Académique Documents

Professionnel Documents

Culture Documents

Approved Maintenance Organizations

Transféré par

adrn321Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Approved Maintenance Organizations

Transféré par

adrn321Droits d'auteur :

Formats disponibles

[Type text]

1

Approved Maintenance Organizations:

Depending upon the size of organization, the functions are subdivided under individual

managers or combined management in number of ways. An approved maintenance

organization should posses some facility and personnel requirements in order to carry

out base maintenance on an aircraft which are described as follows:

FACILITY REQUIREMENTS:

Specialized workshops:

AMO should have all the facilities of spacious aircraft hangers and component

workshops in order to carry out maintenance practices of aircraft in order to

accommodate planned maintenance and avoid working area contamination.

Proof of tenancy should be provided if hanger is not owned by the organization.

Their floors should be sealed so that dust generation can be minimized.

Working environment:

An appropriate working environment should be given that allows maintenance

tasks to be carried out at a comfortable temperature, good lighting conditions and

a minimum level of noise.

Storage:

Considering manufacturers instructions; the storage facilities for components,

tools etc should be clean, well ventilated and secure in order to minimize the

effect of condensation. The unserviceable aeronautical products should be

separated from serviceable equipments and tools and remain packed to avoid

damage and prevent corrosion.

Office accommodation:

AMO should provide an office accommodation or area for certified employees

and management of planned maintenance where they can discuss maintenance

instructions and make maintenance records in proper manner which contributes

to good aircraft maintenance standards. There should be up to date visit plans to

hanger.

[Type text]

2

Tools and Training:

The organization must have the tools, materials and equipments needed to

provide the approved maintenance services. The method of accessing those

equipments should be described in the exposition of the organization.

PERSONNEL REQUIREMENTS:

The organization should have sufficient staff to plan, inspect and perform any particular

maintenance task. Also it should have procedure to revaluate the maintenance work

carried out when the availability of staff is less than the planned maintenance staff for a

specified task. The personnel involved in various maintenance tasks in hanger are

described as follows:

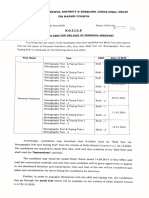

Accountable manager:

Accountable

manager

Line

Maintenance

Manager

Base

maintenance

manager

Workshop

manager

Safety

manager

Quality

manager

[Type text]

3

The organization should have an accountable manager who has the authority to ensure

that the maintenance practices should be financed effectively according to the customer

needs in order to meet the standards required by AMOs approved exposition. He

should make sure that all the necessary resources are available to provide maintenance

services required for the specified task.

Line maintenance manager:

The organization needs a line maintenance manager who should take care whether

external test equipment is required or not for replacement of component like engines

etc. He is also responsible for the minor repair and scheduled maintenance of the

aircraft.

Base maintenance manager:

The base maintenance manager is responsible for the improvement of any defects

detected during the base maintenance of the aircraft. He ensures that the maintenance

tasks which are carried out should meet the specified quality and design standards.

Workshop manager:

The organization should have a workshop manager who makes sure that the various

maintenance activities carried out in hanger should meet the specified standards.

Quality manager:

The quality manager should set up and promote safety and quality management

policies required by the organization. He has the responsibility of keeping an eye on

AMOs quality system. In some cases if all the requirements are accomplished by line

maintenance organization, then the quality manager may accept the maintenance

activities to be done by the said organization.

[Type text]

4

Vous aimerez peut-être aussi

- Small Part 145 Approved Maintenance Organizations:: Specialized WorkshopsDocument4 pagesSmall Part 145 Approved Maintenance Organizations:: Specialized Workshopsadrn321Pas encore d'évaluation

- Hangar 145Document2 pagesHangar 145mostafaPas encore d'évaluation

- Plant Maintenance EngineeringDocument7 pagesPlant Maintenance EngineeringSandeep Singh KharbPas encore d'évaluation

- Chapter 1 MaintenanceDocument16 pagesChapter 1 MaintenanceAbel TayePas encore d'évaluation

