Académique Documents

Professionnel Documents

Culture Documents

Cast Iron Welding Procedure

Transféré par

Anand KesarkarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cast Iron Welding Procedure

Transféré par

Anand KesarkarDroits d'auteur :

Formats disponibles

Cast Iron Welding Procedures: How to Weld Cast Iron

Cast iron is one of the common alloys of iron. It is assumed by many people that cast iron is

impossible to weld. Welding cast iron is not impossible, but it certainly is difficult. Here is a brief

description of cast iron welding procedures.

Cast iron is one of the alloys of iron that has a significant content of carbon in it. The content of

carbon varies from about 2% to 4%. This carbon content is about 10 times greater than it is found in

other alloys like wrought iron or steel. The cast iron manufacturing process is simple as a result of its

simple combination. The process of casting, or molding of cast iron, is relatively easy and it goes as

follows.

Initially, normal iron that has been purified in the blast furnace, is poured out into casts and a

good amount of carbon is mixed-in as it starts cooling down.

This process of mixing takes place when the iron is in a semi-molten form. The temperature of

the molten metal is about 1450 F. This prevents the carbon from burning and helps it blend

with the molten matter.

The iron which has now become cast iron is let to cool down gradually and properly.

This process of cooling down makes the surface of the cast iron smooth and prevents it from

cracking. A disturbance in the cooling down process produces cracks or uneven breaks in the

surface. The carbon that is present in the molten iron, forms flakes of graphite throughout the

alloy that gives it the characteristic of brittleness.

Though cast iron has many uses, its characteristic of being brittle becomes a headache, when it comes

to repairing objects made up of cast iron. The following are some of the processes that prove to be

useful while repairing and welding cast iron.

How to Weld Cast Iron

Before welding and repairing cast iron, it is always advisable to make the surface, that is to be

welded, smooth and clean. The clean surface ensures a very good quality in welding and also prevents

it from cracking. Cast iron welding procedure can be carried out in four ways, which are as follows.

With the help of preheat

Without preheat.

Sealing cracks with the help of welding

Studding method

Cast Iron Welding by Preheating

The cast iron welding procedure that is carried out by applying preheat is usually used in heavy

industries. The concept of application of preheat makes the process a bit complicated as appropriate

heating equipment is also required. Most of the time the whole object that is to be welded, is heated

up till a temperature that ranges between 500 to 1200 degrees Fahrenheit. However one must avoid

heating more than 1400 degrees as the metal starts turning into a molten stage. After the metal

reaches the high temperature, start welding it using a low current. The low current should be used so

to minimize admixture and the residual stress. Sometimes it also becomes necessary to restrict the

width of the welds. Ideally the welds must be minimized to about an inch long segment. An excessive

weld can also lead to cracking of the surface. The cooling process is extremely critical in the preheated

welding process. The object must not be disturbed and must be allowed to cool down gradually. For

gradual cooling the object can be buried in sand or can even be covered with an insulation blanket.

Cast Iron Welding without Preheating

Preheated welding can be easily carried out at the domestic levels for small and manageable objects.

While welding the cast iron without preheating, it is extremely essential to have a good control over

the welding gun and make the welds as small as possible. The best option is to make the welds about

1 inch thick. It is also very important to let the welds cool down gradually. After the cooling process is

complete, it is important to peen the extra welds that are deposited on the surface.

Sealing Cracks

Cracks in the surface of cast iron tend to be very troublesome. It is hence advisable to use the

preheated technique to seal cracks. One can also use the peening action in order to make the welded

crack smooth and even.

Studding Method

The studding process is an extremely complex process due to the fact that one requires a lot of skill

for this method. The first step is to drill and tap holes on the surface that has beveled. The next step

is to put in steel studs and weld them into the surface. The steel studs will help in covering the entire

surface into the location where the surface has cracked. The welded deposit can be further used to

make reinforcement over the crack.

It is recommended that one resorts to the non-preheating cast iron welding procedure for domestic

purposes. While welding cast iron to steel the preheating procedure proves to be highly effective.

Vous aimerez peut-être aussi

- Guidelines For Welding Cast IronDocument3 pagesGuidelines For Welding Cast IronNguyễn Thanh SơnPas encore d'évaluation

- Forging Processes: Satya Amarnadh ParimiDocument26 pagesForging Processes: Satya Amarnadh ParimiamarparimiPas encore d'évaluation

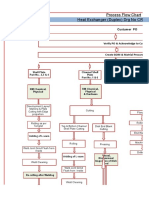

- Process Flow Chart - Heat ExchangerDocument7 pagesProcess Flow Chart - Heat ExchangerAnand KesarkarPas encore d'évaluation

- Aluminum 5083Document2 pagesAluminum 5083razormebackPas encore d'évaluation

- Guide Cast Iron Welding TechniquesDocument8 pagesGuide Cast Iron Welding TechniquesAgustine SetiawanPas encore d'évaluation

- Pressure Testing Safety EssentialsDocument7 pagesPressure Testing Safety EssentialsSuleyman HaliciogluPas encore d'évaluation

