Académique Documents

Professionnel Documents

Culture Documents

Sand Filtration Units

Transféré par

Lauren'sclub EnglishBimbel Sd-sma0 évaluation0% ont trouvé ce document utile (0 vote)

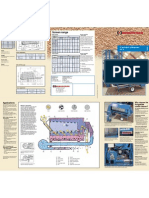

80 vues3 pagesSand filtration units from Airpac Bukom remove sand and solids from well effluent during testing through dual filtration pods containing filter assemblies. The skid-mounted units feature modular design, standard 200 micron cartridges, and quick cleaning. Options include various micron sizes. Flow capacities range from 20 to 50 MM scf/d for gas and up to 5,000 Bpd for liquid.

Description originale:

well done

Titre original

Sand Filtration Units(2)

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSand filtration units from Airpac Bukom remove sand and solids from well effluent during testing through dual filtration pods containing filter assemblies. The skid-mounted units feature modular design, standard 200 micron cartridges, and quick cleaning. Options include various micron sizes. Flow capacities range from 20 to 50 MM scf/d for gas and up to 5,000 Bpd for liquid.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

80 vues3 pagesSand Filtration Units

Transféré par

Lauren'sclub EnglishBimbel Sd-smaSand filtration units from Airpac Bukom remove sand and solids from well effluent during testing through dual filtration pods containing filter assemblies. The skid-mounted units feature modular design, standard 200 micron cartridges, and quick cleaning. Options include various micron sizes. Flow capacities range from 20 to 50 MM scf/d for gas and up to 5,000 Bpd for liquid.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

Sand Filtration Units

Airpac Bukoms rental fleet of 5,000psig, 10,000psig and

15,000psig sand filtration units improve well analysis

during testing operations through the effective removal of

sand and other solids from the well effluent.

The sand filter consists of two vertical vessels, each vessel

holding one inner filter assembly. The two filtration pods are

controlled individually allowing for either single or dual pot

operation. Normally, one vessel is in use, in order to

facilitate cleaning of the other.

The unit is skid mounted and complete with inlet and outlet

manifolding, double gate valves on the downstream side and

connections to register differential pressure across

filters. Each sand filter is supplied with an extensive spares

package and fully equipped tool box.

Features and Benefits

> Modular and rugged filter design

> Standard 200 micron filter cartridge supplied

> Annular flow and sand storage

> Safe & quick cleaning features

> Vertically positioned gate valves (to avoid gate

obstruction)

> Fitted with back up valves

> No post-frac clean up required, production starts

immediately through the facilities

Options

> A range of micron screen sizes are available on

request.

5,000psig - 15,000psig

www.airpacbukom.com 1

5,000psig - 15,000psig

Filtration System

The stainless steel mesh filter consists of one element,

which is mounted concentrically. Opposite to the laser cut

screen, the mesh screen filter has more slots. The filter

assembly element can be altered in an early manufacturing

stage, if required by the application.

Advantages:

> Minimum mesh size 50 Micron

> Filter collapse pressure <100barg

> Maximum OD 14 inch

> Gas flow capacity

5,000psig up to 20 MM scf/d

10,000psig up to 35 MM scf/d

15,000psig up to 50 MM scf/d

> Liquid flow capacity up to 5,000 Bpd

Flow capacity is dependant on filter element mesh size,

viscosity and the amount of pollution. The inner filter

elements are designed to stop sand/debris transport,

without obstructing liquid and or gas flow through the unit.

Gas velocities across the filter elements are greatly reduced,

minimising actual filter wear and increasing its life span.

Cleaning

The 5,000psig and 10,000psig units have a series of high

pressure water injection nozzles positioned on the outer

vessel diameter, to facilitate sand removal between vessel

and filter element. The sand/water mixture exits the vessel

through 2" flow points, positioned on the bottom side of the

vessel. Cleaning time per vessel approx. 15 minutes.

On the 15,000psig units cleaning is effected by using the

2

1

/

16

" manual choke to remove the sediment out of the

vessel. The filters are emptied by removing the screens out

of the top of the vessels, utilising the air operated hoist and

after which the sand can be removed and the screen

inspected.

