Académique Documents

Professionnel Documents

Culture Documents

97481-Evaluation of Air Injection As An IOR Method For The Giant Ekofisk Chalk Field

Transféré par

Laura Natalia SalcedoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

97481-Evaluation of Air Injection As An IOR Method For The Giant Ekofisk Chalk Field

Transféré par

Laura Natalia SalcedoDroits d'auteur :

Formats disponibles

Copyright 2005, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE International Improved Oil Recovery

Conference in Asia Pacific held in Kuala Lumpur, Malaysia, 56 December 2005.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

The Ekofisk fractured chalk reservoir located in the North Sea

south-west of Norway has been exploited successfully for

more than three decades, largely due to injection of sea water.

In a study concluded in 2004, air injection was evaluated as a

method for additional hydrocarbon recovery beyond the

secondary waterflood recovery. Supported by the European

Commission through the fifth framework program, the Ekofisk

Field owners joined forces with leading European research

institutes and a contractor to investigate the potential of air

injection as a cost effective IOR method. Through screening

studies, extensive laboratory experiments, reservoir

simulations, design of processing facilities and project

feasibility evaluations, an extensive knowledge base of the air

injection process for light oil fractured reservoirs was

established.

In the present paper technical results will be presented.

Recovery mechanisms related to an air injection process in a

fractured light oil reservoir have been studied through

laboratory experiments and reservoir modeling. The laboratory

experiments verified air injection as a potential IOR method

for a light oil fractured chalk field. Laboratory experiments

were performed in order to study kinetic properties such as

activation energies and ignition temperatures. In addition,

diffusion coefficients were estimated through laboratory

experiments and verified by numerical simulations. Potential

weakening of the chalk due to heat and CO

2

was evaluated

based on laboratory experiments and geo-mechanical

modeling. Combustion tube experiments were conducted in

order to study propagation of the combustion front through

porous media.

Finally, a field scale air injection feasibility study was

performed. The outcome of this study, including an

evaluation of potential production benefits and main cost items

involved in an air injection project, is presented.

Introduction

The Ekofisk oil field, located in the North Sea south-west of

Norway, is a fractured chalk reservoir containing 1.3 10

9

Sm

3

oil equivalents. Oil production started in 1971. The chalk

matrix has a porosity in the order of 25-40% with permeability

ranging from 0.1 to 10 mD. Due to the fracture system, the

effective permeability of the reservoir is in average

approximately 20 mD. The initial reservoir temperature is 130

o

C, while current reservoir temperature ranges from 30

o

C in

the vicinity of the water injection wells to 130

o

C in the areas

still not affected by the waterflood.

After a period of production decline, a water injection

program was initiated in 1987, which has largely improved the

hydrocarbon recovery from the field.

Several improved oil recovery techniques have been

screened for application to increase the recovery above what is

obtained by waterflooding

1

. Since air injection was evaluated

to have a high potential for cost efficient recovery of

additional hydrocarbons a study was started in 2001. Air

injection has a potential for application in several chalk fields.

Air injection has been applied successfully in many

offshore oil fields. Results being relevant to the Ekofisk case

can be found in the literature from field studies

2-5

, analog field

examples

6-11

and various studies on the air injection process

12-

19

. However, there is no experience reported in open literature

for air injection offshore in low permeable chalk reservoirs. It

was thus necessary to perform in depth studies to evaluate the

potential for application of this technology for the Ekofisk

field. The present paper reports a study which was performed

during 2001-2004 to evaluate the potential, including

laboratory experiments on reaction kinetics, characterization

of oxidation and combustion reaction, diffusion and rock

compaction, calibration of simulation tools and simulation at

reservoir scale, design and cost estimation of surface facilities,

and economic evaluation.

Several uncertainties for the air injection process will have

to be considered if it is going to be applied to Ekofisk. Will the

process work in a waterflooded chalk reservoir? Will ignition

occur? An eventual air breakthrough in the production wells

will be a serious safety issue, and will have to be evaluated

carefully. What will be the reservoir sweep efficiency? Can

the process be modeled with sufficient accuracy at reservoir

scale? Also, weakening of the chalk matrix will have to be

considered, mainly caused by the temperature and the

production of CO

2

. A consequence of chalk weakening can be

increased compaction and subsidence, also potentially causing

well failures. Will separation of flue gas from the sales gas be

SPE 97481

Evaluation of Air Injection as an IOR Method for the Giant Ekofisk Chalk Field

S. Stokka, SPE, RF-Rogaland Research; A. Oesthus, SPE, ConocoPhillips; and J . Frangeul, TOTAL

2 SPE 97481

economically feasible? These aspects were addressed in the

present work.

The Air Injection Process

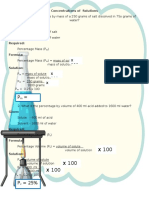

The air injection process is illustrated in Figure 1, as it is

traditionally understood. Air is injected from the left in the

figure. Behind the combustion zone there is a burned zone,

while ahead of it there is an evaporation zone containing

steam, nitrogen, hydrocarbon gases and combustion gases.

Ahead of the evaporation zone is the condensation zone and

then follows the water bank, oil bank and the unswept zone.

The flue gas and steam generated at the combustion front are

stripping, swelling and heating the contacted oil. A total

consumption of 5-10% of the remaining oil in place is

normally expected to maintain a propagation of the in-situ

oxidation process.

In a fractured reservoir, a diffusion process is required for

the air to enter the rock matrix, and the process itself might

also behave somewhat different from the illustration in Figure

1. Further, the temperature increase being important for heavy

oil reservoirs, will probably be less important in the Ekofisk

case, as the reservoir contains light oil.

Project Tasks, Definitions and Theory

The work was organized in five work packages:

1. Field pilot screening, including selection of an eventual

pilot area for a demonstration project, and evaluation of

critical process factors and uncertainties. Sensitivity

simulations were performed to determine which sets of

parameters have the greatest influence on air-injection

efficiency and safety.