- Licensed Engineer (EASA B1) : SummaryDocument2 pagesLicensed Engineer (EASA B1) : SummaryJoyxfulPas encore d'évaluation

- PPQCDocument14 pagesPPQCখালিদহাসানPas encore d'évaluation

- Is 4002 Maintainability EngineeringDocument118 pagesIs 4002 Maintainability Engineeringraj KumarPas encore d'évaluation

- DJJ50212 Maintenance Engineering and Management Chapter 1 Maintenance OrganizationDocument61 pagesDJJ50212 Maintenance Engineering and Management Chapter 1 Maintenance OrganizationMOHD AZIZEE BIN SUKOR (POLIBANTING)Pas encore d'évaluation

- New Topic 1 Introduction To Maintenance ManagementDocument41 pagesNew Topic 1 Introduction To Maintenance ManagementNurul Nabila Sahri100% (1)

- ME 2037 Maintenance Engineering Unit 2 FAQDocument9 pagesME 2037 Maintenance Engineering Unit 2 FAQVaradha YamunanPas encore d'évaluation

- Planned Maintenance SystemDocument9 pagesPlanned Maintenance Systemidzhar AjaPas encore d'évaluation

- Study Notes On CAR-145Document8 pagesStudy Notes On CAR-145sushantreshma100% (1)

- CH 4Document63 pagesCH 4girma workuPas encore d'évaluation

- Tool Room MGMT GuidebookDocument20 pagesTool Room MGMT GuidebookCarlos MoyaPas encore d'évaluation

- Amte 415Document21 pagesAmte 415Humper Isla SampiloPas encore d'évaluation

- Chapter 1 Maintenance Organization NewDocument49 pagesChapter 1 Maintenance Organization Newsofwanazmin100% (1)

- Chapter 1 IntroductionDocument8 pagesChapter 1 IntroductionSachin MohalPas encore d'évaluation

- MGMT 419 Chapter 7Document21 pagesMGMT 419 Chapter 7iqranoorPas encore d'évaluation

- Portfolio in Maintenance and RepairDocument12 pagesPortfolio in Maintenance and RepairCarlos Joshua Oreo100% (1)

- Lecture 1 Introduction To Maintenance EngineeringDocument42 pagesLecture 1 Introduction To Maintenance EngineeringIgombe IsaacPas encore d'évaluation

- TPM - MaterialDocument33 pagesTPM - MaterialRanjeet DongrePas encore d'évaluation

- Maintenance UNIT - 1Document25 pagesMaintenance UNIT - 1rajeshkannahPas encore d'évaluation

- Requirements For A Maintenance ProgramDocument32 pagesRequirements For A Maintenance ProgramAhmet KerimPas encore d'évaluation

- Part M Presentation S P SinghDocument42 pagesPart M Presentation S P SinghSk SathhappanPas encore d'évaluation

- IntroDocument16 pagesIntroKarunakaran DPas encore d'évaluation

- 12.maintain Cleanliness of Maintenance Area and Surroundings. Ensure The Security of The Tool House During Their Duty PeriodDocument4 pages12.maintain Cleanliness of Maintenance Area and Surroundings. Ensure The Security of The Tool House During Their Duty PeriodAnonymous u4MLvpPas encore d'évaluation

- Case Study MaintenanceDocument14 pagesCase Study Maintenancenash vinPas encore d'évaluation

- Maintenance ManagementDocument112 pagesMaintenance ManagementNiveditaKumari100% (11)

- Maintenance ManagementDocument21 pagesMaintenance ManagementRahul WaghmarePas encore d'évaluation

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument19 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88Jj100% (1)

- Chapt 4Document4 pagesChapt 4abhi7840Pas encore d'évaluation

- Maintenance Management: Assignment 1Document17 pagesMaintenance Management: Assignment 1Yogesh SharmaPas encore d'évaluation

- Minimum Learing Material - MaintenanceDocument144 pagesMinimum Learing Material - MaintenanceSaravanan Ak100% (1)

