Académique Documents

Professionnel Documents

Culture Documents

Construction Activities and Process

Transféré par

J.j. Hayashi100%(9)100% ont trouvé ce document utile (9 votes)

2K vues58 pagesCopyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(9)100% ont trouvé ce document utile (9 votes)

2K vues58 pagesConstruction Activities and Process

Transféré par

J.j. HayashiDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 58

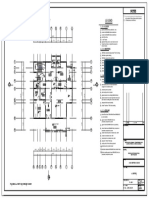

BUILDING CONSTRUCTION 1

CONSTRUCTION ACTIVITIES AND PROCESS

TUTORS: MR. LEE XIA SHENG AR. CHIN TUCK HING, MS. SUJA

LIM JIAN JUN 0316867

1 | P a g e

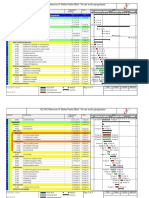

Site preparation

Survey work 1 week

setting out 1 week

Earthwork 1-2 weeks

Foundation

Pile 3 weeks

pile cap 2 weeks

Stump 2 weeks

Ground Beam 2 weeks

Ground Floor

Slab 2 weeks

Column 2 weeks

Beam 2 weeks

Staircase 2 weeks

wall 2 weeks

plastering 2 weeks

First Floor

Slab 2 weeks

Column 2 weeks

Beam 2 weeks

Staircase 2 weeks

wall 2 weeks

plastering 2 weeks

Second Floor

Slab 2 weeks

Column 2 weeks

Beam 2 weeks

Staircase 2 weeks

wall 2 weeks

plastering 2 weeks

Roof Slab

Utility

Electrical Supply 1 week

Water Supply 1 week

Door and Windows Total: 2 week

Finishes

1st floor Kitchen

Plumbing 1 week

Plastering interiors

1st floor 2 week

Plastering Interiors

2nd floor 1 week

Skidding floors

Painting - first coat 2 week

Painting - second

coat 2 week

Sanitary fitting of

bathroom and

kitchen 1 week

Electrical fitting 1 week

Total 57 week

2 | P a g e

WEEK 1

Activity 1: Site survey

Duration: 7 days

Materials: -

Equipment:-

Skilled Workers: Backhoe Loader Operator(1), General workers(4),

Lorry driver(1)

Technical Information: Analysis is done to the construction site by

surveyor and further planning and advices to the site for construction

preparation and development.

Activity 2: Mobilization

Duration: 2-3 days

Materials: Machineries

Equipment: Lorries(2), mobile crane(1), backhoe loaders(1), Hydraulic

Piling Hammer(1), excavator(1), compactor (1), boring machine(1)

Skilled Workers: lorry drivers(2), excavator operator(1), backhoe

loader operator(1), Hydraulic Piling Hammer operator(1), compactor

operators (1), boring machine operator(1)

Technical Information: Machineries required is delivered to the site

and wait for job to be executed.

Activity 3: Site Clearing

Duration: 7 days

Materials: -

Equipment: Backhoe Loader, chainsaw, lorry truck (carry earth &

plants away)

Skilled Workers: Backhoe Loader Operator(1), General workers(4),

Lorry driver(1)

Technical Information: Excavation of unfavorable soil and substances

such as stones and tree barks. Initial leveling is done for the

preparation of earthwork.

3 | P a g e

WEEK 2

Activity 1: Hoarding (setting out), staking (plan boundary)

Duration: 5 days

Materials: blue metal decks, nails, wooden pegs, planks, stakes,

Builders line

Equipment: hammer, measuring tape, theodolite, Dummy level,

construction sign board

Skilled Workers: quantity surveyor (2), general workers (4)

Technical Information: Boundary of the construction site is precisely

measured and borders the site where the construction takes place.

The site is marked with gridlines with a setback of 20 feet from the

road and 10 feet for the porch according to UBBL and the location of

the pile is marked.

Activity 2: Earthwork

Duration: 7 days

Materials: -

Equipment: excavator, compactor

Skilled Workers: Excavator Operator (1), Compactor Operator (1)

Technical Information: Removal of top soil and land leveling. The

land is excavated to around 300mm of the top soil. Keep away or

stored well for reuse due to its high water retentive characteristic.

4 | P a g e

WEEK 3

Activity 1: Earthwork (continued)

Duration: 7 days (continued from last week)

Materials: -

Equipment: excavator, compactor

Skilled Workers: Excavator Operator (1), Compactor Operator (1)

Technical information: Removal of top soil and land leveling. The

land is excavated to around 300mm of the top soil. Keep away or

stored well for reuse due to its high water retentive characteristic

Activity 2: Piling (Grid 13- Grid 15)

Duration: 10-14 days

Materials: Reinforced concrete piles, Concrete Grade 30,

Reinforcement, wooden formworks

Equipment: Hydraulic Piling Hammer(1), Rebar Bending machine(1),

Boring Machine(1), cement concrete mixer (1), hacker (1)

Skilled Workers: Hydraulic Piling Hammer Operator (1), Boring

Machine Operator (1), Rebar Bender (1), General construction

workers (6)

Technical Information: The depth/length of the piles is depending on

the soil condition based on the soil test, after that the engineers will

decide the pile length to fit the soil condition of the site, based on the

result of the test. Difference in height of the piles will be cut below

cap using hacker. The rebar connected to the piles are then removed

and left for the joining of capping reinforcement. Soil specimen is

taken for soil test experiment to determine the length of the pile. The

pile integrity test (Load test) is done to determine the strength to

support the load.

