Académique Documents

Professionnel Documents

Culture Documents

Fuzzy Adaptive PID For Flow Control System Based On OPC: R. Manoj Manjunath S. Janaki Raman

Transféré par

Alex Navas FonsecaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fuzzy Adaptive PID For Flow Control System Based On OPC: R. Manoj Manjunath S. Janaki Raman

Transféré par

Alex Navas FonsecaDroits d'auteur :

Formats disponibles

IJCA Special Issue on Computational Science - New Dimensions & Perspectives

NCCSE, 2011

5

Fuzzy Adaptive PID for Flow Control System based on

OPC

R. Manoj Manjunath

Department of EIE

Hindustan University

Chennai, TN, India

S. Janaki Raman

Assistant Professor, Department of EIE

Hindustan University

Chennai, TN, India

ABSTRACT

The fuzzy adaptive PID control algorithm based on OPC (Open

Process Control) is designed for the flow process station to

improve the control performance better than the conventional

PID controller. PID controller works well only if the

mathematical model of the system could be computed. Hence it

is difficult to implement PID control for variable as well as

complicated systems. But Fuzzy logic control doesnt require any

precise mathematical model and works good for complex

applications also. In this paper, a two input and three output self

adapting fuzzy PID controller was designed to control the final

control element of the flow process station. S7-300 PLC is

connected with the process station. Real time data exchange

between the PLC and MATLAB is realized by means of OPC

server. Fuzzy logic is developed using fuzzy toolbox available in

MATLAB and OPC toolbox helps in fetching data from the OPC

server. The proposed method can be used to realize data process

and advanced control to improve the quality of the control. New

control algorithms created in MATLAB can be checked with real

time systems using this method.

General Terms

Fuzzy systems, Algorithms

Keywords

Fuzzy Adaptive PID, MATLAB, OPC

1. INTRODUCTION

Industrial process control systems have many features such as

non linear, inertial lag, time delay and time varying so on. Due to

this, precise mathematical modeling is not possible. Traditional

PID algorithm doesnt holds well for such systems which has

disturbances. A new algorithm which can deal with these

limitations should be considered. Fuzzy PID has more advantages

as compared to PID. It has fast response, small overshoot and

good anti-interference ability. The fuzzy controller is a non linear

controller, the fuzzy control algorithm are based upon the

intuition and experience about the plant to be controlled.

Therefore it doesnt rely on the precise mathematical modeling.

In this paper a novel method for such system is introduced,

named Fuzzy Adaptive PID. This method has the merits of both

Fuzzy and PID. The fuzzy PID control of these papers was

simulated in simulation platform MATLAB. MATLAB is

important in simulation stages of advanced control system

algorithms and process control. Complex models can be

simulated easily using them. But the drawback is deploying

control system quickly from simulink to real time system is quite

complicated. To make them happen OPC servers are used. In this

paper Matrikon OPC server was used to establish real time

communication between flow process station and S7-300 PLC.

Matrikon OPC is compatible with many industrial instruments

and it is used here. This OPC server provides data exchange

between SCADA, PLC or DCS. When the simulated algorithm is

implemented using hardware through other means, it would be

complex. The use of this method reduces the hardware

complexity that is involved.

Open Process Control (OPC), also known as OLE for Process

Control, is a series of seven specifications defined by the OPC

Foundation for supporting open connectivity in industrial

automation. OPC uses Microsoft DCOM technology to provide

a communication link between OPC servers and OPC clients.

OPC has been designed to provide reliable communication of

information in a process plant, such as a petrochemical refinery,

an automobile assembly line, paper mill and so on.

A two input and three output fuzzy adaptive PID is designed

in this paper. This controller is simulated in MATLAB. The

simulation results show that the controllers adaptive ability and

robustness are better than the conventional PID controller. The

designed controller in MATLAB is made to communicate with

the flow process station using Matrikon OPC and it acquires real

time data.

2. CONTROL SYSTEM OF FLOW

PROCESS STATION

The flow process station consists of a reservoir from which the

liquid is transferred to the overhead tank by means of a motor.