Filter element removal is not required during operations.

If at a point the filter element requires inspection or

replacement due to physical wear, the entire element can be

retrieved from the outer vessel top-end.

Containerised Tool Box

Transportation of Sand Filter

www.airpacbukom.com 2

Technical Specifications

Sand Filtration Units (5,000psig, 10,000psig & 15,000psig)

Performance

*Sand Filtration Unit 5,000psig 10,000psig 15,000psig

Overall Length (Operational) 2680mm 2500mm

Overall Width (Operational) 2400mm 2500mm

Overall Height (Operational)

4200mm

(with lifting beams extended max. 7500mm)

4300mm

(with lifting beams extended max. 7500mm)

Weight 9500kgs

15000kgs

**Tool Box Caged Containerised DNV 2.7-1

Dimensions 2310 x 1300 x 1470mm 1829 x 1524 x 2438mm

Weight 5000kgs 6000kgs

Weights & Dimensions

Model 5,000psig 10,000psig 15,000psig

Working Pressure 5,000psig 10,000psig 15,000psig

Flow-line connections 3

1

/

8

" Flange 3

1

/

16

" Flange 3

1

/

16

" Flange

Gas Flow capacity 20 MM scf/d 35 MM scf/d 50MM scf/d

Liquid flow capacity 5,000 Bpd 5,000 Bpd 5,000 Bpd

Holding capacity per vessel 180 effect litres 180 effect litres 100 litres

Vessel O.D Up to 14 - 16" Up to 14" 14

Filter Element O.D 4 4 6

Filter Mesh Sizes (wire screen) 50 - 800 Microns

Differential Pressure Across the Filter Element 1 barg (clean and empty) in use advised max. 25 barg

Filter Collapse Pressure <100barg 180barg

Inlet Connection 3 1502 Weco Union 4 2202 Weco Union

Flush Line Inlet 2 1502 Weco Union 2 1502 Weco Union n/a

Flush Line Outlet 2 1502 Weco Union (x2) 2 1502 Weco Union (x2) 2 2202 Weco Union (x1)

Temperature class Standard up to 250F

Design Code

ASME & API 6A

Certification Authority Det Norske Veritas

Service

Sour (H

2

S) service, Per NACE MR-01-75 latest rev.

* Sand Filtration Units must be transported horizontally. Transportation dimensions for 5K & 10K (L) 4200mm x (W) 2400mm x (H) 2680mm

Transportation dimensions for 15K (L) 4300mm x (W) 2500mm x (H) 2500mm

** Tool Box - weights and dimensions of the Sand Filter Tool Box will be provided on application.

N 31971 N 31971

Aberdeen, UK Great Yarmouth, UK Singapore Australia Sharjah, U.A.E. Curaao, Netherlands Antilles

t: +44 (0) 1224 715 008 t: +44 (0) 1493 652 732 t: +65 6861 5961 t: +61 8 9418 2177 t: +971 6 557 8283 t: +599 9 868 2599

f: +44 (0) 1224 714 290 f: +44 (0) 1493 657 385 f: +65 6861 5962 f: +61 8 9418 2166 f: +971 6 557 8284 f: +44 (0) 1224 714 290

e: airpac.rentals@vpplc.com e: airpac.rentals@vpplc.com e: airpac@singnet.com.sg e: cwootton@airpac.net.au e: sharjah@vpplc.com e: airpac.rentals@vpplc.com

Airpac Bukom Oilfield Services Aberdeen office is certified to

BS EN ISO 9001:2008 & BS EN ISO 14001:2004

Supplier No. 10044388

E. & O.E. Airpac Bukom Oilfield Services 2013

A division of Vp plc

05.02.13

Vous aimerez peut-être aussi

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Sand Filtration Units150Document3 pagesSand Filtration Units150Smriti PrasadPas encore d'évaluation

- Dual-Pot Sand Filter Type A (DSF-A)Document2 pagesDual-Pot Sand Filter Type A (DSF-A)Balaji SelvarajPas encore d'évaluation

- Filter Separator English LetterDocument2 pagesFilter Separator English Lettermarcoo8Pas encore d'évaluation