2. Supporting experiments, gathering quantitative data on

reaction kinetics at reservoir conditions, gas flow in a

three dimensional fractured medium, and effect of the air

injection process on rock properties.

3. Reservoir simulator, including calibration of the

simulation tool for accurate modeling of the air injection

oxidation process, thermal conditions and flow in a

fractured low permeable medium.

4. Surface facilities, including evaluation of technical and

economic issues of air injection and flue gas downstream

handling, and selection of the most suitable flue gas

handling technology.

5. Economic evaluation on field scale, including production

forecasts, capital and operational expenses and risk

evaluation.

From the experiments it was important to estimate the

activation energy for the oxidation process. The rate of oxygen

consumption is given by the equation:

Rate =

dt

dn

2 O

=K

o

.e

-E/RT

.(Fuel)

m

.(PO

2

)

n

(1)

Where K

O

is the Arrhenius pre-exponential factor, E the

activation energy per mol, R the gas constant, T the

temperature measured in Kelvin, Fuel the fuel concentration,

PO

2

the oxygen partial pressure, m and n the reaction orders

relative to fuel concentration and oxygen partial pressure

(assumed to be equal to one).

When oxygen is introduced to a rock containing oil, low

temperature oxidation will start after a time depending of the

activation energy. High activation energy gives longer time for

starting the oxidation. As oxidation goes on at adiabatic

conditions, the temperature will increase until autoignition

takes place and the reaction is accelerated into a high

temperature oxidation process.

Results

Field Pilot Screening. A suitable area for an air injection pilot

was located on the east flank of the main Ekofisk field, see

Figure 2. Preliminary evaluations based on simulations for a

pilot area sector model gave promising results, and indicated

that as much as 25% of the remaining oil after water flooding

could potentially be recovered by the air injection process.

Sensitivities were run with respect to reservoir parameters

believed to be essential or critical to the effectiveness and

safety of the air injection process. These included effective

permeability, anisotropy and pre-exponential factors. The

results expose that, within variations of these parameters

normally found in the Ekofisk reservoirs, air injection may be

a safe and attractive oil recovery mechanism after the water

flooding has been exploited to its maximum. The simulations

were done in a single porosity mode. Consequently, the results

are only indicative to how the dual porosity and dual

permeability reservoir will behave.

Supporting Experiments

Oxidation experiments on crushed core. The oxidation

kinetics of Ekofisk crude oil was investigated in the presence

of brine and chalk, conducting three types of experiments

19

.

One set of experiments was conducted in a small batch

reactor, having a nominal liquid charge capacity of 100 ml,

and a similar air header volume. Various saturations of

Ekofisk oil and brine were introduced in crushed Ekofisk core

material filling the small batch reactor. The experiments were

operated isothermally, in the temperature range 130 150 C,

and at a total pressure of 300 bars. The rate of oil oxidation, or

rate of oxygen consumption, was determined by measuring the

rate of decline of the total pressure versus time. The rate of

reaction was influenced significantly by the temperature, and

initial saturations of oil and brine. Ekofisk crude oil was

sufficiently reactive in the temperature range investigated, that

the oxygen charged into the reactor was completely consumed

over a number of days.

Another set of experiments were also done on crushed

Ekofisk core material containing various ratios of Ekofisk oil

and brine saturations. These experiments were run in an

accelerating rate calorimeter with continuous injection of air at

300 bars pressure. The calorimeter volume was charged with a

few grams of Ekofisk chalk and a fraction of ml of oil and

brine. The calorimeter was operated adiabatically and self-heat

rate of the crude oil during oxidation was monitored. The

experiments gave information of the Ekofisk crude oil reaction

features. It was observed that the time between the initial onset

of the oxidation reaction and autoignition was reduced with

increasing initial oil saturation. Autoignition started in the

temperature range 155 200

o

C.

A third set of experiments were done on crushed limestone

containing various ratios of Ekofisk oil and brine saturations.

SPE 97481 3

The experiments were run in a combustion tube cell with

continuous injection of air at 200 bars pressure. The

combustion tube was 125 cm long and had a diameter of 10

cm. Experiments were done both at adiabatic and non-

adiabatic conditions. The produced fluids were separated, and

gas flow rate, CO and CO

2

production, and O

2

combustion

were monitored. The non-adiabatic tests showed that stable

combustion front propagation was achieved at sufficiently

high air injection rate. Oil recovery was dependent on air

injection rate.

The experimental results from the small batch reactor and

the accelerating rate calorimeter were used as screening data,

in order to guide the selection of parameters for more detailed

experiments on Ekofisk core. The combustion tube tests were

conducted primarily to provide a onedimensional physical

simulation of the air injection process, against which selected

reaction models of the crude oil oxidation could be validated.

Oxidation experiments on Ekofisk core. Oxidation

kinetics of Ekofisk crude oil in Ekofisk core was investigated

in the presence of brine, conducting three types of

experiments. Key parameters to be used in computer

simulation of the air injection process were measured. In one

experiment the rate of diffusion of nitrogen and oxygen into a

matrix plug was measured under reservoir conditions of

pressure, temperature and fluid saturations. Such experiments

are important to quantify the gas-gas diffusion between the

reservoir fractures and matrix. The experimental setup is

illustrated in Figure 3. A 20 cm

3

pore volume cylindrical chalk

sample was mounted into a steel reactor and was sealed except

at the top of the core. A narrow flow space, the diffusion

chamber, allowed for flow of air past the top side of the plug.

Synthetic air, composed of 20% O

2

and 80% N

2

, was injected

through the diffusion chamber. The effluent from the chamber

was continuously analyzed, thus to determine the amount and

type of hydrocarbons diffusing out of the core as well as the

amount of O

2

and N

2

diffusing into the core.

