Académique Documents

Professionnel Documents

Culture Documents

Timeline Casting

Transféré par

Cam MillerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Timeline Casting

Transféré par

Cam MillerDroits d'auteur :

Formats disponibles

76 ENGINEERED CASTING SOLUTIONS SPRING 2002

S

Timeline of Casting Technology

Our world could not have advanced

at its rapid rate without the

strength, endurance and

ingenuity of the foundryman.

With a history set in motion before the dawn of man, metalcasting was the very cornerstone

of humankinds emergence from the Dark Ages and its continued prosperity today.

Michael J. Lessiter, Editor/Publisher

Ezra L. Kotzin, American Foundry Society (retired)

ince the discovery of the earths minerals, metalcasting has played

an important role in society. An integral part of every technologi-

cal advance, castings have allowed us to build equipment to feed our

people, fight for democracy, build infrastructure and manufacture cars,

trains and airplanes. In general, castings have beenand will continue

to bethe key ingredient in the recipe for a better way of life.

Metalcasters have long been respected and eminent craftsmen in

every community. In many cases, their heroics extended far beyond

the utilization of molten metal in creating usable products. They

have been soldiers, statesmen and inventorsand have reshaped

North America with a first-class, working labor force that produces

goods for the world. In fact, the conception of the U.S.not to

mention the spread of democracy worldwidewas set into motion

by seven foundrymen who signed the Declaration of Independence

from Great Britain in 1776.

During the wars of medieval times, foundrymen produced can-

nons. In peace, they recast the metal back into bells. In the early

Middle Ages, church bells were cast in churches by priests, abbots or

bishops who were also trained metal founders. As the metal was

melted, the brethren stood around the furnace intoning psalms and

prayers. The molten metal was then blessed and divine protection

was asked for the bell, which usually bore the name of a saint.

The 20

th

century saw the explosive refinement of processes

and mat er i al s us ed i n t he

f oundr y f or more t han 400

years. Vannoccio Biringuccio,

the 16

th

century father of the

f oundr y i ndus t r y, recom-

mended using the dregs of beer

vats and human urine as bind-

ers for molding sand, both of

which were in use well into the 1900s.

There has been more casting progress since World War II than

in the previous 3000 years, wrote Bruce L. Simpson in History of the

Metalcasting Industry. Still, the demand goes on for foundries to sur-

pass themselves in quantity and quality. Metalcasting remains a basi-

cally essential industry, as necessary to space vehicles as it was to

mankinds very first machines. As science is applied more and more, so

the skill, education and pay of foundrymen goes up and ever up, in-

creasing in turn the total wealth of the world.

There is no better example of the true creation of national wealth

than the work of the foundryman. He takes a raw material and through

both art and science, creates a product that adds direct value to our

societys ever-progressing way of life.

Beyond the fact that castings are all around us (it is often said

one is never more than 10 ft from a casting), metalcasting was eco-

logically friendly long before it was in vogue. Known as the original

recycler, the foundry industry gives a new useful life to as many as

15 million tons of scrap metal each year that would otherwise be

rendered useless.

From its contributions in providing jobs and employee skills to

delivering the dependable, high-quality and cost-effective compo-

nents necessary to advance technology, metalcasting has impacted

virtually every improvement seen by each passing generation. Sim-

ply put, our world could not have

advanced at its rapid rate without

the strength, endurance and inge-

nuity of the foundryman.

Following are some of the key

technological events that have

changed the face of the casting

process and its end products.

Discovery of molten metal

(copper beads in fire)

B.C.

9000 B.C.Earliest metal objects of

wrought native copper are produced in

the Near East.

3000-2500 B.C.Small objects are cast

via lost wax (investment casting) pro-

cess in the Near East.

3200 B.C.The oldest casting in existence,

a copper frog, is cast in

Mesopotamia.

3000 B.C.Early foundrymen

cast bronze tools and

weapons in permanent

stone molds.

1500 B.C.Wrought iron is

discovered in the Near East.

600 B.C.The first cast iron

object, a 600-lb tripod, is

cast by the Chinese.

233 B.CIron plowshares

are cast.

200 B. C. Ol des t i ron

castings still in existence are pro-

duced during the Han Dynasty.

A.C.

500Cast crucible steel is produced

in India.

1200sLoam or sweep molding is used by

European foundrymen to cast bells for

cathedrals.

1252The colossal statute, the Great

Buddha at Kamakura, Japan, is cast

i n hi gh-l ead ti n bronze. The

project began in the 700s

and i t s head al one

weighed 140 tons.

1313The first can-

non is cast in bronze

by a monk in the city

of Ghent.

1400sDuring the siege

of Constantinople, heavy

guns are cast from bronze

on the spot, virtually

under the walls of the be-

sieged city Movable, cast lead type for

printing presses revolutionizes the

worlds methods of communication.

1480Vannoccio Biringuccio (1480-

1539), the first true foundryman and

the father of the foundry industry, is

born. The founder of the Vatican, his

De La Pirotechnia is the first written

account of proper foundry practice.

1500sSand is introduced as a molding

material in France.

1600s

1612Mined from under the sea, seacoal

is mentioned for the first time by Ger-

man foundryman and inventor, Simon

Sturtevant.

1619North Americas first iron furnace is

built at Falling Creek, VA, a branch of the

James River, 60 miles from Jamestown

colony. Three years later, Native Ameri-

cans destroy it during a raid.

1645Earliest recorded use of term

foundry appears in the Oxford English

Dictionary in its variant founderie.

1646Americas first iron foundry (and sec-

ond industrial plant), Saugus Iron Works,

SUMMER 2002 ENGINEERED CASTING SOLUTIONS 77

Cast copper frog,

3200 B.C.

Early iron foundry

Saugus pot, 1642

near Boston, pours the first American cast-

ing, the Saugus pot. The Saugus River site

was selected by Richard Leader and was

built to produce iron products for Massa-

chusetts and England.

1661First U.S. copper deposits are dis-

covered by Gov. Wi nthrop i n

Middletown, CT.