5 | P a g e

Week 4

Activity 1: Piling (Grid 8 - Grid 12)

Duration: 10-14 days

Materials: Reinforced concrete piles, Concrete Grade 30,

Reinforcement, wooden formworks

Equipment: Hydraulic Piling Hammer(1), Rebar Bending machine(1),

Boring Machine(1), cement concrete mixer (1)

Skilled Workers: Hydraulic Piling Hammer Operator (1), Boring

Machine Operator (1), Rebar Bender (1), General construction

workers (6)

Technical Information: The depth/length of the piles is depending on

the soil condition based on the soil test, after that the engineers will

decide the pile length to fit the soil condition of the site, based on the

result of the test. Difference in height of the piles will be cut below

cap using hacker. The rebar connected to the piles are then removed

and left for the joining of capping reinforcement. Soil specimen is

taken for soil test experiment to determine the length of the pile. The

pile integrity test (Load test) is done to determine the strength to

support the load.

6 | P a g e

Week 5

Activity 1: Leveling of Piles before capping

Duration: 3 days

Materials: Reinforced concrete piles, Concrete Grade 30,

Reinforcement, wooden formworks

Equipment: Hydraulic Piling Hammer(1), Rebar Bending machine(1),

Boring Machine(1), cement concrete mixer (1)

Skilled Workers: Hydraulic Piling Hammer Operator (1), Boring

Machine Operator (1), Rebar Bender (1), General construction

workers (6)

Technical Information: When the piling is penetrated into the soil,

the piles are in different height. The piles need to be cut before cap

by using hacker. The rebar are removed and then the capping

reinforcement are applied.

Activity 2: Pile capping

Duration: 7 -14 days

Materials: Reinforced concrete piles, Concrete Grade 30,

Reinforcement, wooden formworks

Equipment: Hydraulic Piling Hammer(1), Rebar Bending machine(1),

Boring Machine(1), cement concrete mixer (1)

Skilled Workers: Hydraulic Piling Hammer Operator (1), Boring

Machine Operator (1), Rebar Bender (1), General construction

workers (6)

Technical Information: pile caps takes around 2 weeks to reach its

maximum strength, but usually it can be done after it is left curing for

about a week. Stumping can be constructed around that time.

7 | P a g e

Week 6

Activity 1: Stump from Pile caps

Duration:7 days-14 days

Materials: Concrete Grade 30, reinforcements, timber formworks.

Equipment: Concrete Vibrator(1), Rebar bending machine(1),

tablesaw(1)

Skilled Workers: Land Surveyor (1), Carpenter(2), Bar Bender (1),

General worker (2)

Technical Information: After pilings , the land surveyor will identity of

the height required of the stumps and thereafter construct the

stumps based on the data. Steel rebar are bent into cage form, with

starter bar protruding upward to connect for latter construction of

columns. Constructed the same way as the pile capping, the stumps

are left for curing in order to achieve its required structural strength

before the construction of the beams. It is left to cure for a week.

8 | P a g e

WEEK 7

Activity 1: Ground Beam (Grid 13-Grid 17)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical information: Formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pour into the casting form and left for

curing around a week time.

9 | P a g e

WEEK 8

Activity 1: Ground Beam (Grid 8-Grid 13)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical information: Formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pour into the casting form and left for

curing around a week time.

10 | P a g e

Week 9

Activity 1: Ground floor slab (grid 12- grid 17)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beam, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting form and left for curing around a week

time. DPM is laid on the concrete and screeded with long even plank.

11 | P a g e

Week 10

Activity 1: Ground floor slab (grid 8 - 12 ,continued from the first )

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beam, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting form and left for curing around a week

time. DPM is laid on the concrete and screeded with long even plank.

12 | P a g e

Week 11

Activity 1: Ground Floor Columns (Grid 12 Grid 15)

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: Same as the construction of beams, the

formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pouring into the casting form and left for curing around a week

time.

13 | P a g e

Week 12

Activity 1: Ground Floor Columns (Grid 8-Grid 11)

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: Same as the construction of beams, the

formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pouring into the casting form and left for curing around a week

time.

Activity 2: First Floor Beam (Grid 12- Grid 17) , first half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: The formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pouring into the casting form and left

for curing around a week time.

14 | P a g e

Week 13

Activity 2: First Floor Beam (Grid 8 - Grid 12) , second half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: The formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pouring into the casting form and left

for curing around a week time.