The matrix plug temperature was kept close to 80

o

C, and

the air was injected at a constant pressure of 275 bars. The

pressure was maintained by a back-pressure valve located

downstream. The air injection rate was constant during the

experiment at a value of 0.2 cm

3

/hr (pump conditions: 45C,

275 bars).

The molar fractions of produced O

2

, N

2

C

1

, C

2

and C

3

are

shown in Figure 4, and the molar fractions of and C

4

, C

5

and

C

6

, are shown in Figures 5. As expected the O

2

and N

2

concentrations increase with time while the hydrocarbon

component fractions decrease.

The experiment was simulated using diffusion coefficients

based on kinetic theory. See Table 1. These results were

essential for the understanding of the air injection process and

formed a basis for the field simulations.

Another set of experiments was performed at simulated

reservoir conditions using Ekofisk core plugs to characterize

the kinetics of the oxidation and combustion reactions. The

experimental setup, called an adiabatic disc reactor, is

illustrated in Figure 6. An Ekofisk core plug with a volume of

approximately 20 cm

3

was sealed inside the reactor. Synthetic

air (20% oxygen, 80% nitrogen) was injected at constant rate

and constant pressure of 276 bars from top to bottom. At the

reactor inlet air was preheated to the internal core temperature

to avoid thermal losses by gas convection.

In the first phase of the experiment the temperature was

increased in steps via heaters wired around the core. At each

step the oxygen consumption and exothermic response of the

core was measured. The step-wise increase was continued

until the core temperature started increasing by itself. During

the second phase the core temperature evolved freely and the

system was controlled to be at adiabatic conditions.

Experiments were done with cores containing brine and

recombined Ekofisk oil.

Results from experiments with different initial water

saturations are shown in Figures 7 and 8. The temperature for

start of auto-ignition increases with increasing initial water

saturation, and varies in the range 160 350

o

C. The

cumulative oxygen consumption shown in Figure 8 verifying

that oxidation takes place also before self-ignition starts.

The experiments were simulated, and it was possible to

estimate the activation energies both for the oxidation reaction

and the combustion reaction. The average values are given in

Table 2. These values were used in the field simulations. It

was observed that the self-ignition temperature increased with

increasing water saturation. Indeed, if no water is present in

the system, the heat released is transferred to the rock and the

oil. However, when water is present, for the same heat rate

released by the reactions, the heat transferred to the oil is

smaller since part of it is transferred to the water.

A set of long core experiments was performed to

characterize the efficiency of flue gas sweeping, the velocity

and temperature of the combustion front and the air

requirement to sustain a stable front. Three experiments were

performed; first an air flood at reservoir conditions, then an

isothermal flue gas sweeping and finally a high temperature

adiabatic air flood. The experiments were performed on a

composite core (20 plugs) being 85.2 cm long and having a

cross section of 10.7 cm

2

. The core was sealed to the core

holder along its length. The two first experiments were

performed at 130

o

C temperature and 275 bar pressure. In the

third experiment the first zone was heated to 350

o

C.

The reservoir core plugs showed micro-fractures after

mounting in the core holders. To some extent this masked the

interpretation of the experiments, but important results were

obtained. During the air flood at reservoir conditions, no

increase of temperature was observed, but the entire injected

oxygen was consumed inside the core. The cumulative oil

production and nitrogen content in the produced gases of the

two first gas sweeps are shown in Figure 9. Flue gas sweep

efficiency was estimated to 9 % of the hydrocarbon pore

volume after 2.15 pore volume flue gas injection. It was not

possible to sustain a stable combustion front in the core after

the flue gas sweeping, mainly due to too high water saturation

in the first zones and very low core permeability. The entire

injected oxygen was consumed inside the core.

Flue gas flooding test. A flue gas flooding test was carried

out on a composite Ekofisk core (six plugs) at simulated

reservoir conditions. A temperature of 60

o

C and pressure of

320 bars were chosen for the experiment, and the initial water

saturation was 70%. Nitrogen was injected from the top of a

vertically mounted core and was allowed to pass outside the

core but inside the sleeve, thus simulating nitrogen flow

4 SPE 97481

through a reservoir fracture. Hydrocarbons in the core could

only be produced through diffusion. The experiment

demonstrated that the lighter hydrocarbons were stripped from

the reservoir oil originally present in the matrix.

Subsidence and compaction. Rock mechanics experiments

and subsidence and compaction modeling were performed.

Two combusted Ekofisk core samples were used in pore scale

analysis and rock mechanics studies. The samples came from

the experiments performed in the diffusion chamber and the

adiabatic disc reactor, and had been exposed to temperatures

of 80

o

C and 490

o

C, respectively. A combination of electron

microscopy and mercury porosimetry was use to characterize

the grain surfaces and texture.

Figure 10 shows results from constrained pore volume

compressibility measurements on combusted and

uncombusted plugs, indicating that combustion has weakened

the chalk. It was concluded that low temperature oxidation

would not lead to any increased compaction and subsidence.

For the high temperature case, the field center could subside

an additional 5 m at most, with a corresponding reservoir

compaction of up to 6 m. The high temperature combustion

process did not alter pore geometry by melting or destroying

grains other than depositing carbon rich coating on the grains.

The estimated overall field subsidence and combustion is not

considered to be prohibitive for an eventual air injection

project at the Ekofisk field. However, near wellbore effects

impacting well failures are still considered to be a serious

concern.

Reservoir Simulator. In order to reduce complexity without

losing accuracy the reservoir fluid thermodynamics was

adapted to a 7 component fluid model for air injection. It was

compared with a fluid model with 15 components, and the 7

component model reproduced the phase behavior of the 15

component model with reasonable accuracy. It was necessary

to use a reservoir simulator that could handle dual porosity,

gas-gas diffusion, and in-situ oxidation and combustion

18

.

