 10 - Gas Turbine Fuel ValvewalidPas encore d'évaluation

- Hy11-3353 CVG UkDocument36 pagesHy11-3353 CVG UkManuel Carvallo100% (1)

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- Need of Variable Valve ActuationDocument5 pagesNeed of Variable Valve Actuationjayendrakashyap01Pas encore d'évaluation

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperPas encore d'évaluation

- HSE P COW 06 Leak Testing ProcedureDocument19 pagesHSE P COW 06 Leak Testing Procedurehzq1e100% (1)

- How To Setup and Run RSLogix Emulation (SLC500&Micrologix 1000)Document4 pagesHow To Setup and Run RSLogix Emulation (SLC500&Micrologix 1000)hzq1ePas encore d'évaluation

- 04Document1 page04hzq1ePas encore d'évaluation

- ATDRDocument3 pagesATDRKiran KarthikPas encore d'évaluation

- Mli Selection Guide 2013Document50 pagesMli Selection Guide 2013hzq1ePas encore d'évaluation

- Conversion FormulasDocument1 pageConversion Formulaslokesc100% (11)

- Proses PiggingDocument1 pageProses Pigginghzq1ePas encore d'évaluation

- Commisioning Test ProcedureDocument10 pagesCommisioning Test Procedurehzq1ePas encore d'évaluation

- Vibration Analysis A2130a2 Dual Channel Machinery Health AnalyserDocument12 pagesVibration Analysis A2130a2 Dual Channel Machinery Health Analyserhzq1ePas encore d'évaluation

- Diode Failure Scenarios - Brushless ExciterDocument2 pagesDiode Failure Scenarios - Brushless ExciterTiagoFaleirosPas encore d'évaluation

- Vibration DiagnosticsDocument54 pagesVibration Diagnosticshzq1e100% (1)

- COMAP InteliCommunicationGuide February 07 PDFDocument91 pagesCOMAP InteliCommunicationGuide February 07 PDFhzq1ePas encore d'évaluation

- Pocket AlignDocument6 pagesPocket Alignhzq1ePas encore d'évaluation

- Pull AlignDocument4 pagesPull Alignhzq1ePas encore d'évaluation

- Aligneo 2-Page-Flyer Ali-9.110!02!07 GDocument2 pagesAligneo 2-Page-Flyer Ali-9.110!02!07 Ghzq1ePas encore d'évaluation

- Vibscanner ManualDocument76 pagesVibscanner Manualhzq1e100% (1)

- Central I GNDocument2 pagesCentral I GNhzq1ePas encore d'évaluation

- Lev AlignDocument4 pagesLev Alignhzq1ePas encore d'évaluation

- Centralign PresentationDocument31 pagesCentralign Presentationhzq1ePas encore d'évaluation

- Bor AlignDocument4 pagesBor Alignhzq1ePas encore d'évaluation

- Before Applying Power: Standard Start-Up PF70, PF700, PF700VC A and PF700VC BDocument7 pagesBefore Applying Power: Standard Start-Up PF70, PF700, PF700VC A and PF700VC Bhzq1ePas encore d'évaluation

- XM Dyn Vibration Training - Rev3Document38 pagesXM Dyn Vibration Training - Rev3hzq1ePas encore d'évaluation

- Behind The Scene of Why Need Oil AnalysisDocument75 pagesBehind The Scene of Why Need Oil Analysishzq1ePas encore d'évaluation

- Daily Activity HMI Upgrade TEG 9610-9620 Per November 5,2014Document11 pagesDaily Activity HMI Upgrade TEG 9610-9620 Per November 5,2014hzq1ePas encore d'évaluation

- Itawari Cafe & Resto Pasir Ridge at Balikpapan: January FebruaryDocument1 pageItawari Cafe & Resto Pasir Ridge at Balikpapan: January Februaryhzq1ePas encore d'évaluation

- Waplab WP 9200Document2 pagesWaplab WP 9200hzq1ePas encore d'évaluation

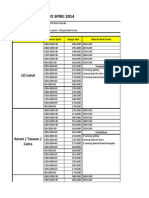

- Daftar Harga Depo Sprei 2014Document10 pagesDaftar Harga Depo Sprei 2014hzq1ePas encore d'évaluation

- Project Handover GuidelinesDocument21 pagesProject Handover GuidelinesAshutosh KumarPas encore d'évaluation