15 | P a g e

Week 14

Activity 1: First Floor Slab (Grid 13-grid 17)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beams, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting, screeded with plank and then left for

curing around a week time. A layer of protection is laid on top of the

concrete during curing.

16 | P a g e

Week 15

Activity 1: First Floor Slab ( second half floor)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beams, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting, screeded with plank and then left for

curing around a week time. A layer of protection is laid on top of the

concrete during curing.

17 | P a g e

Week 16

Activity 1: first floor column (grid 12-grid 17), first half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: Same as the construction of beams, the

formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pouring into the casting form and left for curing around a week

time.

Activity 2: Ground Floor Staircase (to level 1)

Duration: 8-14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1), spirit level.

Skilled Workers: Carpenter (2), Rebar Bender (1), General worker (3)

Technical Information: The formworks of the stairs is constructed

with steel rebar reinforcement and starter bar. Thereafter a mixture

of concrete with aggregates and cement is then pouring into the

casting form and left for curing around a week time. A concrete test is

taken to check the strength of the casting after it was left to cure for

a week.

18 | P a g e

Week 17

Activity 1: first floor column (grid 8-grid 12), second half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: Same as the construction of beams, the

formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pouring into the casting form and left for curing around a week

time.

Activity 2: Second Floor Beam (Grid 12- Grid 17) , first half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: The formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pouring into the casting form and left

for curing around a week time.

Activity 3: Ground Floor Staircase (to level 1, continued)

Duration: 8-14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1), spirit level.

Skilled Workers: Carpenter (2), Rebar Bender (1), General worker (3)

Technical Information: The formworks of the stairs is constructed

with steel rebar reinforcement and starter bar. Thereafter a mixture

of concrete with aggregates and cement is then pouring into the

casting form and left for curing around a week time. A concrete test is

taken to check the strength of the casting after it was left to cure for

a week.

19 | P a g e

Week 18

Activity 1: Second Floor Beam (Grid 8- Grid 12) , second half

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: The formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pouring into the casting form and left

for curing around a week time.

20 | P a g e

Week 19

Activity 1: Second Floor Slab (first half)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beams, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting, screeded with plank and then left for

curing around a week time. A layer of protection is laid on top of the

concrete during curing.

21 | P a g e

Week 20

Activity 1: Second Floor Slab (second half)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beams, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting, screeded with plank and then left for

curing around a week time. A layer of protection is laid on top of the

concrete during curing.

22 | P a g e

Week 21

Activity 1: Second floor column (grid 8-grid 13)

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: Same as the construction of beams, the

formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pouring into the casting form and left for curing around a week

time.

Activity 2: First Floor Staircase (to level 2)

Duration: 8-14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1), spirit level.

Skilled Workers: Carpenter (2), Rebar Bender (1), General worker (3)

Technical Information: The formworks of the stairs is constructed

with steel rebar reinforcement and starter bar. Thereafter a mixture

of concrete with aggregates and cement is then pouring into the

casting form and left for curing around a week time. A concrete test is

taken to check the strength of the casting after it was left to cure for

a week.

23 | P a g e

Week 22

Activity 1: Roof floor Beams (Grid 8- Grid 13) , All floor

Duration: 14 Days

Materials: Concrete Grade 30, reinforcement, timber formwork

Equipment: Concrete Mixer(1), Concrete vibrator (1) , bar bending

machine (1), table saw

Skilled worker: Carpenter (2) , bar bender (2), general worker (4)

Technical information: The formworks is constructed with steel rebar

reinforcement and starter bar. Thereafter a mixture of concrete with

aggregates and cement is then pouring into the casting form and left

for curing around a week time.

24 | P a g e

Week 23

Activity 1: third floor Slab (all floor)

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beams, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting, screeded with plank and then left for

curing around a week time. A layer of protection is laid on top of the

concrete during curing.

25 | P a g e

WEEK 24

Activity 1: brickwalls Ground Level (Grid 3- 4)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

26 | P a g e

WEEK 25

Activity 1: brickwalls Ground Level (Grid 4-5)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

27 | P a g e

Week 26

Activity 1: brickwalls Ground Level (Grid 5-6)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

28 | P a g e

Week 27

Activity 1: Brickwall First Level (Grid 3-4)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

29 | P a g e

Week 28

Activity 1: Brickwall First Level (Grid 4-5)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

30 | P a g e

Week 29

Activity 1: Brickwall First Level (Grid 4-5)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

31 | P a g e

Week 30

Activity 1: Brickwall Second Level (Grid 3-4a)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

32 | P a g e

Week 31

Activity 1: Brickwall Second Level (Grid 4a-5)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

33 | P a g e

Week 32

Activity 1: Brickwall Second Level (Grid 13 -17)

Duration: 15-20 days

Materials: 100mmx 215mmx 75mm Clay Bricks, Cement mortar,

Builders line, Wire mesh reinforcement

Equipment: Wheel barrow (2), Shovel (2), Groovers (5), Edges (5)

Skilled Workers: General Workers (6)

Technical Information: Builders line is used to alight the walls during

stacking of bricks and construction of the wall. The clay bricks are

bonded with mortar and stack together with specific bonding pattern.