The contact of the reservoir fluid with air (79% N

2

, 21%

O

2

) and flue gas (85% N

2

and 15% CO

2

) was simulated

thermodynamically at various temperatures. The results show

that the oil stripping effect is greater than the swelling effect,

as the oil density increases with increased flue gas contact

with the oil.

Phenomenological simulation results showed that diffusion

has a great impact on recovery. The light fractions of the

matrix oil are stripped when air enters into the matrix by

gravity drainage and diffusion. The vaporized oil is recovered

very quickly in the fracture without oxidation. Air mainly

oxidizes the heavy hydrocarbons left in the matrix. Results

from mechanistic simulation runs for a two dimensional model

with 500 m distance between injector and producer are shown

in Figure 11, clearly showing the importance of diffusion and

gravity segregation for the oil production rate.

Simulations of the diffusion experiment and the adiabatic

disc reactor experiment, were essential for the air injection

process understanding and for the field scale simulations. The

activation energies for low temperature oxidation and high

temperature combustion were tuned to fit with the

experimental results. The diffusion coefficients used were

based on kinetic theory of gases. Parameters used in the

simulations are listed in Tables 1 and 2.

Simplified reservoir scale modeling (same two

dimensional model as mentioned above) led to the conclusion

that there is a prevailing probability that the Ekofisk oil will

commence in-situ oxidation when contacted by injected air,

even in the low temperature environment in the vicinity of

water injectors. It is unlikely that oxygen breakthrough will

occur in the producing wells. The importance of diffusion and

segregation for this result is shown in Figure 12. (The first part

of the curve is believed to be masked by a modeling artifact.)

In the Ekofisk case the contribution to oil recovery by

oxidation itself (heat and steam generation etc.) is probably

insignificant. Most of the reservoir will be outside the

oxidation region and will actually experience recovery

mechanisms identical to those of flue gas injection, primarily

gravity segregation and stripping of light components (C

1

-C

4

)

by nitrogen. Simplified reservoir scale simulation confirmed

that the oil production from air injection is close to identical to

the oil production when injecting flue gas. The oxygen is

being consumed by oxidation in a small reservoir volume

close to the injection wells.

The schematics of the process shown in Figure 1 may

therefore be somewhat misleading in this case. Evaporation

and condensation will take place, but not due to the heat itself,

but rather through stripping and swelling initiated by flue

gases from the oxidation process.

Under favorable conditions, we consider that as much as

25 % of the oil remaining after the waterflood may be

recovered through air injection. Under normal circumstances

however, the most likely recovery factor is estimated to 5 % of

the original oil in place, primarily owing to limitation in gas

sweep efficiency (gas override). If a gravity stable gas front

can be established and maintained, this recovery factor may be

significantly improved.

Surface Facilities and Wells. An evaluation was made of the

need for investment in new surface facilities and upgrade of

wells. For full field implementation of air injection on the

Ekofisk field it was concluded that it will be necessary to build

new injection and gas cleaning facilities, and upgrade 30

injection and 30 production wells, summing up to a total

capital expenditure of 2700 million USD. The facilities were

designed to have a capacity of injecting 13 million Sm

3

air per

day and processing 14 million Sm

3

of produced gas. The main

components included in the downstream processing facilities

were units for gas sweetening, dehydration, nitrogen rejection

and gas recompressing. It was assumed that it will be

necessary to handle 6% CO

2

and 52% N

2

in the total gas flow.

The processing facilities were designed to separate flue gas

from sales gas to obtain the current gas sales requirements. An

illustration of how the downstream processing facilities can be

arranged on a separate processing platform is shown in Figure

13.

Economic Evaluation. Production profiles for the Ekofisk

field were produced to estimate the incremental hydrocarbon

production from full field implementation of air injection. The

incremental oil recovery factor is shown in Figure 14, as

percentage of the original oil in place, in three cases.

SPE 97481 5

1. The gas production rate was limited to 700 million SCF

per day on field scale. The gas injection was controlled by

injection pressure (400 bars) without rate limitation. This

resulted in a stabilized injection rate slightly above 700

million SCF per day (Air_700).

2. The gas production rate was limited to 700 million SCF

per day. The gas injection was controlled by injection

pressure (400 bars) with rate limitation of 450 million

SCF per day. Water injection was added to maintain

pressure (Air_450we).

3. The gas production rate was limited to 410 million SCF

per day. The gas injection rate was controlled by injection

pressure (400 bars) without rate limitation. This resulted

in a stabilized injection rate of 450 million SCF per day

(Air_450).

The incremental recovery was 3-4 % of original oil in place,

when injecting air in the period from 2017 to 2041, based on

optimistic assumptions. In addition substantial amounts of

associated gas are being produced resulting in incremental

recovery on the order of 10% of original oil equivalents in

place.

In the economic evaluation the investments were made in

2016 and 2017. Sensitivities were run on capital expenses,

operational expenses, production volumes and product prices.

Expected values in terms of net present values were calculated

through a decision tree analysis using a combination of the

above parameters. Figure 15 shows a negative expected value

of the project in terms of net present value, and low

probability for a positive net present value.

Conclusions

Through laboratory experiments and computer simulations it

was shown that air injection is a feasible process for improved

oil recovery after water flooding in a light oil fractured chalk

reservoir.

It was shown that in-situ oxidation and combustion will

take place when injecting air in a waterflooded Ekofisk

reservoir, resulting in additional hydrocarbon recovery.

Activation energies for in-situ oxidation and combustion were

estimated. There is a prevailing probability that the Ekofisk oil

will commence in-situ oxidation when contacted by injected

air, even in the low temperature environment in the vicinity of

water injectors.