- Company Maintenance Manual: Cooperative Development of Operational Safety & Continuing AirworthinessDocument23 pagesCompany Maintenance Manual: Cooperative Development of Operational Safety & Continuing AirworthinessArdian RizaldiPas encore d'évaluation

- Reliability Assignment 2Document2 pagesReliability Assignment 2Ashu vermaPas encore d'évaluation

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument13 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88JjPas encore d'évaluation

- Ame LNDocument49 pagesAme LNMr. Ehsanur Rahman FaizaniPas encore d'évaluation

- Maintenence BasicsDocument51 pagesMaintenence BasicsKarim Magdy100% (1)

- Module 2 AMQSDocument11 pagesModule 2 AMQStrong7nguyen-12Pas encore d'évaluation

- AMT 219 Mid Term ExaminationDocument10 pagesAMT 219 Mid Term ExaminationCrist SumaPas encore d'évaluation

- Chapter 6 Requirements For A Maintenance Program: Facultad de Ingeniería y Ciencias BásicasDocument24 pagesChapter 6 Requirements For A Maintenance Program: Facultad de Ingeniería y Ciencias BásicasAnonymous OFTUeE6Pas encore d'évaluation

- Equipment Maintenance Management Policies & ScopesDocument3 pagesEquipment Maintenance Management Policies & ScopeshenoksolPas encore d'évaluation

- MaintenanceDocument44 pagesMaintenanceLatifahabubakar Eifa100% (1)

- Maintenance Engineering PDFDocument117 pagesMaintenance Engineering PDFSakshi Bansal100% (2)

- What Are The Different Types of Maintenance SystemsDocument30 pagesWhat Are The Different Types of Maintenance SystemsCollen TsvangirayiPas encore d'évaluation

- How To Implement A Fleet Preventative Maintenance Plan: An Interactive ChecklistDocument3 pagesHow To Implement A Fleet Preventative Maintenance Plan: An Interactive ChecklistJonathan Fox100% (1)

- AC-GEN005 Quality Assurance SystemDocument7 pagesAC-GEN005 Quality Assurance SystemPhilip Madekufamba IIPas encore d'évaluation

- LeadershipDocument79 pagesLeadershipGaiusPas encore d'évaluation

- Ch.1 - Maintenance OrganizationDocument46 pagesCh.1 - Maintenance OrganizationFikriAdhaPas encore d'évaluation

- CAA-AC-AWS012 Draft Quality Assurance SystemDocument9 pagesCAA-AC-AWS012 Draft Quality Assurance SystemPaschalPas encore d'évaluation

- Iso 17020Document7 pagesIso 17020Abusaada2012Pas encore d'évaluation

- What Are The Different Types of Maintenance Systems.?: Uncategorized Edit CategoriesDocument6 pagesWhat Are The Different Types of Maintenance Systems.?: Uncategorized Edit CategoriesArif Khan100% (1)

- Preventive Maintenance Part IDocument20 pagesPreventive Maintenance Part Ismodi20Pas encore d'évaluation

- Define Maintenance MergedDocument73 pagesDefine Maintenance MergedBipul Verma100% (1)

- To Follow Means Any Order Issued by The Director General Under Cars, 94Document4 pagesTo Follow Means Any Order Issued by The Director General Under Cars, 94Ahmed ShahPas encore d'évaluation

- Plant Maintenance PDFDocument26 pagesPlant Maintenance PDFdeecrankson100% (18)

- Maintanance Engg MaterialDocument58 pagesMaintanance Engg MaterialSiva KrishnanPas encore d'évaluation

- R&D MaintenanceDocument31 pagesR&D MaintenanceSajid ChaudharyPas encore d'évaluation

- Empire Aviation GroupDocument2 pagesEmpire Aviation Groupadrn321Pas encore d'évaluation

- Capstone Case StudyDocument4 pagesCapstone Case Studyadrn321Pas encore d'évaluation

- Approved Maintenance OrganizationsDocument4 pagesApproved Maintenance Organizationsadrn321Pas encore d'évaluation