Wire mesh is laid on the bricks in certain layer interval as

reinforcement and stiffer will be constructed between walls to

strengthen the walls.

Activitity 2: Faade roof slab

Duration: 14 days

Materials: Concrete Grade 30, reinforcements, timber formworks,

Damp Proof Membrane (DPM), Rigid Floor Insulation, screed plank

Equipment: Concrete Vibrator(1), Rebar bending machine(1), table

saw(1), concrete mixer(1),

Skilled Workers: Carpenter(2), Rebar Bender (1), General worker (3)

Technical Information: The Ground slab is cast after beam, the

workers can proceed to next construction during curing time.

Formworks is constructed with steel rebar reinforcement and starter

bar. Thereafter a mixture of concrete with aggregates and cement is

then pour into the casting form and left for curing around a week

time. DPM is laid on the concrete and screeded with long even plank.

34 | P a g e

Week 33

Activity 1: Framing (ground floor)

Durations: 7 days

Materials: Openings wooden frame (for door and windows)

Equipment: Spirit level, Measuring tape

Skilled Workers: General Workers (4)

Technical Information: The opening frames are constructed in

position and align after the brick wall is done. Architrave is added

after the door/window frame is added.

Activity 2: Incoming Electrical Circuit Supply Installation

Duration: 10-14 days

Materials: Copper Cables (different sizes), Kilowatt hour meter

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts,

Skilled Workers: Electric Technician (2), Plumbers (2)

Technical Information: Incoming electricity cables are brought into

the house and connected to a circuit box in the house to facilitate the

plumbing works later on.

Week 34

Activity 1: Framing (First floor)

Durations: 7 days

Materials: Openings wooden frame (for door and windows)

Equipment: Spirit level, Measuring tape

Skilled Workers: General Workers (4)

Technical Information: The opening frames are constructed in

position and align after the brick wall is done. Architrave is added

after the door/window frame is added.

Activity 2: Incoming Electrical Circuit Supply Installation

Duration: 10-14 days (continued)

Materials: Copper Cables (different sizes), Kilowatt hour meter

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts,

Skilled Workers: Electric Technician (2), Plumbers (2)

Technical Information: Incoming electricity cables are brought into

the house and connected to a circuit box in the house to facilitate the

plumbing works later on.

35 | P a g e

Week 35

Activity 1: Framing (Second floor)

Durations: 7 days

Materials: Openings wooden frame (for door and windows)

Equipment: Spirit level, Measuring tape

Skilled Workers: General Workers (4)

Technical Information: The opening frames are constructed in

position and align after the brick wall is done. Architrave is added

after the door/window frame is added.

Activity 2: Ground Floor Plumbing (First Fix)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

36 | P a g e

Week 36

Activity 1: First Floor Plumbing (First Fix)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

Week 37

Activity 1: First Floor Plumbing (First Fix)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

Activity 2: Second Floor Plumbing (First Fix)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

Activity 3: Plumbing (Sanitary and Kitchen)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

37 | P a g e

Week 38

Activity 1: Plumbing (Sanitary and Kitchen)

Duration: 14 days

Materials: Copper Cables (different sizes), PVC pipes, socket box

Equipment: Voltmeter, Ammeter, Plyers, Screws and nuts, Hacking

machine

Skilled Workers: Electricians(2), Plumbers (2)

Technical Information: Technicians will determine the location of the

sockets according to the engineering blue print. The brick wall is

hacked to accommodate the wiring pipe from the top to the ground

according UBBL requirements. The wall sockets will be installed after

the wiring is done.

Week 39

Activity 1: Ground floor Wall Plastering (Grid 1-Grid 3)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

38 | P a g e

Week 40

Activity 1: Ground floor wall plastering (Grid 4-4a)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

39 | P a g e

Week 41

Activity 1: Ground floor plastering (Grid 4a-6)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

Activity 2: First floor plastering (Grid 1- Grid 4)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

surface of the rendering preferably wetted before application of

plastering. Rough surface plastering is usually used outdoor to resist

harsh weathering. Smooth surface plastering with pores and easily

defected characteristic is preferably used indoor.

40 | P a g e

Week 42

Activity 1: First floor plastering (Grid 4- Grid 4a)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

41 | P a g e

Week 43

Activity 1: First floor plastering (Grid 4a-6)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

surface of the rendering preferably wetted before application of

plastering. Rough surface plastering is usually used outdoor to resist

harsh weathering. Smooth surface plastering with pores and easily

defected characteristic is preferably used indoor.

Activity 2: Second floor plastering (Grid 1-Grid 4)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

surface of the rendering preferably wetted before application of

plastering. Rough surface plastering is usually used outdoor to resist

harsh weathering. Smooth surface plastering with pores and easily

defected characteristic is preferably used indoor.