The process variable in this process is flow. The desired flow is

set by the user say 500 lph. An orifice meter is employed to

measure the flow rate of the liquid passing through the pipe.

DPT (Differential pressure transmitter) senses the pressure

difference and it is calibrated to provide the correct flow rate.

DPT now sends the measured value to the process computer

where controller is employed.

After the execution of the fuzzy PID algorithm in MATLAB

the control variable is given to the final control element. The

objective here is to maintain the desired flow rate. But due to

IJCA Special Issue on Computational Science - New Dimensions & Perspectives

NCCSE, 2011

6

external disturbances in real time process industries, its difficult

to maintain constantly throughout.

3. FUZZY ADAPTIVE PID CONTROL

ALGORITHM

The structure of fuzzy adaptive PID is shown in fig. 1. It

consists of two parts, one is the conventional PID controller and

the other is fuzzy controller.

Fig.1 Structure of Fuzzy Adaptive PID

As said earlier, a two input and three output fuzzy adaptive

PID is designed in this paper. The inputs are the error and the

error rate. The outputs are the Kp, Ki and Kd values.

The objective is to find the fuzzy relations among Kp, Ki , Kd,

error, and error rate. With continual testing, the three output

parameters are adjusted online so as to meet different

requirements and achieve good stability.

Variable PID controller adds the output value of the fuzzy

controller and default PID values.

3.1 Design of Fuzzy Adaptive PID

Fuzzy controller is the hardcore of the system. It includes the

fuzzification, knowledge base, inference engine and de-

fuzzification. Fuzzy controller makes the input accurate quantity

to fuzzy quantity. It maps the input to the corresponding

discourse. The knowledge base contains the experienced

knowledge of the flow process station. Data base contains the

membership function of every linguistic variable. Control rules

are described by the data base. De- fuzzification again transforms

the fuzzy quantity into accurate quantity.

3.2 Membership Function

The membership function used by fuzzy controller is triangular

membership function and Gaussian function. The input ranges

from -6 to +6 and the fuzzy subset are Negative Big, Negative

middle, Negative small, Zero, Positive small, Positive middle

and Positive Big respectively termed as NB, NM, NS, ZO, PS,

PM, PB.

The quantization factor and the scaling factor play an

important role in the performance of the fuzzy controller.

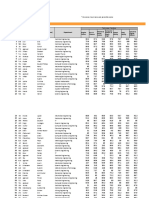

3.3 Control Rules of the Fuzzy Controller

The control rules are framed to achieve the best performance

of the fuzzy controller. In this paper 49 control rules are adopted.

These rules are given in the table 1, 2 & 3.

Table 1

Table 2

Table 3

Using this control rules flow.fis is created. This control rules

are framed using the fuzzy logic toolbox available in MATLAB.

The above said membership function with the mentioned fuzzy

subsets and the control rules form the fuzzy controller. This .fis

file is called in the simulink environment and the connection is

established between them. The inference engine used here is the

Mamdani Inference engine.

IJCA Special Issue on Computational Science - New Dimensions & Perspectives

NCCSE, 2011

7

3.4 Rule Surface Viewer of the Fuzzy

Controller

Based upon the established fuzzy rules, the surface view of

Kp, Ki and Kd are shown in figure 2, 3 and 4 respectively

Fig. 2 Surface view of Kp

Fig. 3 Surface view of Ki

Fig. 4 Surface View of Kd

4. OPC COMMUNICATION

The communication between MATLAB and S7-300 PLC is

realized by means of OPC server. OPC toolbox available in

MATLAB helps in real time data exchange between OPC server

and MATLAB.

Open Process Control (OPC), also known as OLE for Process

Control, is a series of seven specifications defined by the OPC

Foundation for supporting open connectivity in industrial

automation. OPC uses Microsoft DCOM technology to provide

a communication link between OPC servers and OPC clients.