1700s

1709Two developments by Abraham

Darby, Coalbrookdale, England, improve

casting methods. He developed the first

true foundry flask to modernize mold-

ing practices (which had been carried

out in pits on the floor by use of pat-

tern boards tied together or in crude

box frames). He would later initiate

the use of coke as a furnace fuel for

iron production.

1722A.F. de Reamur, recognized as the

worlds first metallurgical chemist, devel-

ops first malleable iron, known today as

European Whiteheart malleable.

1750Benjamin Huntsman reinvents the

cast crucible steel process in England, a

process that disappeared after first being

developed in IndiaThe English

parliament prohibits the refining

of pig iron or the casting of iron

in the American colonies, con-

tributing to the American

Revolution.

1756Coalbrookdales Richard

Reynolds oversees the inven-

tion of cast iron tram-road

rails, replacing wooden rails.

1775Revolutionary patriot Paul

Revere, who operated a bell-

and-fittings foundry in Bos-

ton, rides from Boston to Lex-

ington warning colonists of the

British invasion.

1776Foundrymen Charl es

Carroll, James Smith, George

Taylor, James Wilson, George

Ross, Philip Livingston and Stephen

Hopkins sign the American Declara-

tion of Independence.

1779First iron bridge ever erected (above

Englands Severn River) was cast and

constructed at Coalbrookdale Works.

1794Englishman John Wilkinson invents

the first metal-clad cupola furnace, using

a steam engine to provide the air blast.

1797First cast plow in U.S. is invented by

Charles Newbold, Sauk, NJ.

1800s

1809Centrifugal casting is developed by

A.G. Eckhardt of Soho, England.

1815Cupola is introduced to the U.S.

(Baltimore).

1817First iron water line in the U.S., 400

ft long, is laid in Philadelphia.

1818First U.S. cast steel is produced by

the crucible process at historic Valley

Forge Foundry.

1825Aluminum, the most abundant

metal in the earths crust, is isolated

from al umi num chl ori de by

Denmarks Hans Oerstad.

1830sSeth Boyden, Newark, NJ, pro-

duces U.S. first blackheart mal-

leable iron.

1837First reliable molding ma-

chine on market is made and

used by S. Jarvis Adams Co.,

Pittsburgh.

1832Nickel-bronze is produced

commercially in England.

1847Cast steel guns are

made by Krupp Works in

GermanyAsa Whitney,

Phi l adel phi a, obtai ns a

patent on a process for an-

neal i ng chi l l ed-i ron car

wheel s cast wi th chi l l ed

tread and flange.

1847John Deere commissions

Jones and Quiggs Steel Works,

Pittsburgh, to cast and roll a

steel plow, which it accomplishes at one-

half the products previous cost.

1849A manually operated diecasting ma-

chine is patented to supply rapidly cast

lead type for newspapers.

1850The drop-bottom cupola is

developed.

1863Metallography is developed

by Henry C. Sorby, Sheffield, En-

gland, enabling foundrymen to

polish, etch and microscopically

examine metal surfaces for physi-

cal analysis.

1867James Nasmythe, inven-

tor of the steam hammer, devel-

ops a gear-tilted safety ladle to

prevent pouring accidents.

1870Sandblasting is developed

for large castings by R.E. Tilghman

of Philadelphia.

1874The Colliau cupola, the

first commercially made cupola

in America, is introduced.

1876The first authenticated aluminum cast-

ings were produced by Colonel

William Frishmuth at his Philadel-

phia foundry. Assembled to pro-

duce an engineers transit, these

castings were made from

$1/oz chemically produced

aluminumManganese-

bronze patent is granted to

Parsons in England. Tobin

Bronze develops manganese-

bronze in U.S.

1880-87W.W. Sly, Cleveland,

develops the first casting

cleaning mill, greatly reduc-

ing hand-chipping and

grinding to allow a custom-

finished product.

1884The first architectural application

of aluminum, a cast aluminum pyra-

mi d produced by Col . Wi l l i am

Frishmuth, is mounted on the tip of

the Washington Monument.

1886Charles M. Hall, a 22-year-old student

at Oberlin College, discovers a process of

aluminum reduction through electroly-

sis. The invention replaced chemi-

cal reduction and lowered the

metals cost (from $15/lb in

1884 to $0.50/lb in 1890), spur-

ring a new industry of alumi-

num applications.

1887Eli Millett invents a

core oven for drying small

cores in individual drawers.

1890The first motor-driven

mold conveyor is installed, in-

tegrating molding, pouring and

cooling operations.

1897Iowa dentist B.F.

Philbrook adapts the lost-wax

investment casting process for

producing dental inlays, the

process first non-art application

of the modern metalcasting age.

1898Poulson and Hargraves (U.K.) pro-

duce the first sand molds bonded with

sodium silicateGermanys Imperial

Navy recommends copper-nickel alloys

containing 4-45% Ni for salt-water pip-

ing system.

1899Electric arc furnace, developed by

Frances Paul Heroult, begins commer-

cial production.

1900s

1900Brinnell hardness test machines are

introducedAluminum-bronze begins

regular production in the U.S.

Early 1900sFirst patent for low-pressure

permanent mold casting process is issued

to Englands E.H. Lake.

1901American Steel Foundries (St.

Louis) produces the first centrifugal

cast rail wheels.

1903The Wright Brothers first successful

machine-powered aircraft contains a cast

aluminum block and crankcase (together

weighing 152 lb), produced either at Mi-

ami Brass Foundry or the Buckeye Iron

and Brass Works.

1905H.H. Doehler patents the

diecasting machine.

1906The first electric arc furnace

is installed in U.S. at Halcomb Steel

Co., Syracuse, NY First low-fre-

quency induction furnace is in-

stalled at Henry Diston & Sons,

Tacony, PA.

1907Alfred Wilm discovers that

the properties of cast aluminum

alloys can be enhanced through

heat treating and artificial aging.

1908Stockham Homogenous

Sand Mixer Co., Piqua and New-

ark, OH, releases the sand cutter.