42 | P a g e

Activity 3: Ground Floor Tiling (Grid 13- Grid 17)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

43 | P a g e

Week 44

Activity 1: second floor plastering (Grid 4-4b)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

44 | P a g e

Activity 2: Ground Floor Tiling (Grid 10-13)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

45 | P a g e

Week 45

Activity 1: Second floor plastering (Grid 4b-6)

Duration: 14-21 days (interior and exterior)

Materials: cement plaster, skim coat

Equipment: buckets, cement spatula trowels, groovers, edgers,

planks, sponges, scaffolding, plaster spray

Skilled Workers: general workers (2), plasterers(3)

Technical information: The plaster layer is not more than half inches,

and left for drying about 7 days before the finishing is applied. The

first coating thickness is around 1/2 to 3/4 inches while the finishing

coat will be around 3/16 inches thick. The surface of the rendering

preferably wetted before application of plastering. Rough surface

plastering is usually used outdoor to resist harsh weathering. Smooth

surface plastering with pores and easily defected characteristic is

preferably used indoor.

46 | P a g e

Activity 2: Ground Floor Tiling (Grid 8- Grid 10)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

47 | P a g e

Activity 3: First Floor Tiling (Grid 14-17)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

48 | P a g e

Week 46

Activity 1: First Floor Tiling (Grid 10-14)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

49 | P a g e

Week 47

Activity 1: First Floor Tiling (Grid 8-10)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

50 | P a g e

Activity 2 : Second Floor Tiling (Grid 10 Grid 13)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

51 | P a g e

Week 48

Activity 1: Second Floor Tiling (Grid 8- Grid 10)

Duration: 14-21 days

Materials: Ceramic tiles, Cement mortar, Silicone sealant

Equipment: Spirit level (1), Groovers (3), Tile cutter (1), Carpenters

square (1)

Skilled Worker: General worker (2)

Technical Information: Tiles are precisely measured according to the

application area of the building. This can help to save number of tiles

and as well able to maximize the applying area. The tile will be cut

into varies sizes and shapes to fit those with smaller surface area.

52 | P a g e

Week 49

Activity 1: Finishing undercoat (Ground floor)

Duration: 21 days

Materials: Wall Sealer

Equipment: Edgers, groovers, screed plank, Paint brushes, Point

rollers

Skilled Worker: Painter (5)

Technical Information: Sealer is required to seal the holes, hairline

cracks of the walls. The walls are needed to seal to prevent the

drywall from absorbing the moisture and the paint. By applying a

layer of sealer, it gives the wall an adhesive base for the paint to stick

on firmly without having bubbling and waterborne stain.

Week 50:

Activity 1: Finishing Undercoat (First floor)

Duration: 21 days

Materials: Wall Sealer

Equipment: Edgers, groovers,plank, Paint brushes, Point rollers

Skilled Worker: Painter (5)

Technical Information: Sealer is required to seal the holes, hairline

cracks of the walls. The walls are needed to seal to prevent the

drywall from absorbing the moisture and the paint. By applying a

layer of sealer, it gives the wall an adhesive base for the paint to stick

on firmly without having bubbling and waterborne stain.

Activity 2: Painting Uppercoat (Ground floor)

Duration: 14 days

Materials: Paint

Equipment: Paint brush (3), Point roller (3)

Skilled Worker: Painter (5)

Technical Information: Painting for finishing should be done after the

plastering and undercoating are completely dried up to prevent

bubbling of the wall due to the moisture. Painting requires few layers

for better surface finishes.

53 | P a g e

Week 51

Activity 1: Finishing Undercoat (Second floor)

Duration: 21 days

Materials: Wall Sealer

Equipment: Edgers, groovers,plank, Paint brushes, Point rollers

Skilled Worker: Painter (5)

Technical Information: Sealer is required to seal the holes, hairline

cracks of the walls. The walls are needed to seal to prevent the

drywall from absorbing the moisture and the paint. By applying a

layer of sealer, it gives the wall an adhesive base for the paint to stick

on firmly without having bubbling and waterborne stain.

Activity 2: Painting First coat (First Floor)

Duration: 14 days

Materials: Paint

Equipment: Paint brush (3), Point roller (3)

Skilled Worker: Painter (5)

Technical Information: Painting for finishing should be done after the

plastering and undercoating are completely dried up to prevent

bubbling of the wall due to the moisture. Painting requires few layers

for better surface finishes.

54 | P a g e

Week 52

Activity 1: Painting First coat (Second Floor)

Duration: 14 days

Materials: Paint

Equipment: Paint brush (3), Point roller (3)

Skilled Worker: Painter (5)

Technical Information: Painting for finishing should be done after the

plastering and undercoating are completely dried up to prevent

bubbling of the wall due to the moisture. Painting requires few layers

for better surface finishes.