Diffusion of air into a reservoir sample, and stripping of

lighter hydrocarbons, was demonstrated, and diffusion

coefficients from kinetic theory of gases were confirmed. The

stripping of light oil components is greater than the swelling of

the oil. Diffusion has a significant impact on recovery.

It was demonstrated that a stable combustion front can

form and propagate under favorable reservoir conditions (low

water saturation), and that additional hydrocarbons will be

produced. It is unlikely that oxygen breakthrough will occur in

the producing wells.

Most of the reservoir will be outside the combustion region

and will experience recovery mechanisms being identical to

those of flue gas injection, primarily gravity segregation and

stripping of light components (C

1

-C

4

) by nitrogen.

Additional subsidence and compaction caused by air

injection and in-situ oxidation and combustion was estimated,

and is not considered to be prohibitive for an eventual air

injection project at the Ekofisk field. However, possible well

failures caused by compaction might be a serious concern.

Substantial investments will be necessary to implement an

air injection process at the Ekofisk field, including an air

injection platform, a produced gas processing platform and

wells upgrading.

An additional oil recovery can in an optimistic case be as

high as 5% of the original oil in place, when injecting air in

the period from 2017 to 2041, but the project economics was

estimated to be negative, when taking into account capital and

operational expenses and project uncertainties.

Even optimistic assumptions resulted in unattractive

economics. Consequently, further work to reduce

uncertainties both on production and cost profiles were not

considered.

Presently, competing technologies, e.g. depressurization,

CO

2

injection, and continued water injection are considered to

be more likely options to further increase recovery from

Ekofisk than air injection.

Acknowledgements

The authors acknowledge the European Commission,

ConocoPhillips and the Ekofisk Coventurers, including

TOTAL, ENI, Hydro, Statoil and Petoro, for financing the

work and for the permission to publish this paper.

The project partners IFP, University of Bath and Fabricom

are acknowledged for their contribution to the work.

IFP is also acknowledged for making their ATHOS

software available for the simulation work.

Abbreviations

IFP Institute Francais du Petrole

USD US Dollar

SCF Standard cubic foot

C

i

Hydrocarbon molecule with i carbon atoms

Conversion factors

1 foot =0.3048 m

1 SCF =0.028317 Sm

3

References

1. J ensen, T.B., Harpole, K.J . and Oesthus, A: EOR Screening for

Ekofisk, paper SPE 65124 presented at the 2000 SPE European

Petroleum Conference, Paris, Oct. 24-25.

2. Fraim, M.L., Moffitt, P.D. and Yannimaras, D.V.: Laboratory

Testing and Simulation Results for High Pressure Air Injection

in a Waterflooded North Sea Oil Reservoir, paper SPE 38905

presented at the 1997 SPE Annual Technical Conference and

Exhibition, San Antonio, Oct. 5-8.

3. Sakthikumar, S., Madaoui, K. and Chastang, J ., An

Investigation of the Feasibility of Air Injection into a

Waterflooded Light Oil Reservoir, paper SPE 29806 presented

at the 1995 Middle East Oil Show, Bahrain, March 11-14.

4. Clara, C., Durandeau, M., Quenault, G. and Nguyen, T.H.:

Laboratory Studies of Light Oil Air Injection Projects:

Potential Application in Handil Field, paper SPE 54377

presented at the 1999 SPE Asia Pacific Oil and Gas Conference

and Exhibition, J akarta, April 20-22.

5. Glandt, C.A., Pieterson, R., Dombrowski, A. and Balzarini,

M.A.: Coral Creek Field Study: A Comprehensive Assessment

of the Potential of High-Pressure Air Injection in a Mature

6 SPE 97481

Waterflood Project, paper SPE 52198 presented at the 1999

SPE Mid-Continent Operations Symposium, Oklahoma City,

March 28-31.

6. Fassihi, M.R., Yannimaras, D.V., Westfall, E.E., and Gillham,

T.H.: Economics of Light Oil Air Injection Projects, paper

SPE 35393 presented at the 1996 SPE/DOE Improved Oil

Recovery Symposium, Tulsa, April 21-24.

7. Kumar, V.K and Fassihi, M.R.: Case History and Appraisal of

the Medicine Pole Hills Units Air Injection Project, paper SPE

27792, SPE Reservoir Engineering Journal 10 (1995), 198-202.

8. Fassihi, M.R., Yannimaras, D.V. and Kumar, V.K., Estimation

of Recovery Factor in Light-Oil Air-Injection Projects, paper

SPE 28733 presented at the 1994 International Petroleum

Conference and Exhibition of Mexico, Veracruz, Oct. 10-13.

9. Clara, C., Zelenko, V., Schirmer, P. and Wolter, T.: Appraisal

of the HORSE CREEK Air Injection Project Performance,

paper SPE 49519 presented at the 1998 Abu Dhabi International

Petroleum Exhibition and Conference, Abu Dhabi, Nov. 11-14.

10. Watts, B.C., Hall, T.F. and Petri, D.J .: The Horse Creek Air

Injection Project: An Overview, paper SPE presented at the

1997 SPE Rocky Mountain Regional Meeting, Casper, May 18-

21.

11. Gillham, T.H., Cerveny, B.W., Turek, B.W. and Yannimaras,

D.V.: Keys to Increasing Production Via Air Injection in Gulf

Coast Light Oil Reservoirs, paper SPE 38848 presented at the

1997 SPE Annual Technical Conference and Exhibition, San

Antonio, Oct. 5-8.

12. Fassihi, M.R. and Gillham, T.H.: The use of Air Injection to

Improve the Double Displacement Processes, paper SPE 26374

presented at the 1993 SPE Annual Technical Conference and

Exhibition, Houston, Oct. 3-6.

13. Yannimaras, D.V. and Tiffin, D.L.: Screening of Oils for In-

Situ Combustion at Reservoir Conditions by Accelerating-Rate

Calorimetry, paper SPE 27791, SPE Reservoir Engineering

Journal 10 (1995), 36-39.