1910s

1910Matchplates are developed, fostering

78 ENGINEERED CASTING SOLUTIONS SUMMER 2002

Foundry conveyor,

1890

Lost Foam Pattern, 1950s

the viability of jolt-squeeze machines.

1911Metallurgical microscope is

obtainableFirst electric arc furnace for

metalcasting is installed at Treadwell En-

gineering, Co., Easton, PA.

1912The first muller with individually

mounted revolving mullers of varying

weights is marketed by Peter L.

SimpsonSand slinger is invented by E.O.

Beardsley & W.F. Piper, Oregon Works.

1915Experimentation begins with bento-

nite, a colloidal clay of unusually high green

and dry strength Ajax Metal Co., Phila-

delphia, installs first low-frequency induc-

tion furnace for nonferrous melting.

1916Dr. Edwin Northrup, Princeton Univ.,

invents the coreless induction furnace.

1917Alcoa completes a great deal of early

development work in aluminum as World

War I generates great demand for high-in-

tegrity castings for aircraft engines.

1918The first fully automated foundry in

Rockford, IL, casts hand grenade

hulks for the U.S. Army.

1920s

1921Modification of the sili-

con structure in aluminum

begins as Pacz discovers

that adding metallic so-

dium to molten aluminum

just prior to pouring greatly

improves ductility Cop-

per-silicon alloys are pre-

pared in Germany as a sub-

stitute for tin bronzes.

1924Henry Ford sets pro-

duction record of 1 mil-

lion autos in 132 working

days. Automotive manu-

facturing will grow to consume one-third

of casting demand in the U.S.

1925X-ray radiography is established as

a tool for checking casting quality. By

1940, all military aircraft castings re-

qui re x-ray i nspecti on pri or to

acceptanceAmerican Brass, Water-

bury, CT, installs first medium-fre-

quency induction furnace in the U.S.

1928Alcoa develops the first aluminum

vehicle wheel, a sand-cast 355 alloy de-

signed for truck trailers.

1930s

1930First high-frequency coreless electric

induction furnace is installed at

Lebanon Steel Foundry, Lebanon,

PASpectrography is pioneered by

Univ. of MI professors for metal

analysisDavenport and Bain develop the

austempering process for iron castings.

1937ARL founder Maurice Hasler pro-

duces the first grating spectrograph for

the Geological Survey of California.

Spectrometers begin finding their way

into foundries by the late 1940s, replac-

ing the previous practice of metallurgists

estimating chemical compositions with

a spectroscope and welders arcThe

austempered microstructure in

cast iron is recognized.

1940s

1940Chvorinov develops

the relationship between

solidification time and

casting geometry.

Early 1940sStatistical

process control is first

employed as a quality

control tool in U.S.

machine shops, principally

to control dimensional

tolerancesInoculation of

gray iron becomes common, as high

quality cast irons replace scarce steel.

1941U.S. Lt. Col. W.C. Bliss tells the

AFS St. Louis Chapter that the side

which maintains the larger production

of war goods is going to win the war.

The War Production Board reports

later that each U.S. soldier requires

4900 lb of steel compared to 90

lb in World War I.

1942The use of synthetic

sands increases as a replacement

for many war materials.

1943Keith Millis, a 28-year-

old metallurgist working at

INCO searching for a replace-

ment to chrome due to inter-

rupted supply, discovers that

magnesium alloy in molten

iron produces a spheroidal

graphite structure. In 1949,

he, Albert Gagnebin and

Norman Pilling would receive

a U.S. patent on ductile iron

production via magnesium treatment.

1944The first heat-reactive, chemically-

cured bi nder i s devel oped by

Germanys Johannes Croning to rap-

idly produce mortar and artillery shells

for Axis troops during World

War II. Two years after the

war, his shell process is

discovered among other

inventions in the Ger-

man patent office and

made public. Croning is

recognized with an AFS

Gold Medal in 1957 for

his invention.

1946Allied investigators

uncover German foundry

research on high tem-

perature alloysHaving

heard of the Croning dis-

covery (prior to the re-

lease of the report), Fords Ed Ensign and

E.I. Valyi, Navy Bureau of Ships, at-

tempted to replicate the process and pro-

duced shell-molded castings at Midwest

Foundry, Coldwater, MI.

Late 1940sThermal sand reclama-

tion is applied to core sands and, to

a l i mi t ed degree, cl ay-

bonded sands.

1948First non-labora-

tory ductile iron casting is

produced at Jamestown

Mal l eabl e Iron Co. ,

Jamestown, NY, as a

66-i n. test bar i s

pouredIndustrys first

ductile iron pipe is cast at

Lynchburg Foundr y,

Lynchburg, VA.

1949Keel blocks, diesel

engine parts, a pressure cyl-

inder, an 8-in. cube and two

cylinder liners become duc-

tile irons first commercial castings

at Cooper-Bessemer, Grove Ci t y,

PADevelopment of magnesium-fer-

rosilicon makes ductile iron treatment

far easierBuffalo Pipe & Foundry

Co., Tonawanda, NY, is the first U.S.

operati on to pour cast i ngs usi ng

Cronings shell process.

1950s

Early 1950sExperimentation in high-

pressure molding begins, as foundrymen

begin to increase the air pressure in air

squeeze molding machines to increase

mold hardness (density)Fast-drying

core oils are introducedThe pneumatic

scrubber is developed to reclaim clay-

bonded sands. Several wet reclamation

systems are also in operation.

1951Ford Motor Co. converts 100% of its

crankshaft production to ductile iron.

1952D Process is developed for making

shell molds with fine sand and fast dry

oil by Harry DietertSodium-silicate/

CO

2

system is introduced.

1953Hotbox system of making and cur-

ing cores in one operation is devel-

oped, eliminating the need for dielec-

tric drying ovens.

1954The CO

2

process, a novel

mold and coremaking

process, is introduced from

GermanyWorking closely

with General Motors, B&P

develops a method for coat-

ing individual sand particles

with resin binder. It also in-

troduces a coreblower ca-

pable of producing cores

with resin-coated shell

sanda modification to the

Croning process.

1955Peoples Gas of Chi-

cago is the first to install

ductile iron gas mains.