- Pre & Post Test Course ## Control System Gas Turbine ##Document5 pagesPre & Post Test Course ## Control System Gas Turbine ##hzq1ePas encore d'évaluation

- SG90 Tower ProDocument2 pagesSG90 Tower ProZekah VenerosPas encore d'évaluation

- Parts Manual, Chromlite PDFDocument33 pagesParts Manual, Chromlite PDFAgus SantosaPas encore d'évaluation

- Analysis of 4 Stroke 4 Cylinder Petrol EngineDocument36 pagesAnalysis of 4 Stroke 4 Cylinder Petrol Enginesuri surendraPas encore d'évaluation

- Alternator Model Engine Model: 403D-11G LL1114D / LLB1114D GJ66026R, GJ66034RDocument2 pagesAlternator Model Engine Model: 403D-11G LL1114D / LLB1114D GJ66026R, GJ66034RSutan Paulo100% (1)

- Cummins Engine PartsDocument427 pagesCummins Engine PartsJonas Svidinskas100% (2)

- Cummins Sec 4Document30 pagesCummins Sec 4SpectrumRaijinPas encore d'évaluation

- 12M26 2-GBDocument2 pages12M26 2-GBirdawan0% (1)

- Operational Manual DaihatsuDocument112 pagesOperational Manual Daihatsuseltonjapao100% (3)

- Volvo PentaDocument250 pagesVolvo PentaRuben Antonio Huaranca Cruz86% (22)

- SSP 840193. 3.0 Liter V6 TDI. Clean Diesel EngineDocument108 pagesSSP 840193. 3.0 Liter V6 TDI. Clean Diesel EngineFernando García100% (2)

- Engine Control System Diagram: Engine - 3Uz-Fe Engine 70Document21 pagesEngine Control System Diagram: Engine - 3Uz-Fe Engine 70bob loblaw67% (3)

- 7 3LInjectorDiagnosticDocument6 pages7 3LInjectorDiagnosticimamfadili0% (1)

- S 50 MCCDocument270 pagesS 50 MCCAnonymous 8rb48tZS100% (2)

- Specification Manual 2206-E13 KENR6905 May 08Document36 pagesSpecification Manual 2206-E13 KENR6905 May 08Kornelius David PattiselannoPas encore d'évaluation

- Workshop Manual Datsun 1300 1400 1600 1800 Bluebird 160B 180B 1969Document171 pagesWorkshop Manual Datsun 1300 1400 1600 1800 Bluebird 160B 180B 1969Luis Quispe Becerra100% (1)

- Celtis Engine PDFDocument122 pagesCeltis Engine PDFAntnhe BayuPas encore d'évaluation

- S6D155-4C S/N 10011-UpDocument179 pagesS6D155-4C S/N 10011-UpHelio100% (1)

- N74 Engine WebDocument51 pagesN74 Engine WebSalisbur100% (1)

- ST&R Duplex Piston PumpDocument2 pagesST&R Duplex Piston Pump魏永涛Pas encore d'évaluation

- SZ RR V2.0Document55 pagesSZ RR V2.0Amit Dutta43% (7)

- TAD16 - Service PartsDocument104 pagesTAD16 - Service PartsDaniel MuratallaPas encore d'évaluation

- 07 2984BDocument22 pages07 2984BCHARLES HUMBERTO0% (1)

- The Design of Competition EnginesDocument546 pagesThe Design of Competition EnginesAlex Kuznetsov95% (21)

- Avoiding Seal Contamination With Gas SealDocument9 pagesAvoiding Seal Contamination With Gas Sealashumishra007Pas encore d'évaluation

- l2330h Project Guide PDFDocument292 pagesl2330h Project Guide PDFMuhammad Tri KurniawanPas encore d'évaluation

- Morgan BrochureDocument8 pagesMorgan BrochurePaper-FacePas encore d'évaluation

- 147Document8 pages147Raden Maszoel Part IIPas encore d'évaluation

- 449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineDocument2 pages449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineLUKASPas encore d'évaluation

- Hyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10Document10 pagesHyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10hoàng gia bùiPas encore d'évaluation

- Group 11F Engine OverhaulDocument74 pagesGroup 11F Engine Overhaulamat doankPas encore d'évaluation

- Clark C50 60 70 80DDocument263 pagesClark C50 60 70 80DMarcio100% (5)