- (PEHP7077-05) Turbine PreCleanerDocument4 pages(PEHP7077-05) Turbine PreCleanervictor.ciprianiPas encore d'évaluation

- Filtration SystemDocument11 pagesFiltration Systemwaleed.murad@gmail.comPas encore d'évaluation

- Filtomat M100-6800 - GRPDocument17 pagesFiltomat M100-6800 - GRPJose Angel Malpica PPas encore d'évaluation

- Mobile Grain CleanerDocument2 pagesMobile Grain CleanerDulguunkherlen BudkhandPas encore d'évaluation

- RACOR 500FG Turbine SeriesDocument8 pagesRACOR 500FG Turbine Serieswarrimaint2Pas encore d'évaluation

- Dual-Pot Sand Filter Type B (DSF-B)Document2 pagesDual-Pot Sand Filter Type B (DSF-B)kanchanabalajiPas encore d'évaluation

- Toro Equipment Filter Press Draco PDFDocument12 pagesToro Equipment Filter Press Draco PDFAlfredo CollantesPas encore d'évaluation

- Eurovac High Volume Collector PackageDocument15 pagesEurovac High Volume Collector PackageDaniel AustinPas encore d'évaluation

- Dual Pot Sand Filter PsDocument2 pagesDual Pot Sand Filter PskanchanabalajiPas encore d'évaluation

- SeriesDocument4 pagesSeriesteguheafPas encore d'évaluation

- Micron S602 ECODocument4 pagesMicron S602 ECOTan Kang YaoPas encore d'évaluation

- HFD Catalog BGT PDFDocument6 pagesHFD Catalog BGT PDFPartsGopher.comPas encore d'évaluation

- HFD Catalog CN PDFDocument13 pagesHFD Catalog CN PDFPartsGopher.comPas encore d'évaluation

- Sand Filters Datasheet PDFDocument2 pagesSand Filters Datasheet PDFJamesStenhousePas encore d'évaluation

- STP 125 KLDDocument9 pagesSTP 125 KLDAbhay SisodiaPas encore d'évaluation

- Roto Rainer 2011Document8 pagesRoto Rainer 2011sunilbholPas encore d'évaluation

- 15P/30P Series: High Pressure FiltersDocument12 pages15P/30P Series: High Pressure FiltersPartsGopher.comPas encore d'évaluation

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HDocument13 pagesCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitPas encore d'évaluation

- Wellhead Plug Catcher (WPC)Document2 pagesWellhead Plug Catcher (WPC)Wade DavisPas encore d'évaluation

- Cim-Tek CLMDocument14 pagesCim-Tek CLMAgung WidodoPas encore d'évaluation

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009Pas encore d'évaluation

- Rev D 900FH and 1000FH Turbine FiltersDocument12 pagesRev D 900FH and 1000FH Turbine FiltersJan AhmedPas encore d'évaluation

- Bestec Oil InterceptorsDocument6 pagesBestec Oil InterceptorsSai PrasathPas encore d'évaluation

- RAF Baghouse Filter MikropulDocument4 pagesRAF Baghouse Filter MikropulCharik JainPas encore d'évaluation

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićPas encore d'évaluation

- HighStrengthFAST 1.00 FAST UnitDocument4 pagesHighStrengthFAST 1.00 FAST UnitmutazsalihPas encore d'évaluation

- Dal Am A TicDocument12 pagesDal Am A TicMiguelAngelDavilaPas encore d'évaluation

- 21 20Document1 page21 20Renata ReljacPas encore d'évaluation

- Filtro de Vapor SPIRAX SARCODocument4 pagesFiltro de Vapor SPIRAX SARCOmaurozuriPas encore d'évaluation

- Draco Filter PressDocument12 pagesDraco Filter Presscepong89Pas encore d'évaluation

- SPT High Efficiency Phase Separation Internals BrochureDocument8 pagesSPT High Efficiency Phase Separation Internals BrochurefunctionlakePas encore d'évaluation

- PR BW600Document8 pagesPR BW600tata_77Pas encore d'évaluation

- E Entsorgung-Brikettierpresse Briquetting Presses 03Document8 pagesE Entsorgung-Brikettierpresse Briquetting Presses 03Dragan BogdanPas encore d'évaluation