Mid-1950sSqueeze casting process origi-

nates in Russia.

1956First Betatron is installed in U.S.

foundry at ESCO Corp., Portland, OR, for

radiography of heavy steel castings.

1957The vertically-parted flaskless green

sand molding machine is invented by

Signers of Declaration of

Independence, 1776

SUMMER 2002 ENGINEERED CASTING SOLUTIONS 79

Matchplate Molding

Machine, 1960s

Prototype Vertically

Parted Green Sand Mold

Machine, 1959

Shell Core Machine, 1950s

Vagn Aage Jeppesen, a 40-year-old pro-

fessor at the Technical University of Den-

mark. He was granted a patent in 1959,

which was purchased by Dansk Industri

Syndikat in 1961.

1958Harold F. Shroyer obtains a patent

for the full mold process, a process de-

veloped by artists in which simple pat-

terns and gating systems are carved

from expanded polystyrene and placed

into a green sand mold. The process,

known today as lost foam casting (us-

ing loose, unbonded sand), is patented

a short time laterPhenolic and fu-

ran acid-catalyzed nobake binder sys-

tems are introducedDuctile iron

desulfurization via shaking ladles is de-

veloped in Sweden.

1959General Electric utilizes the Tran-

sient Heat Transfer digital computer

program and successfully applies the

finite difference method to heavy steel

casting production.

1960s

1960Furan hotbox binders are developed

for core productionDeep bed

filters are used commercially

for aluminum casting

at Alcoa and British

Aluminum in the

U.KCompactibility and

methylene blue clay tests

are developed for green

sand control.

1961Alcohol-borne shell

coating process is intro-

duced (warm-coated).

1962New CO

2

sand test-

ing method is intro-

duced for sands bonded

with sodium silicate and

cured with CO

2

Beardsley & Pipers Al

Hunter, Bob Lund and Angello Bisinello

develop the first automated green sand

molding machine. In their design, the

cope and drag are side-blown simulta-

neously and then hydraulically squeezed.

The birth of automated matchplate

molding reportedly improved foundry

productivity by levels as much as 60% in

a short amount of timePhenolic hot-

box binders introduced.

1963Shell flake resin is introduced, elimi-

nating the need for solvents.

1964Dell & Christs paper on mold inocula-

tion spurs the development of many of

todays forms of mold and late stream in-

oculation The first vertically parted green

sand machine (max. 240 molds/hr) is de-

livered to United Danish Iron Foundries in

Frederiksvaerk, Denmark. Early adopters re-

port man-hour per ton improvements on

the order of 50%.

1965Oil urethane nobake binder systems

are used for cores/moldsGeneral

Electrics Jim Henzel and Jack Keverian

predict freezing patterns in large steel

castings via computerCast metal ma-

trix composites are first poured at Inter-

national Nickel Co., Sterling Forest, NY.

1968The coldbox process is introduced by

Larry Toriello and Janis Robins and in-

troduced to the foundry industry by

Ashland Chemical Co. for high-

production coremaking.

Germanys Daimler-Benz

foundry in Mannheim is

the first to run the pro-

cess for automotive

parts. John Deere Silvas

Foundry, Moline, IL, is

the first to use the pro-

cess for mass-produc-

tion in North America.

1969The Chevrolet Vega is

introduced by General

Motors, featuring the

first all-aluminum block with no cast

iron cylinder liners. A total of 2.5 mil-

lion blocks were produced during the

vehicles life cycle.

Late-1960sScanning electron microscope

(SEM) is invented in EnglandThermal

analysis begins to be used in iron found-

ries for the rapid determination of

carbon equivalent and phospho-

rous contents, making it pos-

sible to study the transforma-

tion of an alloy during

coolingManganese Bronze

& Brass Co. and J. Stone & Co.

join to promote nickel-alumi-

num bronze propellers.

1970s

1970The sodium-silicate/

ester catalyzed nobake binder

system is introduced for

cores/moldsSafety-critical

ductile iron steering knuckles are intro-

duced on Chevrolets CadillacA new

phenolic urethane nobake process is in-

troduced by Ashland Chemical, replacing

oil sand dump box operations and sig-

nificantly reducing energy requirements

for core/ mold production throughout

the 1970sDiran Apelians doctoral

work at Massachusetts

Institute of Tech-

nology (MIT) leads

to the develop-

ment of foam fil-

ters for metalcast-

ing by Olin Met-

als. Commercial

ceramic foam fil-

ters will be in use in

foundries by 1974.

1971The vacuum-

forming or V-Process

molding method of using

unbonded sand with the use of a vacuum

is developed in JapanMIT doctoral

candidate David Spencer performs ex-

periments leading to semi-solid molding

(SSM), a process in which a partially fro-

zen metal (fluidity similar to machine oil)

can be poured into a die cavity. Follow-

ing advancement in metal slurry consis-

tencies with Professor Mert Flemings,

Newton Diecasting Co., New Haven, CT,

produces the first semi-solid castings.

1972A 1-lb crankshaft for a

refrigerator compressor pro-

duced at Wagner Castings

(designed and engineered

by Tecumseh) becomes the

first production-volume

austempered ductile iron

(ADI) component. Wagner

also produces first as-cast

ductile iron connecting

rods for passenger cars

CANMET uses real-time radi-

ography to study the flow of

steel in molds Hitchiner Manufactur-

ing, Milford, NH, patents counter-grav-

ity (vacuum) casting process.

1973The first U.S. foundry argon oxygen

decarburization (AOD) unit is installed

at ESCO Corp.

1974Fiat introduces the in-mold process

for ductile iron treatmentThe phe-

nolic urethane nobake binder system is

introduced for mold production.

Mid-1970sAlcoa and Union Carbide com-

mence rotary degassing for wrought alu-

minum. Reading Foundry Products would

apply this technology to aluminum found-

ries in the mid-1980s...Digital codes are

developed to simulate solidification and

fluid flow analysisUltrasonic verification

of ductile iron nodularity is

developedFoundries examine new ben-

eficial reuse routes for spent foundry sand,

leading to applications such as cement and

paving products, bricks and flowable fill.