14. Le Gallo, Y., Le Romancer, J .F., Bourbiaux, B. and Fernandes,

G. : Mass Transfer in Fractured Reservoirs during Gas

Injection : Experimental and Numerical Modeling, paper SPE

38924 presented at the 1997 SPE Annual Technical Conference

and Exhibition, San Antonio, Oct. 5-8.

15. Turta, A.T. and Singhai, A.K.: Reservoir Engineering Aspects

of Oil Recovery from Low Permeability Reservoirs by Air

Injection, paper SPE 48841 presented at the 1998 SPE

International Oil and Gas Conference and Exhibition in China,

Beijing, Nov. 2-6.

16. Ren, S.R., Greaves M. and Rathbone, R.R.: Air Injection LTO

Process: An IOR Technique for Light-Oil Reservoirs, paper

SPE 57005, SPE Journal 7 (2002), 90-99.

17. Surguchev, L.M., Koundin, A. and Yannimaras, D.: Air

Injection Cost Effective IOR Method to Improve Oil Recovery

from Depleted and Waterflooded Fields, paper SPE 57296

presented at the 1999 SPE Asia Pacific Improved Oil Recovery

Conference, Kuala Lumpur, Oct. 25-26.

18. Okamoto, M. and Bourbiaux, B.: A Review of the Challenging

Reservoir Engineering Aspects of Modeling the Recovery from

a Light Oil, Fractured Reservoir by Air Injection, paper

presented at the 2005 European Symposium on Improved Oil

Recovery, Budapest, April 25-27.

19. Greaves, M., Bentaher, A. H. and Rathbone, R.R.: Air Injection

into Light Oil Reservoirs Oxidation Kinetics and Simulation,

paper presented at the 2005 European Symposium on Improved

Oil Recovery, Budapest, April 25-27.

SPE 97481 7

Component Mol fraction

Mol.

Weight

(g/mol)

Gas-Gas diffusion

coefficients

(10

-3

m

2

/day)

N

2

0.0010 28 4.8

O

2

0.0000 32 4.9

CO

2

0.0083 44 4.0

CO 0.0000 28 3.4

C

1

0.4406 16 5.5

LITE 0.1210 35 2.2

MEDIUM 0.0844 80 1.8

HEAVY 0.3445 254 1.0

Table 1. Diffusion coefficients used in simulations

Activation energy from diffusion experiment 36-40 kJ /mol

Activation energy from adiabatic disc reactor experiment 36-40 kJ /mol

Table 2. Acti vation energy estimates from simulation of experiments

Figure 1. Schematic of the air injection process.

Oil

Bank

8 SPE 97481

Figure 2. Greater Ekofisk Area

Analysis

Core

PV = 20 cm

3

Atm Pressure

High Pressure

Diffusion chamber

0.48 cm

3

Liquid trap

Figure 3. Experimental setup for diffusion experiments

Pilot area

SPE 97481 9

Molar fractions of O2, N2, C1, C2 and C3 in produced gas

0

1

10

100

0 1 2 3 4 5 6 7 8

Time (days)

M

o

l

a

r

f

r

a

c

t

i

o

n

(

%

)

%N2 %O2 %C1 %C2 %C3

Figure 4. O

2

, N

2

, C

1

, C

2

and C

3

molar fractions in produced gas vs. time

Molar fractions of C4, C5 and C6 in produced gas

0,01

0,10

1,00

0 1 2 3 4 5 6 7 8

Time (days)

M

o

l

a

r

f

r

a

c

t

i

o

n

s

(

%

)

%iC4 %nC4 %iC5 %nC5 %C6

Figure 5. C

4

, C

5

and C

6

molar fractions in produced gas vs. time

10 SPE 97481

Figure 6. Experimental setup for kinetics experiment

EKOFISK ADR : Temperature variations

0

100

200

300

400

500

600

0 2 4 6 8 10 12 14 16 18 20 22

Time (hours)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Swi = 0 Swi = 13.3% Swi = 22.9% Swi = 42%

165C

347C

268C

323C

Figure 7. Temperature curves for different initial water saturations

SPE 97481 11

Cumulative oxygen consumption

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0 2 4 6 8 10 12 14 16 18 20

Time (hours)

C

u

m

u

l

a

t

i

v

e

O

x

y

g

e

n

C

o

n

s

u

m

p

t

i

o

n

(

m

o

l

e

)

Sw = 0% Sw = 13.3% Sw = 22.9% Sw = 42%

Figure 8. Cumulati ve oxygen consumption vs. time

Oil Production and N

2

History

0

2

4

6

8

10

12

14

16

18

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Time (days)

V

o

l

u

m

e

-

c

m

3

(

1

3

0

C

,

2

7

5

b

)

0

10

20

30

40

50

60

70

80

90

m

o

l

a

r

f

r

a

c

t

i

o

n

(

%

)