55 | P a g e

Week 53

Activity 1: Doors, Windows and Screens installation

Durations: 10-14 days

Materials: precast aluminum window frames, doors, glass windows

panels, door frames, pre-manufactured wooden,wooden crossed

screen , screws, sealer

Equipment: Bolts and Nuts, Screwdriver and related toolkit.

Skilled worker: General worker (4)

Technical information: The doors and windows are then installed to

the walls, replacing the temporary frames and secured with screws

and sealer.

56 | P a g e

Week 54

Activity 1: Doors, Windows and Screens installation

Durations: 10-14 days (continued)

Materials: precast aluminum window frames, doors, glass windows

panels, door frames, pre-manufactured wooden,wooden crossed

screen , screws, sealer

Equipment: Bolts and Nuts, Screwdriver and related toolkit.

Skilled worker: General worker (4)

Technical information: The doors and windows are then installed to

the walls, replacing the temporary frames and secured with screws

and sealer. Prefabricated screen is secured with fixtures and nut onto

the walls.

Activity 2: Electrical & Sanitary fittings

Durations: 14 days

Materials: Wall sockets, Wall plugs and bathroom porcelain

appliances

Equipment: Bolts and Nuts, Screwdriver and related toolkit.

Skilled worker: General worker (4)

Technical information: Standard electrical appliances are then fixed

during the last phase.

57 | P a g e

Week 55

Activity 1: Pavings

Duration: 10-15 days

Materials: paving stones, bricks, Concrete Grade 30, reinforcements,

timber formworks,plank

Equipment: wheel barrow, Concrete Mixer(1), (1), table saw

Skilled Workers: general workers (4)

Technical information: Paving stones to be laid on the soil as

pavement of walkway, parking, and garden.

Week 56

Activity 1: Pavings

Duration: 10-15 days (continued)

Materials: paving stones, bricks, Concrete Grade 30, reinforcements,

timber formworks,plank

Equipment: wheel barrow, Concrete Mixer(1), (1), table saw

Skilled Workers: general workers (4)

Technical information: Paving stones to be laid on the soil as

pavement of walkway, parking, and garden.

Week 57

Activity 1: Grass turfing External work

Duration: 7 days

Materials: lawn turf rolls (depends on the size of garden), bricks

Equipment: wheel barrow, gardening tool kits, water pipes

Skilled Workers: lawn turf layers(2), general workers (2)

Technical information: Soil preparation is done before laying the rolls

of grass turf on the soil surfaces. Excavated soil can be reused as the

base of the courtyard. Loose stones and building rubble will prevent

the turves roots from making contact with the soil and could make

the turf die in patches. The top soil should then be thoroughly

rotivated down to about the first 6 inches to aerate it properly. It is

then raked level and gently treaded down.

Vous aimerez peut-être aussi

- Construction Site Planning and Logistical Operations: Site-Focused Management for BuildersD'EverandConstruction Site Planning and Logistical Operations: Site-Focused Management for BuildersPas encore d'évaluation

- List of Construction ActivitiesDocument48 pagesList of Construction Activitiesvinsun74% (19)

- Sequence of Works For Building ConstructionDocument2 pagesSequence of Works For Building ConstructionBoni Amin76% (34)

- Estimator's General Construction Manhour ManualD'EverandEstimator's General Construction Manhour ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (20)

- House Building ScheduleDocument39 pagesHouse Building Schedulearshad48586% (14)

- Rural Water Supply SR Kalaburagi Circle 2019-20.Document338 pagesRural Water Supply SR Kalaburagi Circle 2019-20.AEE Sub Div 1878% (9)

- Building Construction ScheduleDocument8 pagesBuilding Construction Scheduleengrfarhansiddiqui75% (4)

- Final Research Proposal2.oDocument24 pagesFinal Research Proposal2.oDunhill Guantero50% (2)

- Sample Schedule (5 Storey)Document4 pagesSample Schedule (5 Storey)JA Ramoneda50% (4)

- Construction ScheduleDocument18 pagesConstruction Schedulemuneerpmh100% (8)

- Construction Budget Template - 0Document48 pagesConstruction Budget Template - 0Hani A Menem MahmoudPas encore d'évaluation

- Construction Residential Timeline TemplateDocument10 pagesConstruction Residential Timeline TemplateSehna SerajPas encore d'évaluation

- Construction Site PreparationDocument38 pagesConstruction Site PreparationZach Effah100% (3)

- Construction Estimate GuideDocument70 pagesConstruction Estimate Guidejanetabunar100% (2)

- Building ConstructionDocument88 pagesBuilding Constructionmurad_ce100% (5)

- Construction Project Manager: Problem Solving and Practical Management of WorksD'EverandConstruction Project Manager: Problem Solving and Practical Management of WorksÉvaluation : 1 sur 5 étoiles1/5 (1)

- PDF ResizeDocument56 pagesPDF ResizeAhmad SallehPas encore d'évaluation

- Adaptive Reuse and Conservation of HaveliDocument63 pagesAdaptive Reuse and Conservation of HaveliTarisha Janwani100% (2)