- 3-Vertical Cuttings Dryer System GNCD930Document12 pages3-Vertical Cuttings Dryer System GNCD930GeorgePas encore d'évaluation

- Wet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersDocument17 pagesWet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersAlvaro MathisonPas encore d'évaluation

- Kiekens Dustmaster: Type Cartridge FilterDocument2 pagesKiekens Dustmaster: Type Cartridge FilterYasinYıldızPas encore d'évaluation

- Filter CartDocument28 pagesFilter Cartdavethebox100% (1)

- VERTI-G Cuttings DryerDocument4 pagesVERTI-G Cuttings DryerLoganBohannon100% (1)

- TDS-Dualpotsandfilter 10K HT-HFDocument3 pagesTDS-Dualpotsandfilter 10K HT-HFBambang Yan ArdiantoPas encore d'évaluation

- Specif-Dust Extraction SystemDocument12 pagesSpecif-Dust Extraction SystemChristopher LloydPas encore d'évaluation

- Cascade Air Separator KVT enDocument6 pagesCascade Air Separator KVT enkamjulajayPas encore d'évaluation

- Microfast 0.90 Fast UnitDocument4 pagesMicrofast 0.90 Fast UnitJelena KalcPas encore d'évaluation

- Gansu Qihui Indusry and Trade Co., LTDDocument9 pagesGansu Qihui Indusry and Trade Co., LTDAshfakuzzaman EmuPas encore d'évaluation

- MANUAL DezumidificatorDocument98 pagesMANUAL DezumidificatorcivodulPas encore d'évaluation

- Filtro Tambor RotatorioDocument4 pagesFiltro Tambor Rotatoriocquibajo100% (2)

- Vakuumbandfilter enDocument14 pagesVakuumbandfilter enFrank Vega OrtegaPas encore d'évaluation

- Filtro NiagaraDocument97 pagesFiltro NiagaraLuis Antonio Chiapas Garcia100% (2)

- Baker Hydro Top MountDocument2 pagesBaker Hydro Top MountBakerHydroPas encore d'évaluation

- S5000 Sandfilter ManualDocument20 pagesS5000 Sandfilter ManualAdam MesserPas encore d'évaluation

- Cuno ZPC Zeta Plus Sanitary HousingDocument4 pagesCuno ZPC Zeta Plus Sanitary Housinggeorgadam1983Pas encore d'évaluation

- Conder Separator Brochure NewDocument8 pagesConder Separator Brochure Newednavilod100% (1)

- Filtro de AireDocument7 pagesFiltro de AirejlfyPas encore d'évaluation

- Ceramic Filter-Installation InstructionDocument57 pagesCeramic Filter-Installation InstructionKasjdkasd AksdjasdjPas encore d'évaluation

- Mobile Dual Spin-On SeriesDocument4 pagesMobile Dual Spin-On SerieseliasjrodriguezPas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Risk Register Assmt v1Document24 pagesRisk Register Assmt v1Agus Dohardo ManaluPas encore d'évaluation

- REPORT of Retractable KnivesDocument1 pageREPORT of Retractable KnivesLauren'sclub EnglishBimbel Sd-smaPas encore d'évaluation

- Load Chart Crane LiftingDocument25 pagesLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Specifications & Load Charts: 40 Ton Tele-Boom Crawler CraneDocument16 pagesSpecifications & Load Charts: 40 Ton Tele-Boom Crawler CraneLauren'sclub EnglishBimbel Sd-smaPas encore d'évaluation

- 2000 Rigsafe Air Booster CompressorDocument2 pages2000 Rigsafe Air Booster CompressorLauren'sclub EnglishBimbel Sd-sma100% (1)

- Portable Ladder and Inspection ChecklistDocument1 pagePortable Ladder and Inspection ChecklistLauren'sclub EnglishBimbel Sd-smaPas encore d'évaluation

- Managing Asbestos in Buildings:: Who Is This Guidance For?Document10 pagesManaging Asbestos in Buildings:: Who Is This Guidance For?Lauren'sclub EnglishBimbel Sd-smaPas encore d'évaluation