Matlab 7.0 and its above editions integrate the OPC Toolbox

to facilitate interoperability with other softwares which is used as

an OPC server. By utilizing the OPC Toolbox, we can create the

OPC customer application programming easily to realize the

communication between Matlab and OPC server and realize fast

raw data analysis, measure and control. OPC object hierarchy is

shown in the figure 5

Fig. 5 OPC Object Hierarchy

The above figure is from the reference given by Data Access

Interface Standard Version 2.02

4.1 OPC Communication Realization

The communication between MATLAB and S7-300 PLC is

realized by means of Matrikon OPC. OPC toolbox available in

MATLAB helps to fetch data from the Matrikon OPC.

The basic objects of the OPC Toolbox are OPC data access

client objects, Data access group objects and Data access item

objects.

The OPC data acquisition procedures are as follows

1. Determining server id

2. Connecting to opc servers

3. Creating a client object

4. Connecting a client to the server

5. Create an opc data access group object

6. Browse the server name space

7. Adding opc data access items to groups and configure

8. Log opc server data

IJCA Special Issue on Computational Science - New Dimensions & Perspectives

NCCSE, 2011

8

The exchange of data between MATLAB and OPC Server can

be performed either synchronously or asynchronously. In the

synchronous mode, MATLAB will wait for the operation to

complete before continuing with the next one. But asynchronous

mode allows MATLAB to continue processing while the

operation takes place in the background. The asynchronous mode

is used to realize the data communication between MATLAB

OPC toolbox and Matrikon OPC server in this paper.

5. ESTABLISH SYSTEM SIMULATION

The fuzzy logic toolbox, OPC toolbox and the MATLAB

function are used by the fuzzy adaptive PID control method.

Double click the Fuzzy Logic Controller and input the filename

of flow.fis established above. To complete the simulation,

communication between .fis file and the simulink environment

should be established. The following command should be typed

in the command window to establish this communication.

readfis;

fismat =readfis (flow)

The fis files are read in the workspace, and the connection is

realized between Simulink and the fis files.

A step input is given to the system considered in the simulink

environment. The simulation time is for 35s. Finally the system

simulation is completed.

6. RESULTS

The simulation results of both conventional PID and Fuzzy

Adaptive PID are shown in figure 6 and 7 respectively. The

simulation results show that the Fuzzy Adaptive PID has small

overshoot and fast response compared to the conventional PID.

Moreover this method is feasible due to the effective

communication realization between the process device and

MATLAB with the help of OPC server.

Fig. 6 Step response of Conventional PID

Fig. 7 Step response of Fuzzy Adaptive PID

7. CONCLUSION

A fuzzy self-adapting PID controller is designed for the flow

process station. Fuzzy control combined with conventional PID

controller constitutes an intelligent control, which adjusts the

control parameters depending upon the error. A two input and

three output fuzzy adaptive PID control is presented in this paper

The controller is simulated in MATLAB environment. The

simulation results show that the fuzzy adaptive PID controller

have better stability, small overshoot, fast response. Also

communication realization between the process device and

MATLAB through OPC server is presented. By this the

simulated algorithm can be directly implemented in real time

systems.

8. REFERENCES

[1] OPC Foundation. OPC Data Access Custom Interface

Standard Version 2.02[EB/OL]( 2001-12).

http://www.opcfoundation.org.

[2] Sun Xiang, MATLAB 7.0 Basic Tutorial [M]. Beijing,

China, Tsinghua University Press, 2005.

[3] The Math Works Inc. OPC Toolbox For Use with

MATLAB [P/OL]. 2004-10, http://www.mathworks.

com/access / helpdesk/help/pdf_doc/opc/opc.pdf.

[4] Vue Wei-jie, Liu Yong-xin (2009), Boiler Drum Level

controlled by Fuzzy Self-adapting PID, Second Asia-Pacific

Conference on Computational Intelligence and Industrial

Applications.

[5] Zhang Lieping, Zeng Aiqun, Zhang Yunsheng (2007),

On Remote Real-time Communication between MATLAB

and PLC Based on OPC Technology, Proceedings of the

26th Chinese Control Conference.