1976Foote Mineral Co. and BCIRA

(U.K.) develop compacted graphite

ironAcid-slag cupola practices plus

external desulfurization with CaC

2

begin to replace basic slag cupolas.

1977General Motors installs ADI rear dif-

ferential sets in passenger carsThe alu-

mina phosphate nobake binder system,

an inorganic nonsilicate binder, is in-

troduced for mold production.

1978Furan/SO

2

binder sys-

tem is developed for cores/

moldsPolyol urethane

nobake binder system

is introduced for alumi-

num applications.

1980s

Early 1980sTundish

ladle is embraced by

industry as favored practice

of nodul ari zi ng ducti l e

ironThree-dimensional relational

parameters are developed for CAD

solid models.

1981High-production lost foam casting

80 ENGINEERED CASTING SOLUTIONS SUMMER 2002

begins at General Motors Massena, NY,

plant for aluminum cylinder heads.

1982Warmbox binder system is introduced.

1983Air impulse molding process is

developedFree radical cure/SO

2

binder system is introduced.

1984Charles Hull applies

for a patent on stereo-

lithography process.

Other rapid prototyping

techniques emerge

shortly afterPhenolic

ester nobake binder is

introducedThermal

analysis makes break-

through in molten alumi-

num processing for determi-

nation of grain refinement

and silicon modification.

1985Phenolic ester coldbox binder is

developedNew automaker Saturn

makes a strategic decision to select lost

foam process for its aluminum cylinder

blocks and heads and ductile iron crank-

shafts and differential cases.

Mid-1980sComputer solidification soft-

ware is commercializedAmine recy-

cling is introduced to enhance the envi-

ronmental benefits of the amine-cured

coldbox processUbe Machinery intro-

duces first squeeze casting equip-

ment...Aikohs (Japan) flux injection

technology is initiated into U.S. alumi-

num foundry market.

Late 1980s3-D visualization techniques

are developedCaO/CaF

2

desulfuriza-

tion of cupola-melted ductile base

iron begins to replace CaC

2

methodLanxide, Newark, DE, devel-

ops pressureless metal infiltration pro-

cess for particulate-reinforced metal

bodiesMg wire injection method for

ducti l e i ron treatment i s fi rst

testedCasting solidification model-

ing software gains in acceptance, al-

lowing foundries to optimize quality,

production and cost prior to actually

pouring a casting.

1988Rapid prototyping and CAD/CAM

technologies combine in a breakthrough

to shorten tooling development

timeFord adapts Cosworth process pre-

cision sand casting process for high pro-

duction...Metaullics Systems combines

flux injection/rotary degassing technolo-

gies for aluminum processing.

1989IMI (Yorkshire, UK) begins experi-

menting with bismuth as a lead substi-

tute in copper alloys.

1990s

1990Equipment for semi-solid

casting is introduced by Alumax

Engineered Materials and Buhler,

Inc Foseco patents a direct-

pour system that permits casting

production without conventional

gating/risering. Major automotive

application would come in 1995

with CMI Internationals upper in-

take manifoldPrecision sand cast-

ing and casting quality for engine blocks

are improved in mass production by major

automotive companies with the Cosworth

and Zeus processes for aluminum and

the Loramendi Key Core pro-

cess for precision sand cast

iron applications.

1991Dry ice CO

2

pro-

cess is developed for

cleaning coreboxes and

foundry toolingA

noncontact gauge for ac-

curate dimensional

analysis of lost foam pat-

terns and sand cores is

developed through the

AFS Lost Foam Consor-

tium. Eight years later, the

consortium develops an instrument to

measure the gas permeability of lost foam

pattern coatings (which controls flow of

metal and has a dominant effect on cast-

ing quality.)

1993First foundry application of a

plasma ladle refiner (melting and re-

fining in one vessel) occurs at Maynard

Steel Casting Co., Milwaukee.

1994Use of low-expansion synthetic mul-

lite sand for lost foam is patented by

Brunswick Corp., Lake Forest, IL, to en-

able precision casting of large

componentsDelphi Chassis Systems and

Casting Technology Co. begin program on

squeeze-cast aluminum front knuckle, the

first high-volume production (1.5 million

cars) two-cavity squeeze-cast aluminum

conversion of its kind.

Mid-1990sMicrostructure simulation is

developed, contributing to better under-

standing of metallurgy effects and the

prediction and control of mechanical

properties in castings Semi-solid cast-

ing makes commercial inroads and mar-

ket penetration.

1996Cast metal matrix composites (brake

rotors) are used for the first time in a pro-

duction model automobile, the Lotus

EliseEnvironmentally-friendly (fluo-

rine-free) fluxes are developed at the

Worcester Polytechnic Institute and com-

mercialized General Motors Corp. in-

troduces GMBond, a water-soluble

biopolymer-based core sand binder that

is nontoxic and recyclable.

1997AFS Consortium research at

CANMET, Ottawa, Canada, results

in the development and

commercialization of lead-free

copper alloys using bismuth

and seleniumFollowing

tests at the Germanys

Aachen Univ., American

Cast Iron Pipe Co., Bir-

mingham, AL, builds a

continuously operated

electric arc furnace for cast

iron production.

Late 1990sStress and

distortion simulation in-

troduces the benefits of

controlling casting dis-

tortion, reducing residual stresses,

eliminating hot tears and cracking,

minimizing mold distortion and in-

creasing mold life.

2000s

2001NASA and the Dept. of Energy/OIT re-

lease physics-based software tool to accu-

rately predict the filling of expanded poly-

styrene patterns and sand cores as numer-

ous variables are changedMercury Ma-

rine installs North Americas first pressur-

ized lost foam casting line at its new

foundry in Fond du Lac, WI.