- Construction Activities and ProcessDocument57 pagesConstruction Activities and ProcessJ.j. Hayashi100% (2)

- Construction ScheduleDocument10 pagesConstruction Schedulejunlab0807100% (3)

- Construction ScheduleDocument3 pagesConstruction ScheduleRobbin Daniel Jones100% (2)

- Sequence of Civil WorkDocument33 pagesSequence of Civil WorkDevendra Potdar100% (6)

- Construction ScheduleDocument3 pagesConstruction Schedulegroup2sd1314100% (1)

- Construction ActivitiesDocument20 pagesConstruction ActivitiesErika Kirby100% (19)

- Construction ScheduleDocument14 pagesConstruction ScheduleDhananjay SinghPas encore d'évaluation

- Construction ScheduleDocument3 pagesConstruction Schedulegroup2sd1314100% (1)

- Checking of Construction ScheduleDocument15 pagesChecking of Construction Scheduleb16583% (6)

- Construction ManagementDocument37 pagesConstruction ManagementShirley Munoz100% (4)

- RCC Dam PJ Schedule SampleDocument18 pagesRCC Dam PJ Schedule SampleDanielPas encore d'évaluation

- Residential ConstructionDocument11 pagesResidential ConstructionJoan Pajaganas100% (2)

- Construction ScheduleDocument1 pageConstruction ScheduleNorman Oder50% (2)

- Pre Construction PlanningDocument79 pagesPre Construction PlanningNathaniel Lansang100% (1)

- Group 1 - Building Construction Methodology 1Document206 pagesGroup 1 - Building Construction Methodology 1Jovan Bucol100% (1)

- Construction MethodologyDocument3 pagesConstruction MethodologyLauren M. Olivos100% (1)

- Civil Construction ActivitiesDocument3 pagesCivil Construction ActivitiessreeluPas encore d'évaluation

- Construction Material Estimate SheetDocument14 pagesConstruction Material Estimate SheetMa Kirste Cabrera100% (1)

- Construction Scheduling Manual: Prepared by Construction ManagementDocument44 pagesConstruction Scheduling Manual: Prepared by Construction ManagementccemilovaPas encore d'évaluation

- Standard Cost CodesDocument17 pagesStandard Cost CodesThahir HussainPas encore d'évaluation

- Master Construction ScheduleDocument6 pagesMaster Construction ScheduleJing Jing0% (1)

- Construction Schedule - 150902 RobinsonsDocument1 pageConstruction Schedule - 150902 RobinsonspulangratzPas encore d'évaluation

- 102.982 Monsoon at Dubai Outlet Mall - Fit Out ProgrammeDocument3 pages102.982 Monsoon at Dubai Outlet Mall - Fit Out Programmesampath_priyashanthaPas encore d'évaluation

- Updated Project ScheduleDocument38 pagesUpdated Project ScheduleAhmad Ramin Abasy100% (6)

- Weekly Construction Report - 2011.10.15Document22 pagesWeekly Construction Report - 2011.10.15Farouq SHah100% (5)

- Internal Construction ScheduleDocument1 pageInternal Construction ScheduleTahir BajwaPas encore d'évaluation

- Quantity SurveyingDocument34 pagesQuantity SurveyingVaruni_Gunawardana100% (2)

- Building MethodologyDocument79 pagesBuilding MethodologyAbrar Hussain Khan100% (4)

- Gulf Productivity RateDocument108 pagesGulf Productivity Ratekarthik100% (1)

- Quantity Take Off ManualDocument61 pagesQuantity Take Off ManualJerrold Quiñola100% (4)

- Chap. 3 - Project Control and MonitoringDocument46 pagesChap. 3 - Project Control and MonitoringRuzengulalebih ZEta's-Listik40% (5)

- Construction ManagementDocument16 pagesConstruction ManagementAnarold Joy100% (2)

- Construction Project ManagementDocument63 pagesConstruction Project ManagementAmy Mengistu50% (2)

- Construction L3 Schedule - RevDocument2 pagesConstruction L3 Schedule - RevMohit PurwarPas encore d'évaluation

- Civil Construction ScheduleDocument4 pagesCivil Construction ScheduleXozanPas encore d'évaluation

- Almohileb Productivity Rates PDFDocument6 pagesAlmohileb Productivity Rates PDFAnonymous 94TBTBRksPas encore d'évaluation

- Cost Estimation Techniques For Construction IndustryDocument47 pagesCost Estimation Techniques For Construction Industrybkhumalo100% (13)

- S-Curve Cash Flow Manpower EquipmentDocument3 pagesS-Curve Cash Flow Manpower Equipmentfreann100% (1)

- How to Write Construction Programmes & SchedulesD'EverandHow to Write Construction Programmes & SchedulesÉvaluation : 4 sur 5 étoiles4/5 (9)