[6] Qingbao Huang,Qianzhong She,Xiaofeng Lin (2010),

Adaptive Fuzzy PID Temperature Control System Based on

OPC and Modbus/TCP Protocol, 2nd International Asia

Conference on Informatics in Control, Automation and

Robotics.

[7] Qingjin Meng, Baoling Xing, Hongliang Yu, Jingjian

Wu (2009), The Application of Intelligent Control to

Combustion Control System of CFB Boiler, Ninth

International Conference on Hybrid Intelligent Systems.

Vous aimerez peut-être aussi

- International Journal of Engineering Research and Development (IJERD)Document7 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDPas encore d'évaluation

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsD'EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsPas encore d'évaluation

- PLC Based Real Time Process Control Using Scada and Matlab: C.B.Kadu P.S.VikheDocument5 pagesPLC Based Real Time Process Control Using Scada and Matlab: C.B.Kadu P.S.VikheGoutam ChandraPas encore d'évaluation

- FPGA Implementation of High Speed PI Like Fuzzy Control System For Industrial Automation ApplicationsDocument7 pagesFPGA Implementation of High Speed PI Like Fuzzy Control System For Industrial Automation ApplicationsIJMERPas encore d'évaluation

- Discrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsD'EverandDiscrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsPas encore d'évaluation

- EATHD-15022 (By Ravi Kumar Sahu)Document4 pagesEATHD-15022 (By Ravi Kumar Sahu)B Widya OktariaPas encore d'évaluation

- Design and Simulation of Speed Control of DC Motor by Fuzzy Logic Technique With Matlab/SimulinkDocument4 pagesDesign and Simulation of Speed Control of DC Motor by Fuzzy Logic Technique With Matlab/SimulinkHakanBolatPas encore d'évaluation

- On Remote Real-Time Communication Between MATLAB and PLC Based On OPC TechnologyDocument4 pagesOn Remote Real-Time Communication Between MATLAB and PLC Based On OPC TechnologyjhoeduzapaPas encore d'évaluation

- Boiler Flow Control Using PID and Fuzzy Logic ControllerDocument5 pagesBoiler Flow Control Using PID and Fuzzy Logic Controllerحسين شنيقيPas encore d'évaluation

- 3571 PDFDocument4 pages3571 PDFAuliaPas encore d'évaluation

- A Generalized Direct Approach For DesignDocument27 pagesA Generalized Direct Approach For DesignLê UyênPas encore d'évaluation

- Recent Successful Fuzzy Logic Applications in Industrial AutomationDocument7 pagesRecent Successful Fuzzy Logic Applications in Industrial Automationjhosset20112539cPas encore d'évaluation

- GAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFDocument6 pagesGAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFGlan DevadhasPas encore d'évaluation

- Fractional Order Pid Controller ThesisDocument7 pagesFractional Order Pid Controller Thesissoniasancheznewyork100% (2)

- Ijcse PCMTDocument7 pagesIjcse PCMTwigaYeHtetPas encore d'évaluation

- A Rulebased Adaptive Pid ControllerDocument6 pagesA Rulebased Adaptive Pid ControllerJoseph JosePas encore d'évaluation

- A Simple PID Controller With Adaptive Parameter in A DsPICDocument5 pagesA Simple PID Controller With Adaptive Parameter in A DsPICAlfian Apin Ma'arifPas encore d'évaluation

- Step by Step Modeling and Tuning For Fuzzy Logic ControllerDocument12 pagesStep by Step Modeling and Tuning For Fuzzy Logic ControlleraymanPas encore d'évaluation

- Comparison of Control System Using PLC & PIDDocument6 pagesComparison of Control System Using PLC & PIDhamidouhouPas encore d'évaluation

- Implementation of Motor Speed Control Using PID Control in Programmable Logic ControllerDocument6 pagesImplementation of Motor Speed Control Using PID Control in Programmable Logic ControllermanisegarPas encore d'évaluation