Comments on the timeline should be directed to

mlessiter@afsinc.org

Sources of Metalcasting Historical Information

C.F. Walton, T.J. Opar, Iron Castings Handbook, Iron Castings Society, Inc., (1981). J. Gerin Sylvia, Cast Metals Technology, AFS, (1990). E.L. Kotzin, Metalcasting

& Molding Processes, AFS (1981). J.P. LaRue, Basic Metalcasting, AFS (1989). C.A. Sanders and D.C. Gould, History Cast in Metal, AFS, (1976). Proceedings of

1992 Coreless Induction Melting Conference, AFS, (1992). B.L. Simpson, History of the Metalcasting Industry, AFS (1948). J.A. Gitzen, Progress in the Develop-

ment and Utilization of Additives in the Foundry Industry, AFS (1957). 1995 Lost Foam Technology and Applications Conference Proceedings, AFS (1995).

Aluminum: Design and Application (Vol. II), ASM, (1967). High-Pressure Molding, 2nd Edition, AFS (1987). Foundry Trade Journal (Sept. 11, 1986). Metals

Handbook, Ninth Edition, Vol. 15 Casting, ASM International (1988). 1991 AFS International Sand Reclamation Conference, AFS (1991) AFS/CMI Conference on

Green Sand TechnologyProductivity for the 80s, AFS (1983). ADI: The New Benchmark Material video, Applied Process, Inc. 1997 Hoyt Memorial Lecture:

Lost Wax to Lost Foam: Reflections on the Past, Present and Future, E.L. Kotzin, July 1997 MODERN CASTING, p. 42-45. 1999 Charles Edgar Hoyt Memorial

Lecture: From a Monument to the Vega: The Journey of the Aluminum Casting Industry, J.R. Bodine, May 1999 MODERN CASTING, p. 60-63. A Tribute to Keith

Millis and the Unveiling of Ductile Iron 50 Years Ago, October 1998 MODERN CASTING MODERN CASTINGs A Look Back at the 20th Century Series (2000-

2001). Special thanks to Bill Henning, Miller & Co. (retired); Diran Apelian, Worcester Polytechnic Institute; Paul Carey and Jim Archibald, Ashland Specialty

Chemical Co.; Stubbs Davis, Durametal Corp.; Raymond Donahue, Mercury Marine Div.; Matt Granlund, Foundry Systems Control; Roy Lobenhofer, Lobenhofer

Consulting, Inc.; Norris Luther, Luther & Assoc.; Mahi Sahoo, CANMET; Geary Smith, Manufacturers Brass & Aluminum; Bob Voigt, Penn State Univ.; David

Neff, Metaullics Systems, LLC; and Norm Bliss, Ian Kay, Wayne Rasmussen, Steve Robison and Joe Santner, AFS/CMI.

SSM billet, 1971

GMBond-produced

engine block, 1996

Vous aimerez peut-être aussi

- Timeline of Casting TechnologyDocument11 pagesTimeline of Casting TechnologyEr WidodoPas encore d'évaluation

- Timeline of Casting TechnologyDocument5 pagesTimeline of Casting TechnologyAl Engg100% (3)

- Lijevani Viktorijanski NamještajDocument22 pagesLijevani Viktorijanski NamještajJoško BogdanovićPas encore d'évaluation

- History of SteelDocument79 pagesHistory of SteelChrissa100% (2)

- How the Industrial Revolution Transformed Building Materials and ConstructionDocument24 pagesHow the Industrial Revolution Transformed Building Materials and ConstructionHafsah SiddiquaPas encore d'évaluation

- Layout: 4.1 Steel's GenesisDocument2 pagesLayout: 4.1 Steel's GenesisDroffy GuyPas encore d'évaluation

- The Steel StoryDocument48 pagesThe Steel StoryChen Hsiang-ChunPas encore d'évaluation

- Sheet Metal and TinsmithryDocument22 pagesSheet Metal and TinsmithryVictor EvangelioPas encore d'évaluation

- Unit 2: Begining of A New Era Industrial RevolutionDocument27 pagesUnit 2: Begining of A New Era Industrial RevolutionManoj KumarPas encore d'évaluation

- VISLDocument78 pagesVISLKshama Asha SunderPas encore d'évaluation

- Engineering in the Industrial RevolutionDocument18 pagesEngineering in the Industrial RevolutionbalingbinglorieannePas encore d'évaluation

- E. T. Barnum Iron & Wire Works Catalog No. 770Document84 pagesE. T. Barnum Iron & Wire Works Catalog No. 770Ted HaighPas encore d'évaluation

- The Importance of Steel PDFDocument3 pagesThe Importance of Steel PDFahmedd55Pas encore d'évaluation

- The Ilfracombe Iron Ore Bells: Discovery, Smelting, Casting and ProvenanceD'EverandThe Ilfracombe Iron Ore Bells: Discovery, Smelting, Casting and ProvenancePas encore d'évaluation

- Sssssssss DsDocument5 pagesSssssssss DsAsia VelascoPas encore d'évaluation

- The Substance of Civilization: Materials and Human History from the Stone Age to the Age of SiliconD'EverandThe Substance of Civilization: Materials and Human History from the Stone Age to the Age of SiliconPas encore d'évaluation

- TechnologyDocument8 pagesTechnologyStefanus BrianPas encore d'évaluation

- Steam, Steel and Spark: The People and Power Behind the Industrial RevolutionD'EverandSteam, Steel and Spark: The People and Power Behind the Industrial RevolutionPas encore d'évaluation

- History of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Document584 pagesHistory of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Artisan Ideas75% (4)

- Earth Metalpdf PDFDocument2 pagesEarth Metalpdf PDFmacky02 sorenatsacPas encore d'évaluation

- History of Arc WeldingDocument35 pagesHistory of Arc WeldingRosciane BallesterosPas encore d'évaluation

- History of Stainless SteelDocument65 pagesHistory of Stainless SteelMayank100% (1)

- The USS Tecumseh in Mobile Bay: The Sinking of a Civil War IroncladD'EverandThe USS Tecumseh in Mobile Bay: The Sinking of a Civil War IroncladPas encore d'évaluation

- Ironwork - Part III - A Complete Survey of the Artistic Working of Iron in Great Britain from the Earliest TimesD'EverandIronwork - Part III - A Complete Survey of the Artistic Working of Iron in Great Britain from the Earliest TimesPas encore d'évaluation