- Proj ManagementDocument8 pagesProj Managementadrn321Pas encore d'évaluation

- (Sears) DeluxeDemandWaterSoftenersownersmanualsDocument32 pages(Sears) DeluxeDemandWaterSoftenersownersmanualsGreg Reyneke100% (1)

- Session 12. Facilities layout-IIDocument34 pagesSession 12. Facilities layout-IIsandeep kumarPas encore d'évaluation

- Discussion Lab 2Document2 pagesDiscussion Lab 2nazrin0% (1)

- Communication Technology The New Media in Society PDFDocument2 pagesCommunication Technology The New Media in Society PDFElma0% (5)

- Scope of The WorkDocument5 pagesScope of The Worklogu RRPas encore d'évaluation

- UTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal AssistantDocument2 pagesUTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal Assistantneekuj malikPas encore d'évaluation

- Indian CyberSecurity Product Landscape PDFDocument56 pagesIndian CyberSecurity Product Landscape PDFShaik InayathPas encore d'évaluation

- Dimensões S7 1200Document1 pageDimensões S7 1200iuctmePas encore d'évaluation

- H07RN-F - (LTC) - 4Document6 pagesH07RN-F - (LTC) - 4Faizal AzwaryPas encore d'évaluation

- B3Document3 pagesB3Jericho MoralesPas encore d'évaluation

- Reading and Writing Writing An EmailDocument1 pageReading and Writing Writing An EmailferfonsegonPas encore d'évaluation

- DD FC Basix ConfDocument18 pagesDD FC Basix ConfwstanzlPas encore d'évaluation

- New Horizons and Opportunities of Modular Constructions and Their TechnologyDocument9 pagesNew Horizons and Opportunities of Modular Constructions and Their TechnologyPhD. Arch. Klodjan XhexhiPas encore d'évaluation

- Fluorescence Activated Cell SortingDocument6 pagesFluorescence Activated Cell SortingAjit YadavPas encore d'évaluation

- 213078Document38 pages213078Mbade NDONGPas encore d'évaluation

- Nissan in EuropeDocument24 pagesNissan in Europeonlyur44Pas encore d'évaluation

- The Hydraulic Pumping SystemDocument12 pagesThe Hydraulic Pumping SystemCarlos Lopez DominguezPas encore d'évaluation

- Manual de Estudiante Mitel 3300Document466 pagesManual de Estudiante Mitel 3300Romeo VelasquezPas encore d'évaluation

- CHE3161 - Semester1 - 2011 - SolutionsDocument12 pagesCHE3161 - Semester1 - 2011 - Solutionsvenkiee50% (2)

- 4213 TPS Industrial Thermal BookDocument76 pages4213 TPS Industrial Thermal BookDinesh VaghelaPas encore d'évaluation

- Dahua ITC302-RU1A1Document2 pagesDahua ITC302-RU1A1Dms TsPas encore d'évaluation

- As 3638-1993 Test Sieving ProceduresDocument7 pagesAs 3638-1993 Test Sieving ProceduresSAI Global - APACPas encore d'évaluation

- Kapil Sharma ResumeDocument4 pagesKapil Sharma ResumeKapil SharmaPas encore d'évaluation

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsDocument10 pagesId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniPas encore d'évaluation

- Mazda rx7Document3 pagesMazda rx7Jon WestPas encore d'évaluation

- MS150093 01e PDFDocument181 pagesMS150093 01e PDFAntonio MartinPas encore d'évaluation

- Degassed Cation Conductivity MeasurementDocument11 pagesDegassed Cation Conductivity MeasurementPhạm Nhật MinhPas encore d'évaluation

- CMA June 2018 ExamDocument2 pagesCMA June 2018 ExamMuhammad Ziaul HaquePas encore d'évaluation

- CBBEDocument23 pagesCBBECharuJagwaniPas encore d'évaluation

- Modes in Optical FibersDocument10 pagesModes in Optical FibersAdamStone100% (1)