- PID ReportDocument38 pagesPID ReportNishiya Vijayan100% (1)

- Monitoring and Control of A Variable Frequency Drive Using PLC and SCADADocument7 pagesMonitoring and Control of A Variable Frequency Drive Using PLC and SCADAEditor IJRITCCPas encore d'évaluation

- Design and Implementation of PID Controller in ProDocument6 pagesDesign and Implementation of PID Controller in ProBAGAS ADIYATMA Mahasiswa PNJPas encore d'évaluation

- MotivationDocument11 pagesMotivationChandrashekar Reddy0% (1)

- Mydcmotorcontrol: Applying Control Theory To A Real DC Motor System in An Open-Loop ConfigurationDocument5 pagesMydcmotorcontrol: Applying Control Theory To A Real DC Motor System in An Open-Loop ConfigurationnorickespinosPas encore d'évaluation

- APCDocument25 pagesAPCTawanda Precious SingiziPas encore d'évaluation

- HTTPWWW Jamris Org012010saveas Phpquestjamrisno012010p08-19Document12 pagesHTTPWWW Jamris Org012010saveas Phpquestjamrisno012010p08-19agivereccPas encore d'évaluation

- Real-Time Implementation of Model Predictive Control On A 16-Bit Microcontroller For Speed Control of A DC MotorDocument21 pagesReal-Time Implementation of Model Predictive Control On A 16-Bit Microcontroller For Speed Control of A DC MotorShubham JagtapPas encore d'évaluation

- Studies On BLDC Motor For Position Control Using PID-Fuzzy-Neural Network and Anti-Windup ControllersDocument6 pagesStudies On BLDC Motor For Position Control Using PID-Fuzzy-Neural Network and Anti-Windup ControllershesaPas encore d'évaluation

- Abs TrackDocument2 pagesAbs TrackRicHi SEtiajiPas encore d'évaluation

- Apendix D - PLC ApplicationsDocument30 pagesApendix D - PLC ApplicationsHassan El-MansyPas encore d'évaluation

- Comparative Study and Implementation of Speed Control of BLDC Motor Using Traditional Pi and Fuzzy Pi Controller IJERTV9IS040527Document6 pagesComparative Study and Implementation of Speed Control of BLDC Motor Using Traditional Pi and Fuzzy Pi Controller IJERTV9IS040527DIVYA PRASOONA CPas encore d'évaluation

- Model Predictive Control in LabVIEWDocument22 pagesModel Predictive Control in LabVIEWBrankko Jhonathan Torres SaavedraPas encore d'évaluation

- PID Controller Based DC Motor Speed ControlDocument4 pagesPID Controller Based DC Motor Speed ControlEditor IJRITCCPas encore d'évaluation

- 2Document28 pages2Srikanth Mudiraj100% (1)

- Project Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationDocument9 pagesProject Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationSaumya TripathiPas encore d'évaluation

- Fuzzy Logic ControllerDocument4 pagesFuzzy Logic ControllerSalma KhanPas encore d'évaluation

- Design and Implementation of Adaptive Fuzzy Controller For Speed Control of Brushless DC MotorsDocument6 pagesDesign and Implementation of Adaptive Fuzzy Controller For Speed Control of Brushless DC MotorsAndy MeyerPas encore d'évaluation

- Fuzzy Based Turbine Governor For Hydro Power Plant: Nanaware R.A., Dr. S.R. Sawant and Dr. B.T. JadhavDocument10 pagesFuzzy Based Turbine Governor For Hydro Power Plant: Nanaware R.A., Dr. S.R. Sawant and Dr. B.T. JadhavLuis Andrew LumbrePas encore d'évaluation

- Gridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsDocument8 pagesGridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsIrfan Akbar BarbarossaPas encore d'évaluation

- Ejaet 2 11 43 48Document6 pagesEjaet 2 11 43 48Mekonnen ShewaregaPas encore d'évaluation

- Control TheoryDocument13 pagesControl TheoryAlexander DeckerPas encore d'évaluation