- A Tale of Wootz SteelDocument11 pagesA Tale of Wootz SteelBijay Prasad UpadhyayPas encore d'évaluation

- ASM History of QuenchingDocument9 pagesASM History of QuenchingDonald MacKenziePas encore d'évaluation

- The Blacksmith in Eighteenth Century WilliamsburgDocument37 pagesThe Blacksmith in Eighteenth Century WilliamsburgCarmela GabrielePas encore d'évaluation

- Historical DevelopmentDocument3 pagesHistorical DevelopmentShakil AkhterPas encore d'évaluation

- Timeline of Materials TechnologyDocument3 pagesTimeline of Materials TechnologyBradley KenneyPas encore d'évaluation

- History of IronsDocument18 pagesHistory of Ironsocok28Pas encore d'évaluation

- Welding HistoryDocument87 pagesWelding HistoryKarlaColina100% (2)

- Modern Architecture Origins & ImpactsDocument38 pagesModern Architecture Origins & ImpactsSadia HusainPas encore d'évaluation

- 1 Historical Development and Characteristics of Structural SteelsDocument30 pages1 Historical Development and Characteristics of Structural Steelsron_dany100% (1)

- Muss On 1960Document25 pagesMuss On 1960marcosPas encore d'évaluation

- History of Metal in ConstructionDocument2 pagesHistory of Metal in ConstructionAsh Denem0% (1)

- MODERN ARCHITECTURE ORIGINS & MANIFESTATIONSDocument38 pagesMODERN ARCHITECTURE ORIGINS & MANIFESTATIONSDeepan ManojPas encore d'évaluation

- Evolution of shipbuilding materials from wood to steelDocument3 pagesEvolution of shipbuilding materials from wood to steelbrandondavis1011Pas encore d'évaluation

- Vasilyev Metals and ManDocument285 pagesVasilyev Metals and Manatto_11100% (1)

- Metalwork: Iron and SteelDocument8 pagesMetalwork: Iron and Steelverne4444Pas encore d'évaluation

- India's Legendary 'Wootz' SteelDocument90 pagesIndia's Legendary 'Wootz' SteelRonak Shah100% (1)

- English Ironwork of the XVIIth and XVIIIth Centuries - An Historical and Analytical Account of the Development of Exterior SmithcraftD'EverandEnglish Ironwork of the XVIIth and XVIIIth Centuries - An Historical and Analytical Account of the Development of Exterior SmithcraftPas encore d'évaluation

- Materials Intro. 1 Phys of MaterialsDocument11 pagesMaterials Intro. 1 Phys of Materialsoyamo markPas encore d'évaluation

- Incremental Bulk Metal FormingDocument22 pagesIncremental Bulk Metal FormingYonjon SubhaPas encore d'évaluation

- Lecture 1Document2 pagesLecture 1deepzsohlPas encore d'évaluation

- 117 Section 8 Brief History of BrassDocument1 page117 Section 8 Brief History of Brasssonnyoneand2Pas encore d'évaluation

- The History of WeldingDocument2 pagesThe History of Weldingjoselyn22Pas encore d'évaluation

- Bessemer ProcessDocument22 pagesBessemer ProcessJosua Aditya PratamaPas encore d'évaluation

- Material Research Project - Nadine Dragan Ia 312Document15 pagesMaterial Research Project - Nadine Dragan Ia 312api-378499363Pas encore d'évaluation

- Handbook of Extractive Metallurgy: CopperDocument9 pagesHandbook of Extractive Metallurgy: Copper1394203031Pas encore d'évaluation

- Second Industrial RevolutionDocument4 pagesSecond Industrial RevolutionFrancesco PacePas encore d'évaluation

- Cantaloupe Nutrition - Google SearchDocument1 pageCantaloupe Nutrition - Google SearchCam MillerPas encore d'évaluation

- Jamaican Curry Powder - Immaculate BitesDocument1 pageJamaican Curry Powder - Immaculate BitesCam MillerPas encore d'évaluation

- Option To Purchase Real Property Agreement: DateDocument1 pageOption To Purchase Real Property Agreement: DateCam MillerPas encore d'évaluation

- ME 470: Senior DesignDocument5 pagesME 470: Senior DesignCam MillerPas encore d'évaluation

- Design Constraint ReportDocument11 pagesDesign Constraint ReportCam MillerPas encore d'évaluation

- Screenshot 2019-12-04 at 11.13.35 AMDocument1 pageScreenshot 2019-12-04 at 11.13.35 AMCam MillerPas encore d'évaluation

- Matlab Tutorial - ShortDocument20 pagesMatlab Tutorial - ShortCam MillerPas encore d'évaluation

- Shaokai PaperDocument9 pagesShaokai PaperCam MillerPas encore d'évaluation

- Alabama A&M University Department of Mechanical EngineeringDocument3 pagesAlabama A&M University Department of Mechanical EngineeringCam MillerPas encore d'évaluation

- Automated Washing Process For Microarray PlatesDocument11 pagesAutomated Washing Process For Microarray PlatesCam MillerPas encore d'évaluation

- Alabama A&M University School of Engineering and Technology Department of Mechanical EngineeringDocument11 pagesAlabama A&M University School of Engineering and Technology Department of Mechanical EngineeringCam MillerPas encore d'évaluation

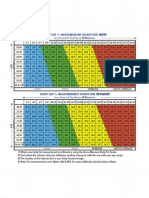

- Weight (LBS.) BF% LBM (LBS.) BMR Active Cals. Cut (-1 LBS/WK) 2844Document22 pagesWeight (LBS.) BF% LBM (LBS.) BMR Active Cals. Cut (-1 LBS/WK) 2844Cam MillerPas encore d'évaluation

- Ejemplos de Cartas Recom PDFDocument5 pagesEjemplos de Cartas Recom PDFjjsandovalcta2Pas encore d'évaluation

- Introduction To Engineering Design, Manufacturing, and AssemblyDocument19 pagesIntroduction To Engineering Design, Manufacturing, and AssemblyCam MillerPas encore d'évaluation