- Build Like The Big Primes: A Contractor's Guide to Building Your Business While Balancing Your LifeD'EverandBuild Like The Big Primes: A Contractor's Guide to Building Your Business While Balancing Your LifePas encore d'évaluation

- Lesson 10 - Construction - FieldworkDocument66 pagesLesson 10 - Construction - FieldworkJubillee MagsinoPas encore d'évaluation

- Building Construction ReportDocument51 pagesBuilding Construction ReportAndrew Chee Man ShingPas encore d'évaluation

- Building Construction 1: Project 2: Construction Activities and ProcessDocument41 pagesBuilding Construction 1: Project 2: Construction Activities and Processfaizal azizPas encore d'évaluation

- Ce Elective: Description Unit Material Cost Unit Planning QtyDocument37 pagesCe Elective: Description Unit Material Cost Unit Planning QtyMichael Christ IcagoyPas encore d'évaluation

- 2-Approximate Quantities MethodDocument5 pages2-Approximate Quantities MethodMUMO MussPas encore d'évaluation

- Primavera Project Planner Sample Project: Prepared By: Luay Dwaikat, Msc. Construction ManagementDocument3 pagesPrimavera Project Planner Sample Project: Prepared By: Luay Dwaikat, Msc. Construction ManagementkrajeshkumarxPas encore d'évaluation

- Group 7 - TileworksDocument93 pagesGroup 7 - TileworksPercival ArcherPas encore d'évaluation

- Floor FinishesDocument32 pagesFloor FinishesJuno Pajel100% (1)

- Weberfix PU - DatasheetDocument7 pagesWeberfix PU - DatasheetAnonymous PkvM83sPas encore d'évaluation

- A B CD E F G H I J: Notes NotesDocument1 pageA B CD E F G H I J: Notes NotesNORTSEN ALBERTPas encore d'évaluation

- 01-10-24 Revised II Cost EstimateDocument2 pages01-10-24 Revised II Cost Estimateleo.salonga30Pas encore d'évaluation

- Sound Absorbing Materials and ConstructionsDocument60 pagesSound Absorbing Materials and Constructionsss100% (1)

- Costing Per Square Meter - Reference - 2023Q1Document3 pagesCosting Per Square Meter - Reference - 2023Q1Cecilia UmagtangPas encore d'évaluation

- Essential Kitchen Bathroom Bedroom March 2013 PDFDocument164 pagesEssential Kitchen Bathroom Bedroom March 2013 PDFabrahamiohan100% (5)

- Civil Rate 68-69 PDFDocument65 pagesCivil Rate 68-69 PDFSushil DhunganaPas encore d'évaluation

- Estimate of Labs& Multipurpose Hall GEC GirlsDocument32 pagesEstimate of Labs& Multipurpose Hall GEC GirlsBryan OscoPas encore d'évaluation

- V - Park: Premium Plots & VillasDocument12 pagesV - Park: Premium Plots & VillassudheerPas encore d'évaluation

- M40Document6 pagesM40dandragutescuPas encore d'évaluation

- Gardenia Brochure 7.06.11Document15 pagesGardenia Brochure 7.06.11Ankush KaranwalPas encore d'évaluation

- Kitchen ToiletDocument1 pageKitchen ToiletSwapnil JainPas encore d'évaluation

- Gemma Generalcatalogue2019floorDocument117 pagesGemma Generalcatalogue2019floorahmed elkafafyPas encore d'évaluation

- Building Construction EngineeringDocument41 pagesBuilding Construction EngineeringUsama KardarPas encore d'évaluation

- 1BHK Bungalow PDFDocument2 pages1BHK Bungalow PDFJayson MalaaPas encore d'évaluation

- Granito-Lookbook 2016 PDFDocument17 pagesGranito-Lookbook 2016 PDFGagan Achmad GunawanPas encore d'évaluation

- Kitchen Bath News 022017Document68 pagesKitchen Bath News 022017valysaPas encore d'évaluation

- Floors, Walls and Windows: Cleaning For HealthDocument30 pagesFloors, Walls and Windows: Cleaning For HealthMALOU ELEVERAPas encore d'évaluation

- Vastu Shastra KnjigaDocument29 pagesVastu Shastra KnjigaCocosh AnelPas encore d'évaluation

- Schluter Price List CanadaDocument196 pagesSchluter Price List CanadaMurea SebastianPas encore d'évaluation

- Biofix 2022 inDocument5 pagesBiofix 2022 inSahil KaliaPas encore d'évaluation

- Start of Tender Document: Approx Cost: Date of Opening: 08-08-2011Document54 pagesStart of Tender Document: Approx Cost: Date of Opening: 08-08-2011Suhavi KapoorPas encore d'évaluation

- Types of Flooring: Interior DesignDocument20 pagesTypes of Flooring: Interior DesignJoshua SainiPas encore d'évaluation

- NAS+DW FICCI Blue PotteryDocument105 pagesNAS+DW FICCI Blue Potterydurgesh khatriPas encore d'évaluation