- Fractional Order Fuzzy PID Controller For A Rotary Servo SystemDocument5 pagesFractional Order Fuzzy PID Controller For A Rotary Servo SystemAKU BUKAN SIAPA-SIAPAPas encore d'évaluation

- PLCBased Real Time Process Controlusing MATLABDocument6 pagesPLCBased Real Time Process Controlusing MATLABusmankhalid6854Pas encore d'évaluation

- Pi Control of Level Control System Using PLC and Labview Based ScadaDocument6 pagesPi Control of Level Control System Using PLC and Labview Based ScadaAna Karen Frias SanchezPas encore d'évaluation

- ProccessDocument10 pagesProccessAN.ADAMMSPas encore d'évaluation

- Pid Controller Research PaperDocument4 pagesPid Controller Research Papernbaamubnd100% (1)

- 1 en 42 Chapter AuthorDocument12 pages1 en 42 Chapter AuthorFrancisco ChangoPas encore d'évaluation

- Real-Time Flow Control System Based On Siemens PLCDocument6 pagesReal-Time Flow Control System Based On Siemens PLCdamara fernandoPas encore d'évaluation

- A Novel Fractional Order Fuzzy PID Contr PDFDocument30 pagesA Novel Fractional Order Fuzzy PID Contr PDFAlejandroHerreraGurideChilePas encore d'évaluation

- Fractional Order PID Controller Tuning Based On IMCDocument15 pagesFractional Order PID Controller Tuning Based On IMCijitcajournalPas encore d'évaluation

- Implementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicDocument4 pagesImplementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicJessica RossPas encore d'évaluation

- Self-Tuning Analog Proportional-Integral-Derivative (PID) ControllerDocument8 pagesSelf-Tuning Analog Proportional-Integral-Derivative (PID) ControllerJun LeePas encore d'évaluation

- Study of Fuzzy-PID Control in MATLAB For Two-Phase Hybrid Stepping Motor ZHANG Shengyi and WANG XinmingDocument4 pagesStudy of Fuzzy-PID Control in MATLAB For Two-Phase Hybrid Stepping Motor ZHANG Shengyi and WANG XinmingMadhusmita BeheraPas encore d'évaluation

- Paper Documentation of Fuzzy Logic B12Document8 pagesPaper Documentation of Fuzzy Logic B12SharikaPas encore d'évaluation

- Block Based Fuzzy Controllers: IJRRAS 3Document11 pagesBlock Based Fuzzy Controllers: IJRRAS 3guynearby007Pas encore d'évaluation

- The Application of Embedded System and LabVIEW in Flexible Copper Clad Laminates Detecting SystemDocument5 pagesThe Application of Embedded System and LabVIEW in Flexible Copper Clad Laminates Detecting SystemSEP-PublisherPas encore d'évaluation

- Research Papers On Pid Controller File Type PDFDocument8 pagesResearch Papers On Pid Controller File Type PDFaflbrozzi100% (1)

- Datasheet 2Document12 pagesDatasheet 2Alex Navas FonsecaPas encore d'évaluation

- Micro GridsDocument321 pagesMicro GridsMadhava Reddy ChemikalaPas encore d'évaluation

- Irfp 260 NDocument9 pagesIrfp 260 NJolaine MojicaPas encore d'évaluation

- HDL-MSD08.40 Datasheet PDFDocument1 pageHDL-MSD08.40 Datasheet PDFAlex Navas FonsecaPas encore d'évaluation

- GHF 15AB Price 1 PDFDocument2 pagesGHF 15AB Price 1 PDFAlex Navas FonsecaPas encore d'évaluation

- C1 - A Simple ApproachDocument15 pagesC1 - A Simple ApproachAlex Navas FonsecaPas encore d'évaluation

- Predicting Practice X 4Document1 pagePredicting Practice X 4Alex Navas FonsecaPas encore d'évaluation