- The Truth About Fibonacci TradingDocument34 pagesThe Truth About Fibonacci TradingAnand KesarkarPas encore d'évaluation

- Effect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Document10 pagesEffect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Kaushik SenguptaPas encore d'évaluation

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdPas encore d'évaluation

- Welding of Cast IronDocument35 pagesWelding of Cast IronincaurcoPas encore d'évaluation

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainPas encore d'évaluation

- Common Metallurgical Defects in Ductile Cast Iron PDFDocument1 pageCommon Metallurgical Defects in Ductile Cast Iron PDFsskiitb100% (2)

- Feeder Design & AnalysisDocument18 pagesFeeder Design & Analysismecaunidos7771Pas encore d'évaluation

- ForgingDocument26 pagesForgingamarparimiPas encore d'évaluation

- Stainless Steel Welding by Weld RealityDocument50 pagesStainless Steel Welding by Weld RealitylightwinterdayPas encore d'évaluation

- The Complete Guide To Trading PDFDocument116 pagesThe Complete Guide To Trading PDFvkverma352Pas encore d'évaluation

- Welding of Nickel AlloysDocument12 pagesWelding of Nickel Alloysaj87_goswamiPas encore d'évaluation

- Hot Dip GalvanizingDocument3 pagesHot Dip Galvanizingapply19842371Pas encore d'évaluation

- Gating Design V3Document31 pagesGating Design V3Chinh Thong TranPas encore d'évaluation

- HEAT TREATMENT of SteelDocument33 pagesHEAT TREATMENT of Steelparamaguru vPas encore d'évaluation

- Broken or Cracked Castings - Chapter 1: DescriptionDocument24 pagesBroken or Cracked Castings - Chapter 1: DescriptionSachin Kumbhar100% (1)

- ASME B31.3 Pipe Material Impact Test RequirementsDocument13 pagesASME B31.3 Pipe Material Impact Test Requirementsbounatiro Hatem0% (1)

- What causes defects in stainless steelDocument27 pagesWhat causes defects in stainless steelPrabhakar Kattula33% (3)

- Hydrostatic Testing Procedures for FacilitiesDocument17 pagesHydrostatic Testing Procedures for Facilitiesprakash07343Pas encore d'évaluation

- 904LDocument5 pages904LManish542Pas encore d'évaluation

- Casting Defect - Fissure DefectsDocument3 pagesCasting Defect - Fissure Defectsvivek1312Pas encore d'évaluation

- IIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.auDocument28 pagesIIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.aukatfy1Pas encore d'évaluation

- Gray Cast Iron-1Document18 pagesGray Cast Iron-1ManicharanPas encore d'évaluation

- Basics of welding procedures and standardsDocument133 pagesBasics of welding procedures and standardsmoonstar_dmePas encore d'évaluation

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDocument32 pagesMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraPas encore d'évaluation

- Welding Residual StressDocument10 pagesWelding Residual Stressaap1Pas encore d'évaluation

- Design of Heat Treatment CyclesDocument5 pagesDesign of Heat Treatment CyclesAnonymous s6xbqCpvSWPas encore d'évaluation

- Pin HolesDocument4 pagesPin HolesEr WidodoPas encore d'évaluation

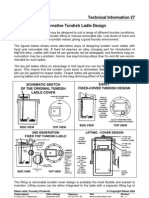

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646Pas encore d'évaluation

- Como Soldar 4140Document4 pagesComo Soldar 4140Luis Jose DuranPas encore d'évaluation

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoPas encore d'évaluation

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoPas encore d'évaluation

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoPas encore d'évaluation

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarPas encore d'évaluation

- Defects Hydrogen Cracks IdentificationDocument5 pagesDefects Hydrogen Cracks Identificationarif maulanafPas encore d'évaluation

- 21 Weldability of SteelsDocument40 pages21 Weldability of Steelssaeidian100% (2)

- Candlestick Patterns Every Trader Should KnowDocument65 pagesCandlestick Patterns Every Trader Should KnowDxtr V Drn100% (1)

- Breakout Trading Strategies Quick GuideDocument10 pagesBreakout Trading Strategies Quick GuideAnand Kesarkar100% (1)

- Heat Treatment DefectsDocument13 pagesHeat Treatment DefectsAbu HurairaPas encore d'évaluation

- Lamellar tearing in welded steel platesDocument6 pagesLamellar tearing in welded steel platesguru_terexPas encore d'évaluation

- ELMAGDocument2 pagesELMAGthomazfabricioPas encore d'évaluation

- Use Niyama Criterion To Predict Shrinkage LeaksDocument18 pagesUse Niyama Criterion To Predict Shrinkage LeaksCarlos Ortega Jones100% (1)

- A270Document6 pagesA270Anonymous O39pjWPas encore d'évaluation

- GUIDE Weld Cast Iron Esab PDFDocument10 pagesGUIDE Weld Cast Iron Esab PDFdanilamariusseba100% (1)