- Bulldog Transformation PlanDocument2 pagesBulldog Transformation PlanCam MillerPas encore d'évaluation

- Ejemplos de Cartas Recom PDFDocument5 pagesEjemplos de Cartas Recom PDFjjsandovalcta2Pas encore d'évaluation

- Double Pipe Heat Exchanger Lab AnalysisDocument6 pagesDouble Pipe Heat Exchanger Lab AnalysisCam MillerPas encore d'évaluation

- SBS Plate Microarray Auto Processor: Key RequirementsDocument2 pagesSBS Plate Microarray Auto Processor: Key RequirementsCam MillerPas encore d'évaluation

- STR2 34 1Document1 pageSTR2 34 1Cam MillerPas encore d'évaluation

- Melatih AnjingDocument0 pageMelatih Anjingsoegi_1983Pas encore d'évaluation

- Fall Semster Status Report - ME 470-Senior DesignDocument2 pagesFall Semster Status Report - ME 470-Senior DesignCam MillerPas encore d'évaluation

- 212CSDocument3 pages212CSCam MillerPas encore d'évaluation

- 2013 Convention Agenda For Website13113Document17 pages2013 Convention Agenda For Website13113Cam MillerPas encore d'évaluation

- Tabla PlieguesDocument1 pageTabla PlieguesIgnacio VivalloPas encore d'évaluation

- Lecture 11 GearDocument96 pagesLecture 11 GearMohd Naim Bin KaramaPas encore d'évaluation

- Lecture 11 GearDocument96 pagesLecture 11 GearMohd Naim Bin KaramaPas encore d'évaluation

- Kris Gethin Weekly Shopping List PDFDocument1 pageKris Gethin Weekly Shopping List PDFCam MillerPas encore d'évaluation

- Chapter 9, Problem 1Document7 pagesChapter 9, Problem 1Cam MillerPas encore d'évaluation

- Kobelco 9% Steel WeldingDocument12 pagesKobelco 9% Steel WeldingElias KapaPas encore d'évaluation

- MBa ProjectDocument2 pagesMBa Projectsahil100% (1)

- R5.0 Starters for On-Road Applications Quick Reference GuideDocument2 pagesR5.0 Starters for On-Road Applications Quick Reference Guidehelp3rPas encore d'évaluation

- Filler Metals Selector GuideDocument32 pagesFiller Metals Selector GuideAleiser Quevedo AcuñaPas encore d'évaluation

- Fortune 500 2011 (American & Global Tabs)Document326 pagesFortune 500 2011 (American & Global Tabs)TinaPapadopoulouPas encore d'évaluation

- MHRA Approved Manufacturers ListDocument265 pagesMHRA Approved Manufacturers ListWFree100% (1)

- The Disposable Diaper IndustryDocument6 pagesThe Disposable Diaper IndustryMike CagePas encore d'évaluation

- Wright Brothers Achieve First Powered FlightDocument3 pagesWright Brothers Achieve First Powered FlightBara Giri WardhanaPas encore d'évaluation

- PVCDocument1 pagePVCGuillianPas encore d'évaluation

- Valve Standards ISO API ASMEDocument1 pageValve Standards ISO API ASMEGohilakrishnan ThiagarajanPas encore d'évaluation

- Retail Supply Chain: Professor Edward FoxDocument23 pagesRetail Supply Chain: Professor Edward FoxPriyanka SarkarPas encore d'évaluation

- Welding ReportDocument13 pagesWelding ReportNordiana IdrisPas encore d'évaluation

- Logistics Individual AssignmentDocument5 pagesLogistics Individual AssignmentJeffery MillefiorePas encore d'évaluation

- MultiCam Corporate BrochureDocument32 pagesMultiCam Corporate BrochureDaniel AustinPas encore d'évaluation

- Major Retail Companies in South IndiaDocument2 pagesMajor Retail Companies in South IndiaSriniPas encore d'évaluation

- MN-5-034-1 - Safety Inspection ProgramDocument4 pagesMN-5-034-1 - Safety Inspection ProgramcatalinPas encore d'évaluation

- Zodiac Aerospace BriefDocument7 pagesZodiac Aerospace BriefAkshit AroraPas encore d'évaluation

- Agrochem Prods Cover FINALDocument2 pagesAgrochem Prods Cover FINALTony OkinyiPas encore d'évaluation

- Inventory Control Models ExplainedDocument34 pagesInventory Control Models ExplainedBehbehlynn75% (4)

- Electronic Ticket Sivanandam Selvaraju SuDocument2 pagesElectronic Ticket Sivanandam Selvaraju SuDoss MartinPas encore d'évaluation

- Nelson Stud Properties - Esr-2856Document3 pagesNelson Stud Properties - Esr-2856ellisblPas encore d'évaluation

- EilbeckCranes Oil&Gas 2014Document11 pagesEilbeckCranes Oil&Gas 2014Jessica DickersonPas encore d'évaluation

- OSCMExercises2 200416 WITHSOLUTIONS PDFDocument22 pagesOSCMExercises2 200416 WITHSOLUTIONS PDFManuel ManuPas encore d'évaluation

- A Study of Air Launch Methods For RLVs PDFDocument16 pagesA Study of Air Launch Methods For RLVs PDFwizz33Pas encore d'évaluation

- Introduction to Fabric Finishing and Garment CareDocument45 pagesIntroduction to Fabric Finishing and Garment CareSweetu NancyPas encore d'évaluation

- Lec3-Stir Casting& Squeeze CastingDocument16 pagesLec3-Stir Casting& Squeeze Castingguru prasad50% (2)

- Ancon Wind PostsDocument44 pagesAncon Wind Postsamir365Pas encore d'évaluation

- DVS 2011 Table of ContentsDocument8 pagesDVS 2011 Table of ContentsJennifer JenkinsPas encore d'évaluation

- Shaft Drilling Jumbo SDJ DB GB 20130205Document2 pagesShaft Drilling Jumbo SDJ DB GB 20130205MinaSaeedPas encore d'évaluation

- Sub Sec 1 To 9Document7 pagesSub Sec 1 To 9khan4luvPas encore d'évaluation