- Cheat SheetDocument9 pagesCheat SheetAlex Navas FonsecaPas encore d'évaluation

- IELTS - Writing Test-1 StructureDocument5 pagesIELTS - Writing Test-1 StructureAswin RajaPas encore d'évaluation

- Listening Practice TestDocument8 pagesListening Practice TestAlex Navas FonsecaPas encore d'évaluation

- Tablas de Frecuencia para T-StudentDocument2 pagesTablas de Frecuencia para T-StudentMayre CelePas encore d'évaluation

- DS18S20Document23 pagesDS18S20lupin91Pas encore d'évaluation

- Vocabulary Improvement Plan PDFDocument1 pageVocabulary Improvement Plan PDFAnonymous ocRr3W5NPas encore d'évaluation

- Predicting Practice X 4Document1 pagePredicting Practice X 4Alex Navas FonsecaPas encore d'évaluation

- Ab LicencesDocument3 pagesAb LicencesAlex Navas FonsecaPas encore d'évaluation

- 0200 4420 PDFDocument12 pages0200 4420 PDFAlex Navas FonsecaPas encore d'évaluation

- PDFDocument8 pagesPDFAlex Navas FonsecaPas encore d'évaluation

- Purpose:: Configuring The DASABCIP IO Server (V 4.x)Document8 pagesPurpose:: Configuring The DASABCIP IO Server (V 4.x)Alex Navas FonsecaPas encore d'évaluation

- 101-0007 USB MicroLink ManualDocument8 pages101-0007 USB MicroLink ManuallizandroaroniPas encore d'évaluation

- Process For Including Support For Your Field Device in The 375 / 475 Field CommunicatorDocument3 pagesProcess For Including Support For Your Field Device in The 375 / 475 Field CommunicatorAlex Navas FonsecaPas encore d'évaluation

- Op ClinkDocument58 pagesOp ClinknonebrePas encore d'évaluation

- Ab LicencesDocument3 pagesAb LicencesAlex Navas FonsecaPas encore d'évaluation

- Ab LicencesDocument3 pagesAb LicencesAlex Navas FonsecaPas encore d'évaluation

- 0200 4410 PDFDocument12 pages0200 4410 PDFAlex Navas FonsecaPas encore d'évaluation

- Desarrollo Empresarial - CompetenciasDocument28 pagesDesarrollo Empresarial - CompetenciaskathyrsPas encore d'évaluation

- 10 2008 TiseDocument9 pages10 2008 TiseAlex Navas FonsecaPas encore d'évaluation

- Lukas PIC TutorialDocument16 pagesLukas PIC Tutorialg@vo100% (3)

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconFhidli Sang Pangeran BiruPas encore d'évaluation

- TutorialDocument9 pagesTutorialAlex Navas FonsecaPas encore d'évaluation

- Advanced Programme In: Fintech and Financial BlockchainDocument13 pagesAdvanced Programme In: Fintech and Financial BlockchainAshish mPas encore d'évaluation

- Associate Cloud Engineer - Study NotesDocument14 pagesAssociate Cloud Engineer - Study Notesabhi16101Pas encore d'évaluation

- EEM336 - 01 - Introduction To The Microprocessor and ComputerDocument53 pagesEEM336 - 01 - Introduction To The Microprocessor and ComputersakalanPas encore d'évaluation

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraPas encore d'évaluation

- Ervina Ramadhanti 069 Ptn17aDocument12 pagesErvina Ramadhanti 069 Ptn17aMac ManiacPas encore d'évaluation

- Conceptualizing Teacher Professional LearningDocument33 pagesConceptualizing Teacher Professional LearningPaula Reis Kasmirski100% (1)

- Feedback For Question 1-MIDTERM 2 AFM 451Document2 pagesFeedback For Question 1-MIDTERM 2 AFM 451jason fPas encore d'évaluation

- Confidence Limits in StatisticsDocument30 pagesConfidence Limits in StatisticsaassmmrrPas encore d'évaluation