- Atmospheric Corrosion Resisting Structural Steel: National Standard of The People'S Republic of ChinaDocument6 pagesAtmospheric Corrosion Resisting Structural Steel: National Standard of The People'S Republic of ChinaBaoPas encore d'évaluation

- 254smo (Uns 31254)Document8 pages254smo (Uns 31254)Yang Gul LeePas encore d'évaluation

- Dss 2205 Wps PQR WPQDocument8 pagesDss 2205 Wps PQR WPQAnand KesarkarPas encore d'évaluation

- Cast Irons: Job Knowledge 25 Weldability of MaterialsDocument3 pagesCast Irons: Job Knowledge 25 Weldability of Materialskevin herryPas encore d'évaluation

- Feeding Steel and Ductile Iron CastingDocument22 pagesFeeding Steel and Ductile Iron Castingjosemiguelzu100% (1)

- 50 Casting DefectsDocument49 pages50 Casting DefectsmohammadPas encore d'évaluation

- BCIRA Broadsheet 41Document4 pagesBCIRA Broadsheet 41Justin Dixon100% (1)

- SG Iron ProductionDocument20 pagesSG Iron ProductionShreyashri Nayak100% (1)

- MSI DC 01 FosecoDocument4 pagesMSI DC 01 FosecoVivek Shrivastava100% (1)

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocument23 pages1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Pickling Heat Tint For SSDocument2 pagesPickling Heat Tint For SSTuan DangPas encore d'évaluation

- Alloy 6moDocument2 pagesAlloy 6moqshaath100% (1)

- Inspection of The Hot Dipped Galvanizing ProcessDocument5 pagesInspection of The Hot Dipped Galvanizing ProcessIrinaPas encore d'évaluation

- Dross Inclusions and Galvanized SteelDocument2 pagesDross Inclusions and Galvanized SteelcurtisvaleroPas encore d'évaluation

- Senior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateDocument6 pagesSenior Welding Inspector: Multiple Choice Questions Paper 1: Name: . . DateFuaz SukaryaPas encore d'évaluation

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 pagesCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdPas encore d'évaluation

- CR StandardsDocument6 pagesCR Standardsalpha_beta48Pas encore d'évaluation

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkPas encore d'évaluation

- StraighteningDocument10 pagesStraighteningSimbu ArasanPas encore d'évaluation

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocument11 pagesCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalPas encore d'évaluation

- Unusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionDocument2 pagesUnusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionparmindersinPas encore d'évaluation

- Soldering March IntakeDocument49 pagesSoldering March IntakeoriverbmwasotemwasotePas encore d'évaluation

- Welding Cast Iron in HouseDocument5 pagesWelding Cast Iron in Housesharif1974Pas encore d'évaluation

- The Truth About Fibonacci TradingDocument34 pagesThe Truth About Fibonacci TradingAnand KesarkarPas encore d'évaluation

- Name Contact No. Location DOB Age SR No. Employee CodeDocument5 pagesName Contact No. Location DOB Age SR No. Employee CodeAnand KesarkarPas encore d'évaluation

- Corona Kavach Policy-Oriental Insurance - Rate ChartDocument3 pagesCorona Kavach Policy-Oriental Insurance - Rate ChartAnand KesarkarPas encore d'évaluation

- ANUGRAHA TEJAS Automatic power loom for Coir Geo TextilesDocument16 pagesANUGRAHA TEJAS Automatic power loom for Coir Geo TextilesAnand KesarkarPas encore d'évaluation

- Dynamic Print Solution: D P E PDocument8 pagesDynamic Print Solution: D P E PAnand KesarkarPas encore d'évaluation

- Unit 8 - Week 7: Assignment 07Document3 pagesUnit 8 - Week 7: Assignment 07Anand KesarkarPas encore d'évaluation

- Manufacturing Processes UNIT Test-I - Series A With SolutionsDocument1 pageManufacturing Processes UNIT Test-I - Series A With SolutionsAnand KesarkarPas encore d'évaluation

- Astm A70Document1 pageAstm A70Anand KesarkarPas encore d'évaluation

- 1.4 BG00381946 - ADocument1 page1.4 BG00381946 - AAnand KesarkarPas encore d'évaluation

- Let's Discuss Your Next Project.: Contact USDocument8 pagesLet's Discuss Your Next Project.: Contact USAnand KesarkarPas encore d'évaluation

- Cap 3 Dse CutoffDocument614 pagesCap 3 Dse CutoffAnand KesarkarPas encore d'évaluation

- Change Address Contact Details Email IdDocument1 pageChange Address Contact Details Email IdAnand KesarkarPas encore d'évaluation

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarPas encore d'évaluation

- Maharashtra State Road Transport Corporation Public Online Reservation System TicketDocument1 pageMaharashtra State Road Transport Corporation Public Online Reservation System TicketAnand KesarkarPas encore d'évaluation

- M CR 601r1Document14 pagesM CR 601r1nazari123Pas encore d'évaluation

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Cr10830005 - 3 Heat Exchanger 01Document1 pageCr10830005 - 3 Heat Exchanger 01Anand KesarkarPas encore d'évaluation