- Ijet V3i6p54Document6 pagesIjet V3i6p54International Journal of Engineering and TechniquesPas encore d'évaluation

- Winter Internship Report (23/09/2016 - 31/01/2017)Document56 pagesWinter Internship Report (23/09/2016 - 31/01/2017)AyushPas encore d'évaluation

- Wireless - How Can I Tell If An RF Transmitter Is Transmitting - Electrical Engineering Stack ExchangeDocument2 pagesWireless - How Can I Tell If An RF Transmitter Is Transmitting - Electrical Engineering Stack ExchangeAkhil Paul VPas encore d'évaluation

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- Conjoint SpssDocument28 pagesConjoint SpssstatsoumyaPas encore d'évaluation

- Software TestingDocument4 pagesSoftware TestingX DevilXPas encore d'évaluation

- Ex Delta Ex Delta - Dia: OVAL CorporationDocument8 pagesEx Delta Ex Delta - Dia: OVAL CorporationDaniela GuajardoPas encore d'évaluation

- Technical Information: Chemical Resistance ChartDocument7 pagesTechnical Information: Chemical Resistance ChartthessandPas encore d'évaluation

- DVMDocument197 pagesDVMLeonardLapatratPas encore d'évaluation

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4Document4 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4Muthu KumarPas encore d'évaluation

- Treatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityDocument25 pagesTreatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityAbsharinaPas encore d'évaluation

- Mastering Microcontrollers Helped by ArduinoDocument23 pagesMastering Microcontrollers Helped by ArduinoMeri Terihaj100% (2)

- L18 PDFDocument8 pagesL18 PDFrashmi sahooPas encore d'évaluation

- Rubber FaberDocument10 pagesRubber FabersoldatechPas encore d'évaluation

- Op Amp TesterDocument2 pagesOp Amp TesterPhay KhamPas encore d'évaluation

- Velocloud OverviewDocument29 pagesVelocloud OverviewFebri RawlinsPas encore d'évaluation

- Constraints in DBMS - Types of Constraints in DBMS - Gate VidyalayDocument5 pagesConstraints in DBMS - Types of Constraints in DBMS - Gate VidyalayBivek Man SinghPas encore d'évaluation

- Chapter 2 Magnetic Effects of Current XDocument25 pagesChapter 2 Magnetic Effects of Current XPawan Kumar GoyalPas encore d'évaluation

- The Importance of Subscale Jet Engine TestingDocument8 pagesThe Importance of Subscale Jet Engine TestingKKayPas encore d'évaluation

- On-Farm Composting Methods 2003 BOOKDocument51 pagesOn-Farm Composting Methods 2003 BOOKlalibPas encore d'évaluation

- Jrules Installation onWEBSPHEREDocument196 pagesJrules Installation onWEBSPHEREjagr123Pas encore d'évaluation

- LM6 AluminiumDocument4 pagesLM6 AluminiumRajaSekarsajjaPas encore d'évaluation

- Clevo M620ne-UDocument34 pagesClevo M620ne-UHh woo't hoofPas encore d'évaluation

- DRM Transmitter PresentationDocument22 pagesDRM Transmitter PresentationJuan Jose PerezPas encore d'évaluation

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDocument39 pages02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezePas encore d'évaluation

- Head Office:: Speciality Urethanes Private LimitedDocument9 pagesHead Office:: Speciality Urethanes Private Limitedashsatao8929Pas encore d'évaluation

- 2ND 3RD Typical Floor Plan PDFDocument1 page2ND 3RD Typical Floor Plan PDFSamuel ZaraPas encore d'évaluation

- Communicating With Instromet Q-Sonic Ultrasonic Gas FlowmetersDocument13 pagesCommunicating With Instromet Q-Sonic Ultrasonic Gas Flowmeterssyed jeelani ahmedPas encore d'évaluation

- University of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: PhysicsDocument18 pagesUniversity of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: Physicsdbhansali57Pas encore d'évaluation

- MB m.2 Support Am4Document2 pagesMB m.2 Support Am4HhhhCaliPas encore d'évaluation