- RealviewDocument62 pagesRealviewXaxo PapoPas encore d'évaluation

- 2011bibliography Part I (Preparation and Initial Assessment)Document188 pages2011bibliography Part I (Preparation and Initial Assessment)Espiritu MineralPas encore d'évaluation

- HSG11 V3+AnswersDocument10 pagesHSG11 V3+AnswershaPas encore d'évaluation

- Flashes of Light From The Spirit-Land - J ConantDocument397 pagesFlashes of Light From The Spirit-Land - J ConantmcadaviesPas encore d'évaluation

- Part 1 - Install PfSense On ESXi - Calvin BuiDocument8 pagesPart 1 - Install PfSense On ESXi - Calvin Buiandrei2andrei_3Pas encore d'évaluation

- Fruits Basket - MemoryDocument1 pageFruits Basket - Memorywane10132100% (1)

- HT 02 Intro Tut 07 Radiation and ConvectionDocument46 pagesHT 02 Intro Tut 07 Radiation and ConvectionrbeckkPas encore d'évaluation

- Gate Question (Limit) PDFDocument4 pagesGate Question (Limit) PDFArpit Patel75% (4)

- Operating Temperature Considerations and Performance PDFDocument12 pagesOperating Temperature Considerations and Performance PDFccprado1Pas encore d'évaluation

- Nina Harris Mira Soskis Thalia Ehrenpreis Stella Martin and Lily Edwards - Popper Lab Write UpDocument4 pagesNina Harris Mira Soskis Thalia Ehrenpreis Stella Martin and Lily Edwards - Popper Lab Write Upapi-648007364Pas encore d'évaluation

- Generalization of The Lavallée and Hidiroglou AlgorithmDocument11 pagesGeneralization of The Lavallée and Hidiroglou AlgorithmCristian MoisésPas encore d'évaluation

- Membrane TypesDocument92 pagesMembrane TypesVanditaa Kothari100% (1)

- 20 Issues For Businesses Expanding InternationallyDocument24 pages20 Issues For Businesses Expanding InternationallySubash RagupathyPas encore d'évaluation

- Session ManagementDocument4 pagesSession ManagementahamedyaseenPas encore d'évaluation

- Lab ManualDocument69 pagesLab ManualPradeepPas encore d'évaluation

- Director Product Development Engineering in Detroit MI Resume Brian ThompsonDocument2 pagesDirector Product Development Engineering in Detroit MI Resume Brian ThompsonBrianThompson2Pas encore d'évaluation

- How To Build TelescopeDocument50 pagesHow To Build TelescopeSachin VermaPas encore d'évaluation

- Engineering Council of South Africa: 1 PurposeDocument5 pagesEngineering Council of South Africa: 1 Purpose2liePas encore d'évaluation

- Vmod Pht3d TutorialDocument32 pagesVmod Pht3d TutorialluisgeologoPas encore d'évaluation

- PTE Self Study - Lfib v3.0Document57 pagesPTE Self Study - Lfib v3.0Jewel AhmedPas encore d'évaluation

- Abstract - Freezing Point Depression Is ADocument5 pagesAbstract - Freezing Point Depression Is AMinahPas encore d'évaluation

- Chapter-12 Perf Appraisal & Career Strategy (I.m.s)Document4 pagesChapter-12 Perf Appraisal & Career Strategy (I.m.s)Waris KhanPas encore d'évaluation

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980D'Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Évaluation : 4 sur 5 étoiles4/5 (21)

- Pale Blue Dot: A Vision of the Human Future in SpaceD'EverandPale Blue Dot: A Vision of the Human Future in SpaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (588)

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (81)

- Packing for Mars: The Curious Science of Life in the VoidD'EverandPacking for Mars: The Curious Science of Life in the VoidÉvaluation : 4 sur 5 étoiles4/5 (1395)

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationD'EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (122)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPas encore d'évaluation

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (54)

- The Weather Machine: A Journey Inside the ForecastD'EverandThe Weather Machine: A Journey Inside the ForecastÉvaluation : 3.5 sur 5 étoiles3.5/5 (31)