Oil Prod. % N2

N

2

Breakthrough

Oil produced due to Air and Flue Gas sweep

Figure 9. Oil production from long core experiment

12 SPE 97481

Figure 10. Constrained pore volume compressibility

Figure 11. Oil production sensitivity to diffusion and gravity segregation

Constrained Pore Volume Compressibility of Air-Oil Test Plugs

Ekofisk Reservoir Chalk, Initial Porosity ~39%

0.0E+00

5.0E-06

1.0E-05

1.5E-05

2.0E-05

2.5E-05

3.0E-05

0 1 2 3 4 5 6

Test Number

C

o

n

s

t

r

a

i

n

e

d

P

o

r

e

V

o

l

u

m

e

C

o

m

p

r

e

s

s

i

b

i

l

i

t

y

,

/

p

s

i

Combusted Composite Plug

UncombustedIntact Plug

Uncombusted Composite Plugs

Air Diffusion Plug

AirOilMaterilProps

Constrained Pore Volume Compressibility of Air-Oil Test Plugs

Ekofisk Reservoir Chalk, Initial Porosity ~39%

0.0E+00

5.0E-06

1.0E-05

1.5E-05

2.0E-05

2.5E-05

3.0E-05

0 1 2 3 4 5 6

Test Number

C

o

n

s

t

r

a

i

n

e

d

P

o

r

e

V

o

l

u

m

e

C

o

m

p

r

e

s

s

i

b

i

l

i

t

y

,

/

p

s

i

Combusted Composite Plug

UncombustedIntact Plug

Uncombusted Composite Plugs

Air Diffusion Plug

AirOilMaterilProps

SPE 97481 13

Figure 12. Outflow of oxygen as function of diffusion and gravity segregation

Figure 13. Downstream processing facilities

UTILITY

GAS

SWEETENING

FIREPUMP-

ROOM

NITROGEN

REJ ECTION

RECOMPRESSION

PKG.

MOLECULAR

SIEVE PKG.

14 SPE 97481

Increased Oil Recovery due to Air Injection

-0,5 %

0,0 %

0,5 %

1,0 %

1,5 %

2,0 %

2,5 %

3,0 %

3,5 %

4,0 %

2015 2020 2025 2030 2035 2040 2045

O

i

l

R

e

c

o

v

e

r

y

F

a

c

t

o

r

b

a

s

e

d

o

n

O

O

I

P

,

%

Ai r_450we

Ai r_700

Ai r_450

Figure 14. Increased oil recovery factor as percentage of original oil in place

Figure 15. Cumulati ve probability plot of expected values in terms of net present values

Cumulative Probability Plot

Air Inj ection Value

0,0

0,2

0,4

0,6

0,8

1,0

-3000 -2000 -1000 0 1000 2000

Net Present Value

C

u

m

P

s

0

Positive

Negative

Cumulative Probability Plot

Air Inj ection Value

0,0

0,2

0,4

0,6

0,8

1,0

-3000 -2000 -1000 0 1000 2000

Net Present Value

C

u

m

P

s

0

Positive

Negative

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Gravity and AntigravityDocument3 pagesGravity and AntigravityAnon BoletusPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- History of Orbiting Solar Observatory OSO-2Document110 pagesHistory of Orbiting Solar Observatory OSO-2Bob AndrepontPas encore d'évaluation

- P&ID SymbolDocument18 pagesP&ID SymbolBagus Okti100% (1)

- Gas Separator Sizing SpreadsheetDocument19 pagesGas Separator Sizing SpreadsheetSaid FerdjallahPas encore d'évaluation

- Chemistry Project on Cosmetic ChemistryDocument48 pagesChemistry Project on Cosmetic ChemistryShubham SehgalPas encore d'évaluation

- Extraction and Selective Purification of Gallium (III), Vanadium (IV) From Aluminum (III) Contained Acid Sulphate Solutions Using D2ehfaDocument5 pagesExtraction and Selective Purification of Gallium (III), Vanadium (IV) From Aluminum (III) Contained Acid Sulphate Solutions Using D2ehfaInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- CoA Parasetamol EditDocument2 pagesCoA Parasetamol EditTitin Martini100% (1)

- BIOCHEMISTRY CARBOHYDRATESDocument100 pagesBIOCHEMISTRY CARBOHYDRATESJiezl Abellano AfinidadPas encore d'évaluation

- The Habits Scorecard: Rate Your Daily RoutinesDocument2 pagesThe Habits Scorecard: Rate Your Daily Routinesaldo100% (3)

- Generate Your Market Opportunity Set: List The Venture's Core Abilities or Technological ElementsDocument1 pageGenerate Your Market Opportunity Set: List The Venture's Core Abilities or Technological ElementsLaura Natalia SalcedoPas encore d'évaluation

- Worksheet 3 PDFDocument1 pageWorksheet 3 PDFLaura Natalia SalcedoPas encore d'évaluation

- Template: Implementation Intention: Ou Are Two To Three TimesDocument2 pagesTemplate: Implementation Intention: Ou Are Two To Three TimesAndrea Kassandra PepitoPas encore d'évaluation

- Olarijie (2015) - A Reviewofoilfield Scalemanagementtechnologyforoilandgas ProductionDocument15 pagesOlarijie (2015) - A Reviewofoilfield Scalemanagementtechnologyforoilandgas ProductionJefferson Lima AndradePas encore d'évaluation

- Service-Blueprint Template PDFDocument1 pageService-Blueprint Template PDFLaura Natalia SalcedoPas encore d'évaluation

- Calcium Carbonate Scale in Oilfield OperationsDocument16 pagesCalcium Carbonate Scale in Oilfield OperationsWilmarAlexisRamirezPas encore d'évaluation

- Personal Business Model Canvas v1.1.8 A2Document1 pagePersonal Business Model Canvas v1.1.8 A2Laura Natalia SalcedoPas encore d'évaluation

- Evaluate Market Opportunity WorksheetDocument1 pageEvaluate Market Opportunity WorksheetLaura Natalia SalcedoPas encore d'évaluation

- Personal Service Model Canvas v1.1.8 A1 PDFDocument1 pagePersonal Service Model Canvas v1.1.8 A1 PDFSpil_vv_IJmuidenPas encore d'évaluation

- A Complete Theory ofDocument13 pagesA Complete Theory ofLaura Natalia SalcedoPas encore d'évaluation

- Template: Habit Stacking: Ne of The Best WaysDocument2 pagesTemplate: Habit Stacking: Ne of The Best WaysKrishna Mytreya100% (1)

- 2010 Effect of PH and Scale Inhibitor Concentration On Phosphonate-Carbonate InteractionDocument18 pages2010 Effect of PH and Scale Inhibitor Concentration On Phosphonate-Carbonate Interactionandrea cunhaPas encore d'évaluation

- Evaluation of Scale Inhibitors PerformanceDocument14 pagesEvaluation of Scale Inhibitors PerformanceLaura Natalia SalcedoPas encore d'évaluation

- Nan Coll As 1979Document5 pagesNan Coll As 1979Laura Natalia SalcedoPas encore d'évaluation

- 2018 - Hamon - Joshua Jacob - DissertationDocument173 pages2018 - Hamon - Joshua Jacob - DissertationLaura Natalia SalcedoPas encore d'évaluation

- Evaluation of DTPPADocument130 pagesEvaluation of DTPPALaura Natalia SalcedoPas encore d'évaluation

- The Modelling and Design of Scale Inhibitor Squeeze Treatments PDFDocument14 pagesThe Modelling and Design of Scale Inhibitor Squeeze Treatments PDFLaura Natalia SalcedoPas encore d'évaluation

- Phosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreDocument14 pagesPhosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreLaura Natalia SalcedoPas encore d'évaluation

- Steve Jobs' Leadership as the Ultimate Director of InnovationDocument5 pagesSteve Jobs' Leadership as the Ultimate Director of InnovationLaura Natalia SalcedoPas encore d'évaluation

- Chapter 10 Material Balance2Document20 pagesChapter 10 Material Balance2Laura Natalia SalcedoPas encore d'évaluation

- 1 s2.0 S1001605808600621 MainDocument8 pages1 s2.0 S1001605808600621 MainLaura Natalia SalcedoPas encore d'évaluation

- Introduction To DrillingDocument2 pagesIntroduction To DrillingLaura Natalia SalcedoPas encore d'évaluation

- 1 s2.0 S1001605808600621 MainDocument8 pages1 s2.0 S1001605808600621 MainLaura Natalia SalcedoPas encore d'évaluation

- 02 Dise+ o CSG TablasDocument15 pages02 Dise+ o CSG TablasLaura Natalia SalcedoPas encore d'évaluation

- Homework 1Document5 pagesHomework 1Laura Natalia SalcedoPas encore d'évaluation

- Unidades de Bombeo HandbookDocument37 pagesUnidades de Bombeo HandbookLaura Natalia SalcedoPas encore d'évaluation

- Computational Chemistry Analysis of Hydrodesulfurization Reactions Catalyzed by Molybdenum Disulfide NanoparticlesDocument37 pagesComputational Chemistry Analysis of Hydrodesulfurization Reactions Catalyzed by Molybdenum Disulfide Nanoparticleshameed66Pas encore d'évaluation

- TDS Clorious2 EN BE 2017.04Document4 pagesTDS Clorious2 EN BE 2017.04Sophies SophiesPas encore d'évaluation

- Smart materials enable responsive constructionDocument10 pagesSmart materials enable responsive constructionNiveditha jPas encore d'évaluation

- Crystalline and Amorphous SolidsDocument10 pagesCrystalline and Amorphous SolidsAham GtyPas encore d'évaluation

- 09-11-2016 University Exam PaperDocument34 pages09-11-2016 University Exam PaperSirisha AsadiPas encore d'évaluation

- Tabelul Periodic - Google SearchDocument1 pageTabelul Periodic - Google SearchMariaPas encore d'évaluation

- CHE-504 Lecture 4 Basics of Mass Spectrometery by Dr. Charu C. PantDocument13 pagesCHE-504 Lecture 4 Basics of Mass Spectrometery by Dr. Charu C. PantAbhishek Singh ChandelPas encore d'évaluation

- Chemical Process Control Stephanopoulos PDFDocument376 pagesChemical Process Control Stephanopoulos PDFWahid NoorPas encore d'évaluation

- HL Paper 2: Full Electron Configuration of The Ruthenium (II) IonDocument20 pagesHL Paper 2: Full Electron Configuration of The Ruthenium (II) IonfuduPas encore d'évaluation

- Structural System and Codes of Tall BuildingsDocument29 pagesStructural System and Codes of Tall BuildingsRatul HasanPas encore d'évaluation

- 3-4 Gas Laws Int - Reader - Study - Guide PDFDocument6 pages3-4 Gas Laws Int - Reader - Study - Guide PDFVara BikkinaPas encore d'évaluation

- Physics homework solutions for chapter 23 problemsDocument12 pagesPhysics homework solutions for chapter 23 problemsSandeep BadigantiPas encore d'évaluation

- Tanol Speed: Developing Times ChartDocument1 pageTanol Speed: Developing Times ChartArkady YakhnisPas encore d'évaluation

- Team Quastars ReportDocument25 pagesTeam Quastars ReportMedhansh GargPas encore d'évaluation

- Enzyme Controlled Reaction LabDocument2 pagesEnzyme Controlled Reaction Labapi-291218692Pas encore d'évaluation

- ReynaDocument8 pagesReynaLuke BelmarPas encore d'évaluation

- The Dirac Sea and The AetherDocument8 pagesThe Dirac Sea and The AetherFrederick David TombePas encore d'évaluation

- Ecosurf SA-4Document1 pageEcosurf SA-4Agenk VambudyPas encore d'évaluation

- Inorganic_Chemistry # BrahmastraDocument73 pagesInorganic_Chemistry # BrahmastraNooman ShaikhPas encore d'évaluation

- A4.3-93 R2006PVDocument6 pagesA4.3-93 R2006PVMohamed YousufPas encore d'évaluation

- Microstructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsDocument5 pagesMicrostructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsastronotusPas encore d'évaluation

- M on o cr ys t a l l i n e P ho t o v o l t ai c M o dule Features Under 40 CharactersDocument2 pagesM on o cr ys t a l l i n e P ho t o v o l t ai c M o dule Features Under 40 CharactersAntonioPas encore d'évaluation